Patents

Literature

59results about How to "Reduce viscous drag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

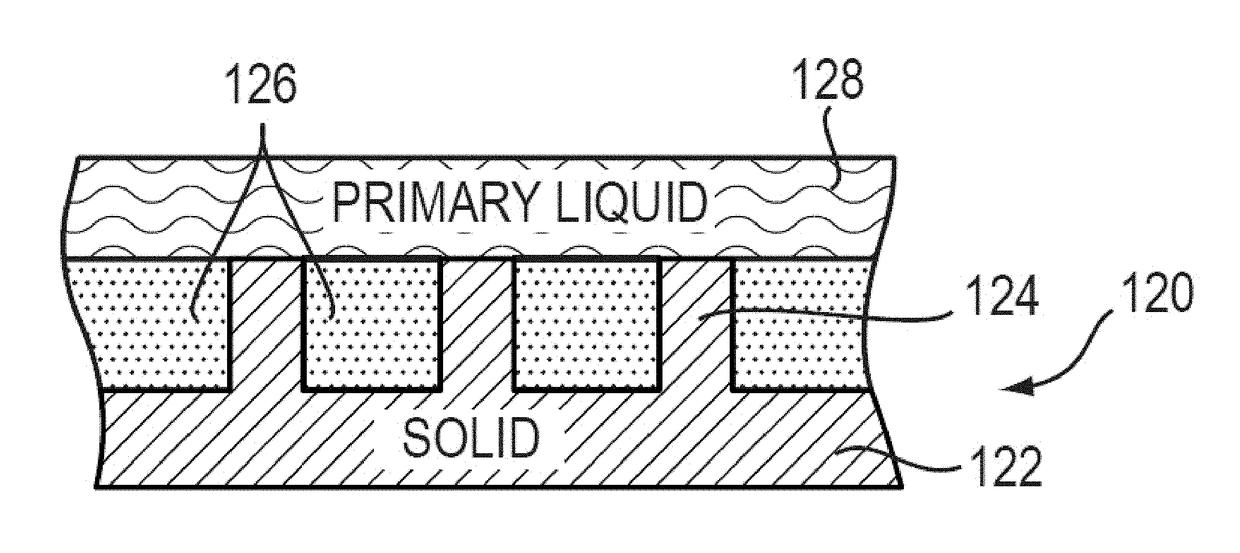

Liquid-Impregnated Surfaces, Methods of Making, and Devices Incorporating the Same

InactiveUS20130032316A1Improve skidReduce resistanceFouling preventionDe-icing equipmentsNon wettingFrost

