Fuel injector flow measurement system and measurement method

A flow measurement and measurement system technology, which is applied in the fuel injector flow measurement system and measurement field, can solve the problems of low pressure control accuracy, high measurement cost, error in operation results, etc., so as to shorten the pressure build-up time, improve the measurement efficiency, reduce The effect of small temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

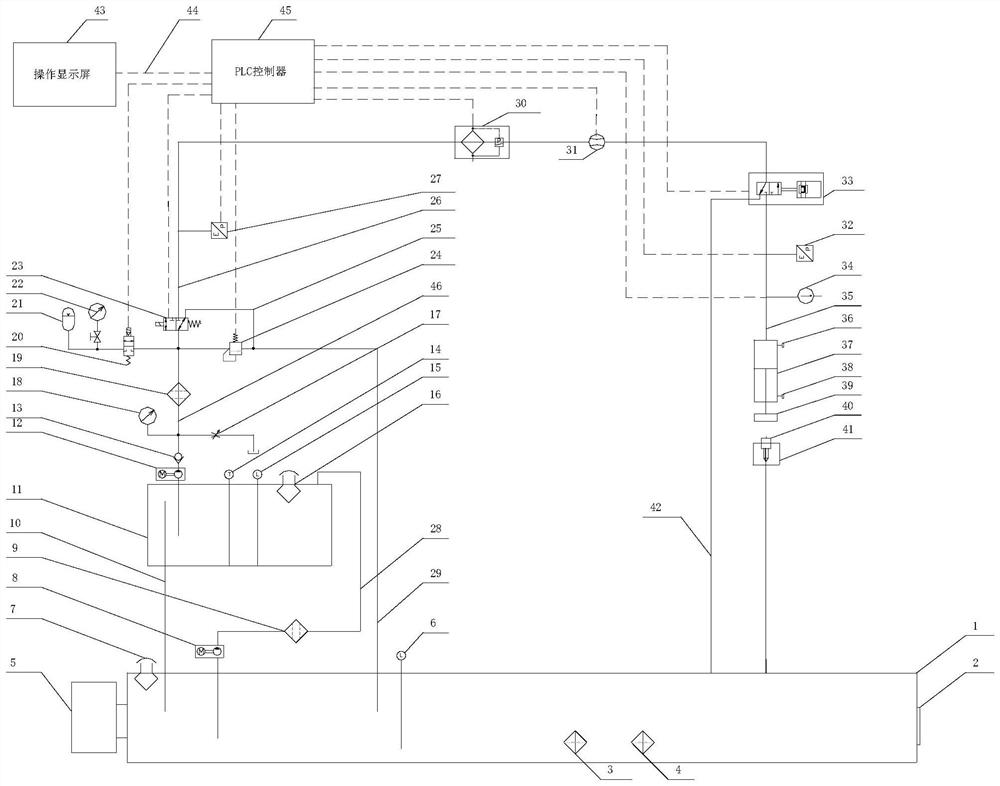

[0069] In order to clearly and completely describe the technical solution of the present invention and its specific working process, with reference to the accompanying drawings, the specific embodiments of the present invention are as follows:

[0070] The invention discloses a fuel injection nozzle flow measurement system, such as figure 1 As shown in the figure, the measurement system adopts a double oil tank structure in which the filter oil tank 1 and the working oil tank 11 are connected in series. A voltage stabilizing component and a pneumatic pressure regulating valve 24 are installed in parallel between one side, and the other side of the reversing valve 11 at the outlet end is connected to the mass flow meter 31 and one side pipeline of the reversing valve 33 at the measuring end in turn through the working oil pipe 26 Connection, one oil outlet on the other side of the reversing valve 33 at the measuring end is connected to the pipeline of the measuring assembly thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com