Electro-hydraulic brake-by-wire device with redundancy function and control method

An electro-hydraulic wire and functional technology, applied in the field of electro-hydraulic wire-controlled brake devices, can solve the problems of vehicle brake precision control, brake fluid pressure fluctuations, increase the length of brake pipelines, etc., to improve brake response Effects of speed and control accuracy, solving braking hysteresis, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

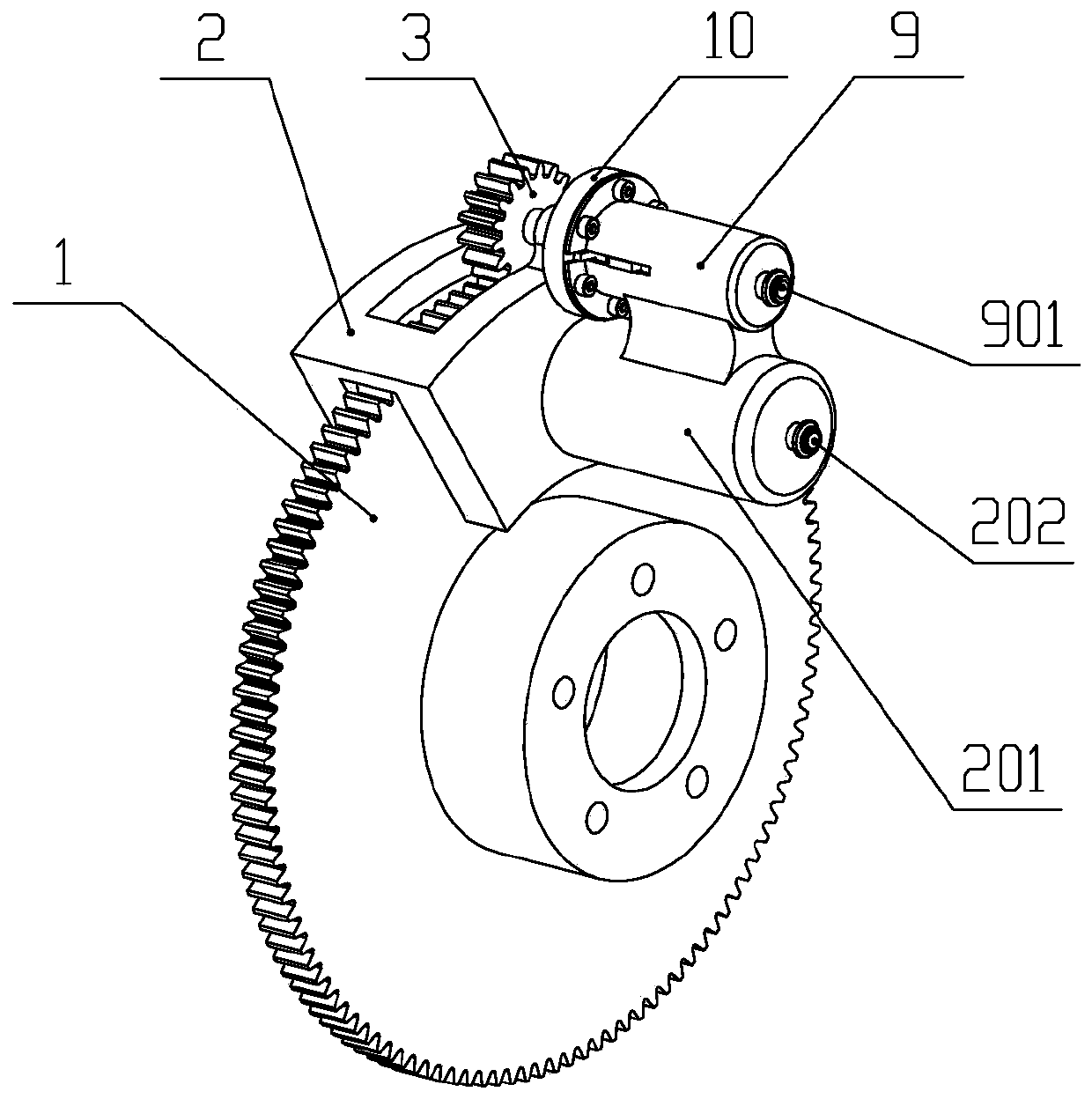

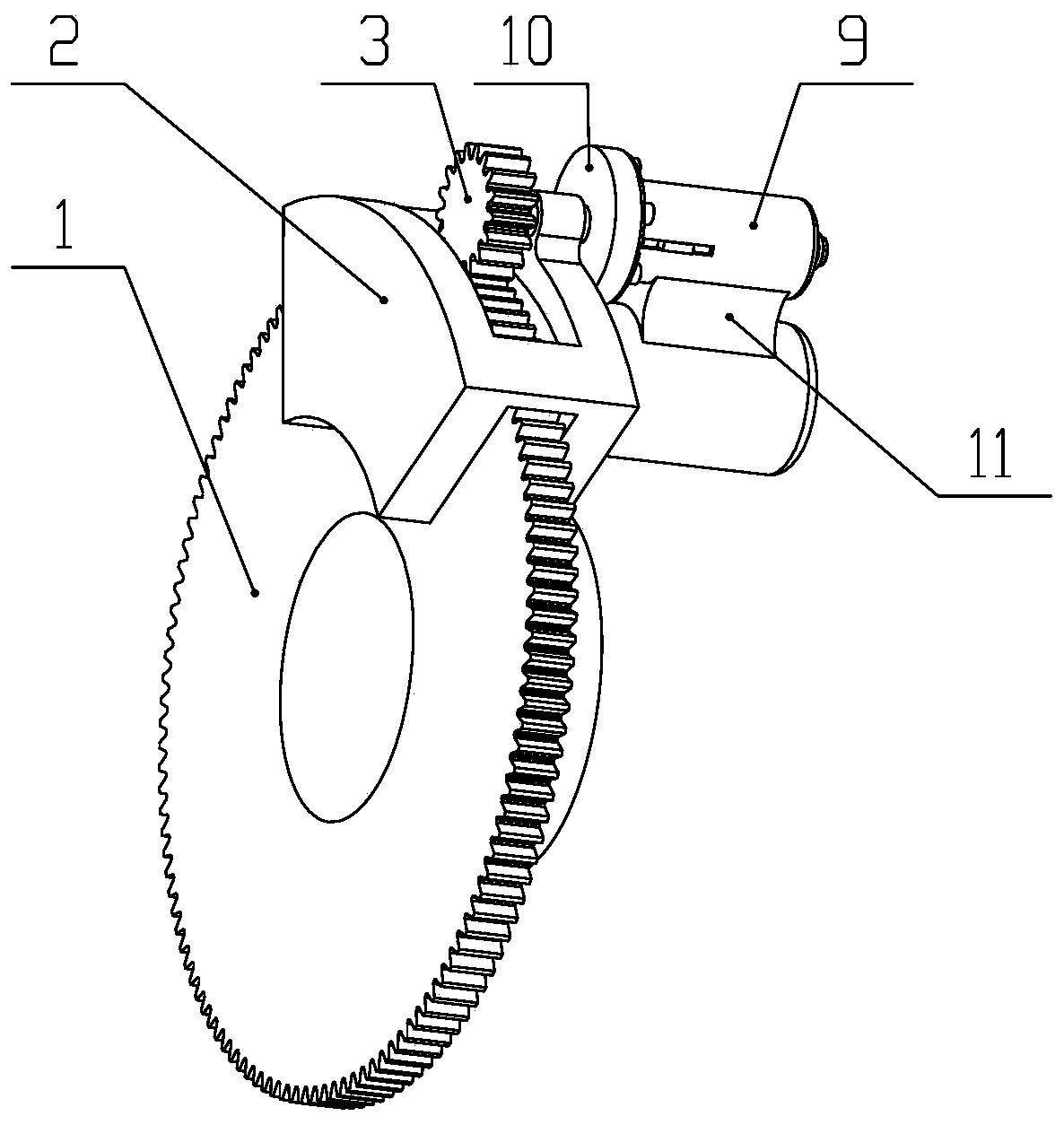

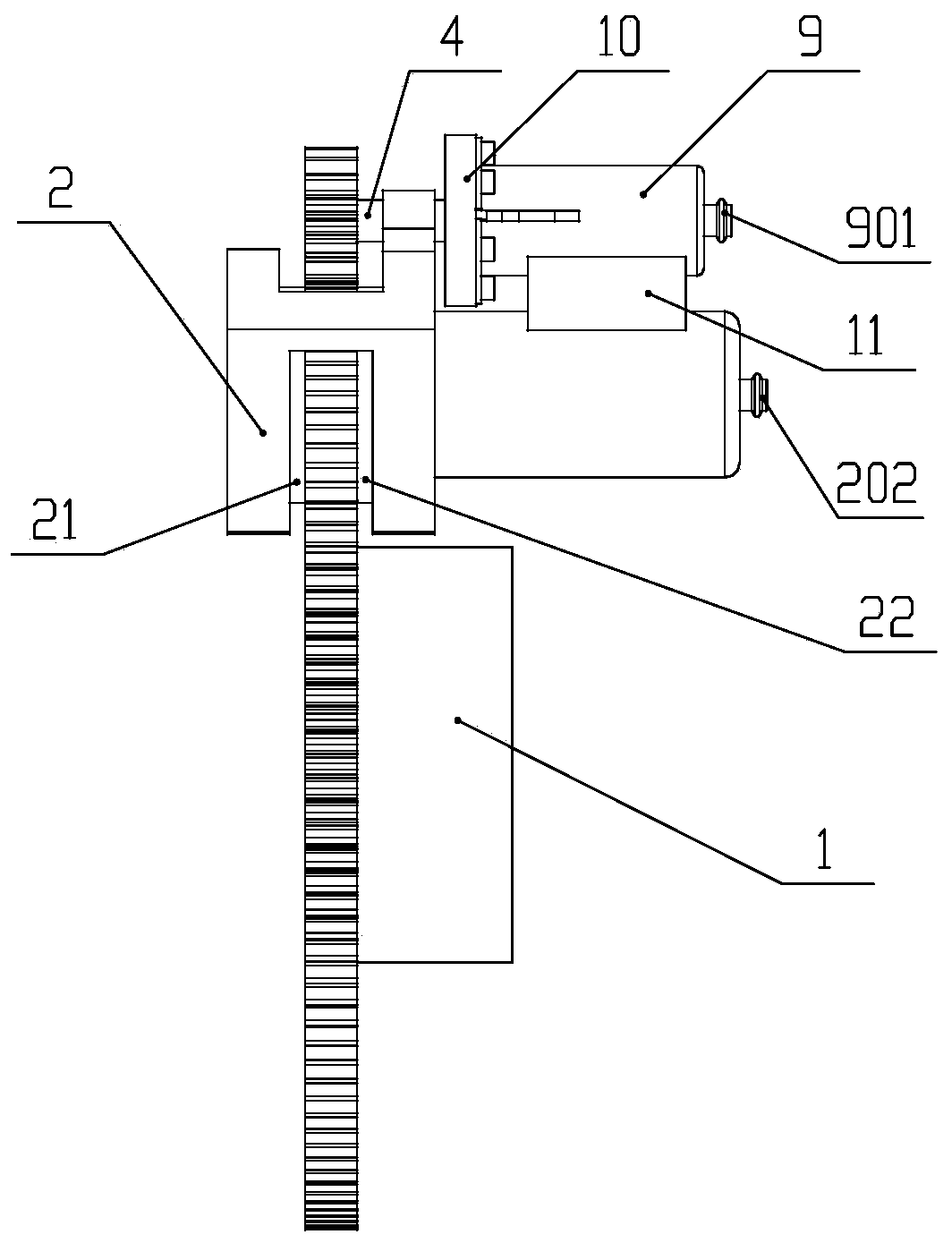

[0043] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0044] An electro-hydraulic brake-by-wire device with redundant functions such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes brake disc 1, caliper 2, power take-off gear 3, gear shaft 4, lead screw 5, return spring 6, piston nut 7, sealing ring 8, high-pressure oil cylinder housing 9, electromagnetic clutch 10, and fixing seat 11. Hydraulic control unit 12, split fluid storage tank 13, accumulator 14, fluid storage tank 15, angle sensor 16, brake pedal 17, brake push rod assembly 18, brake master cylinder 19, controller 20, The left friction plate 21 and the right friction plate 22; the end cap on the brake disc 1 is fixedly installed on the wheel by bolts; the described caliper 2 is fixedly installed on the vehicle body, and the left friction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com