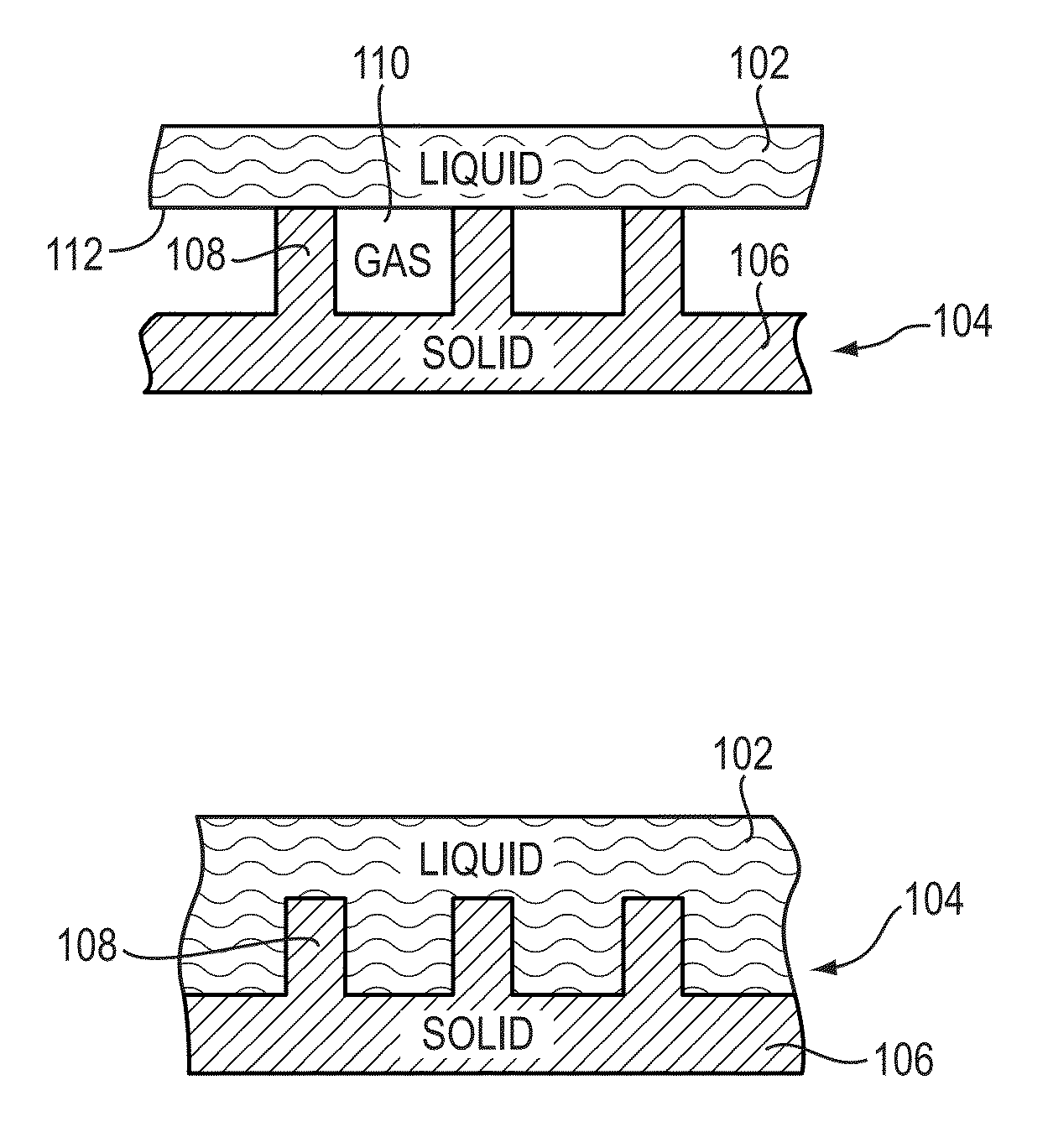

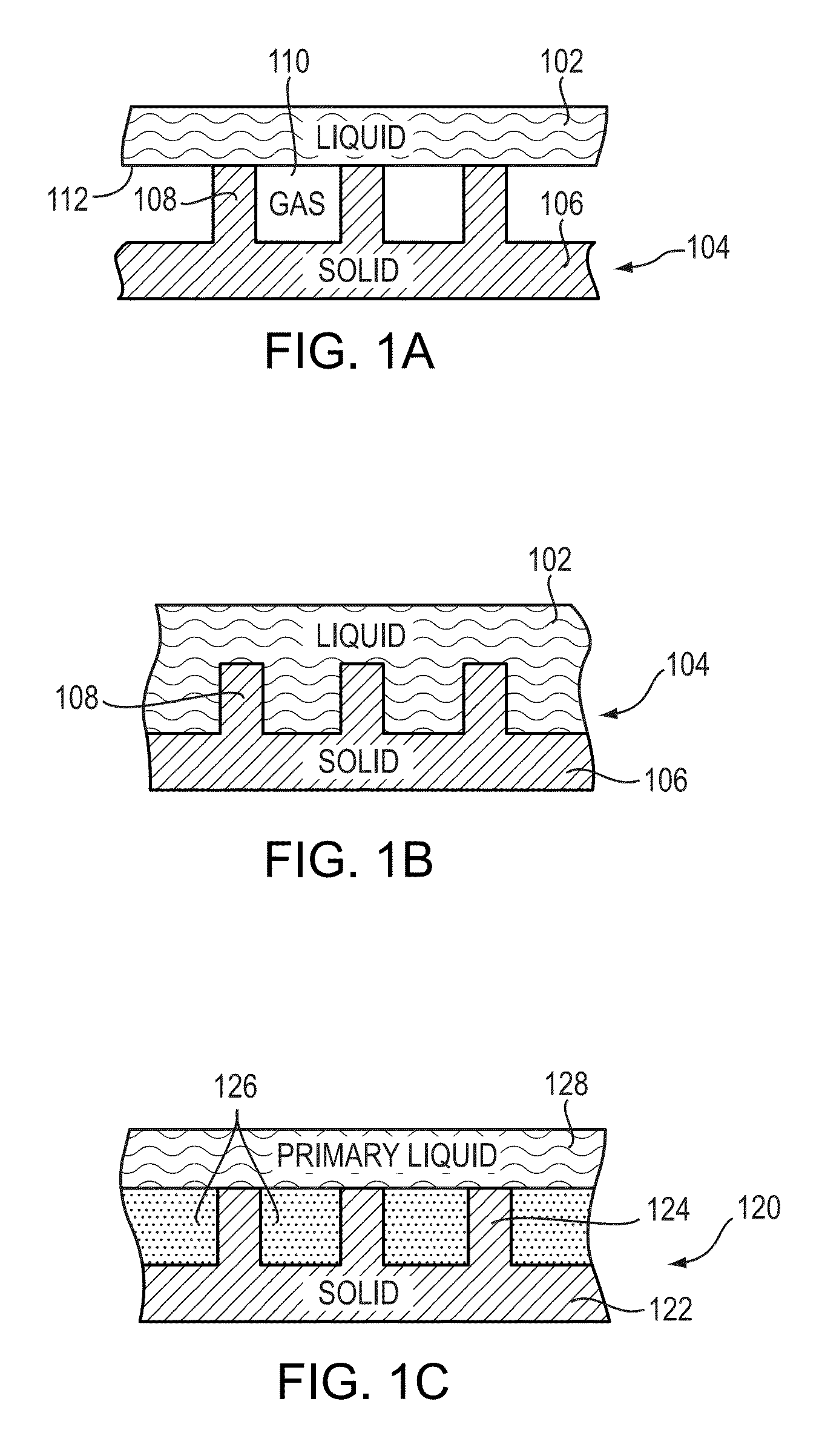

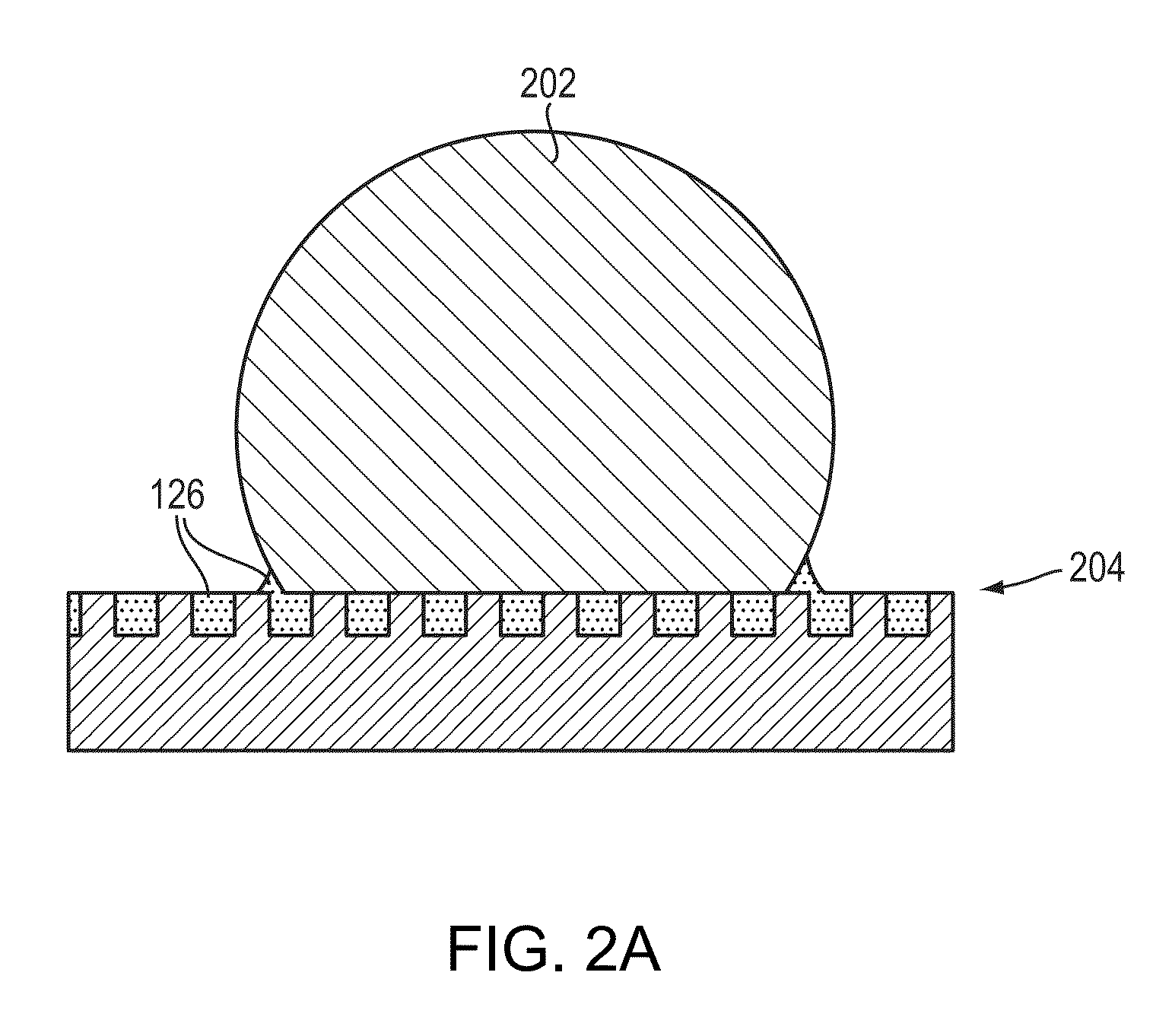

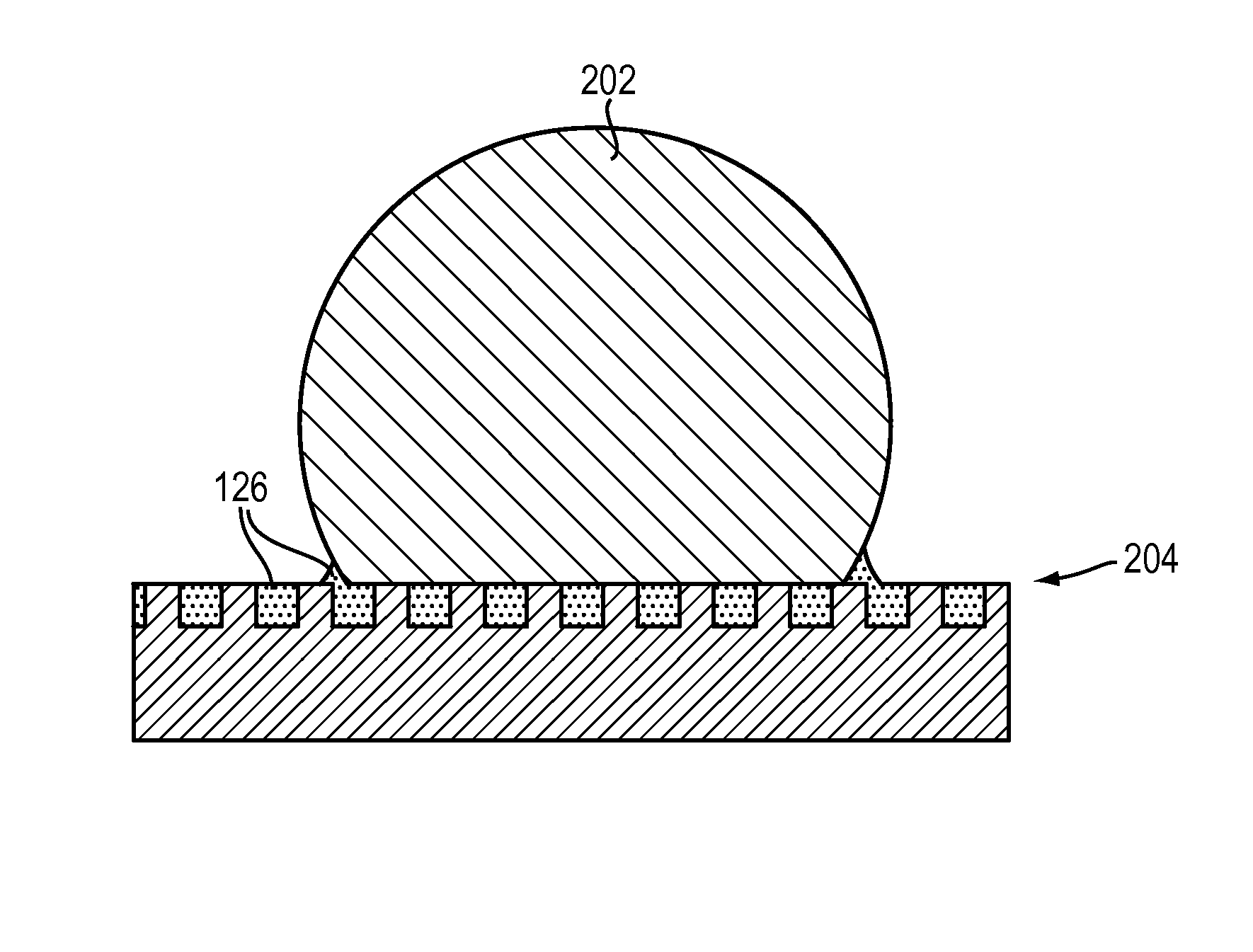

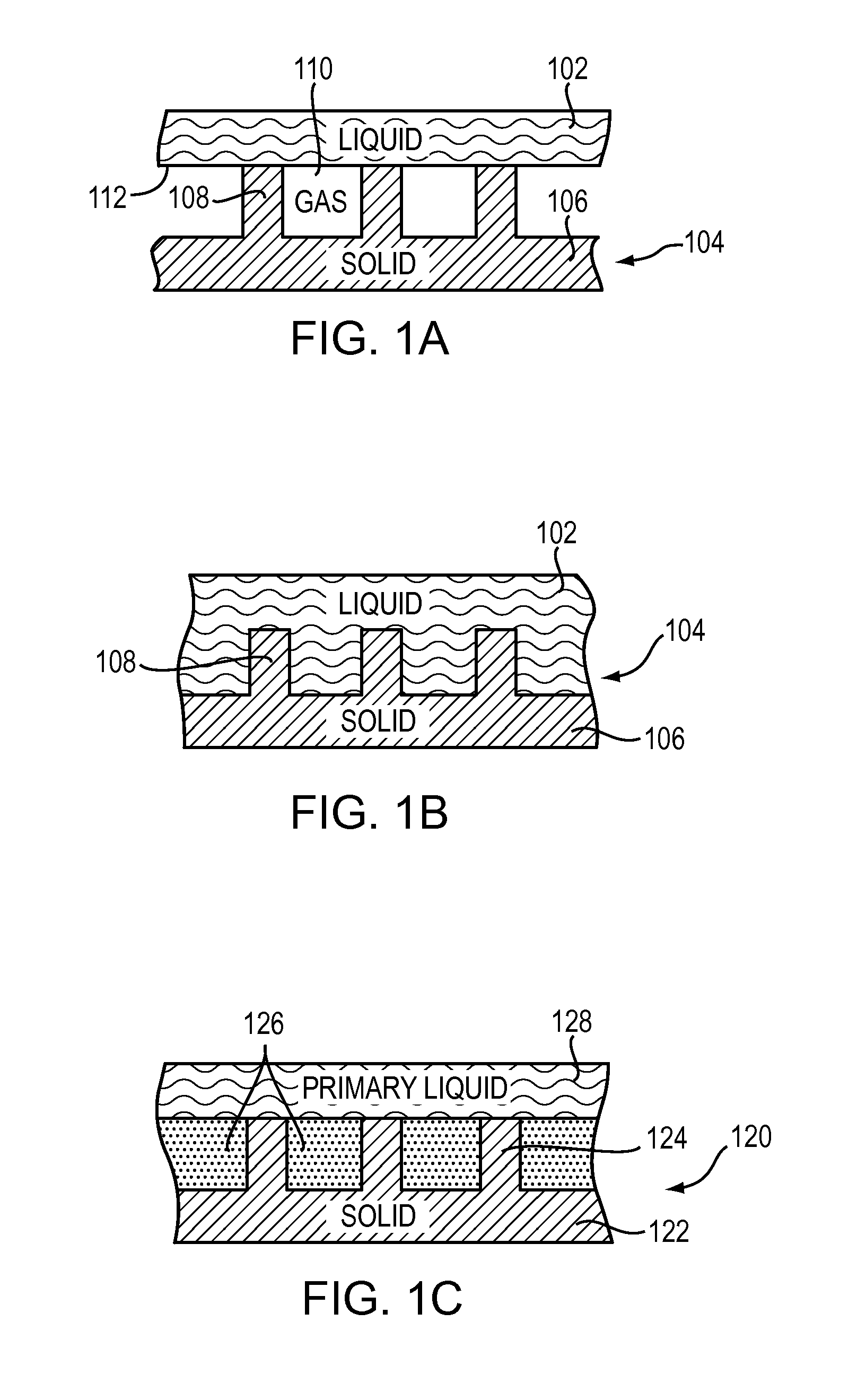

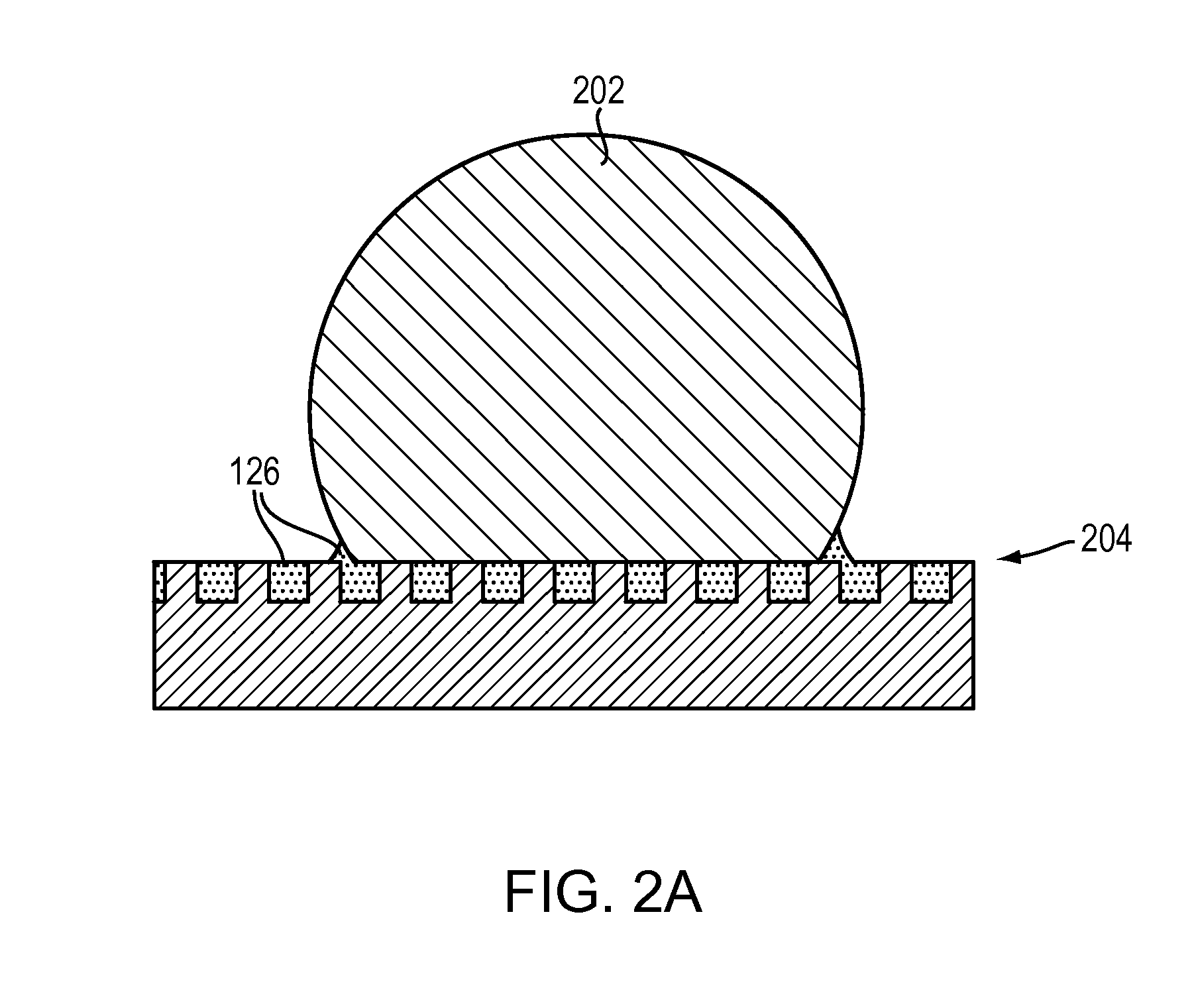

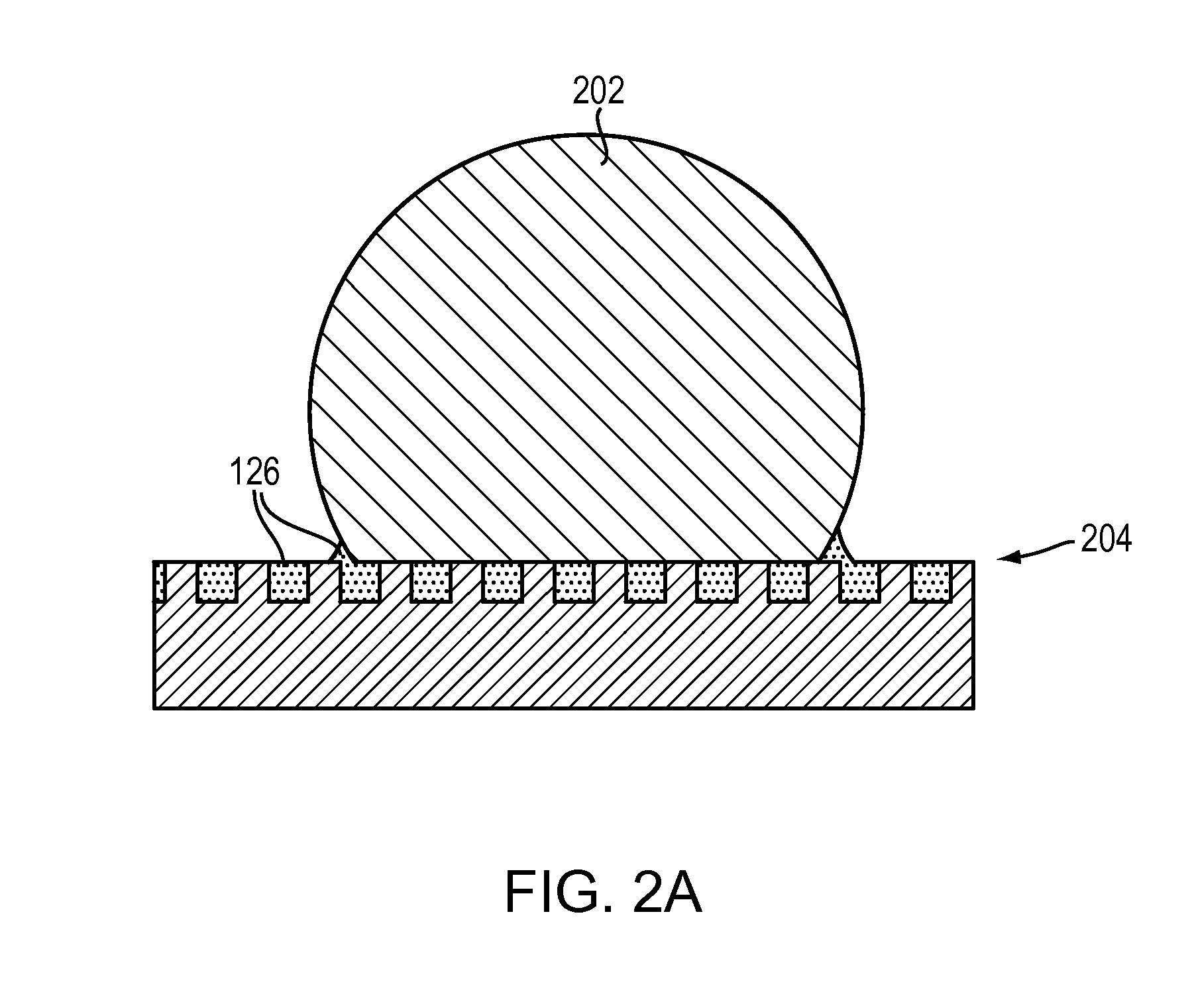

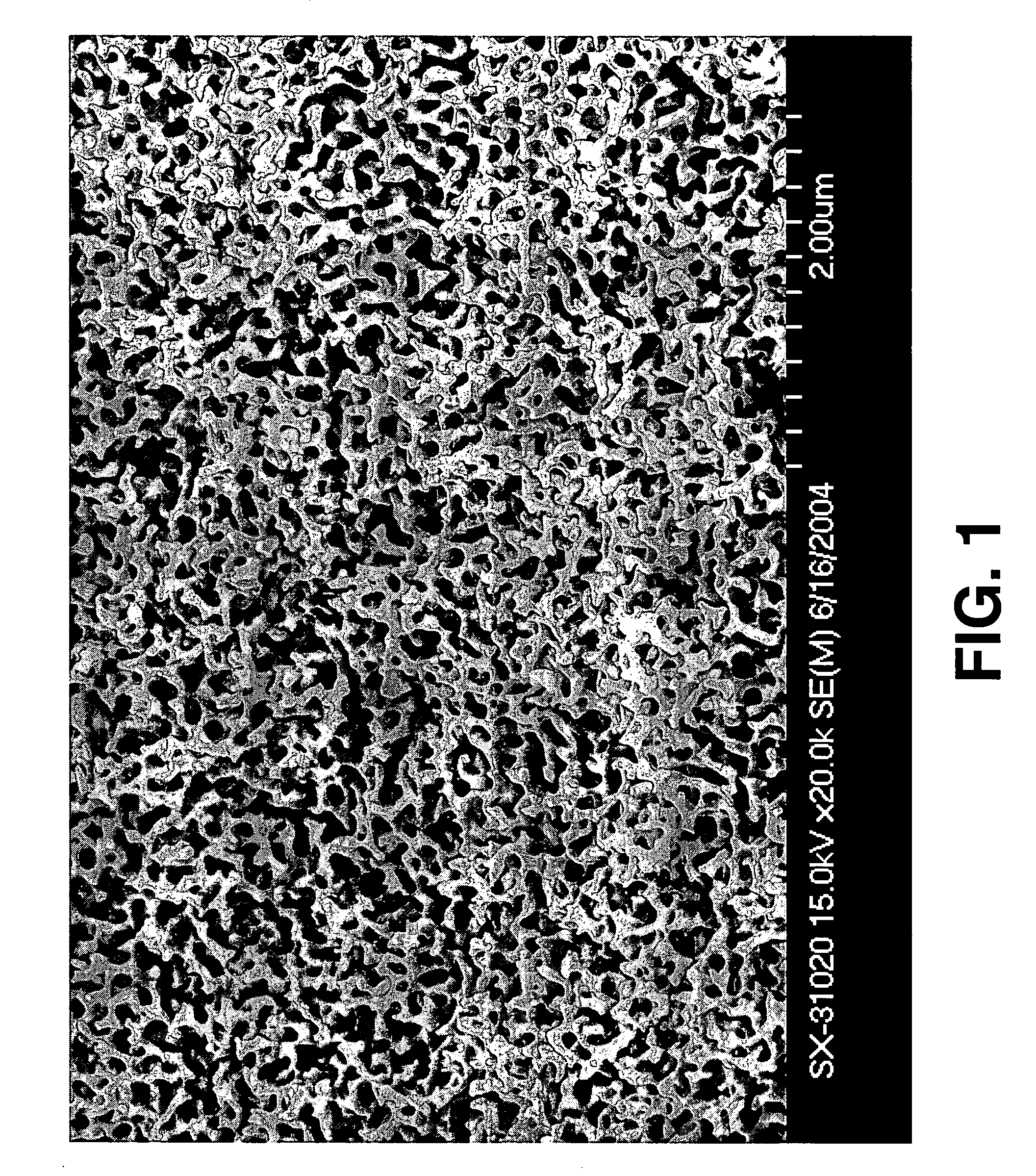

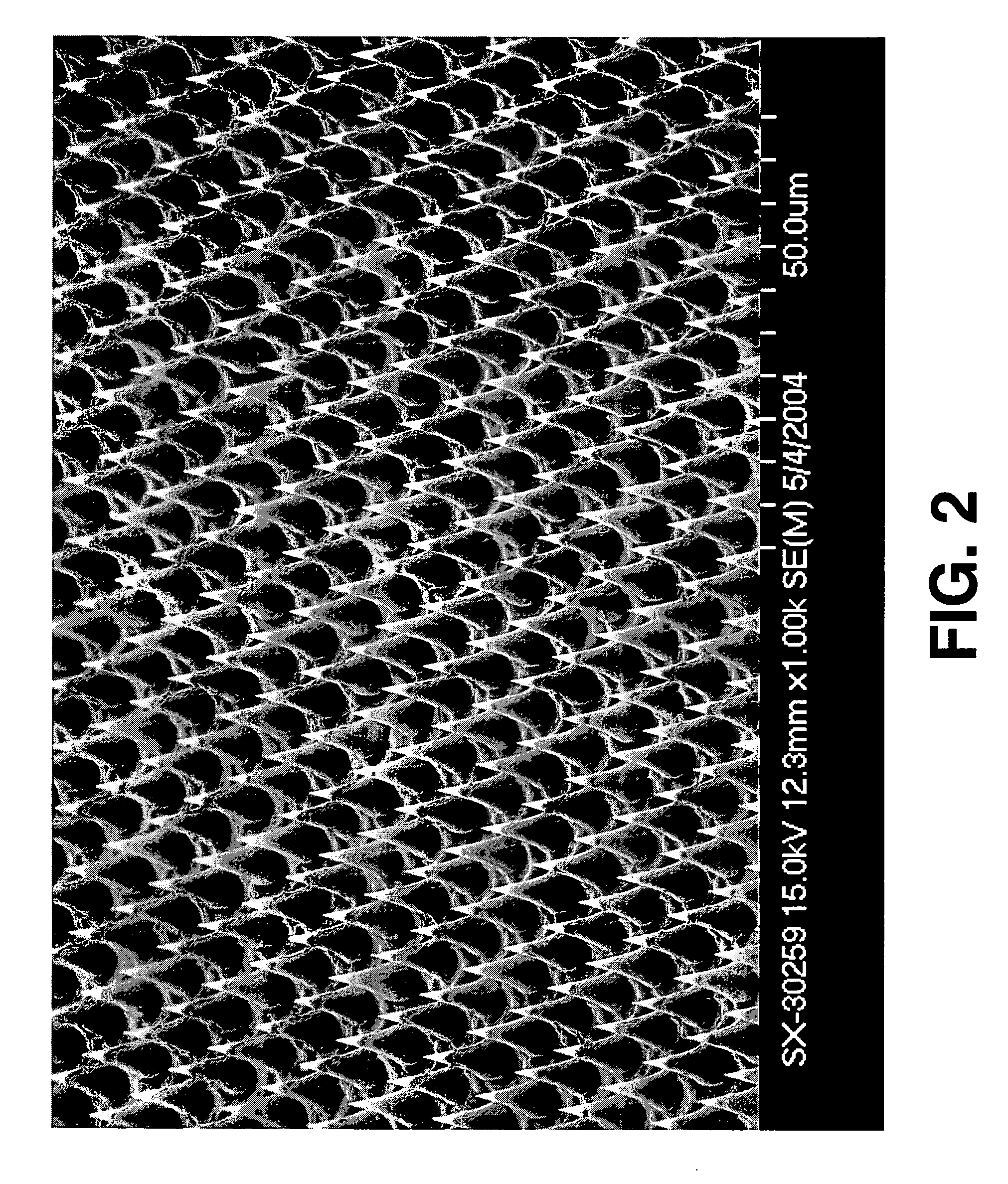

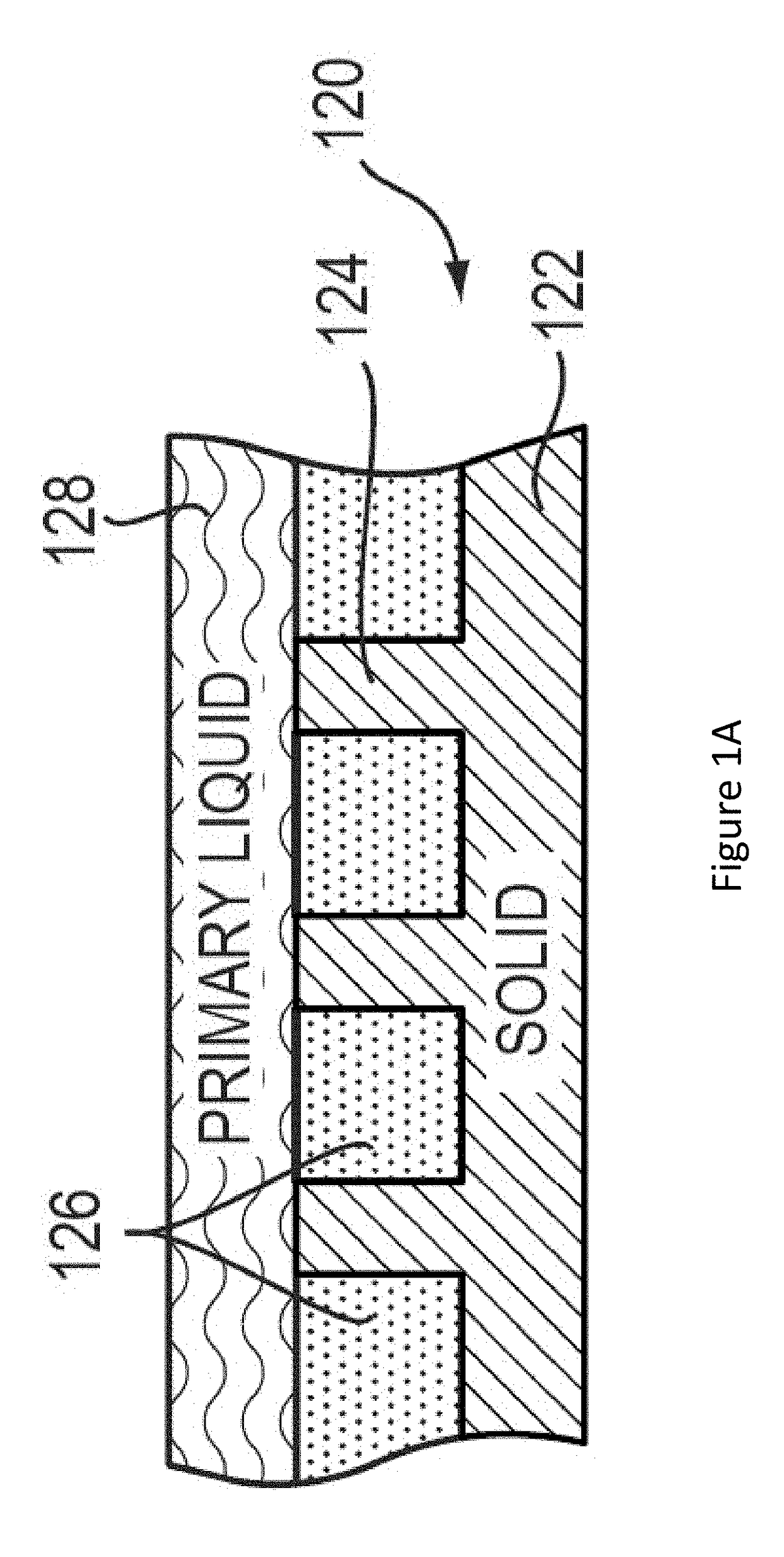

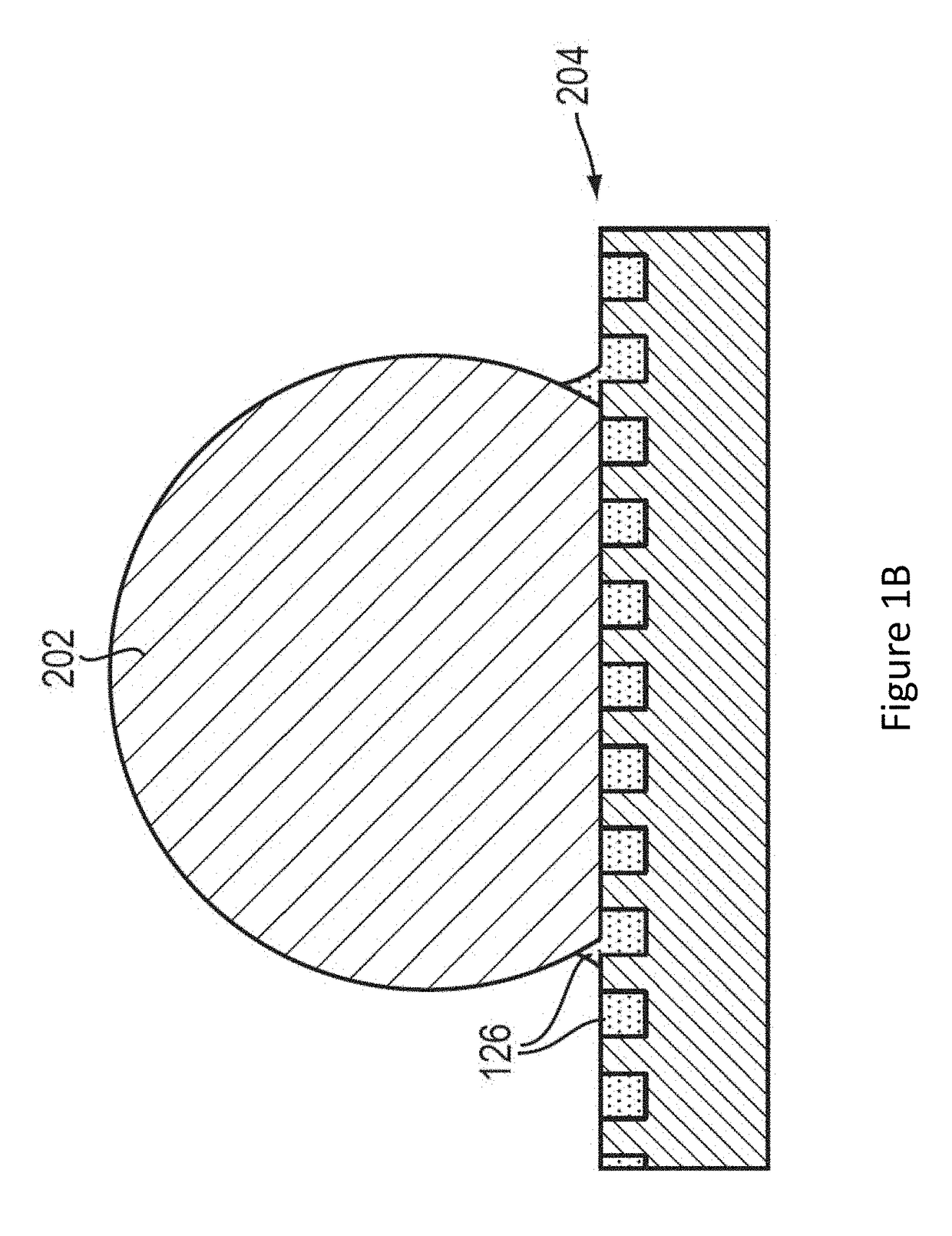

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS8574704B2Reduce viscous dragMinimizes accumulationLayered productsDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS20130034695A1Improve skidReduce resistanceDe-icing equipmentsRecord information storageNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

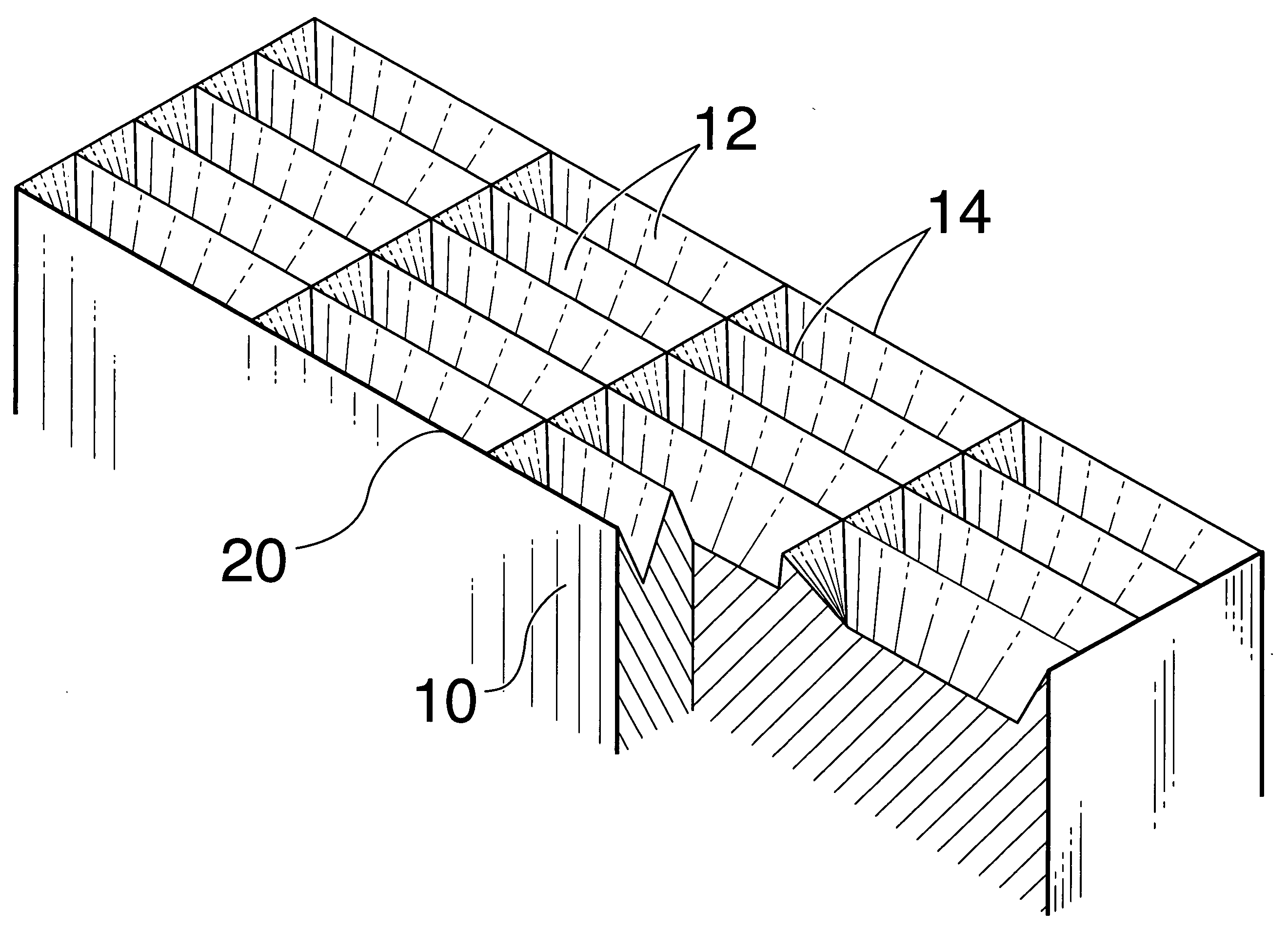

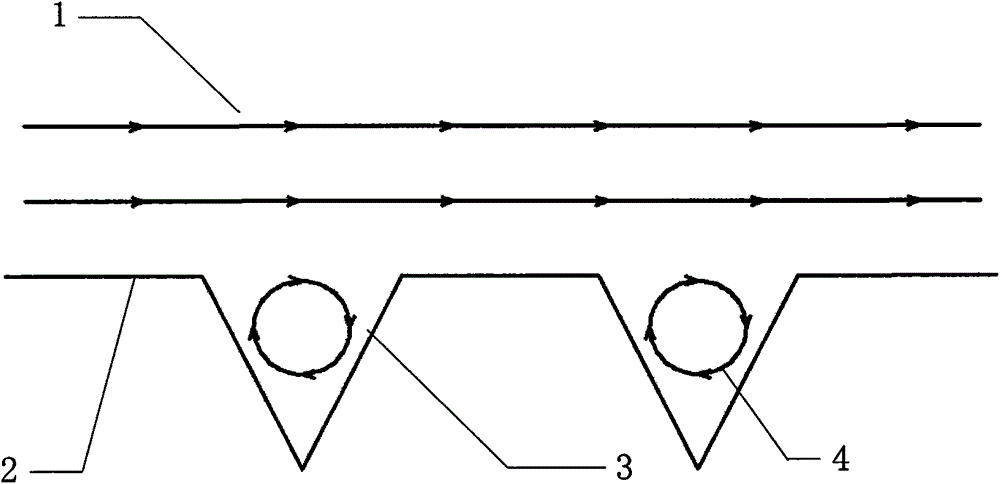

Friction drag-reducing surface

InactiveUS20060251859A1Reduce viscous dragMaterial nanotechnologyLayered productsViscous resistanceMechanical engineering

An article includes a body having at least one viscous drag-reducing surface defining a multiplicity of macro-scale depressions separated and enframed by ridges, at least a portion of the surface being phobic to a preselected liquid so that gas bubbles may be trapped in the macro-scale depressions in order to reduce viscous drag between the article and the liquid.

