Intra-furnace flue gas denitration ammonia spraying intelligent system and control method thereof

An intelligent system and flue gas technology, applied in the direction of flow control, non-electric variable control, control/regulation system, etc., can solve problems such as increasing desulfurization cost and equipment corrosion, improve utilization efficiency, avoid equipment corrosion, and reduce popularization and application. the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

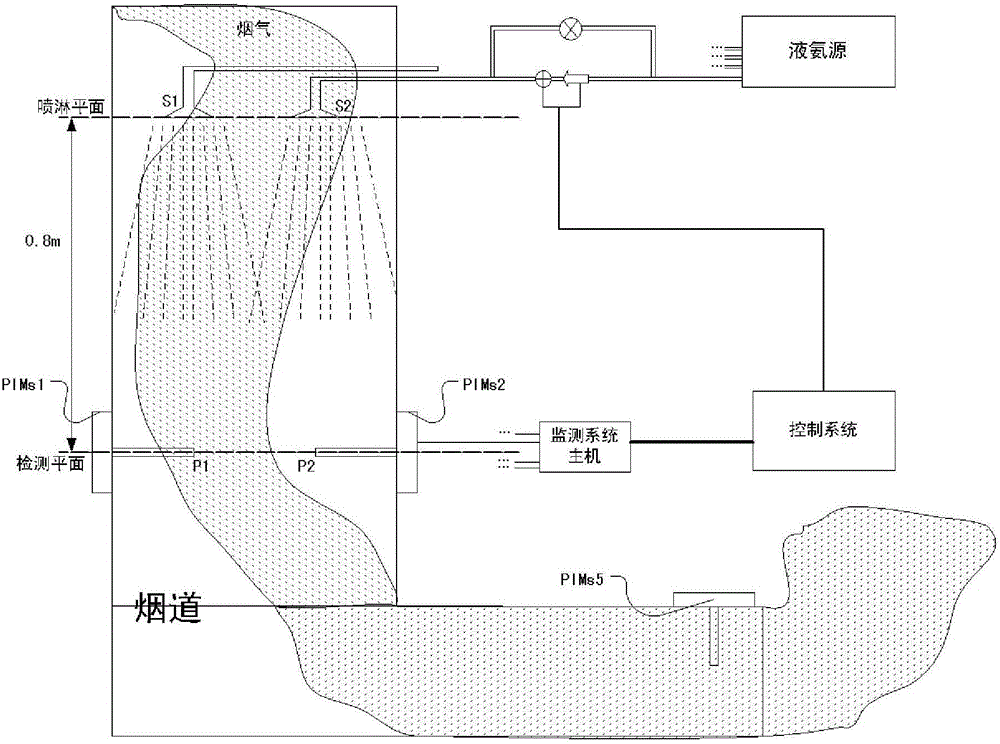

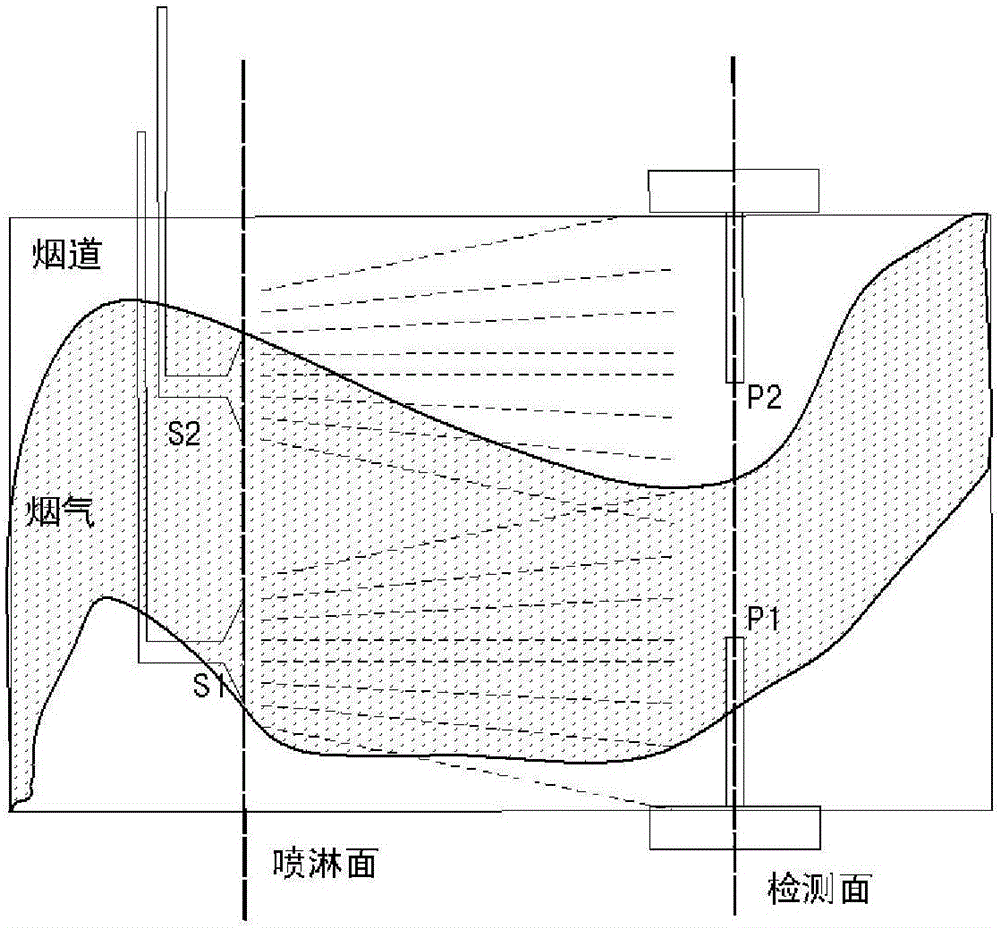

[0037] In the process of realizing the present invention, the applicant found that: since the flue cannot be a long cylindrical structure extending infinitely, there must be a bend. In this case, the flue gas forms a reflection during the movement. The