Double-path oil feeding resonance bypass type electrically controlled oil sprayer with engraved groove

An electronically controlled fuel injection and fuel injector technology, which is applied to machines/engines, fuel injection devices, engine components, etc. It can improve the control accuracy and flexibility, reduce the formation of nitrogen oxides, and reduce the fluctuation of fuel pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

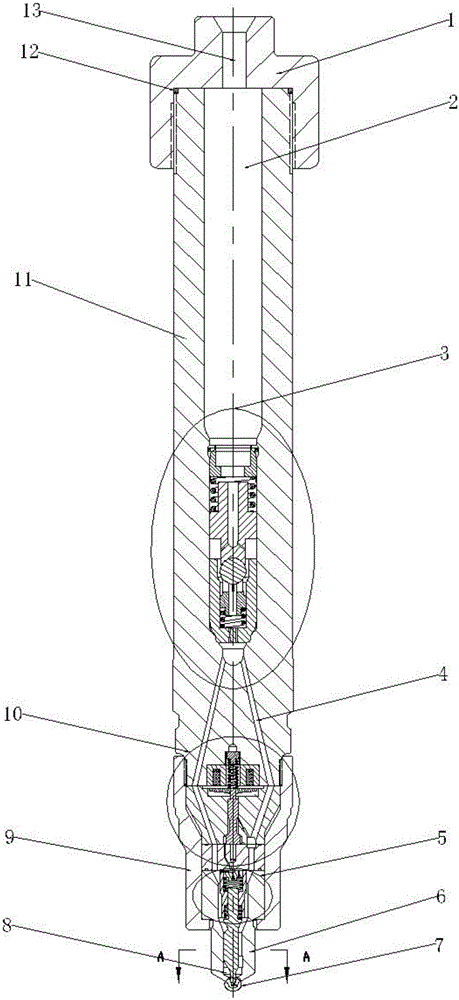

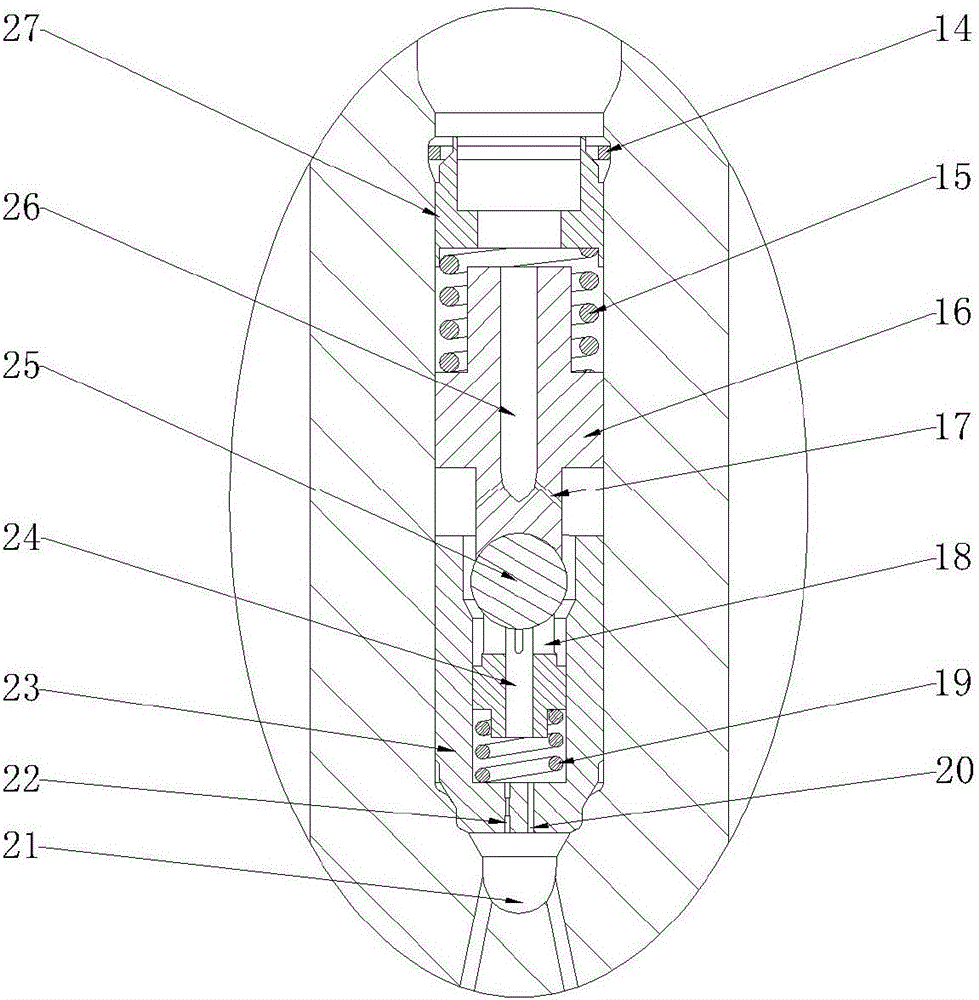

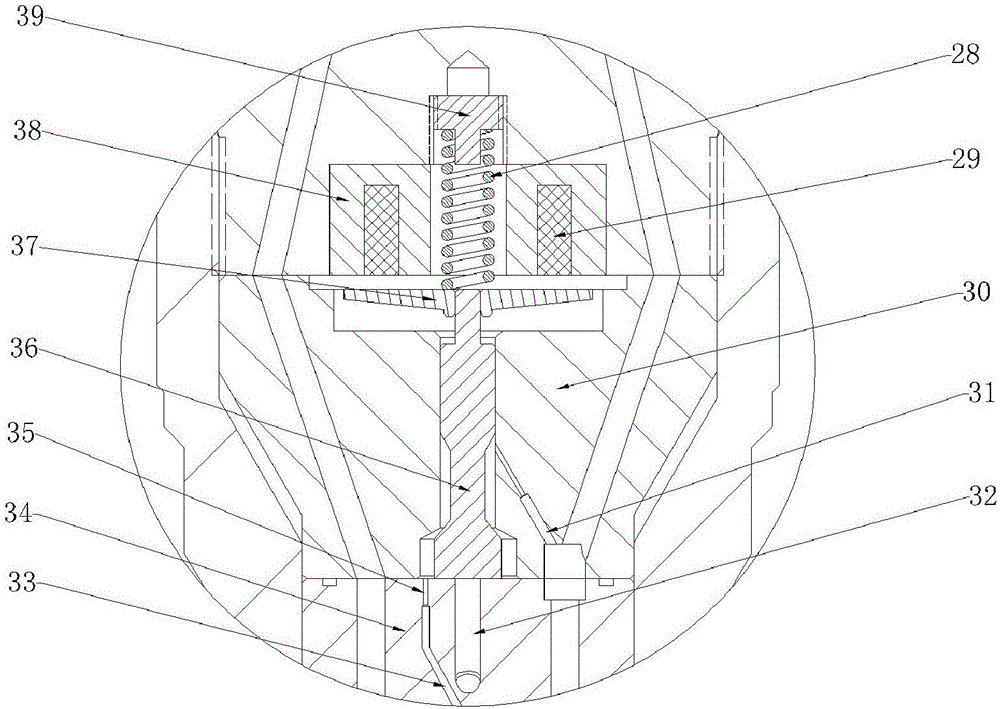

[0025] combine Figure 1-6 , the main structure of the present invention is a two-way oil-inlet resonant bypass type electronically controlled fuel injector with grooves, including a fuel injector head 1, a fuel injector body 11, a restrictor valve assembly 3, a solenoid valve assembly 10, a tight Cap 9, needle valve assembly 5, needle valve seat 6, nozzle 7. The fuel injector head 1 is connected with the fuel injector body 11 through threads, and is sealed with a sealing ring 12 placed on the fuel injector body 11 . The main oil inlet hole 13 on the injector head 1 communicates with the accumulator chamber 2 in the injector body 11 . Below the injector body 11 is a solenoid valve assembly 10 , a needle valve seat 6 and a needle valve assembly 5 , which are assembled and connected by a tight cap 9 . The flow limiting valve assembly 3 is placed inside the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com