Owner:UT BATTELLE LLC

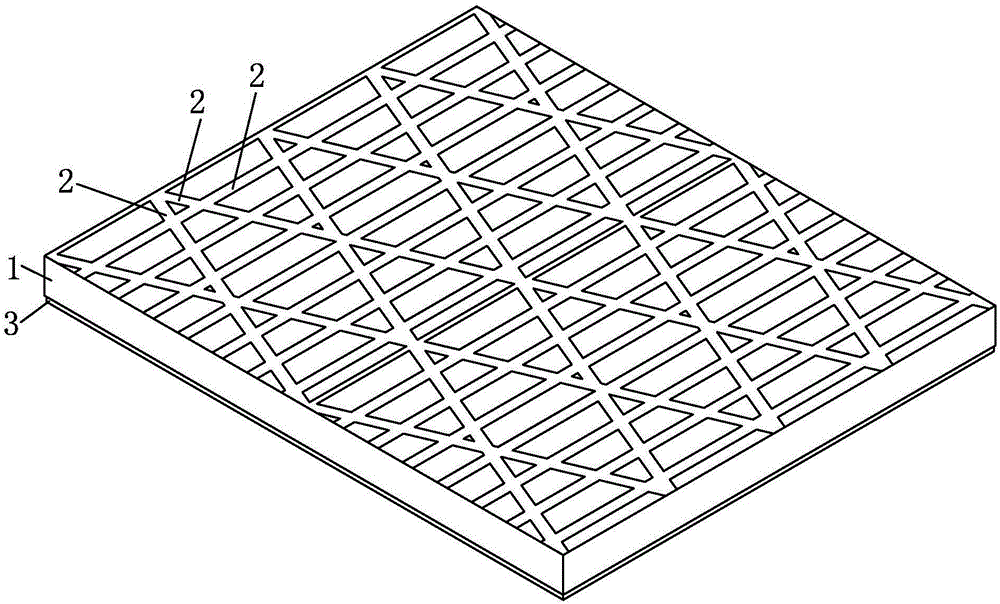

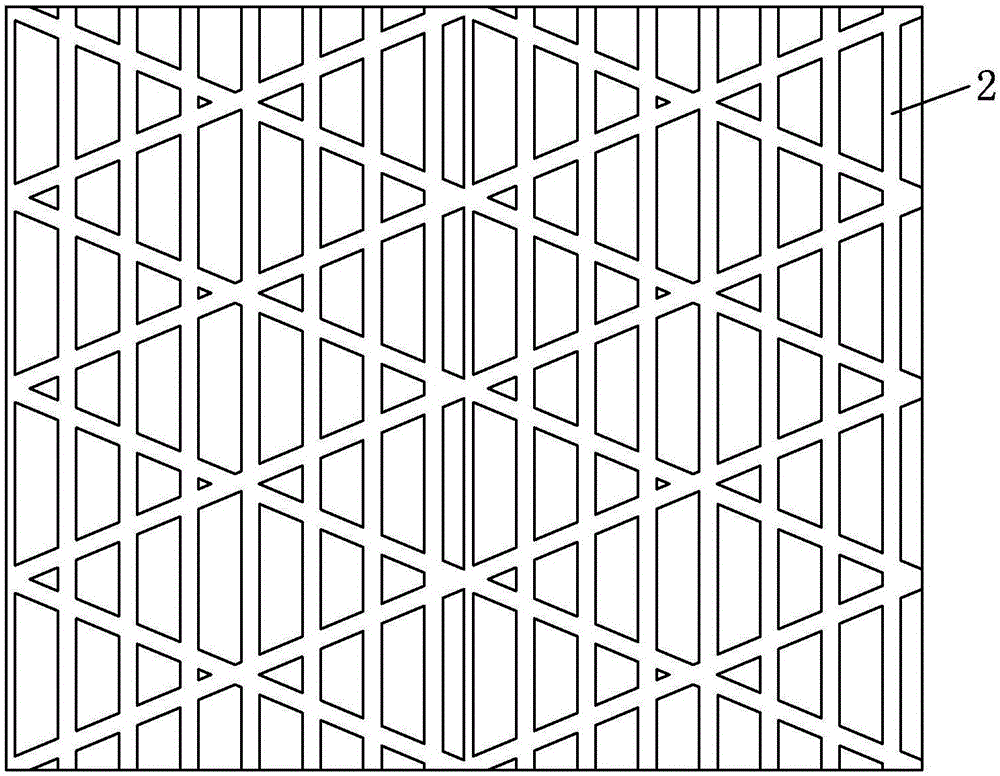

Bionic sharkskin structure capable of reducing drag

ActiveCN106585949AReduced wall shear stressMade softFuselage bulkheadsNanotechnologyConductive coatingAerospace engineering

The invention relates to wings of an aircraft and provides a bionic sharkskin structure capable of reducing drag to overcome the problems that conventional aircrafts cannot improve the off-line pneumatic performance of the whole flight bag in the case of different pneumatic environment conditions on the occasion of a disordered gas field and that the aircrafts encounter great flight drag and cannot meet the demand of flying at different flight speeds in the disordered gas field. The bionic sharkskin structure comprises a dielectric elastomer, a flexible electrode layer and nano-wire conductive coatings, wherein the dielectric elastomer is of a plate structure; one plate surface of the dielectric elastomer is coated with a plurality of the nano-wire conductive coatings; the plurality of the nano-wire conductive coatings are applied along a horizontal direction and along two oblique directions in oblique crossing with the horizontal direction to form a net structure; and other plate surface, opposite to the above plate surface, of the dielectric elastomer is coated with the flexible electrode layer. The bionic sharkskin structure capable of reducing drag in the invention is applied to wing roots.

Owner:HARBIN INST OF TECH

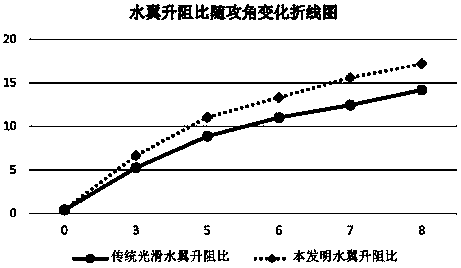

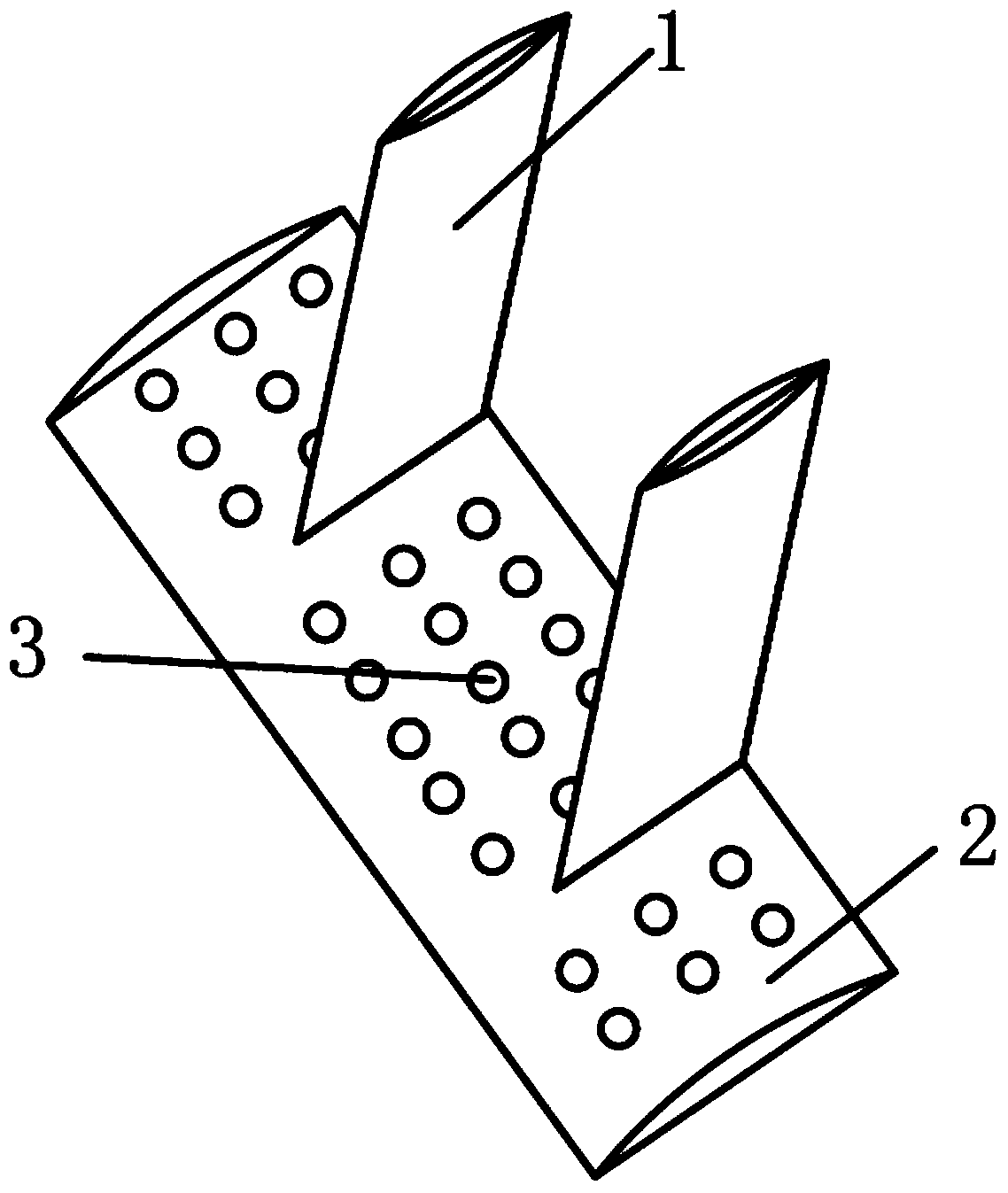

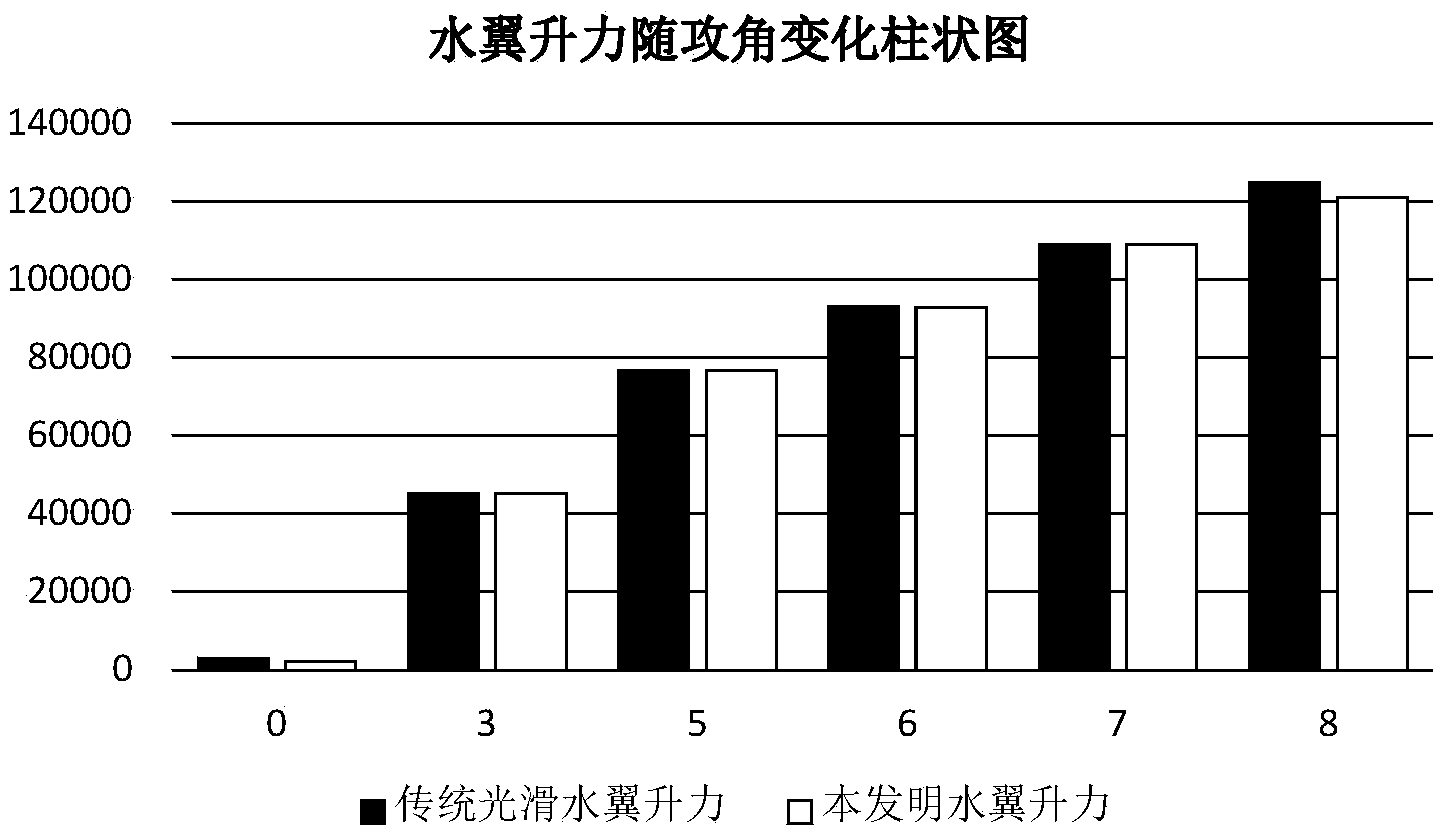

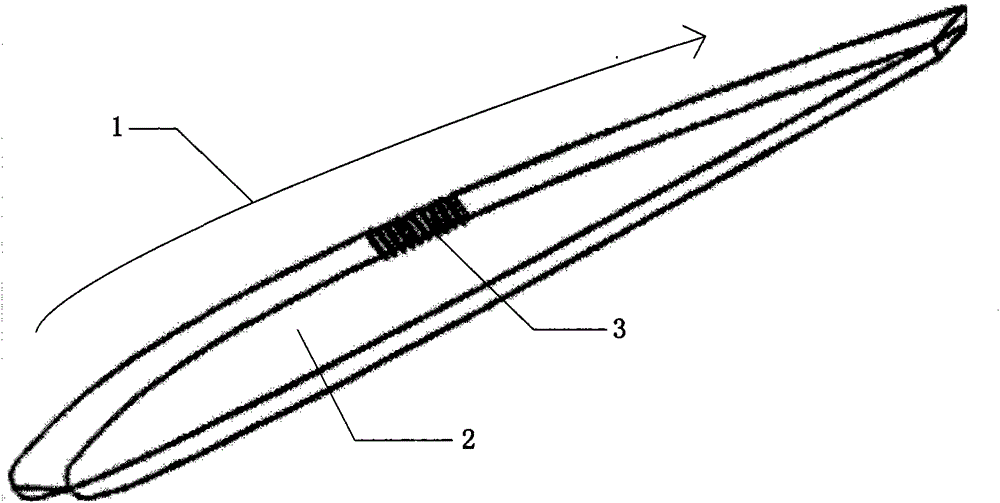

Novel efficient hydrofoil

ActiveCN103910023AReduce viscous dragReduce energy consumptionHydrodynamic/hydrostatic featuresMarine engineeringHigh lift

The invention provides a novel efficient hydrofoil. The novel efficient hydrofoil comprises hydrofins and a hydrofoil strut. The hydrofins are fixedly mounted below a naval ship through the hydrofoil strut, and the outer surfaces of the hydrofins are provided with antidrag structures composed of rough belts, grooves, pits or texture structures. The hydrofins with the antidrag structures have high lift-drag ratio when moving in the water, frictional drag and viscous drag of the hydrofoil to the water can be reduced, energy efficiency of driving delivery tools such as foilcrafts can be improved, and the novel efficient hydrofoil has the advantages that ship navigation speed is improved and energy conservation and emission reduction are realized.

Owner:ZHEJIANG OCEAN UNIV

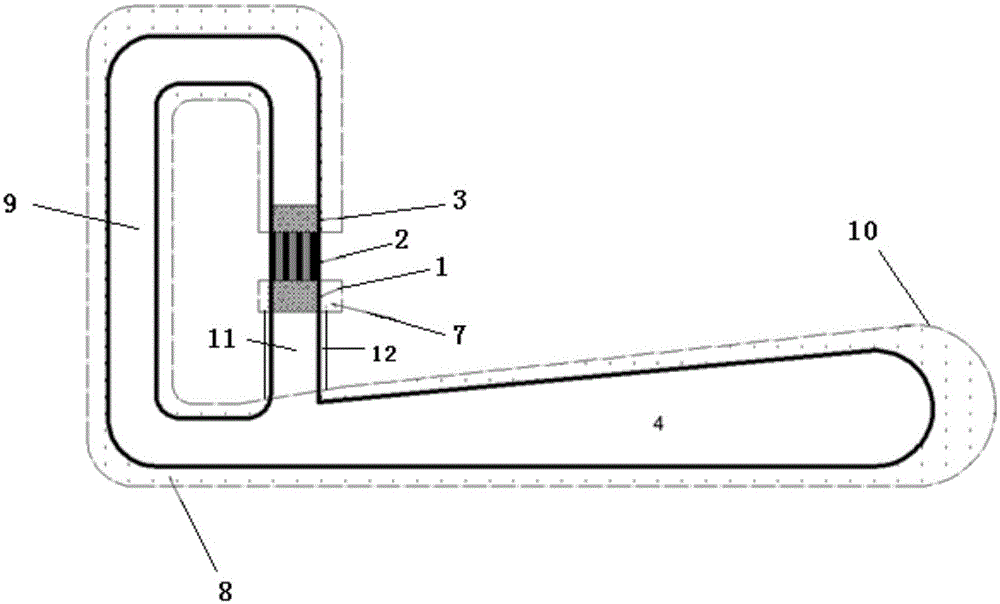

Thermo-acoustic engine device

ActiveCN105649904AImprove efficiencySimple structureMachines/enginesMechanical power devicesThermoacousticsRoom temperature

The invention relates to a thermo-acoustic engine device which comprises a thermo-acoustic engine component, an acoustic power utilization component and an acoustic power outputting component, wherein the thermo-acoustic engine component works in the low-temperature environment; the acoustic power utilization component works in the room temperature environment; the two ends of the acoustic power outputting component are connected with the thermo-acoustic engine component and the acoustic power utilization component respectively. Compared with the prior art, the thermo-acoustic engine device has the advantages of small acoustic power loss, high efficiency, simple device structure, stability in running and the like.

