Jellyfish-like printing and dyeing wastewater fiber adsorption device and use method thereof

A printing and dyeing wastewater and adsorption device technology, applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve problems such as filter blockage, promote oil dissolution, reduce oil content, and increase escape volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

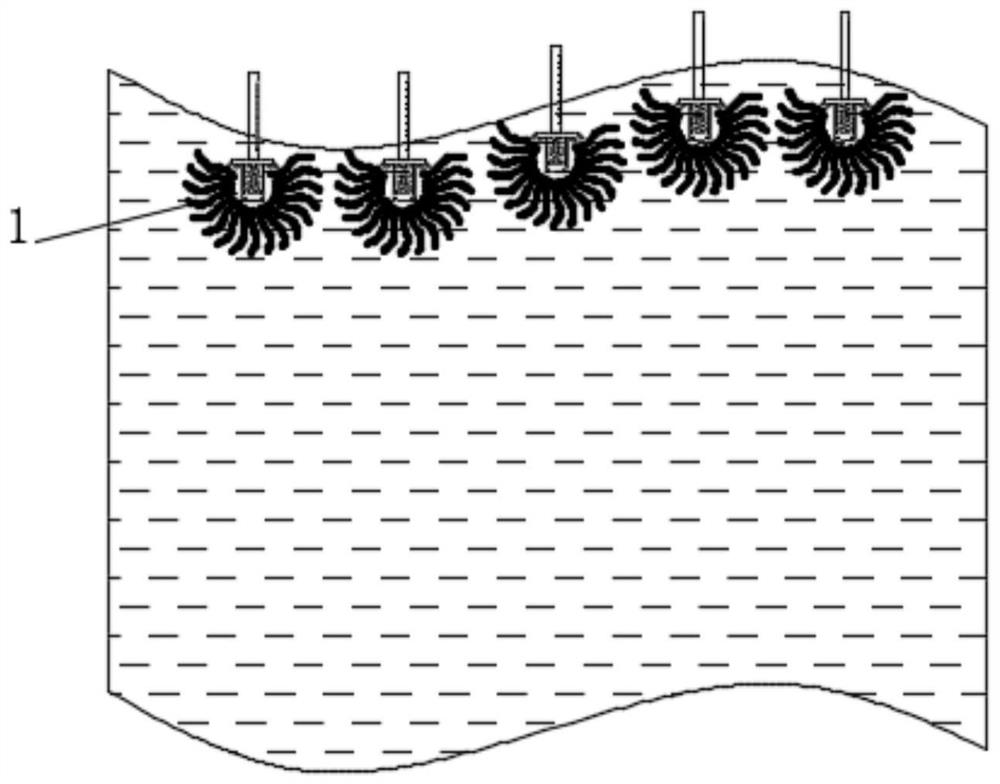

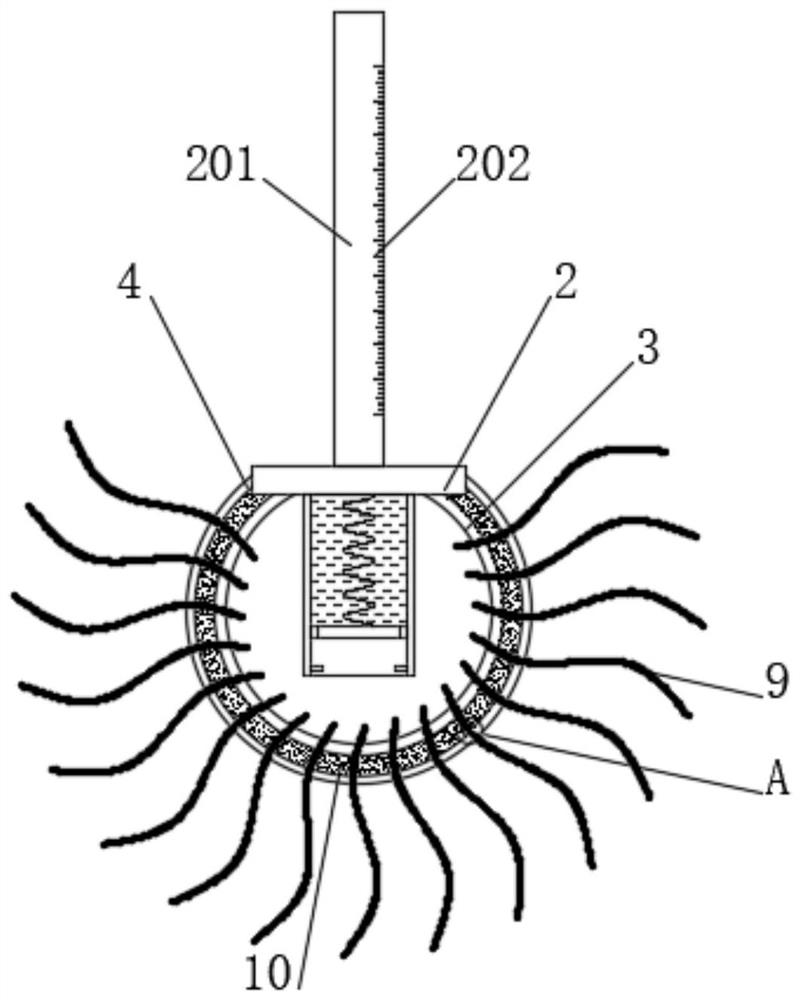

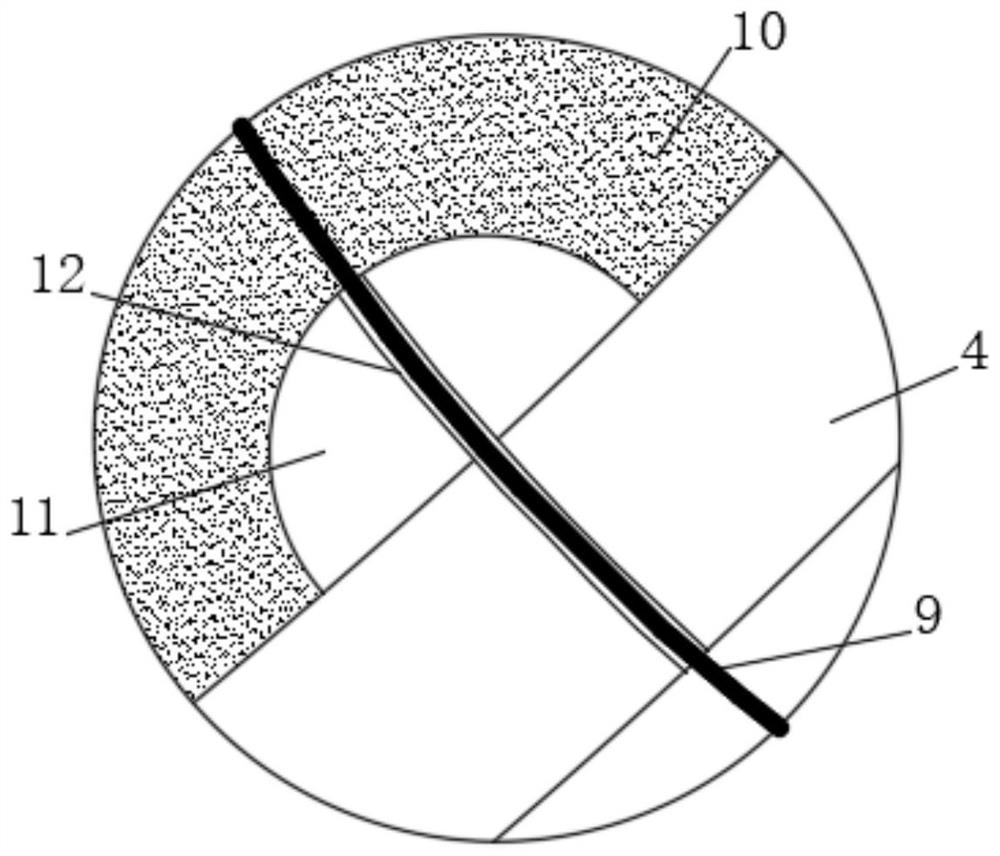

[0043] see Figure 1-4 , a jellyfish-like printing and dyeing wastewater fiber adsorption device, including a plurality of adsorption floating balls 1 floating in the printing and dyeing wastewater, the adsorption floating balls 1 include a receiving disc 2, and an inner elastic balloon 3 is fixedly connected to the lower end of the receiving disc 2 , the outer end of the inner elastic balloon 3 is provided with an outer spherical frame 4 fixedly connected with the receiving disc 2, the surface of the outer spherical frame 4 is coated with a hot melt adhesive layer, and the bottom end of the receiving disc 2 is fixedly connected with an inner elastic The fixed cylinder 5 in the balloon 3 is slidably connected with a movable disc 6, and a tension spring 7 is fixedly connected between the movable disc 6 and the receiving disc 2, and the fixed cylinder 5 is filled with The carbon dioxide aqueous solution 8 on the side, the outer end of the inner elastic balloon 3 is embedded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com