Orifice-plate type adjustable throttle valve and manufacturing method thereof

A manufacturing method and adjustable technology, applied in the petrochemical field, can solve problems such as short service life, high noise of throttle valve, poor safety, etc., and achieve the effect of improving service life, increasing escape volume, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

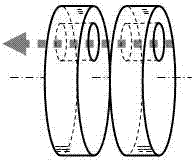

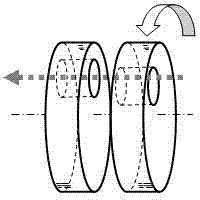

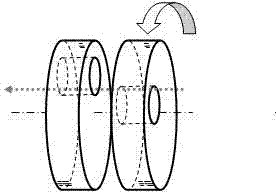

Image

Examples

Embodiment Construction

[0051] The present invention takes Figure 5 The oil (gas) wellhead orifice throttle valve is used as the best example to illustrate the specific implementation method:

[0052] A. Preparation:

[0053] First, according to the design requirements, determine the shape and size of the throttle valve components that match the parameters such as pressure, temperature, flow rate, and ambient operating temperature. Considering the high temperature, high pressure, high corrosion, and high frequency operating environments of oil (gas) wells, generally High-strength, corrosion-resistant chrome-molybdenum steel forgings are used as the main material of the throttle valve; hard alloy steel is used as the base material of vulnerable parts.

[0054] Tempering of prefabs:

[0055] After the chrome-molybdenum steel forging is processed by red forging, a large amount of forging stress is accumulated inside the material. If it is not eliminated, it will seriously affect the processing of sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com