Owner:TONGJI UNIV

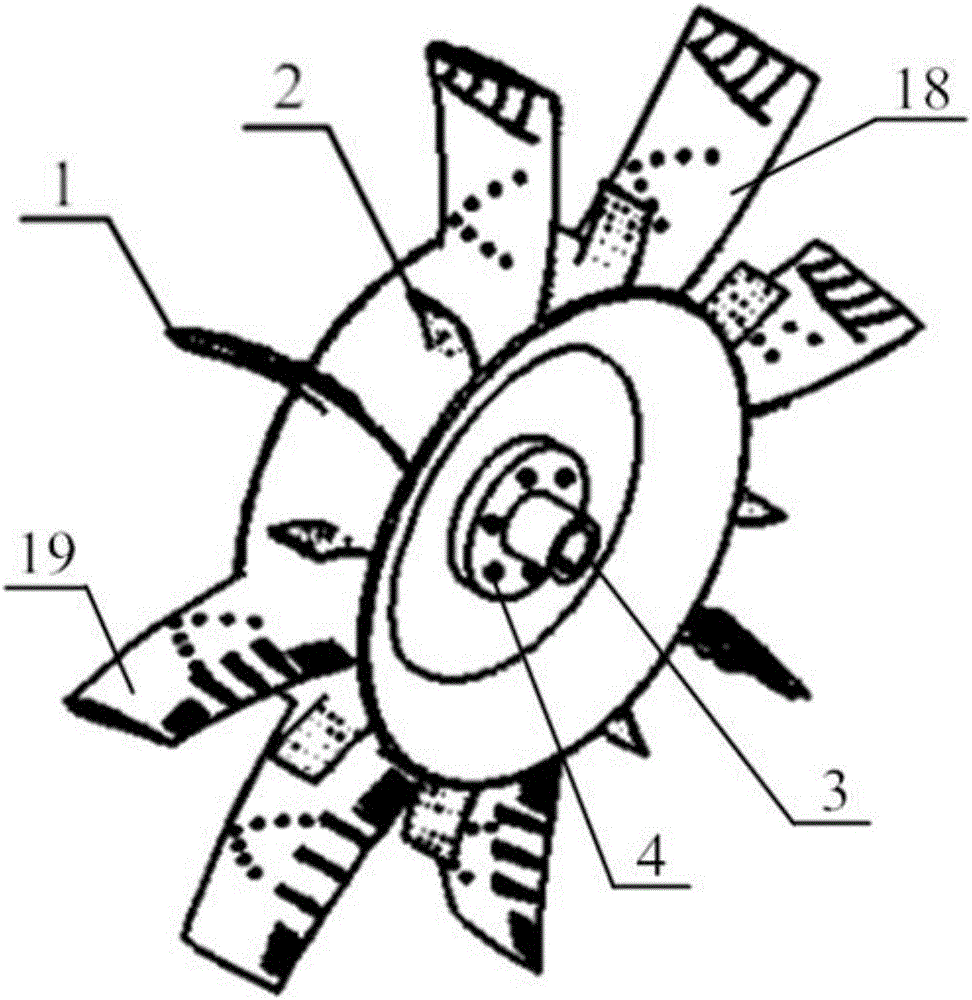

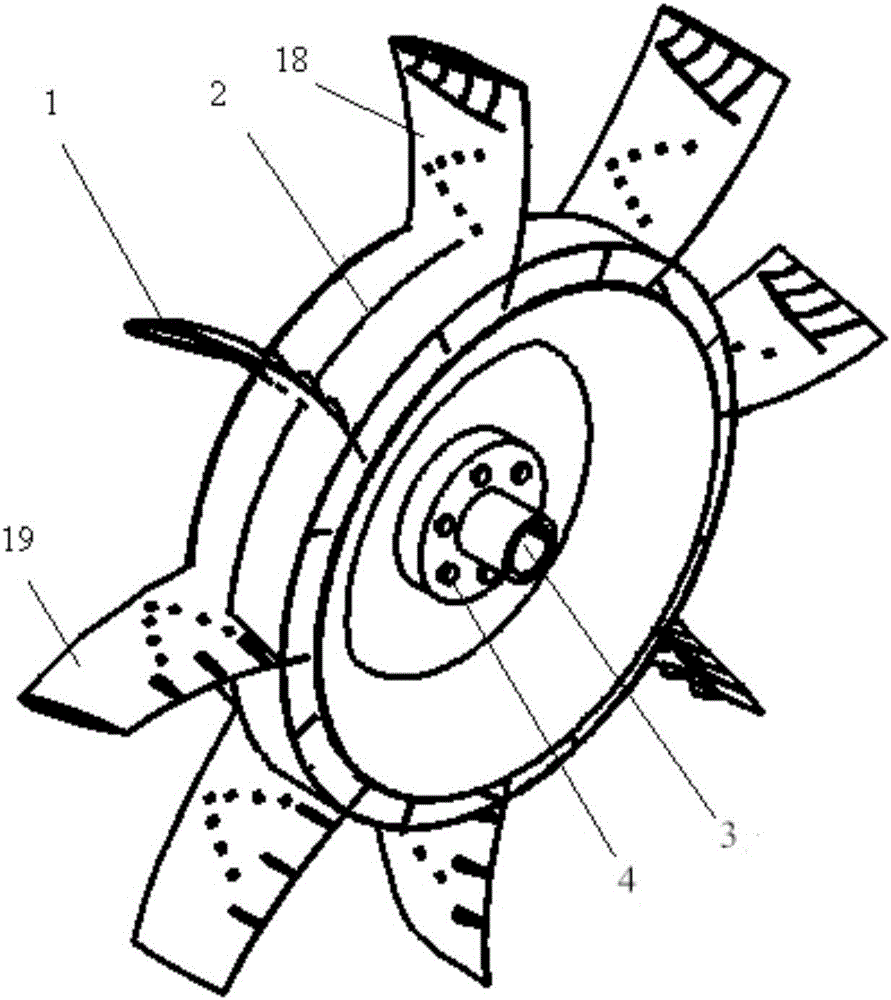

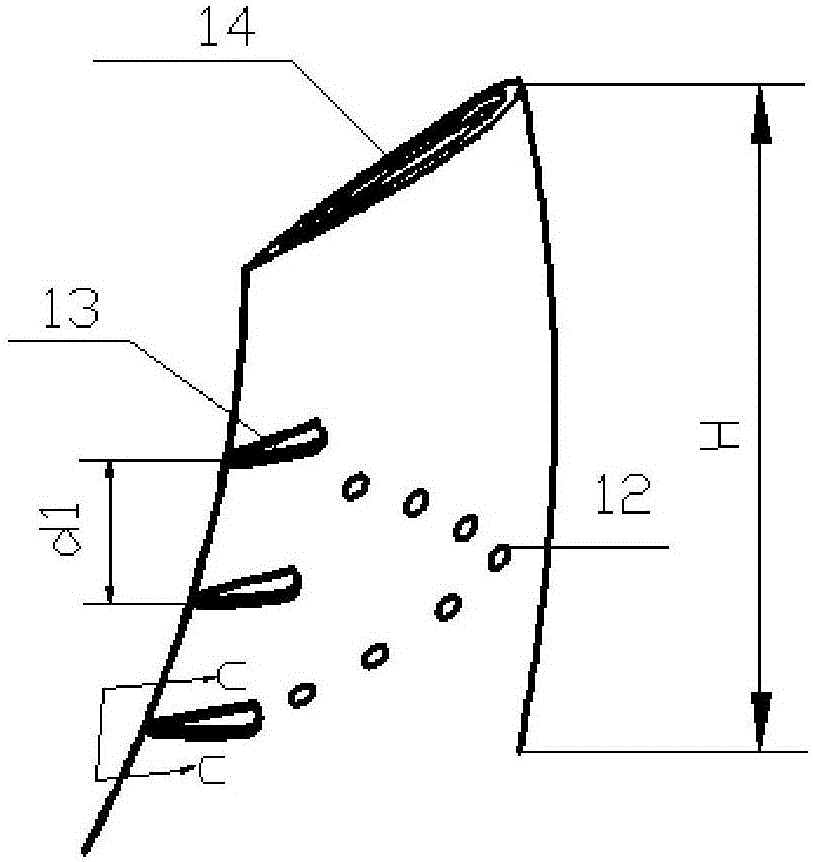

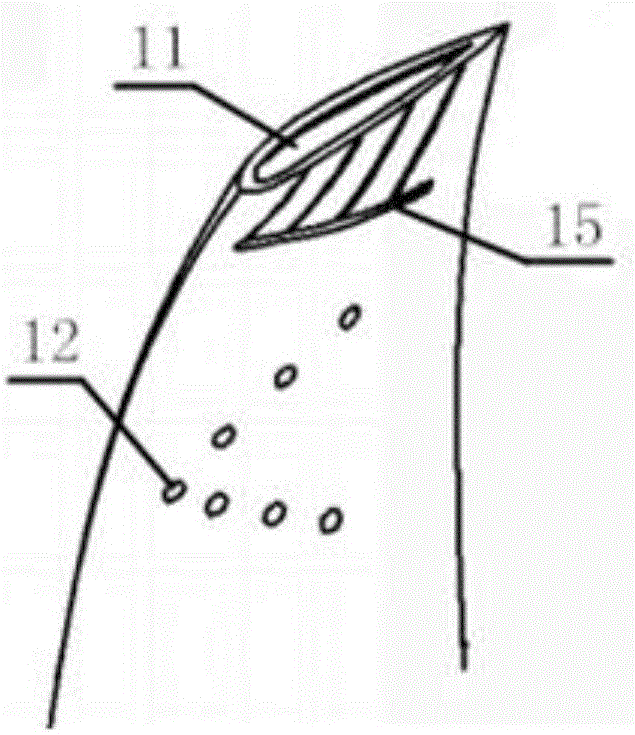

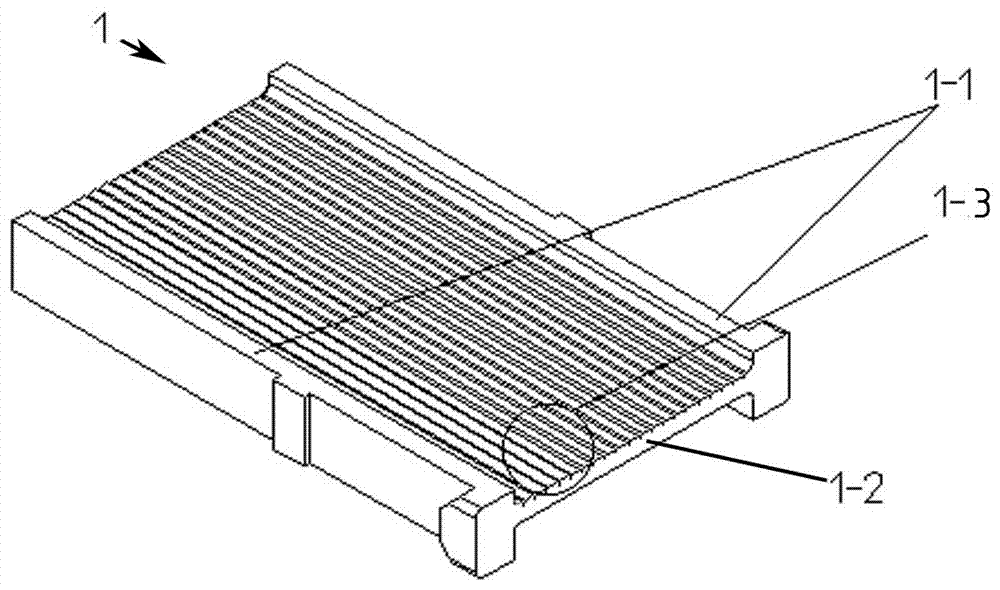

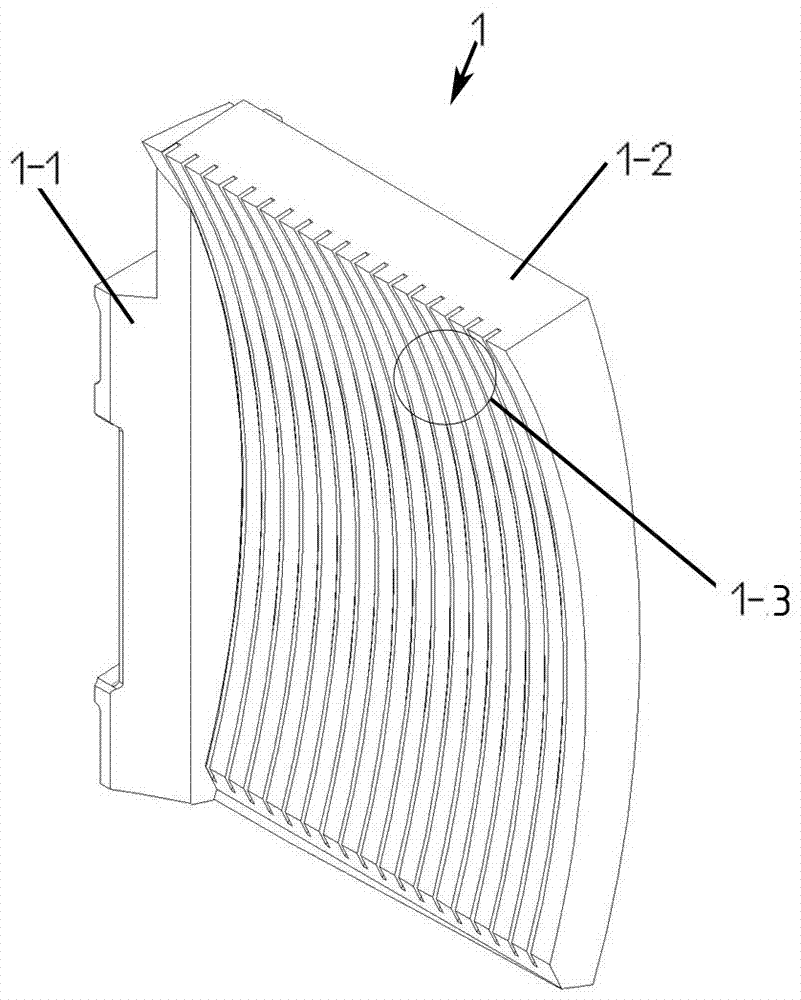

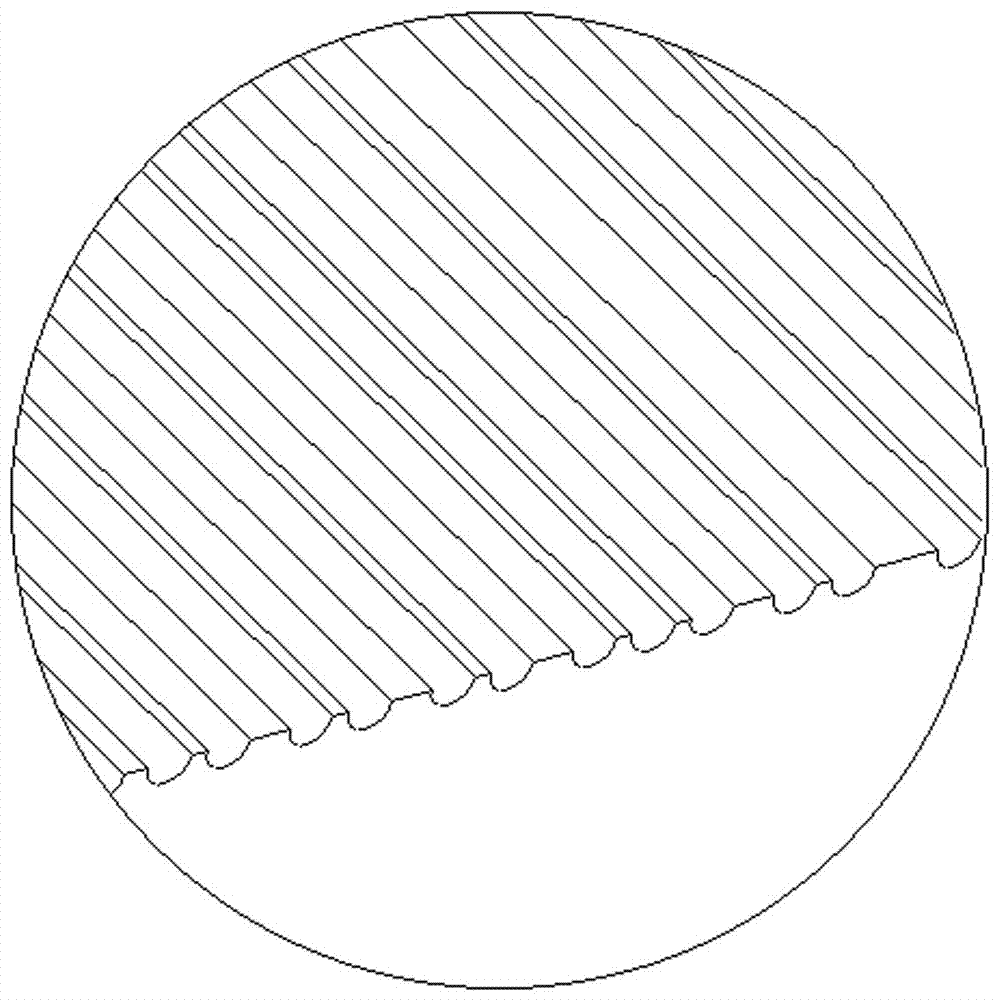

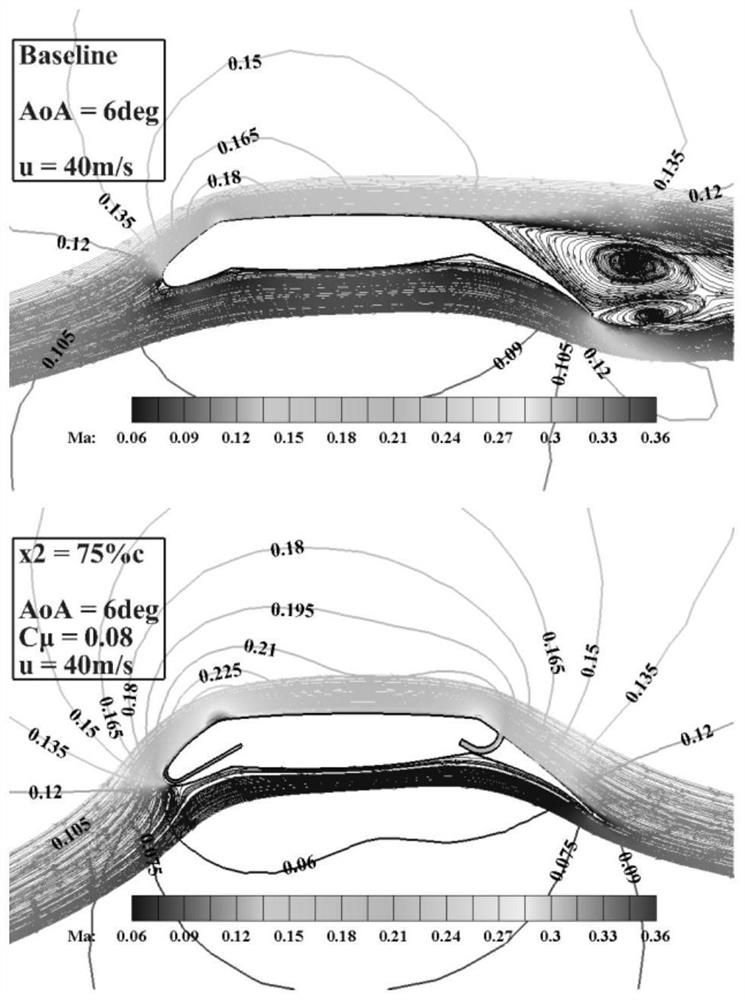

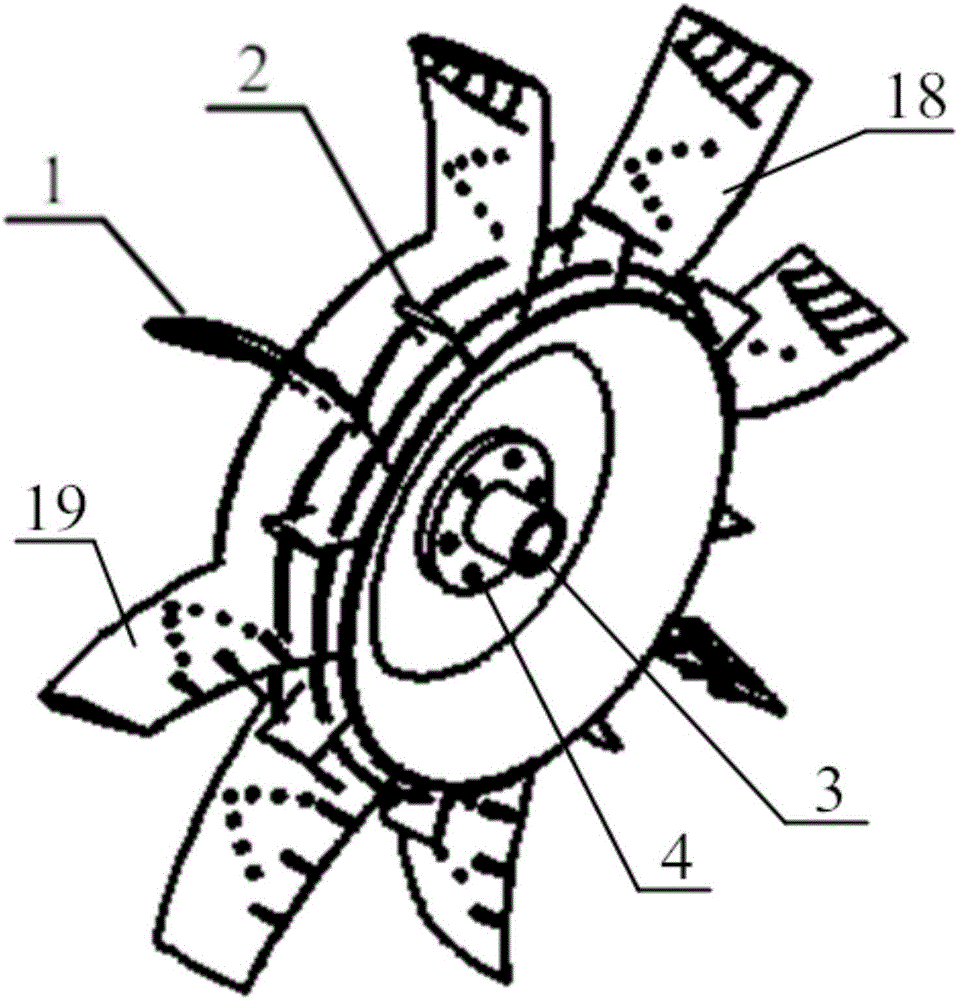

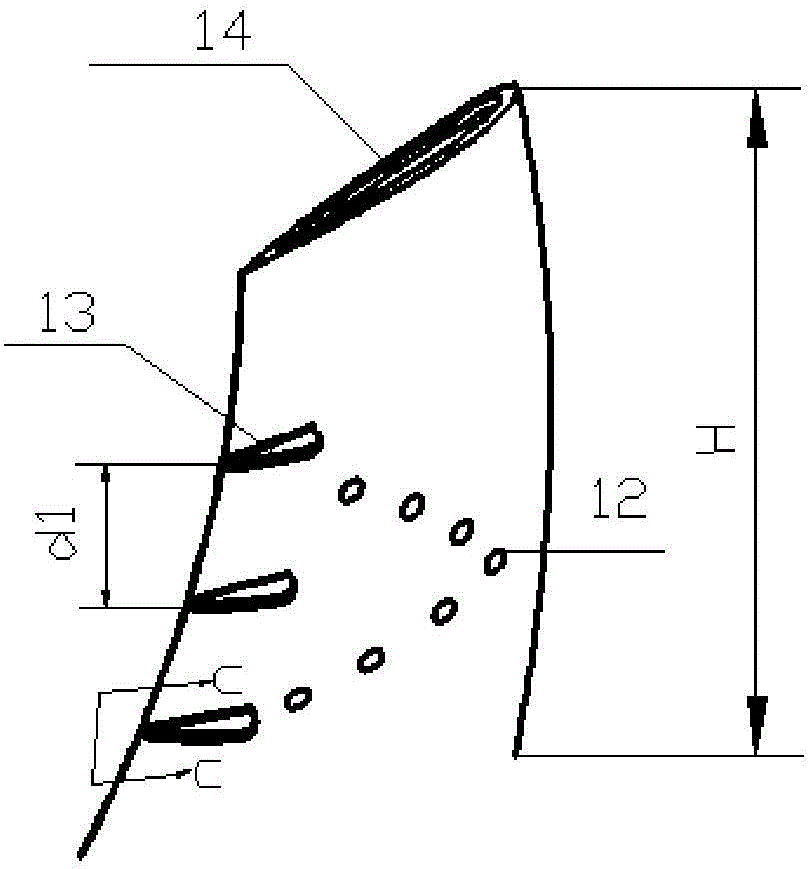

Axial flow fan ternary impeller with vein-shaped structure and nonuniform empennage

The invention discloses an axial flow fan ternary impeller with a vein-shaped structure and a nonuniform empennage. The axial flow fan ternary impeller comprises a hub, and a connecting piece for a shaft sleeve fixed on the hub. The axial flow fan ternary impeller further comprises twisted blades and splitter blades fixedly connected to the hub; the twisted blades include suction surfaces and pressure surfaces; wing-shaped grooves are formed in the tops of the twisted blades; vein-shaped grooves are formed in the upper half parts of the pressure surfaces of the twisted blades; the wing-shaped grooves are communicated with the vein-shaped grooves through exhaust ports; winglet projections and dense winglets are arranged at the tail parts of the suction furnaces of the twisted blades; the dense winglets are arranged on two sides of the winglet projections; parabola small holes are formed in the twisted blades; the splitter blades are arranged between two adjacent twisted blades; and the heights of the splitter blades are smaller than the heights of the twisted blades by one half.

Owner:杭州宏德智能装备科技有限公司

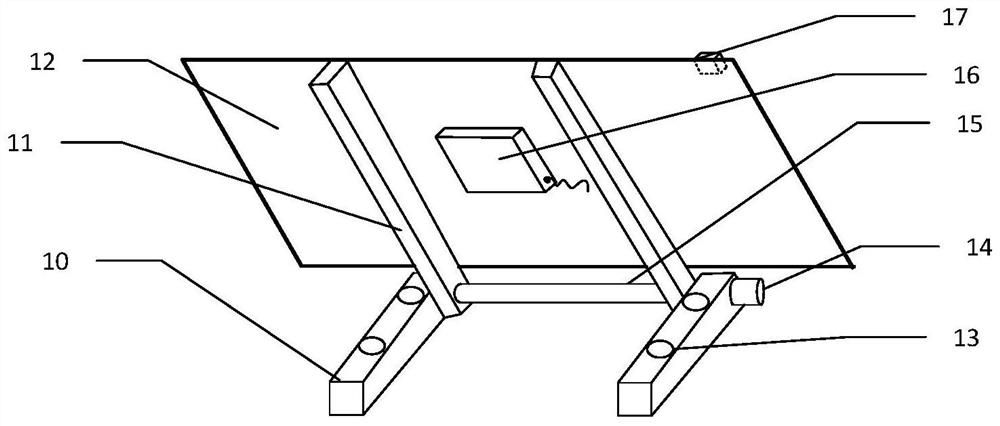

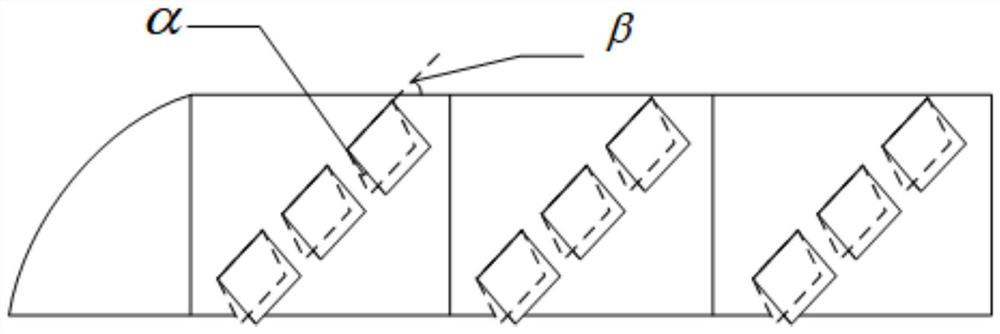

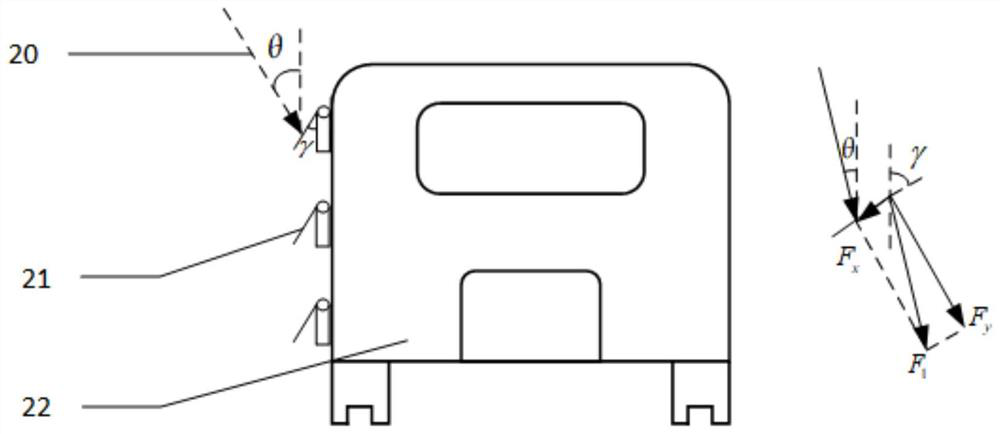

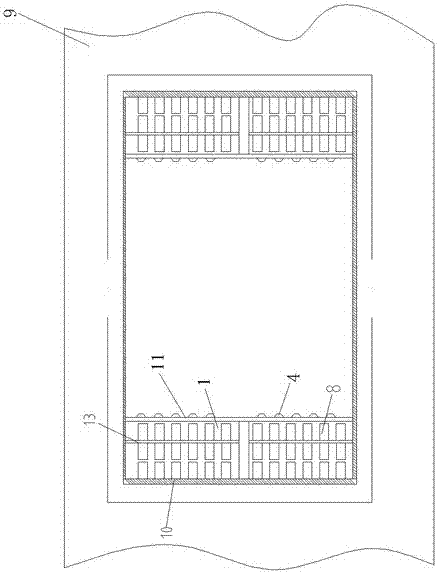

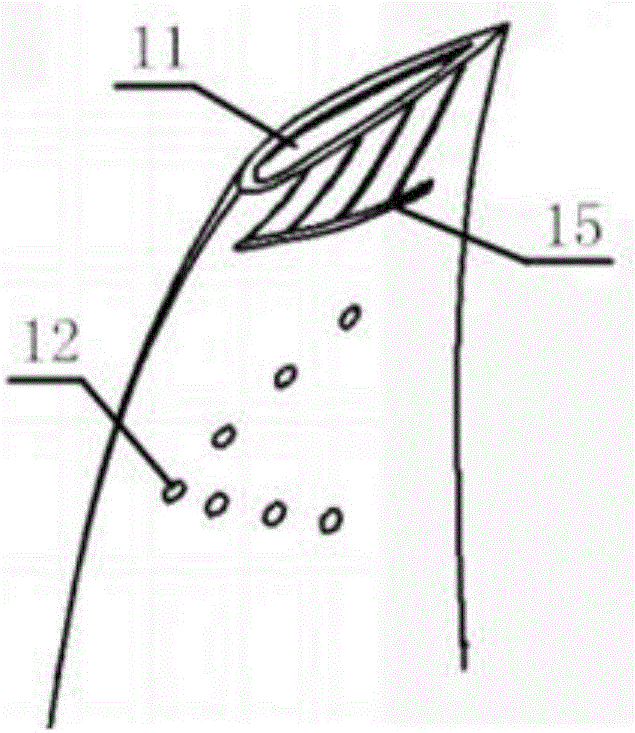

Train imitation fish scale anti-overturning structure

ActiveCN112498386BReduced risk of capsizingReduce viscous dragRailway transportAxle-box lubricationRotational axisAir velocity

The invention relates to the field of train operation safety, and discloses a train imitation fish scale anti-overturning structure to ensure the safety of train operation. Including: base, mounting hole, support frame, rotating shaft, scales, micro motor, control box and wind speed detection device; the base is provided with a mounting hole for fixing with the car body; one end of the base is provided with a support frame; The lower end of the frame is provided with a rotating shaft; the rotating frame is fixedly connected with the supporting frame; scales are fixed on the supporting frame; a wind direction detection device is arranged on the windward side of the scales; the micro motor is used to drive the rotation of the rotating shaft; the micro motor and the wind speed detection device are also Connect with the control box respectively; the control box is used to obtain the wind speed and wind direction angle during the train travel through the wind speed detection device, evaluate the risk level according to the wind speed and wind direction angle, and calculate the scale that minimizes the overturning moment when evaluating the risk Opening angle, and command the micro motor to drive the scales through the rotating shaft to reach the opening angle of the scales that minimizes the overturning moment.