local irregular structure will also cause the swirling movement of the flue gas. These factors work together to cause the flue gas concentration (NO X concentration) unpredictability. In this case, the use of the same liquid ammonia spray mode must not satisfy all situations, or cause NO X Remove impurities, or spray excessive liquid ammonia to cause waste.

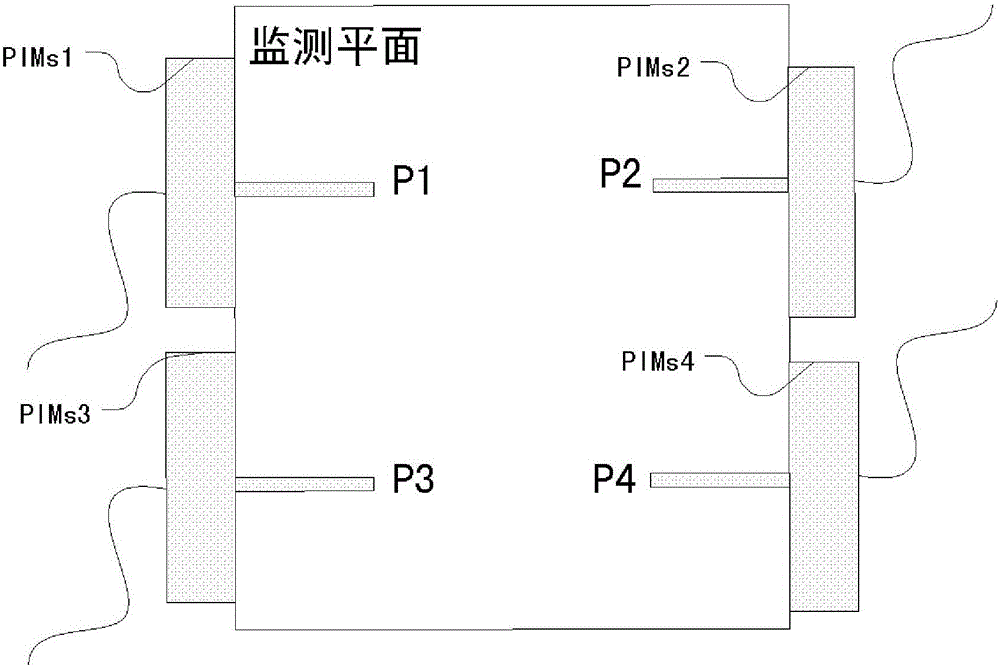

[0038] In the present invention, a spray plane and a detection plane perpendicular to the extension direction of the flue are defined in the flue, wherein N spray heads are set on the spray plane, and M local sampling positions at different positions are set on the detection plane, Establish the corresponding relationship between local sampling positions and sprinkler hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com