Ship SCR system ammonia spraying amount control method based on ARMAX and MMPC

A technology of SCR system and control method, which is applied in the direction of electronic control of exhaust gas treatment device, exhaust gas treatment, mechanical equipment, etc., can solve the problems of weak robustness, low denitration efficiency, and large amount of ammonia escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

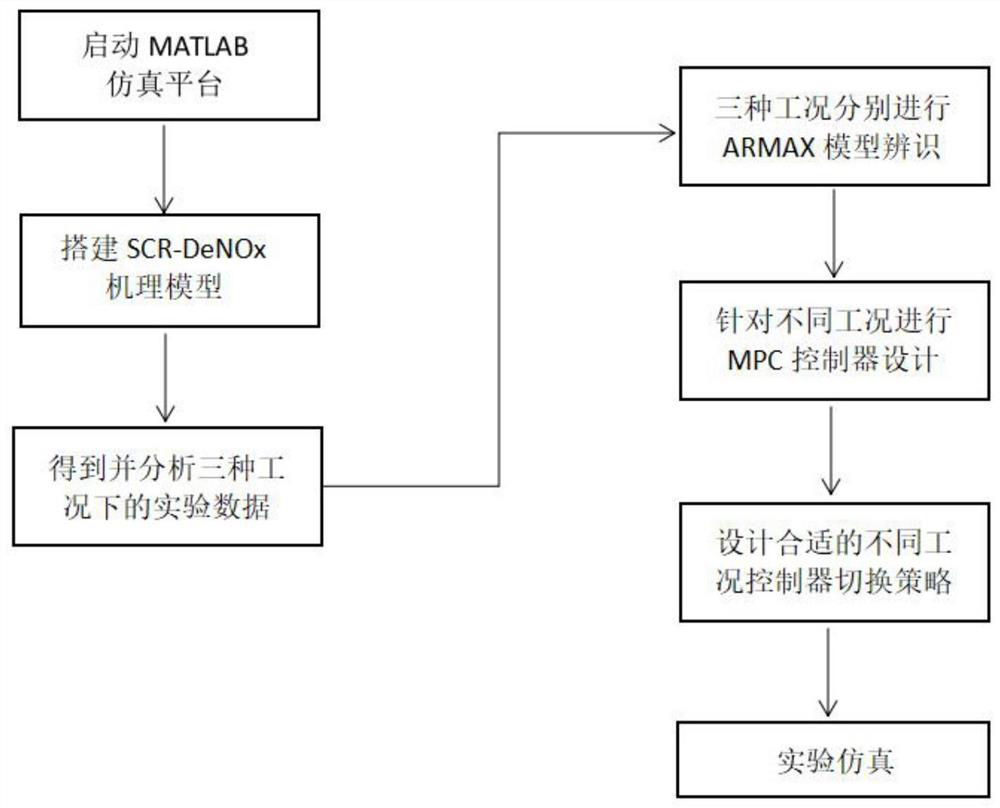

[0067] S1, S2: According to the change of diesel engine exhaust NOx concentration obtained from the data of a marine diesel engine experimental platform, according to S1, the working state of marine diesel engine is mainly divided into three working conditions: economic working condition, standard working condition and overload working condition. According to the division of these three working conditions, the marine diesel engine exhaust data is divided into three parts; then according to S2, the diesel engine exhaust data is used as the entry data of the SCR denitrification mathematical mechanism model for simulation. Figure 6 It is the inlet and outlet NOx concentration map under economic conditions, the inlet NOx concentration changes mainly in the range of 3500-5500ppm, and the concentration amplitude change range is about 2000ppm; Figure 7 It is the inlet and outlet NOx concentration diagram under the standard working condition. The concentration change of the inlet NOx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com