Owner:CENT SOUTH UNIV

System and method for reducing viscous force between a fluid and a surface

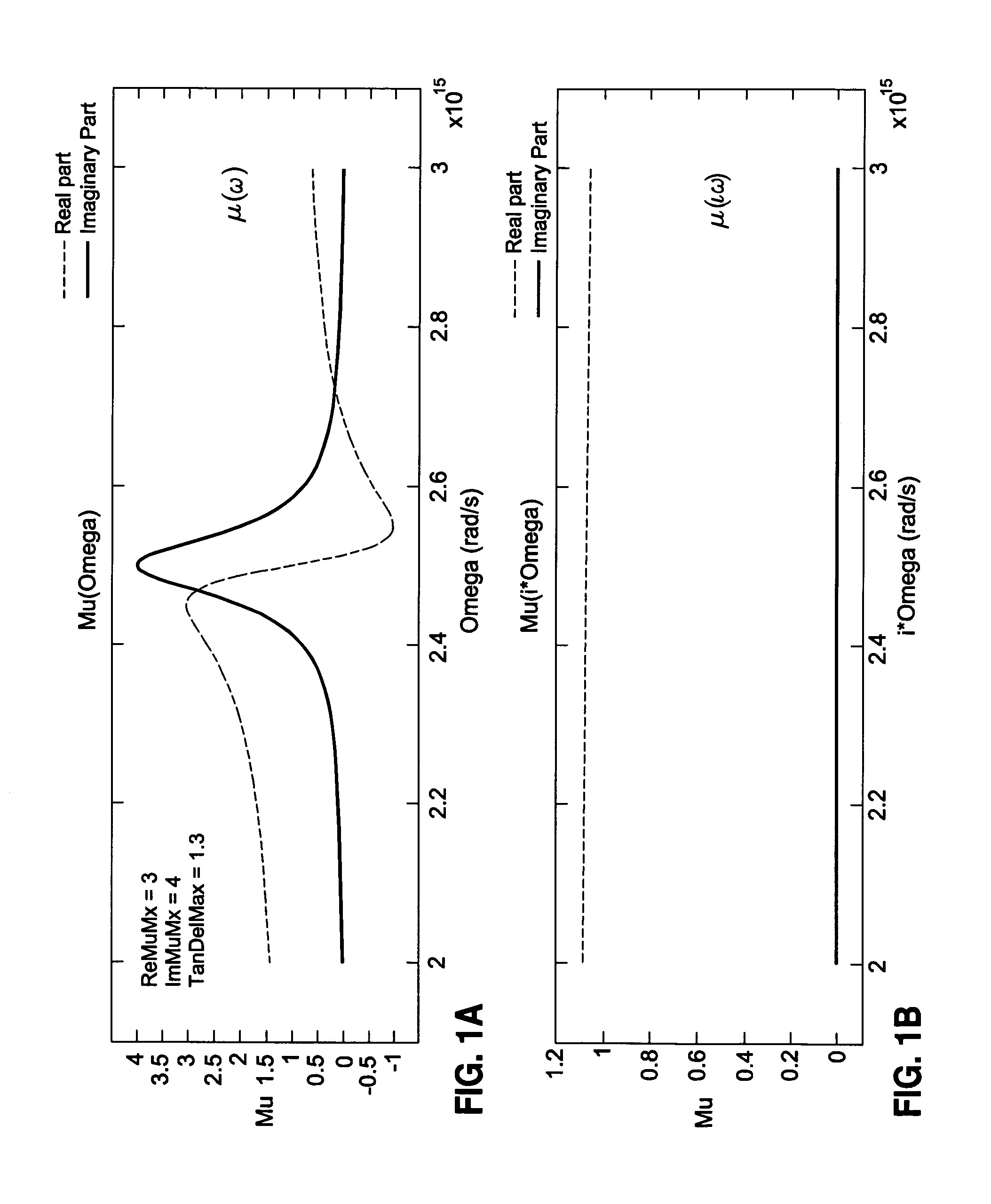

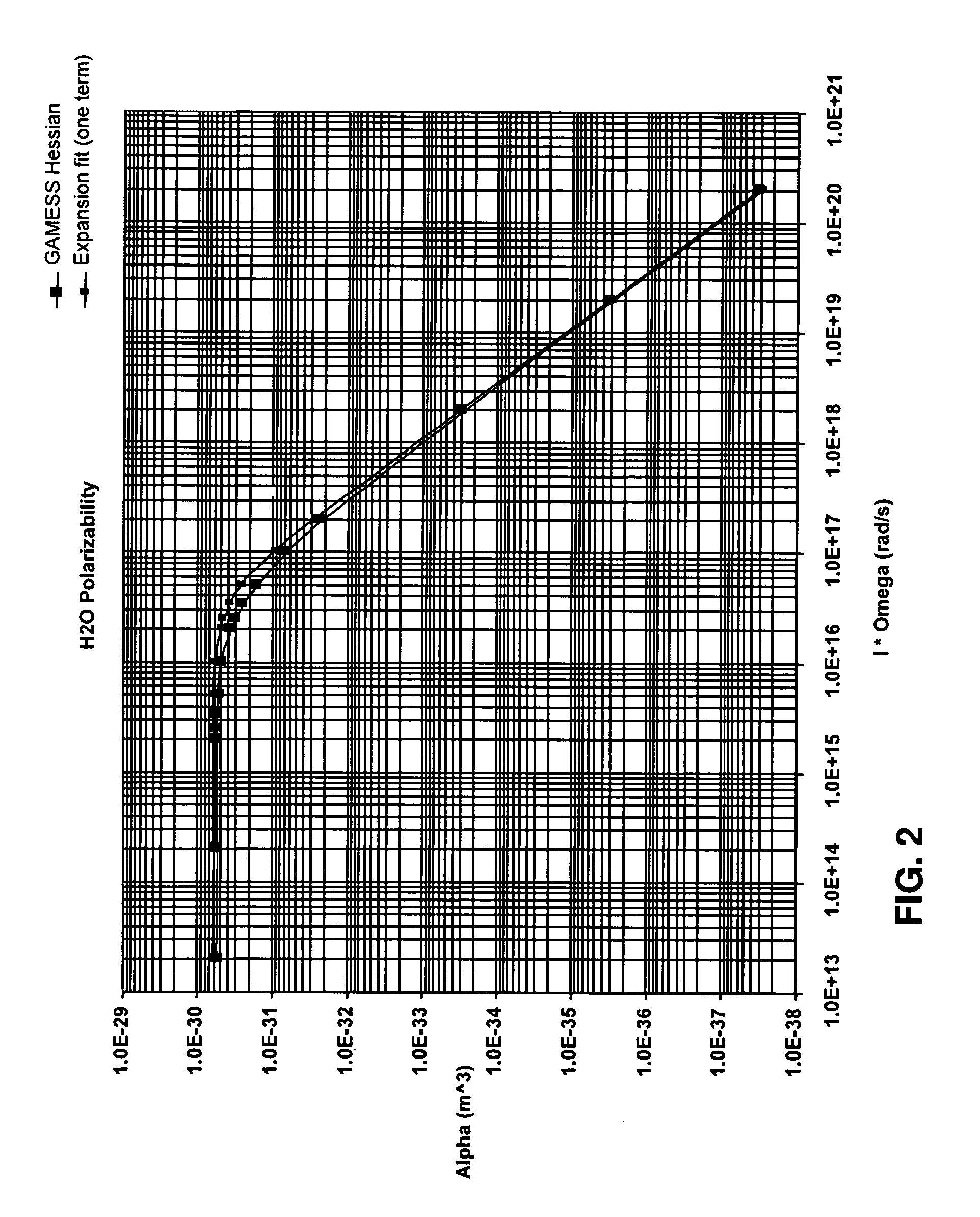

ActiveUS8240609B2Cut surfaceReduces active surfaceCircuit elementsBoundary layer controlsRelative motionPermittivity

A metamaterial has a magnetic permeability response at frequencies sufficient to generate a repulsive force between a fluid and a surface to which the metamaterial may be applied. The metamaterial may be nanofabricated such that an absolute value of the magnetic permeability of the metamaterial is substantially greater than an absolute value of an electric permittivity of the metamaterial. The metamaterial may generate a repulsive force between the surface and the fluid moving relative to the surface and thereby reduce viscous drag of the fluid on the surface. A method of reducing the viscous drag of the fluid moving past the surface includes producing relative motion between the surface and the fluid and generating the repulsive force between the surface and the fluid.

Owner:THE BOEING CO

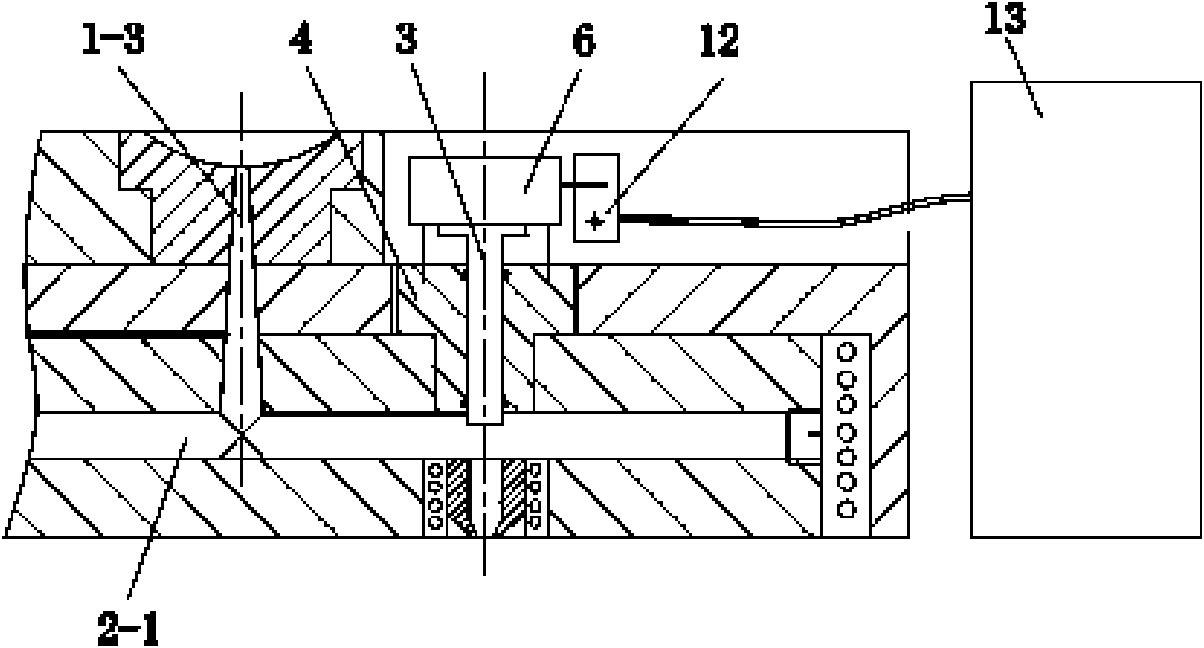

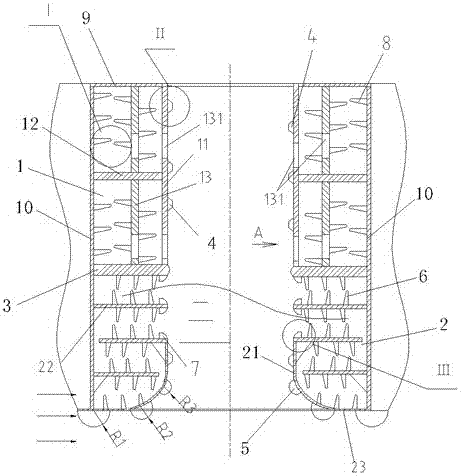

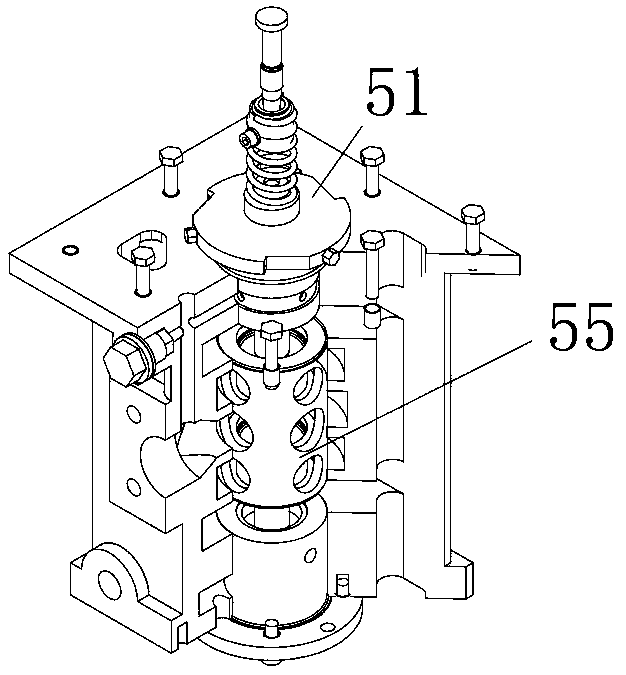

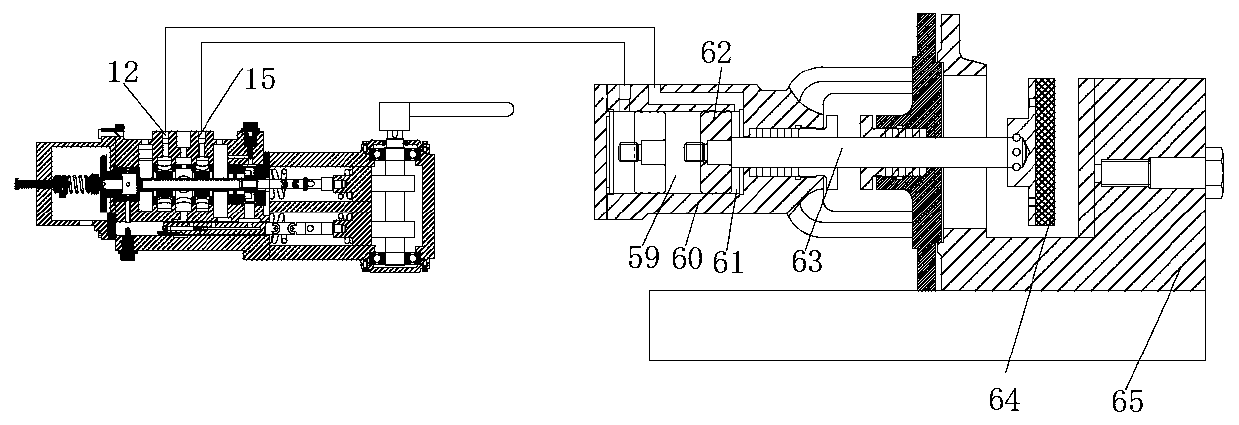

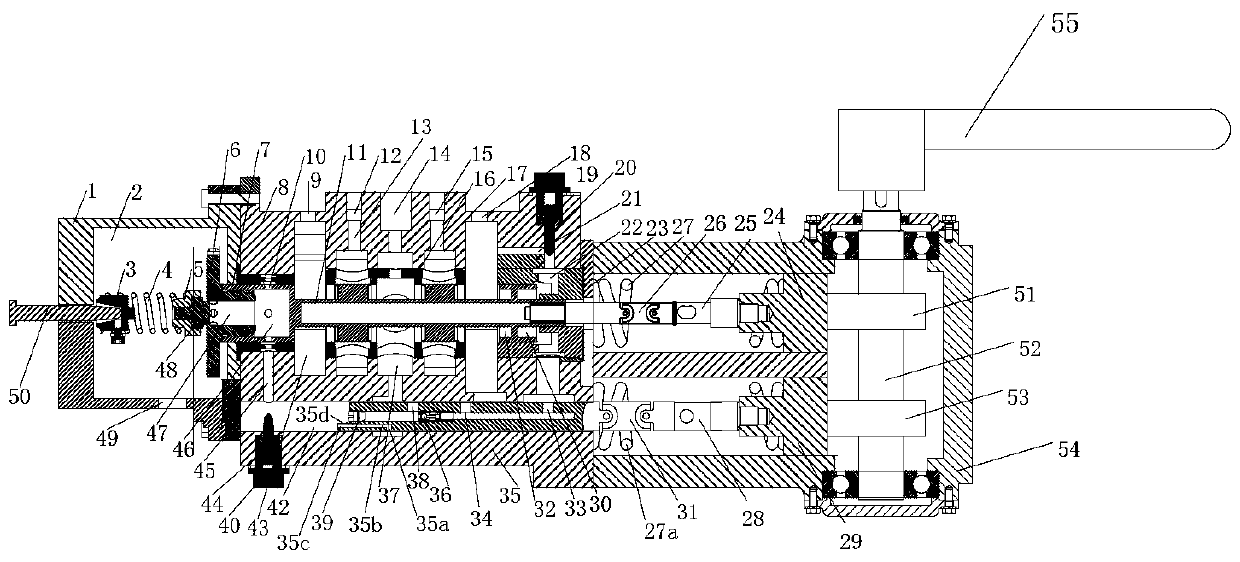

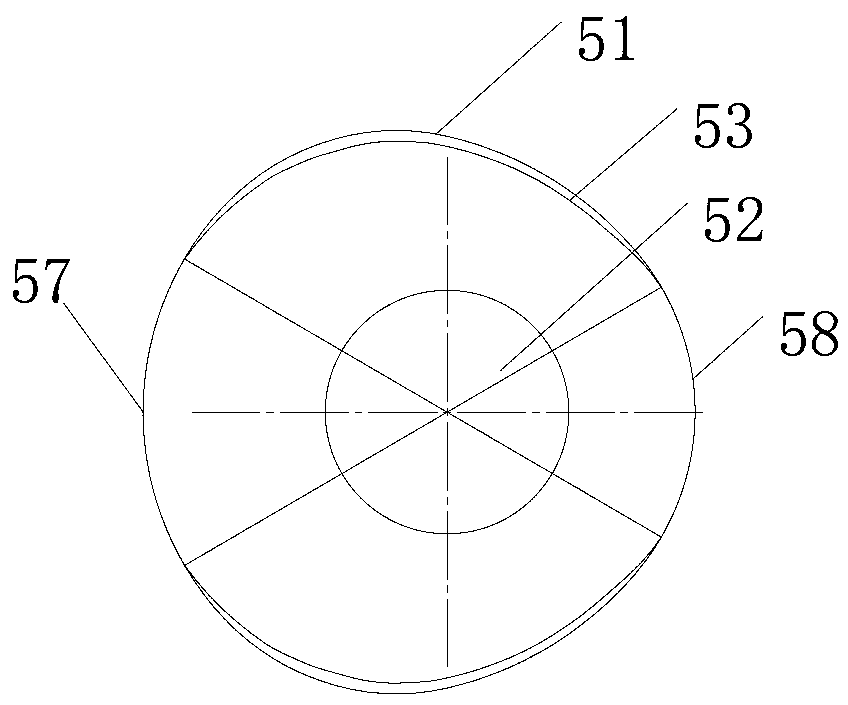

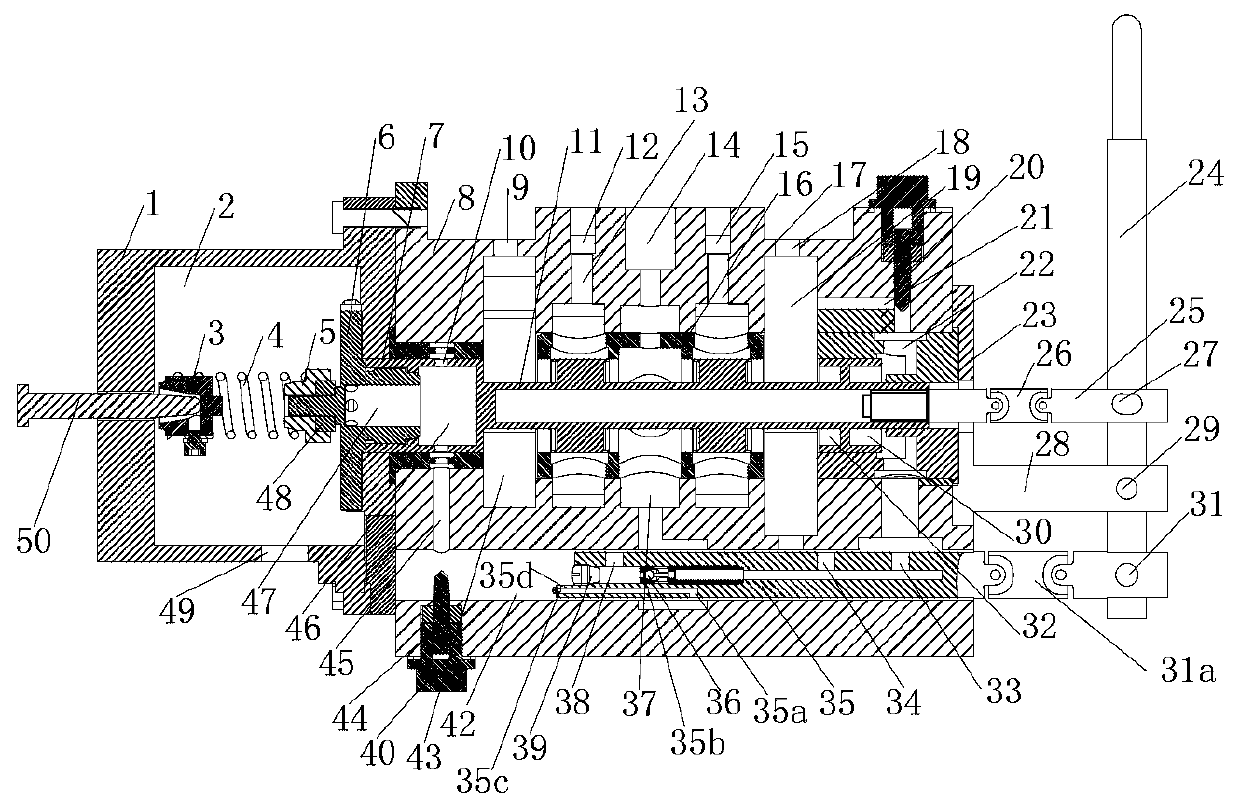

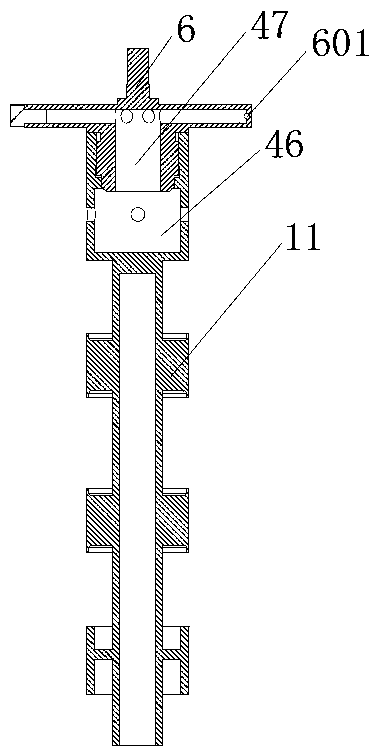

Injection mold hot runner valve type vibration type nozzle device

An injection mold hot runner valve type vibration type nozzle device is provided with a mold body which comprises a fixed template and a shunting template, wherein the shunting template is provided with a sub-runner and the fixed template is provided with a fixed template main runner and at least two fixed template valve holes; the upper part of the shunting template is provided with a shunting template main runner and a shunting template valve hole; a valve rod is respectively arranged in each fixed template valve hole and the shunting template valve hole below the fixed template valve hole;discharging holes are arranged at the lower part of the shunting template; a nozzle is arranged in each discharging hole; the diameter of the bottom part of the valve rod is larger than the diameter of the upper port of the nozzle; a vibration-starting piece which is connected at the upper end of the valve rod, a gate switch located at the side of the vibration-starting piece, and a spring locatedbelow the vibration-starting piece, are arranged in each fixed template valve hole; the vibration-starting piece comprises a shell body and a vibration-starting ring; the switch of the valve rod to the nozzle is controlled by the gate switch; and each vibration-starting coil and the gate switch are controlled by a control circuit. The injection mold hot runner valve type vibration type nozzle device has the advantages of simple structure, low energy consumption and convenient adjustment.

Owner:SHANGHAI HUFAN AUTOMOTIVE PLASTIC PARTS

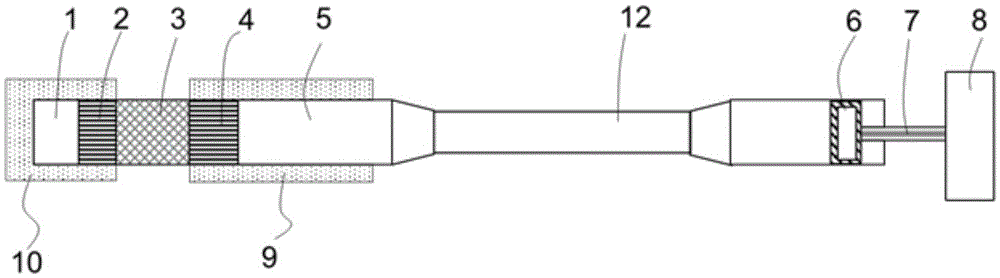

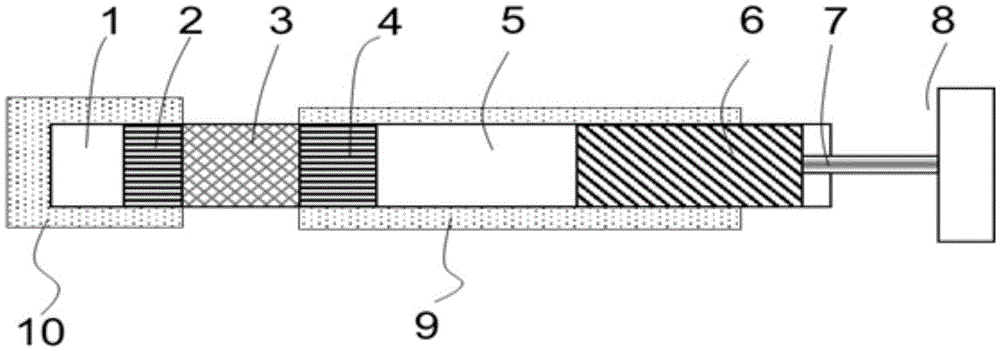

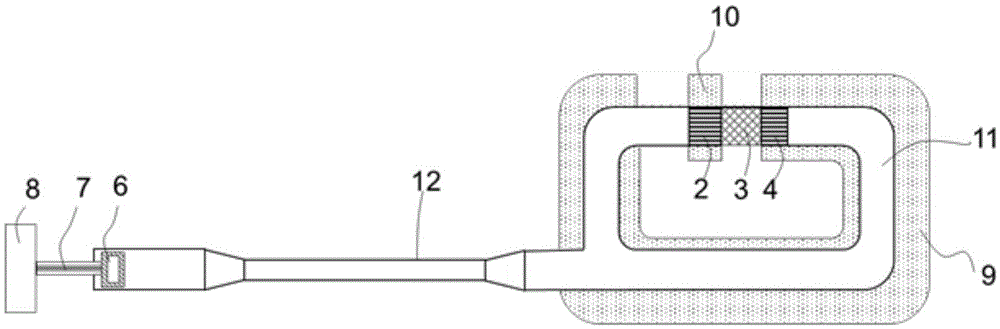

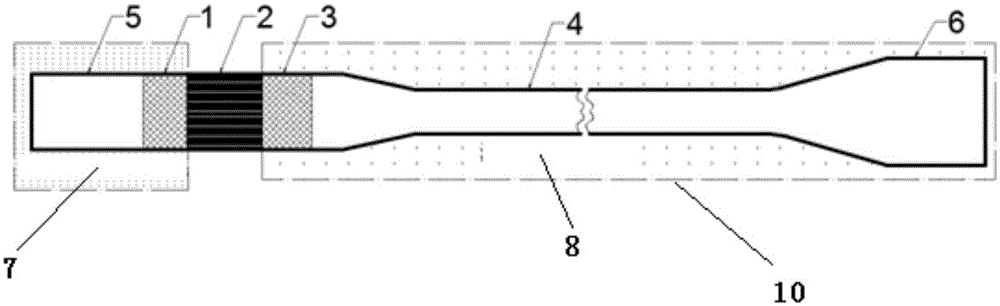

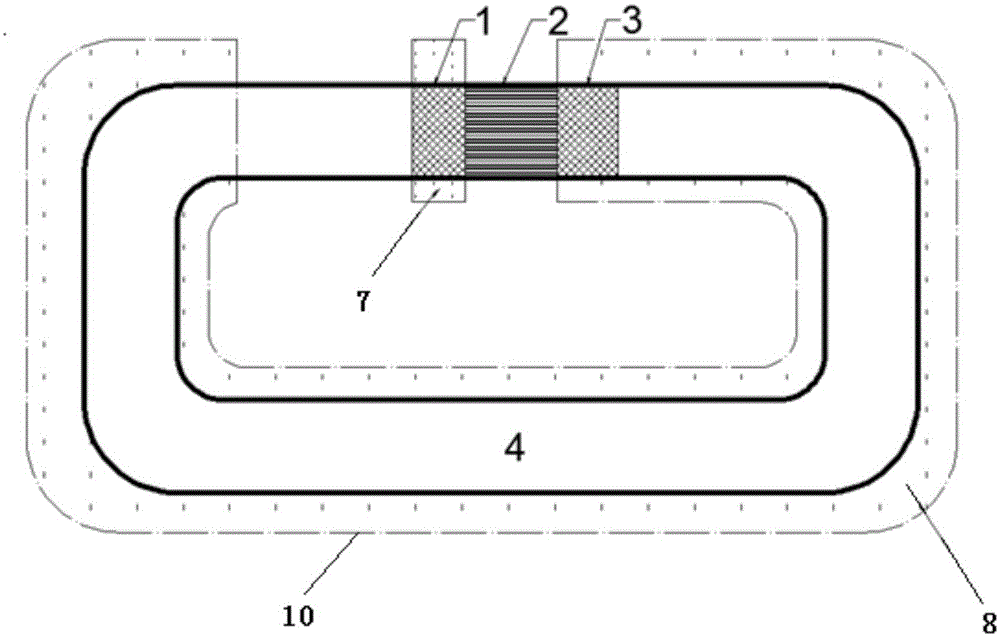

Thermo-acoustic system driven by liquefied natural gas cold energy

InactiveCN105114268AImprove cooling capacity utilizationImprove efficiencyMachines/enginesMechanical power devicesResonant cavityThermoacoustics

The invention relates to a thermo-acoustic system driven by a liquefied natural gas cold energy. The thermo-acoustic system comprises a heat source (7), a liquefied natural gas cold energy (8), a hot end heat exchanger (1), a heat regenerator (2), a cold end heat exchanger (3) and a resonant cavity, wherein the hot end heat exchanger, the heat regenerator, the cold end heat exchanger and the resonant cavity are connected in sequence; the hot end heat exchanger (1) is connected with the heat source (7); the cold end heat exchanger (3) and a resonant tube (4) are arranged in the liquefied natural gas cold energy (8); the temperature difference of the hot end heat exchanger (1) and the cold end heat exchanger (3) is utilized, and a temperature gradient is built inside the heat regenerator (2), so that pressure fluctuation is generated in the resonant tube (4), and cold energy is converted into acoustic power. Compared with the prior art, the thermo-acoustic system driven by the liquefied natural gas cold energy has the advantages that the structure is simple; the acoustic power loss is low; the efficiency of the thermo-acoustic system is high, and the like.

Owner:TONGJI UNIV

Axial flow fan three-dimensional impeller with leaf vein structures and seagull-shaped splitter blades

Owner:ZHEJIANG SCI-TECH UNIV

Lubricant-impregnated surfaces for electrochemical applications, and devices and systems using same

ActiveUS9947481B2Reduce viscous dragControl flowFuel and primary cellsHybrid capacitor electrolytesEngineeringElectrochemistry

In certain embodiments, the invention relates to an electrochemical device having a liquid lubricant impregnated surface. At least a portion of the interior surface of the electrochemical device includes a portion that includes a plurality of solid features disposed therein. The plurality of solid features define a plurality of regions therebetween. A lubricant is disposed in the plurality of regions which retain the liquid lubricant in the plurality of regions during operation of the device. An electroactive phase comes in contact with at least the portion of the interior surface. The liquid lubricant impregnated surface introduces a slip at the surface when the electroactive phase flows along the surface. The electroactive phase may be a yield stress fluid.

Owner:MASSACHUSETTS INST OF TECH

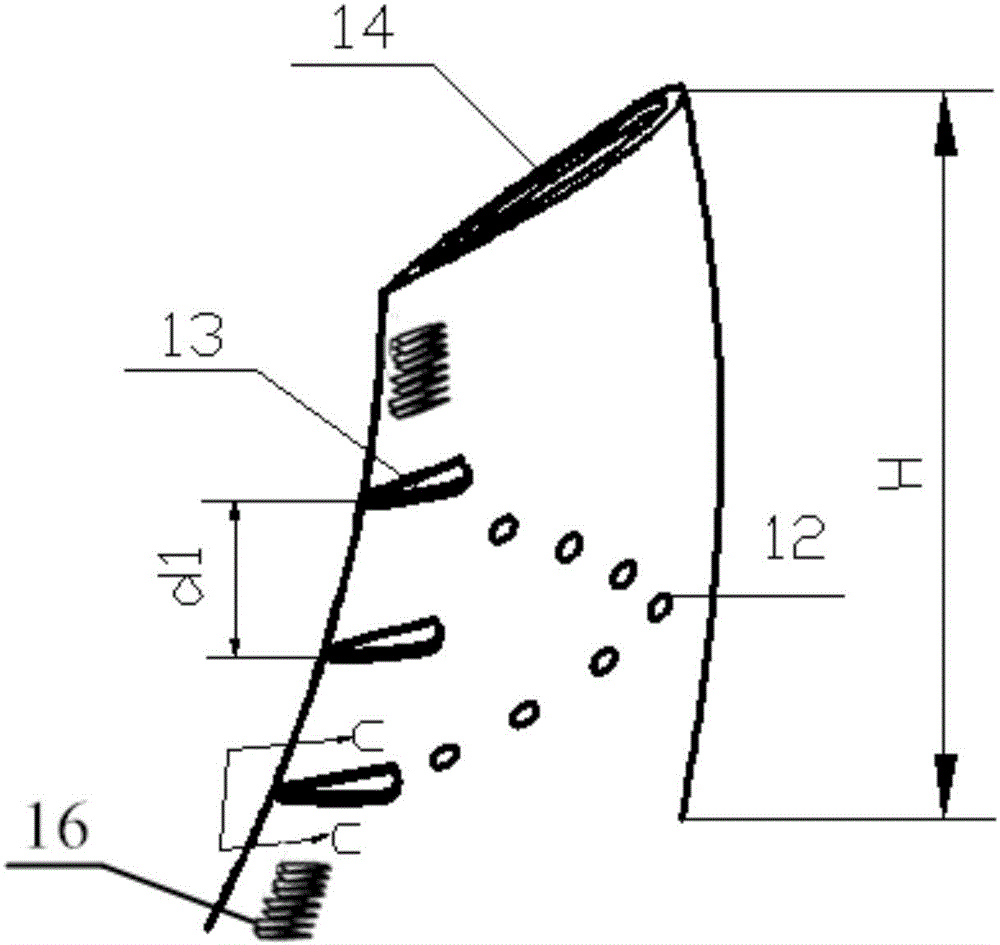

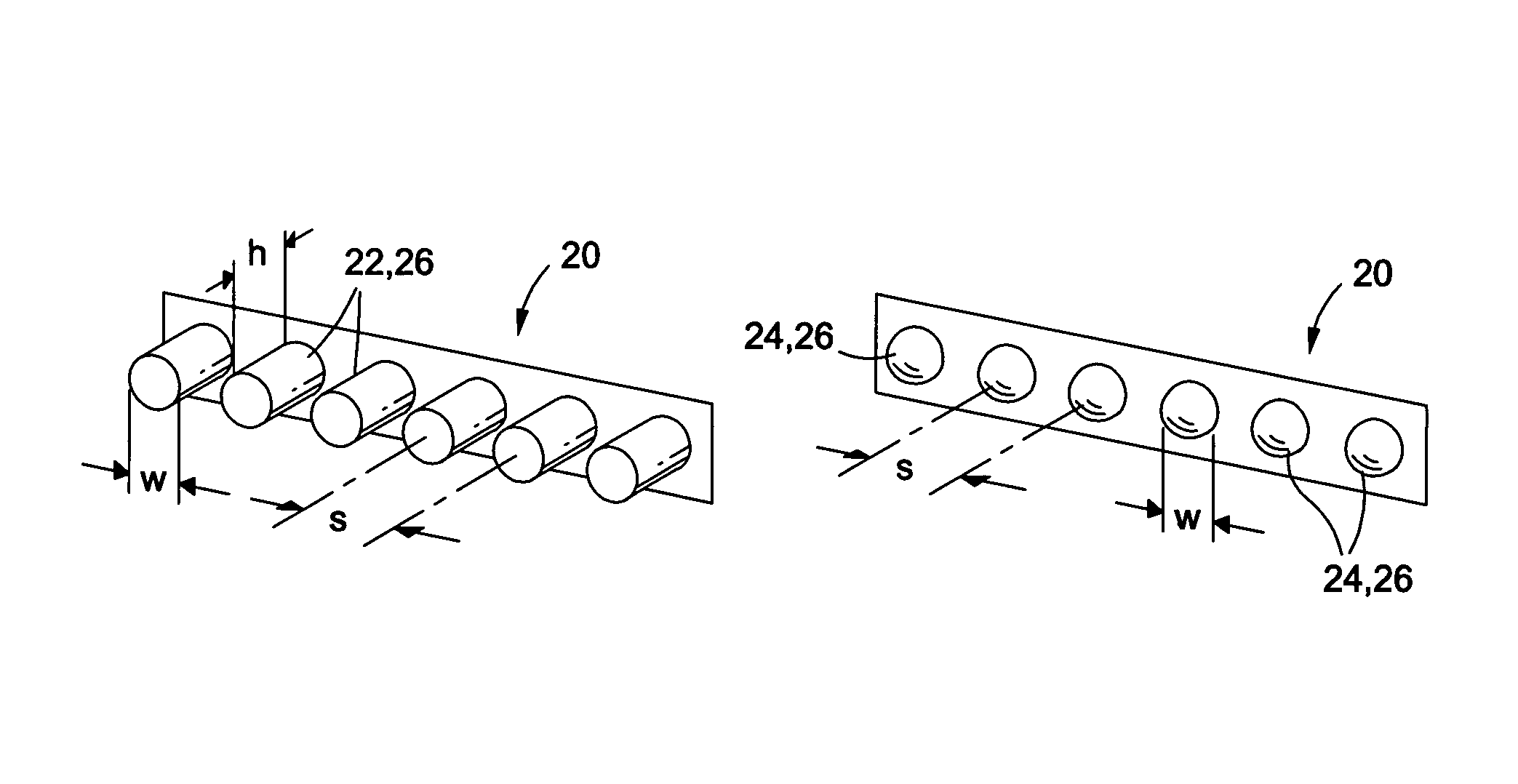

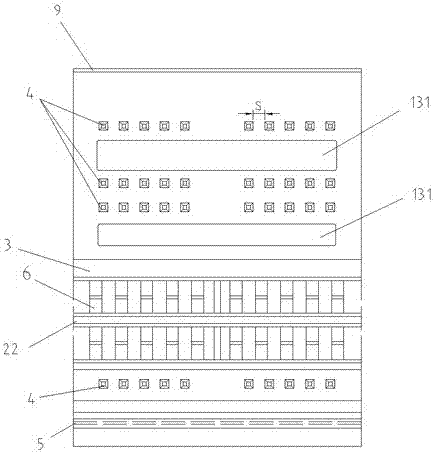

Aerofoil blade of ridged surface drag reduction

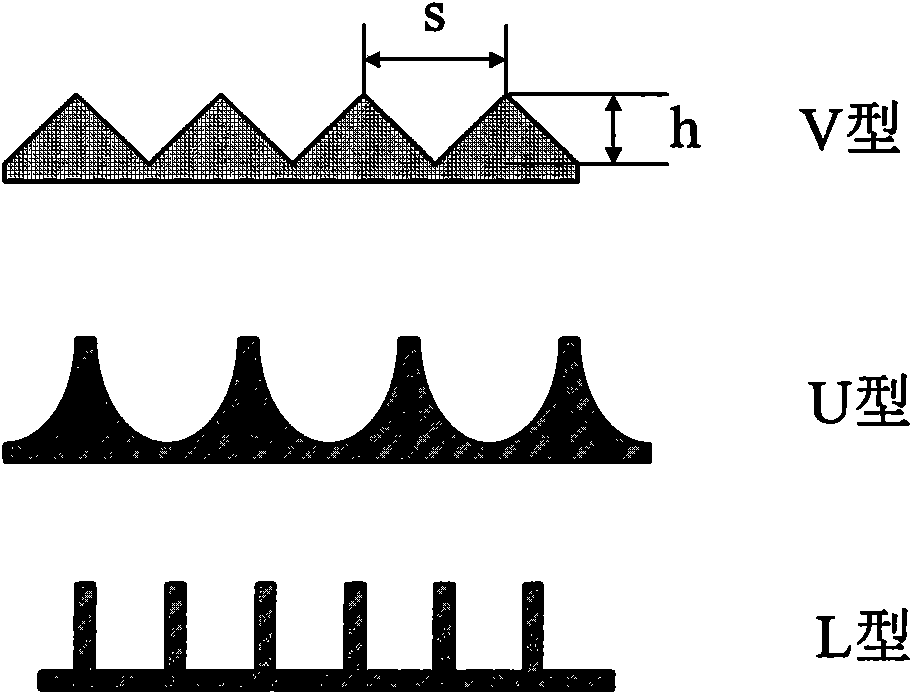

InactiveCN105317734AReduce viscous dragReduce the average velocity gradientPump componentsPumpsEngineeringViscous resistance

The invention relates to an aerofoil blade of ridged surface drag reduction. The aerofoil blade of ridged surface drag reduction is used for reducing flow resistance and energy loss in operation of a pump and a draught fan, particularly, V-shaped ridged structures are arranged on the surface of the aerofoil blade, relative distance sizes among the ridged structures are set to be a, h and s, when airflow flows through a blade passage, stable secondary vortexes are formed in ridged structure gullies, and viscous resistance can be obviously reduced. According to the aerofoil blade of ridged surface drag reduction, resistance between the blade and the airflow is reduced, and the aerofoil blade of ridged surface drag reduction has the advantage of reducing the energy consumption.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Shot blaster blades and impeller body assembly of shot blaster

The invention discloses shot blaster blades and an impeller body assembly of a shot blaster and belongs to the technical field of shot blasters. The impeller body assembly comprises an impeller body, and the impeller body comprises an impeller plate. The impeller plate is provided with clamping grooves. The shot blaster blades are connected to the clamping grooves in a clamped mode. Each shot blaster blade comprises a base and a blade body, and the blade body is provided with a surface texture. According to the shot blaster blades and the impeller body assembly of the shot blaster, viscosity resistance can be reduced, abrasion to the blades is reduced, the blasting speed of the shot blaster is increased, the work efficiency is greatly improved, energy consumption is reduced, and the use cost is reduced.

Owner:UNIV OF JINAN

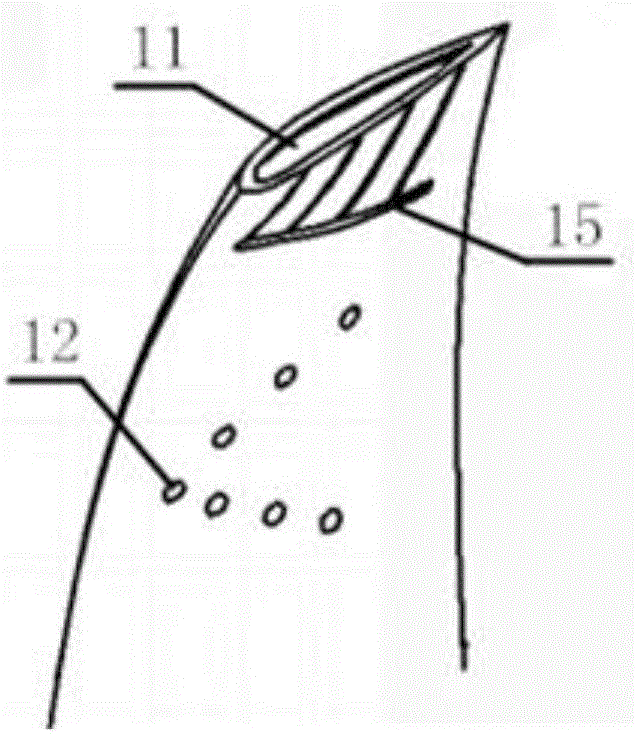

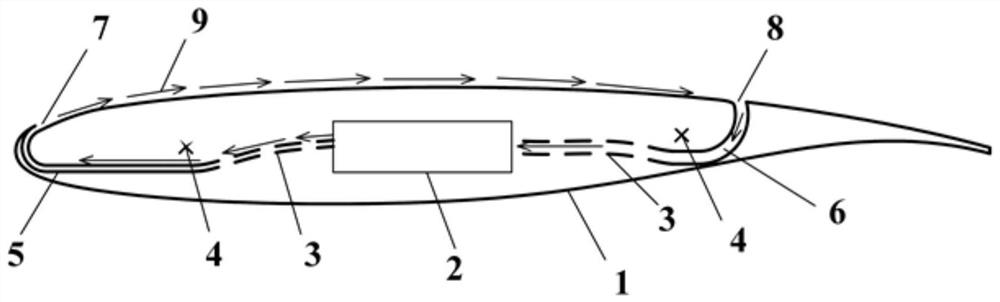

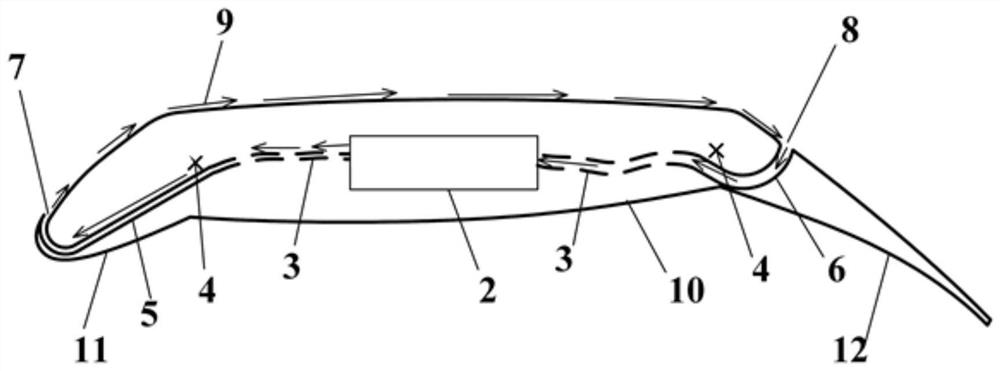

Deformable flap with enhanced blowing-suction synergistic high lift force

ActiveCN112977803AIncrease airflowDelayed air separationBoundary layer controlsWing lift eficiencyLeading edgeJet flow

The invention provides a deformable flap with enhanced blowing-suction synergistic high lift force. The deformable flap comprises a wing composed of a leading edge flap, a wing body and a trailing edge deformable flap, wherein a jet flow cabin is arranged in the leading edge flap, and jet flow holes connected with the jet flow cabin are formed in the upper surface of the leading edge flap; a flow suction cabin is arranged in the trailing edge deformation flap, and flow suction holes connected with the flow suction cabin are formed in the upper surface of the trailing edge deformation flap; and a micro compressor is embedded in the wing body, is respectively connected with the jet flow cabin and the flow suction cabin through rubber pipes, and sucks air flow from the flow suction holes, pressurizes the air flow and then ejects the air flow from the jet flow holes. According to the invention, a blowing-suction synergistic active flow control technology is combined with the deformation flap, and the flap is used for a large fixed-wing aircraft, so a high lift enhancement effect is generated, take-off and landing aerodynamic characteristics are improved, short-distance take-off and landing are realized, airport pressure is relieved, cruising efficiency can be improved, and voyage can be increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

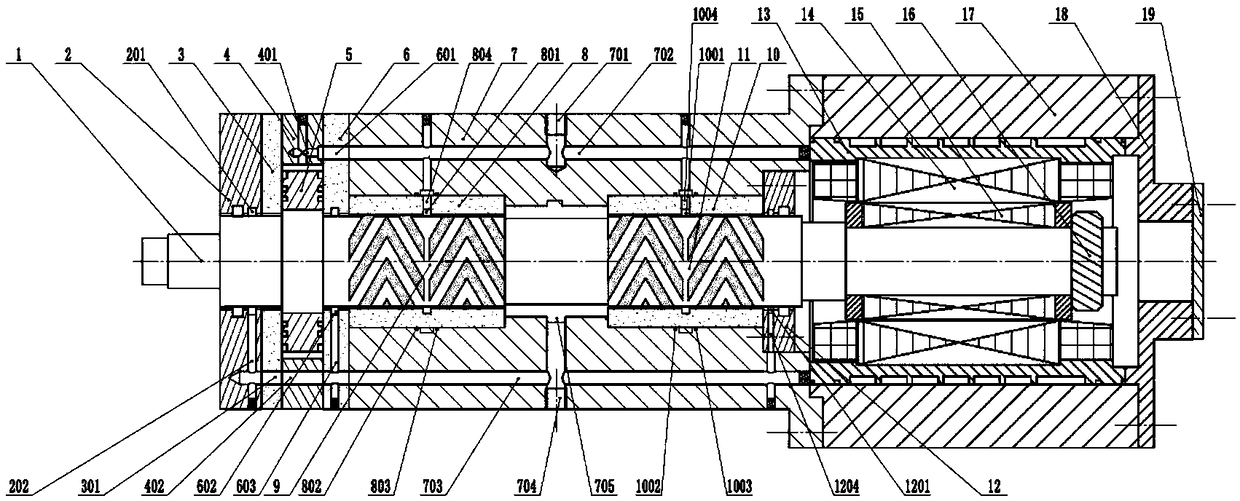

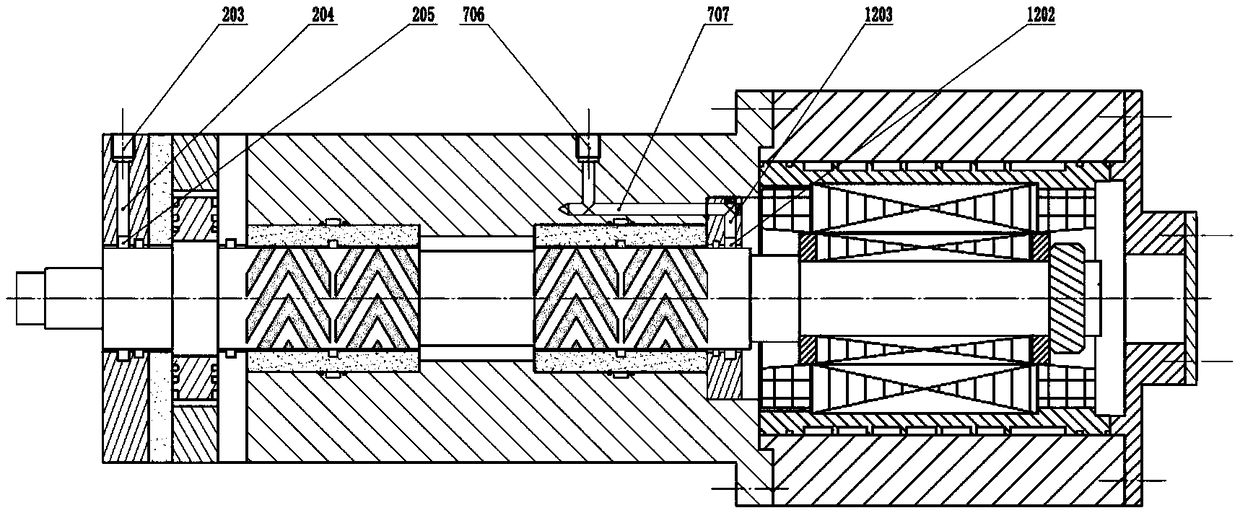

High-speed water lubrication dynamic pressure spiral groove bearing electric spindle

InactiveCN109128224ALow running costReduce frictionLarge fixed membersMaintainance and safety accessoriesRare earthCarbon graphite

The invention discloses a high-speed water lubrication dynamic pressure spiral groove bearing electric spindle. The spindle comprises a shaft neck, a radial bearing bush, a thrust disc, a thrust bearing bush, a spindle body, a gas injection sealing ring, a motor stator, a motor rotor, a cooling water jacket, a shell and peripheral equipment. Water serves as lubricant of a radial (thrust) bearing,spiral grooves are engraved in the shaft neck and in the thrust disc, and an anti-drag micro-textures are machined in a table area; the radial (thrust) bearing bush is made of special carbon graphite,and a Ta-Si-based nano composite coating is prepared on the surface of the neck shaft (thrust disc); the spindle body adopts dynamic pressure spiral groove radial supporting and thrust bearing mixingsupporting, the special non-contact gas injection sealing ring is designed at the ends of the bearings, and the spindle body is driven by a rare earth permanent magnet brushless direct current motor;and the motor stator is cooled through the cooling water jacket. The spindle has the advantages that the temperature rise of the bearings is low, the friction power consumption is low, the rotation precision is high, the stability is good, the cavitation erosion resistance is high, pollution is avoided, and the spindle is particularly suitable for a high-speed precision machining machine tool.

Owner:SOUTHEAST UNIV

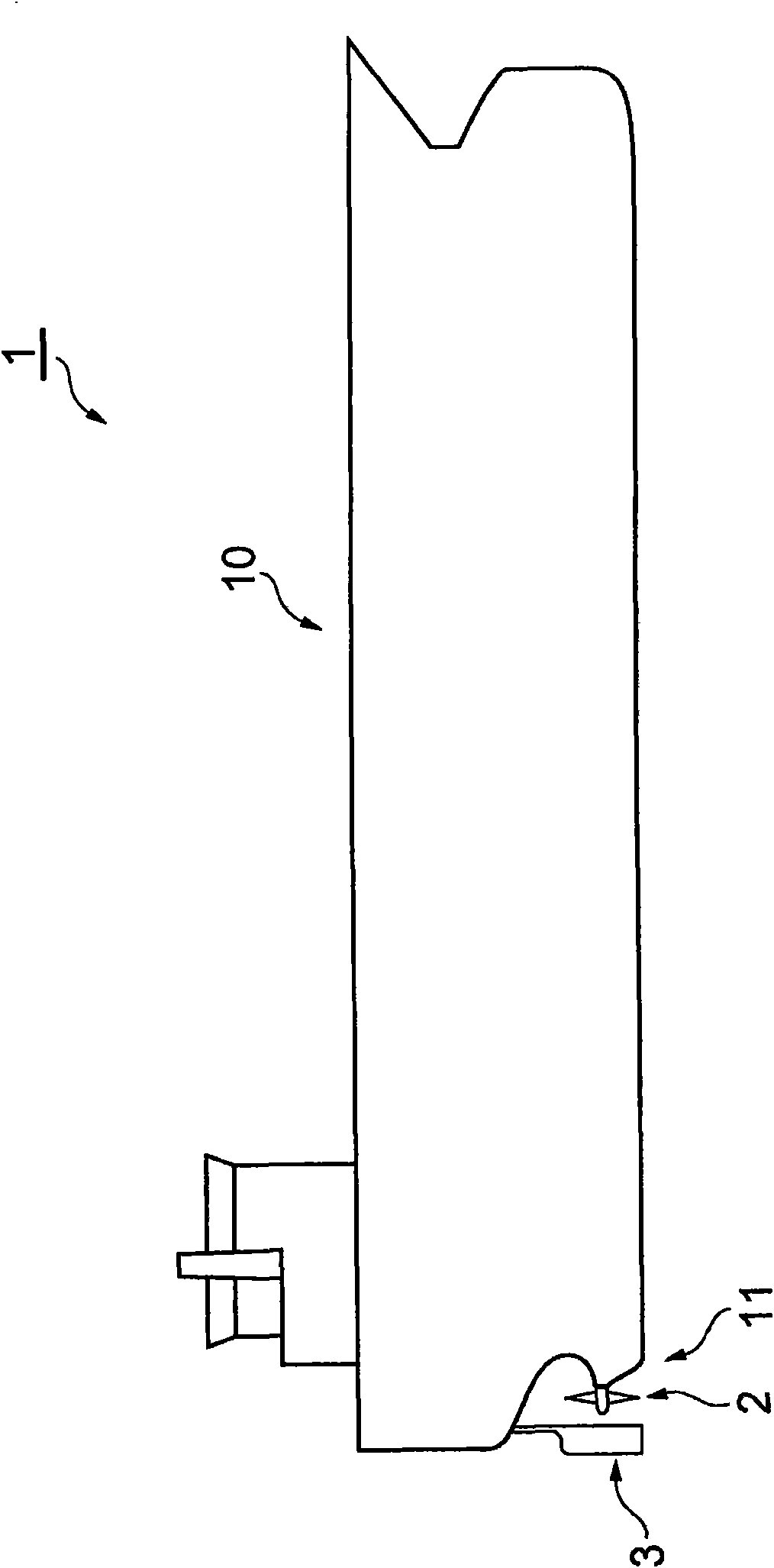

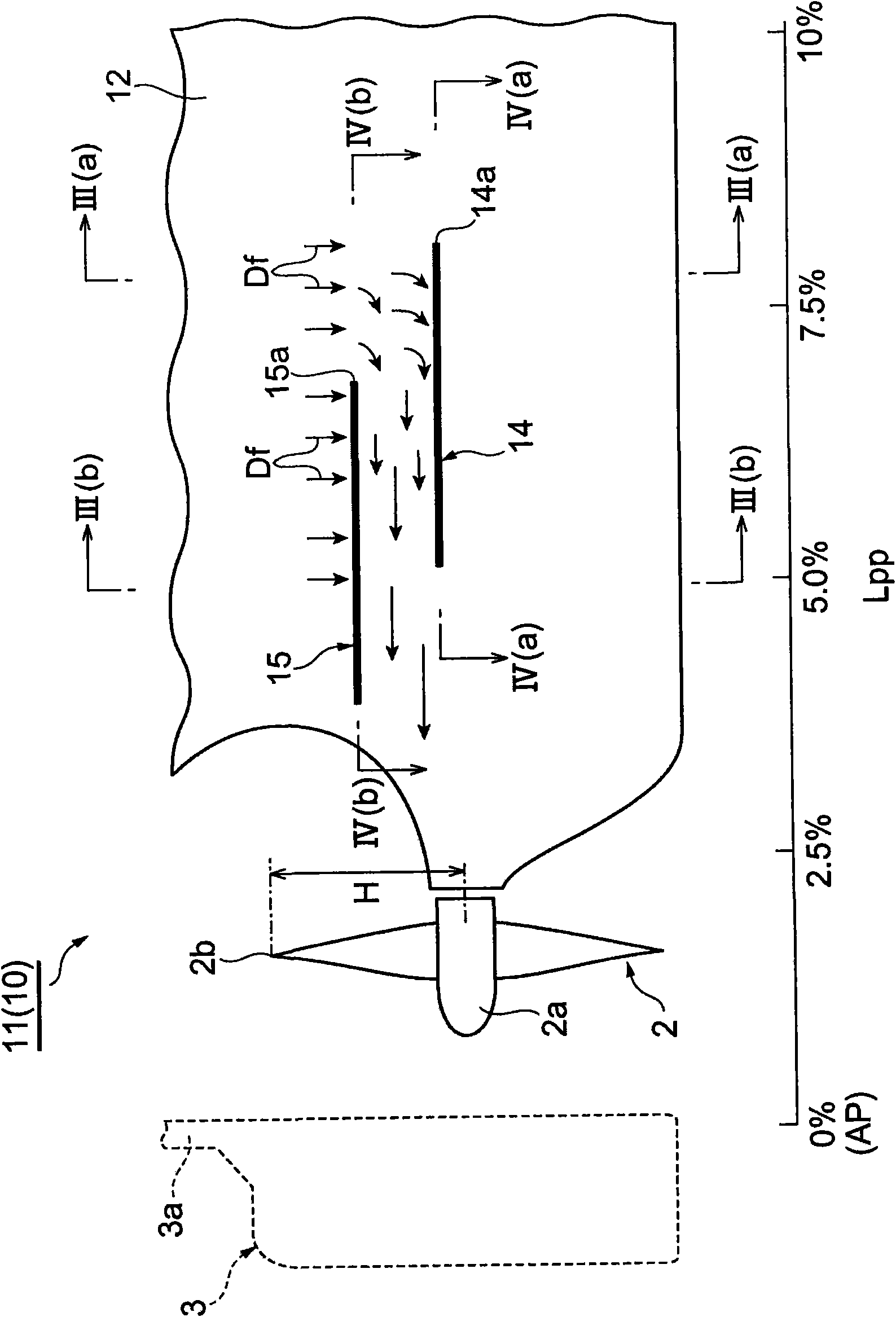

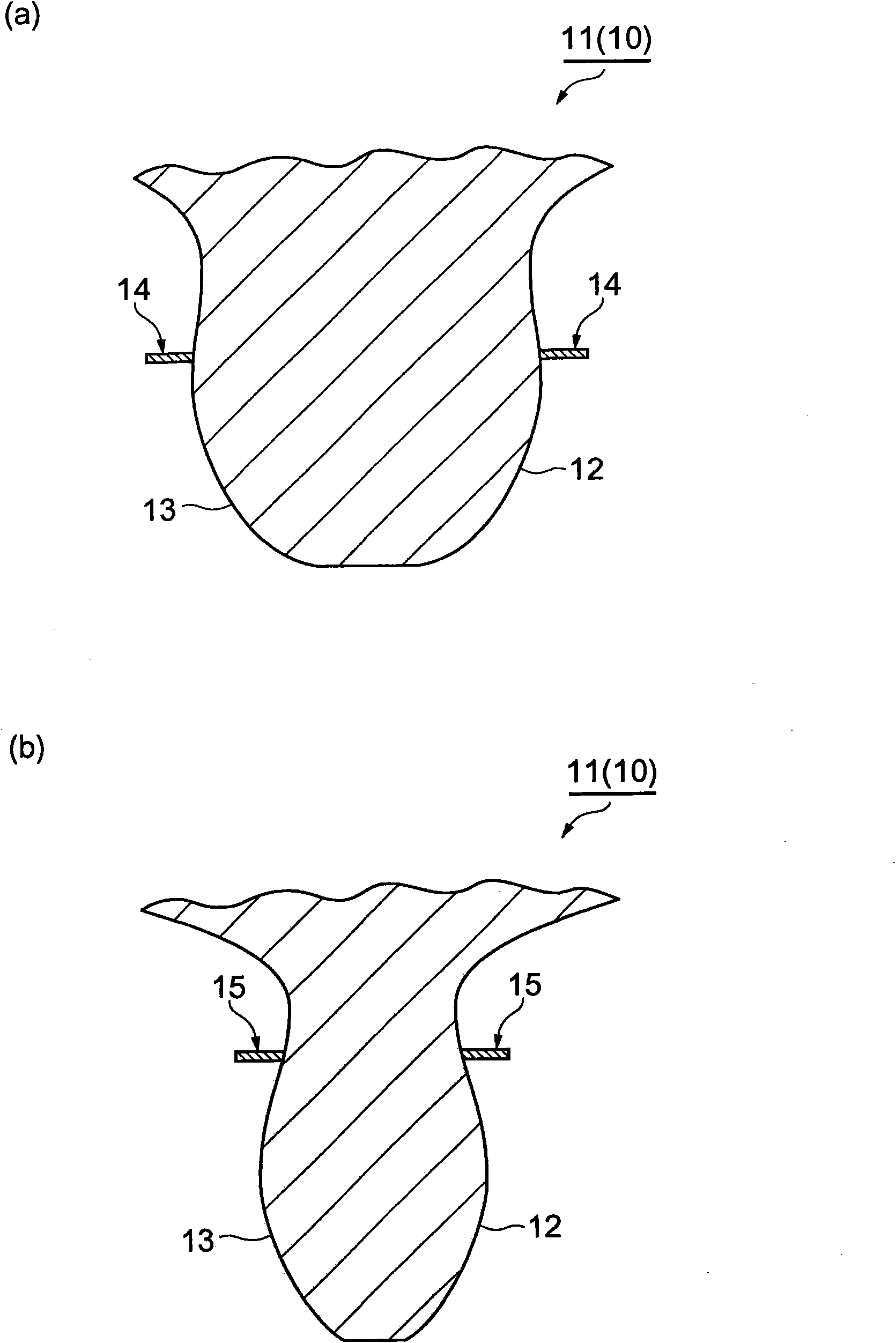

Hull structure

ActiveCN101612978ADowndraft reductionDownwellingPropulsion based emission reductionWatercraft hull designHull structureWater flow

The invention provides a hull structure capable of sufficiently improving pushing performance. A hull (10) has a first tail fin and a second tail fin (14, 15) respectively installed at right board hull side (12) and left board hull side in outwards extending manner. The first and the second tail fin (14, 15) are extended in horizontal direction, and installed between the after-perpendicular AP and the front position away from 10% of perpendicular length Lpp of the after-perpendicular AP. The first and the second tail fin (14, 15) can shade downward current and reduce downward current. The front end (14a) of the first tail fin (14) positioned below the second tail fin (15) is positioned in front of the front end (15a) of the second tail fin (15). Therefore, the current of the downward current Df controlled by the first tail fin (14) is guided between the first and the second tail fins (14, 15) so that the downward current Df is totally current to the back in horizontal direction and is accelerated.

Owner:SUMITOMO HEAVY IND MARINE & ENG

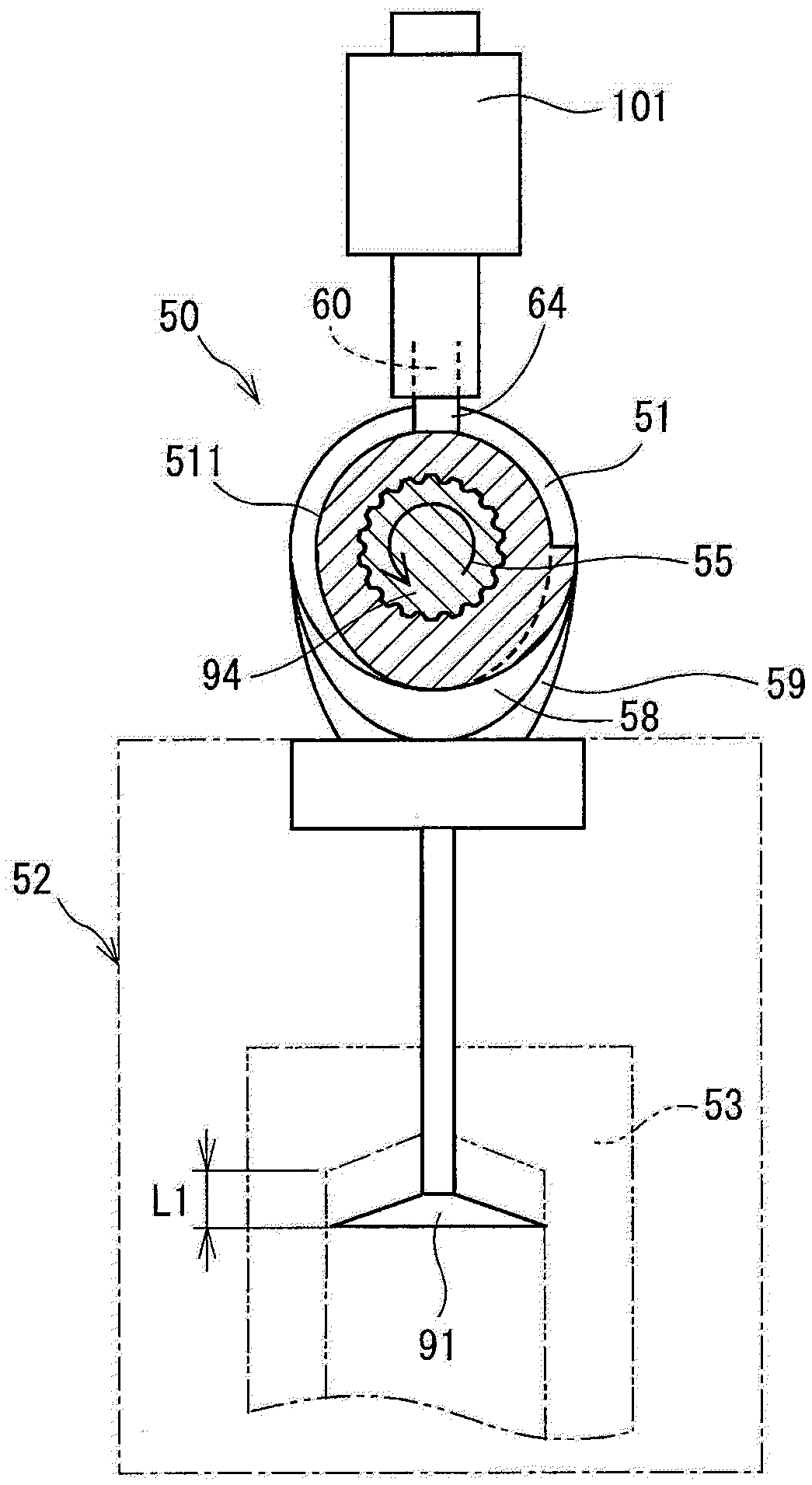

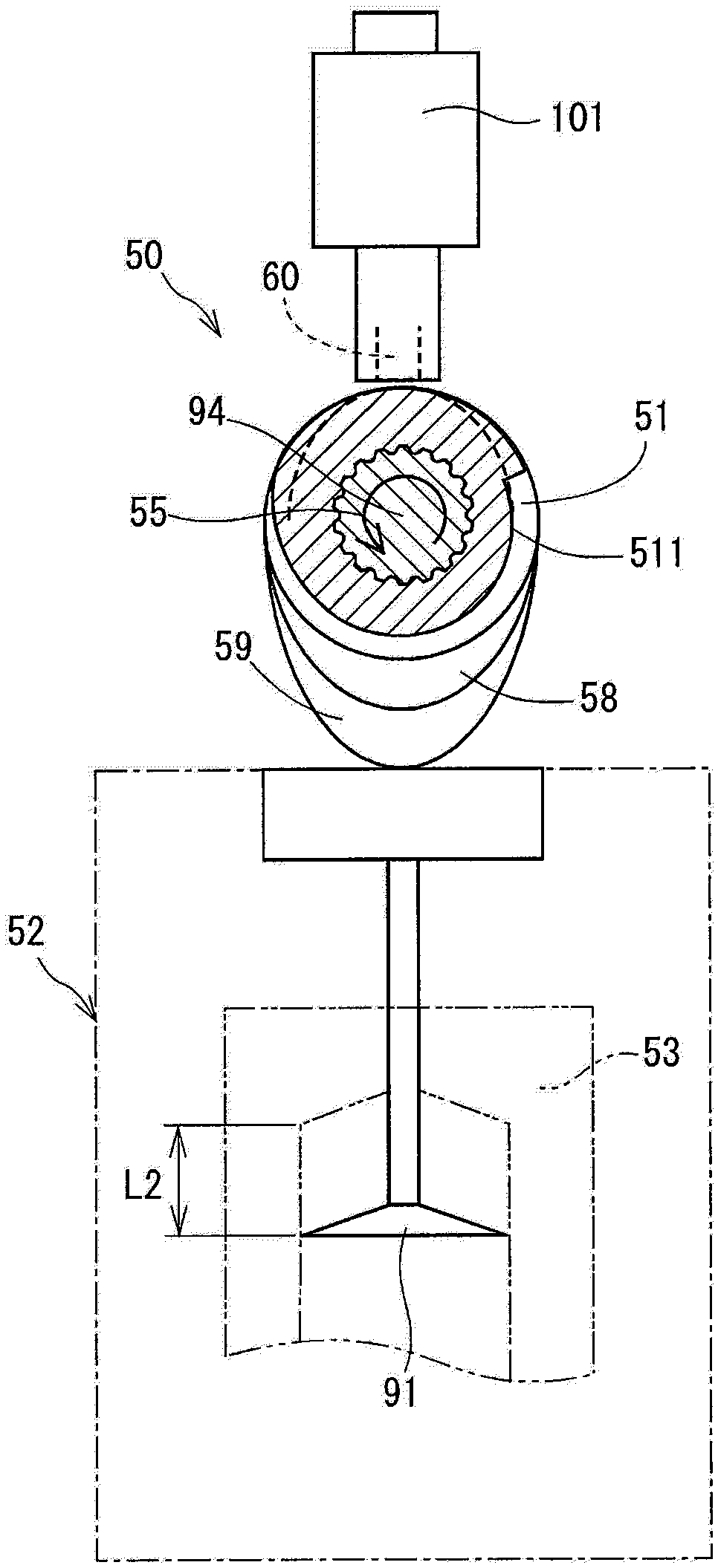

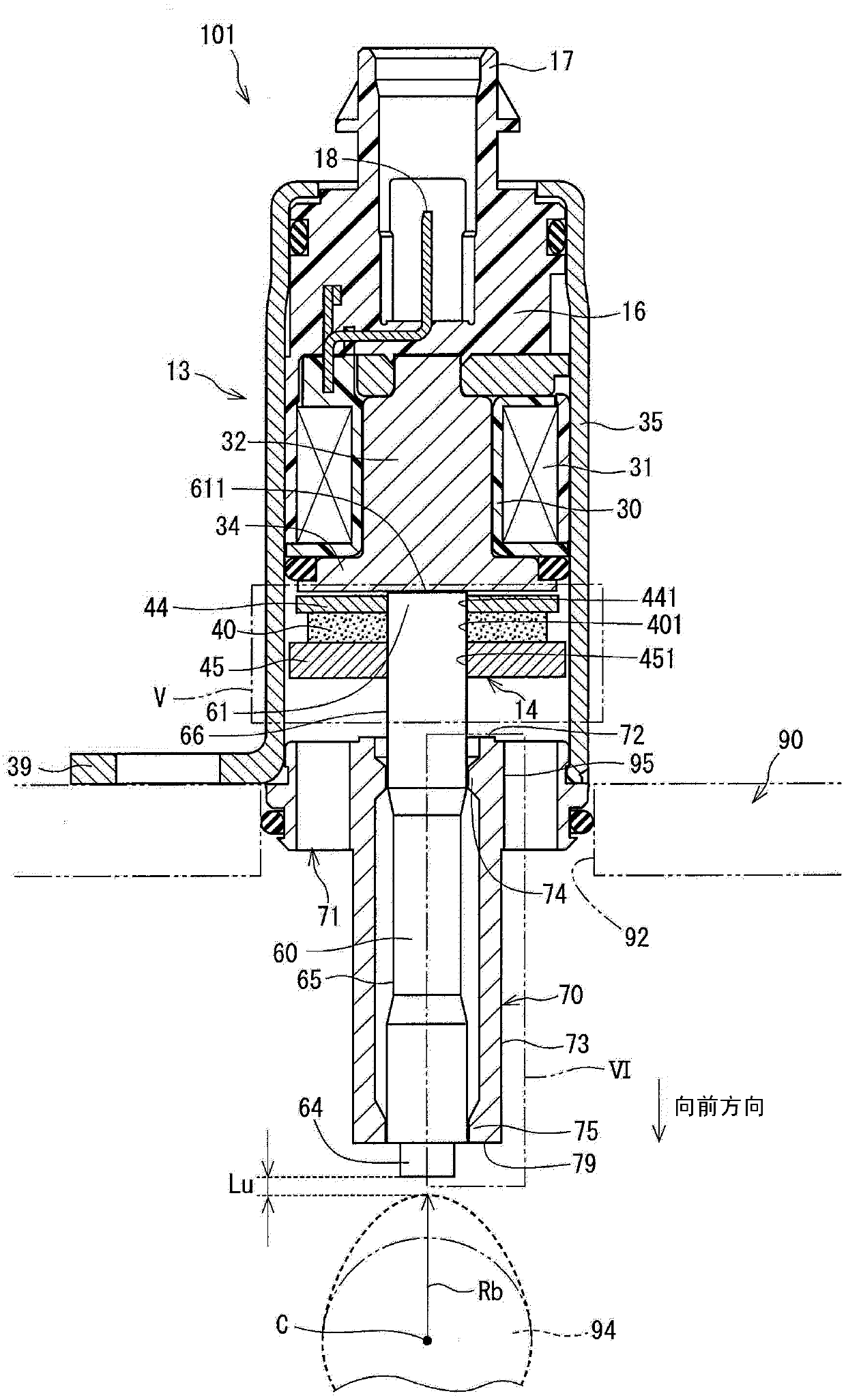

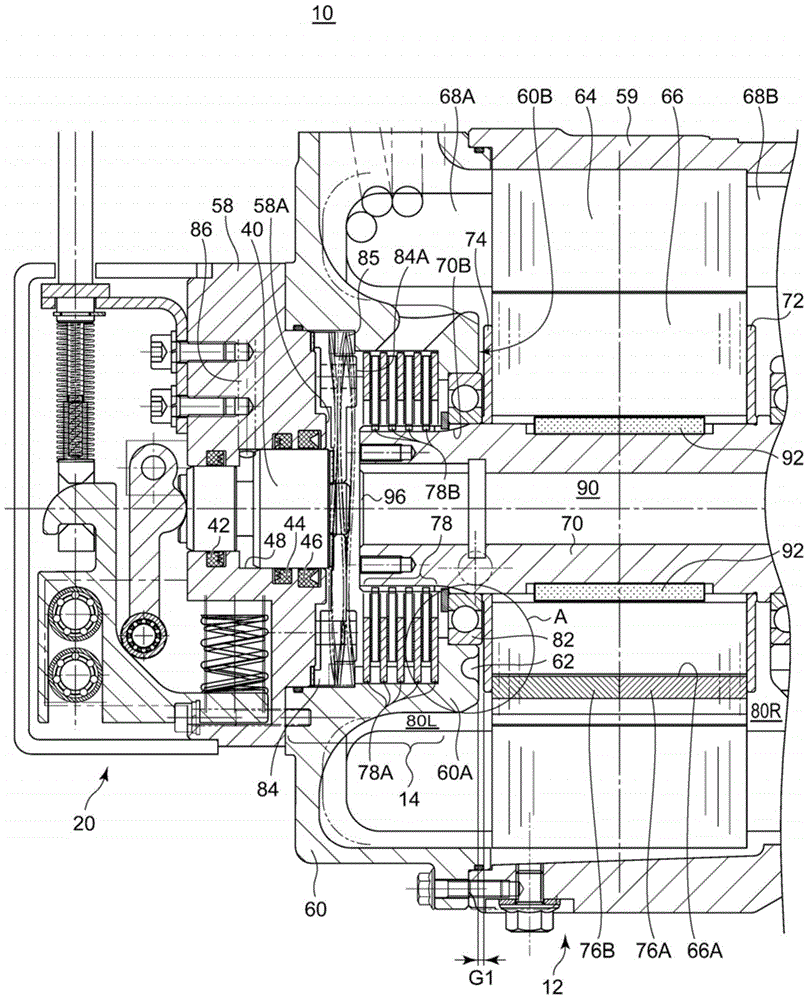

Electromagnetic Actuator

InactiveCN107676143AQuick responseIncreased viscous resistanceValve arrangementsMagnetsEngineeringMechanical engineering

An electromagnetic actuator (101) is composed of a movable unit (14) and a stationary unit (13). The movable unit (14) has an output pin (60) movably supported by a guide member (70). The guide member(70) has a cylindrical portion (73) and a first support portion (74) and a second support portion (74) which are formed on an inner peripheral surface of the cylindrical portion (73). A radially inwardly recessed portion (65) is formed on an outer peripheral surface of the output pin (60). Straight portions (66, 68) are formed in the output pin at both axial sides of the radially inwardly recessed portion, wherein an outer diameter of the straight portion is larger than an outer diameter of the radially inwardly recessed portion (65). Each of the straight portions of the output pin (60) is movably in contact with the first and second support portions (74, 75).

Owner:DENSO CORP

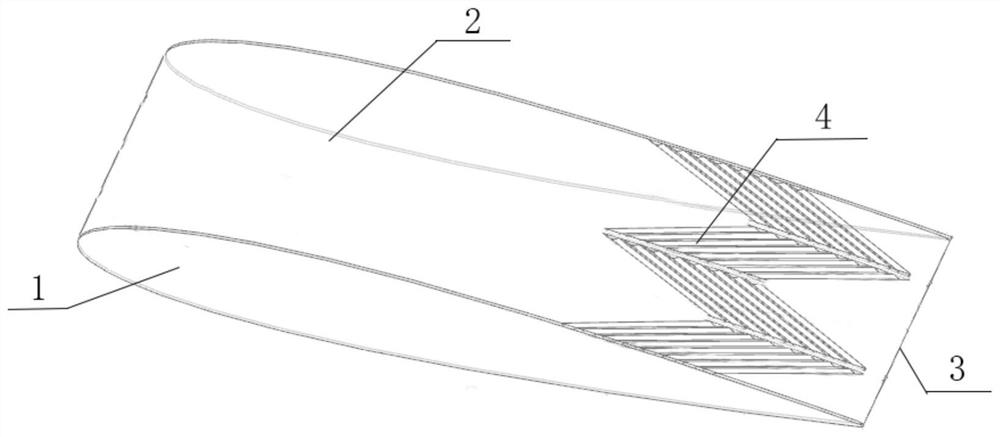

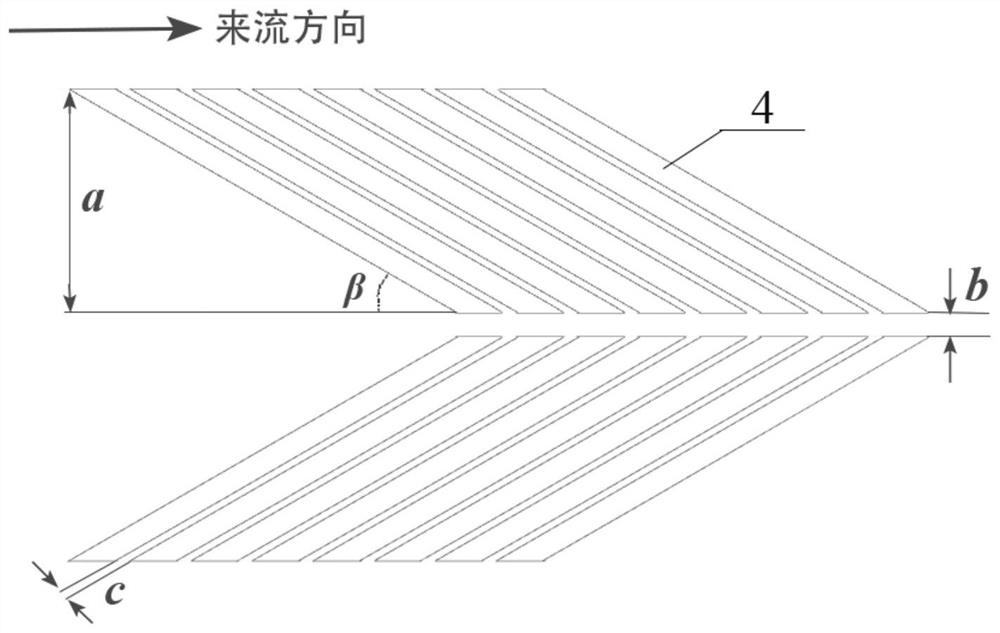

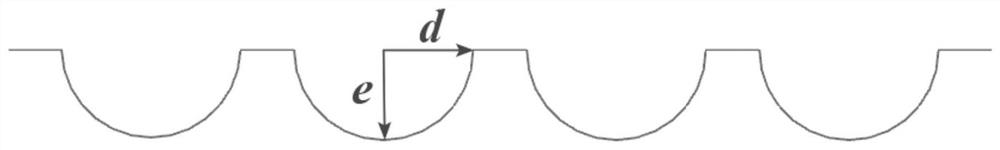

Low-Reynolds-number lower wing with oblique grooves

ActiveCN113460284AAvoid separationEnhanced blendingInfluencers by generating vorticesWingsRolling-element bearingEngineering

The invention relates to a low-Reynolds-number lower wing with oblique grooves. A plurality of inclined groove groups which are alternately distributed in a left-inclined manner and a right-inclined manner are arranged near the tail edge of the upper surface; each oblique groove group consists of a plurality of inclined grooves which are arranged in parallel at intervals in the chordwise direction, so that a spanwise array is formed; and the adjacent inclined groove groups are arranged at intervals, so that the plurality of inclined groove groups are integrally zigzag. The inclined grooves are formed in the tail edge of the upper surface of the wing, on one hand, a stable secondary vortex can be formed in the inclined grooves, the effect of a rolling bearing in machinery is achieved, and the effect of reducing viscous resistance is achieved; and on the other hand, the inclined grooves play a role of a vortex generator, secondary flow is formed in the boundary layer of the upper wing surface of the wing, mixing of high-speed flow of main flow and low-speed flow of the boundary layer is enhanced, propagation of the low-speed flow to the main flow is blocked, the capability of resisting reverse pressure gradient is higher, separation of the boundary layer can be restrained, and the lift-drag ratio is effectively increased.

Owner:CIVIL AVIATION UNIV OF CHINA

Platform Moon Pool Drag Reduction Device

InactiveCN105416521BSafe and stable jobShallow draftWaterborne vesselsFloating buildingsEngineeringKinetic energy

Owner:JIANGSU UNIV OF SCI & TECH

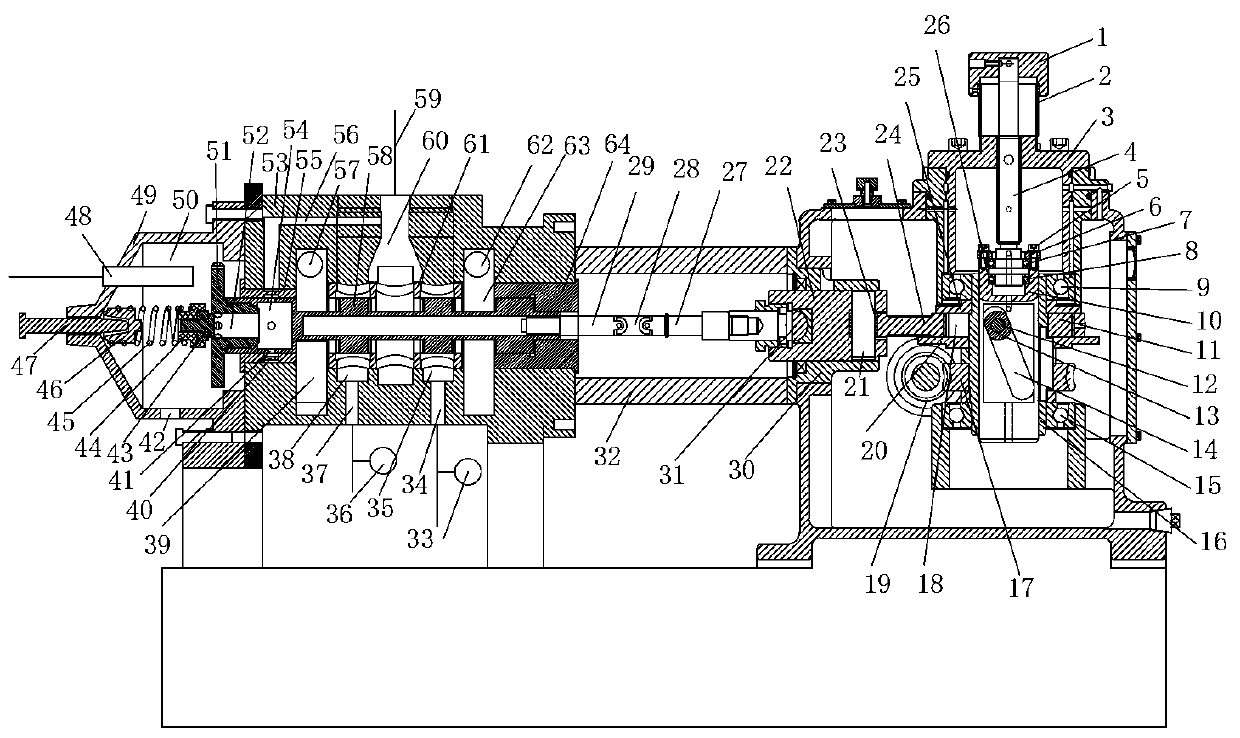

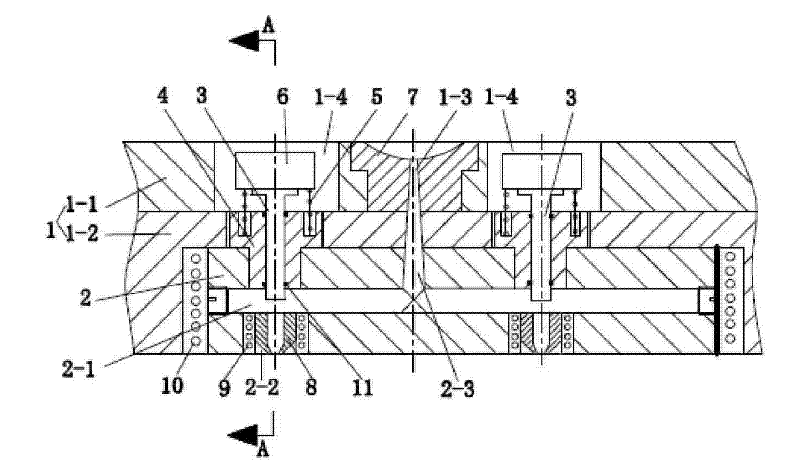

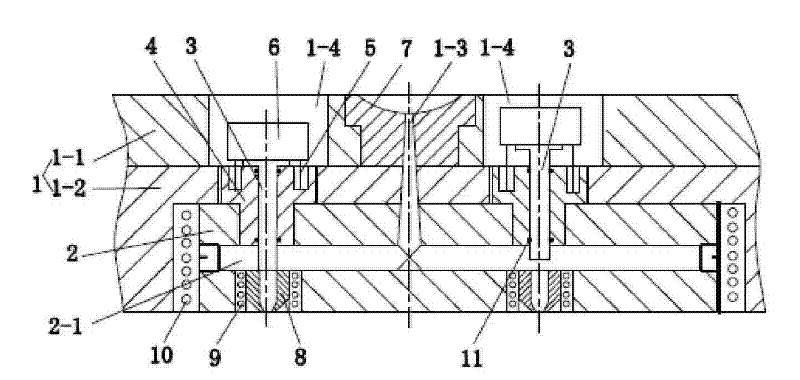

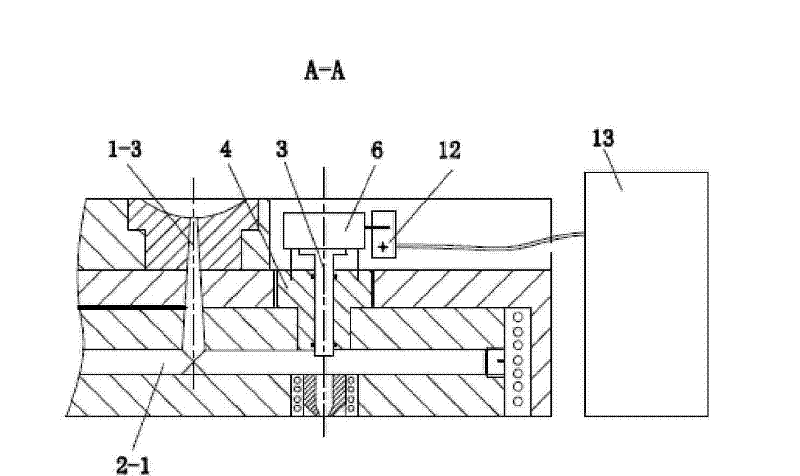

Steam-turbine large hydraulic valve performance life test device

PendingCN110261097AUniform speedReduce viscous dragMachine valve testingReciprocating motionEngineering

The invention discloses a steam-turbine large hydraulic valve performance life test device and belongs to the fatigue test device technology field. The device comprises a reversing valve driven by a driving mechanism. The driving mechanism comprises a machine body. A worm and a worm wheel which are mutually transmitted and cooperated are arranged in the machine body. The worm is driven by a motor installed on the machine body. The worm wheel is fixedly connected to a lower middle portion of a stroke adjusting sleeve. The stroke adjusting sleeve is rotatably cooperated with the machine body. An upper portion of the stroke adjusting sleeve is clamped with a stroke adjusting block which is integrally rotated. The stroke adjusting block and the stroke adjusting sleeve are radially and slidably cooperated. An external portion of the stroke adjusting block is firmly cooperated and fixed with a concentric cam. One side of the concentric cam forms top contact cooperation with a slide block. The slide block is linked and cooperatively connected to a main valve core of the reversing valve. By using the steam-turbine large hydraulic valve performance life test device, the driving mechanism drives the main valve core of the reversing valve to carry out left and right reciprocating motion. The device is suitable for performance testing of the reversing valve.

Owner:HANGZHOU DIANZI UNIV

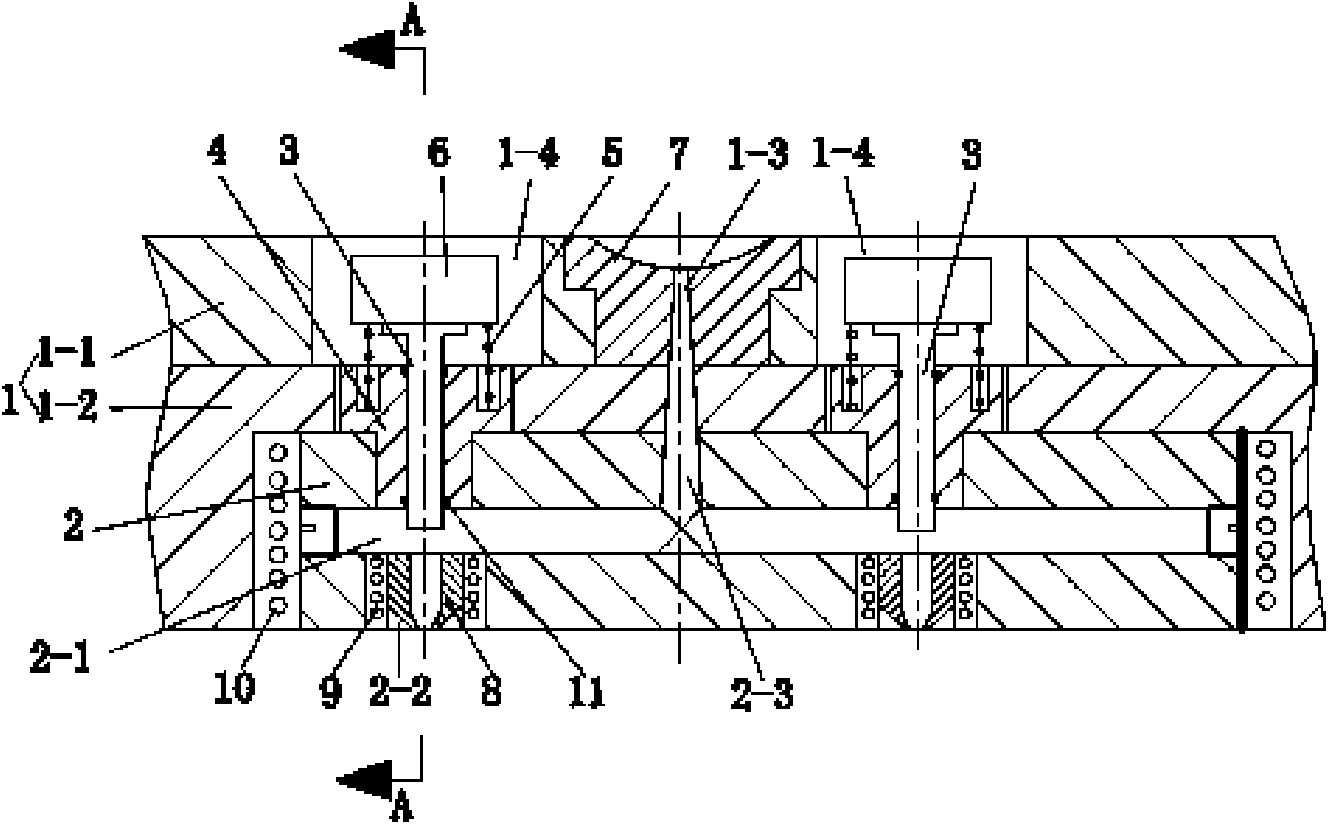

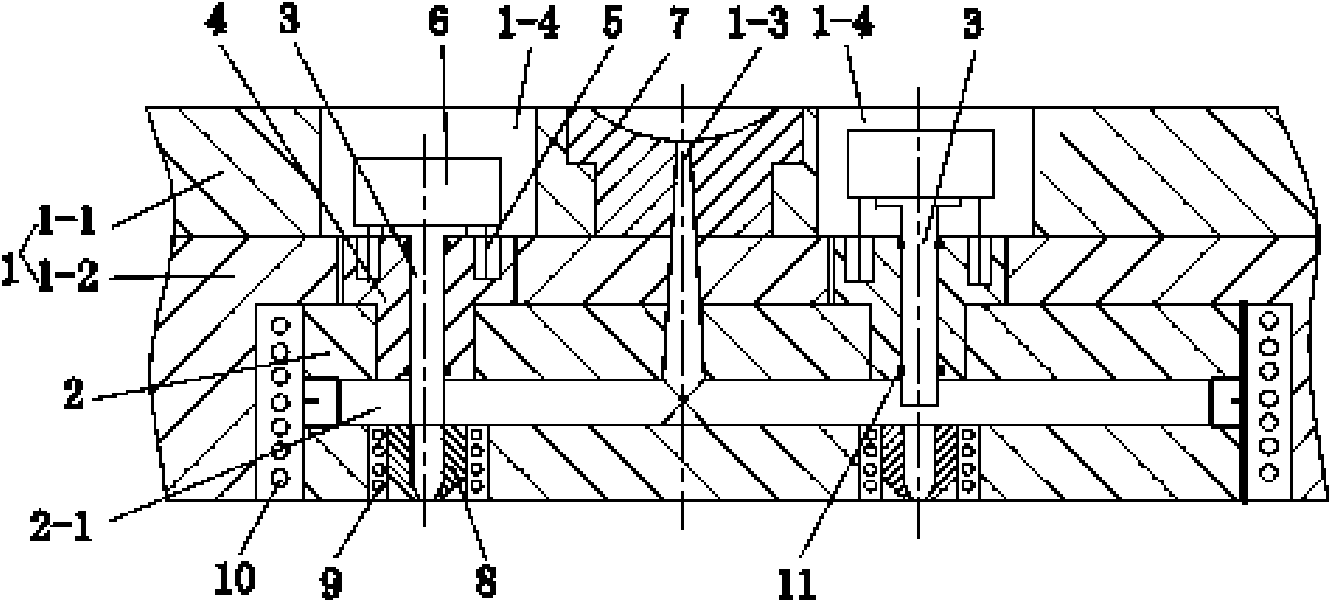

Injection mold hot runner valve type vibration type nozzle device

An injection mold hot runner valve type vibration type nozzle device is provided with a mold body which comprises a fixed template and a shunting template, wherein the shunting template is provided with a sub-runner and the fixed template is provided with a fixed template main runner and at least two fixed template valve holes; the upper part of the shunting template is provided with a shunting template main runner and a shunting template valve hole; a valve rod is respectively arranged in each fixed template valve hole and the shunting template valve hole below the fixed template valve hole;discharging holes are arranged at the lower part of the shunting template; a nozzle is arranged in each discharging hole; the diameter of the bottom part of the valve rod is larger than the diameter of the upper port of the nozzle; a vibration-starting piece which is connected at the upper end of the valve rod, a gate switch located at the side of the vibration-starting piece, and a spring located below the vibration-starting piece, are arranged in each fixed template valve hole; the vibration-starting piece comprises a shell body and a vibration-starting ring; the switch of the valve rod to the nozzle is controlled by the gate switch; and each vibration-starting coil and the gate switch are controlled by a control circuit. The injection mold hot runner valve type vibration type nozzle device has the advantages of simple structure, low energy consumption and convenient adjustment.

Owner:SHANGHAI HUFAN AUTOMOTIVE PLASTIC PARTS

Phase difference hydraulic tightening and loosening type clamp device

ActiveCN110193792AReduce viscous dragImprove work efficiencyServomotor componentsWork holdersPhase differenceEngineering

The invention discloses a phase difference hydraulic tightening and loosening type clamp device, and belongs to the technical field of fatigue testing devices. The phase difference hydraulic tightening variable clamp device comprises a handle and a rotating shaft connected with the handle in a matched mode, wherein the rotating shaft is coaxially provided with a cam I and a cam II, a phase difference is arranged between the cam I and the cam II, and the cam I and the cam II are synchronously provided with an opening A stable pressure maintaining area and an opening B stable pressure maintaining area; and the device further comprises an reversing valve and a clamping tool. According to the technical scheme of the phase difference hydraulic tightening and loosening type clamp device, when the reversing valve is reversed to a reversing opening A, hydraulic oil enters a piston chamber II, a push plate moves leftward, and a clamping plate is loosened; and when the reversing valve is reversed to a reversing opening B, the hydraulic oil enters a piston chamber I, the push plate moves to the right, and the clamping plate clamps. The device has simple and convenient use.

Owner:富兰克润滑科技(台州)有限公司

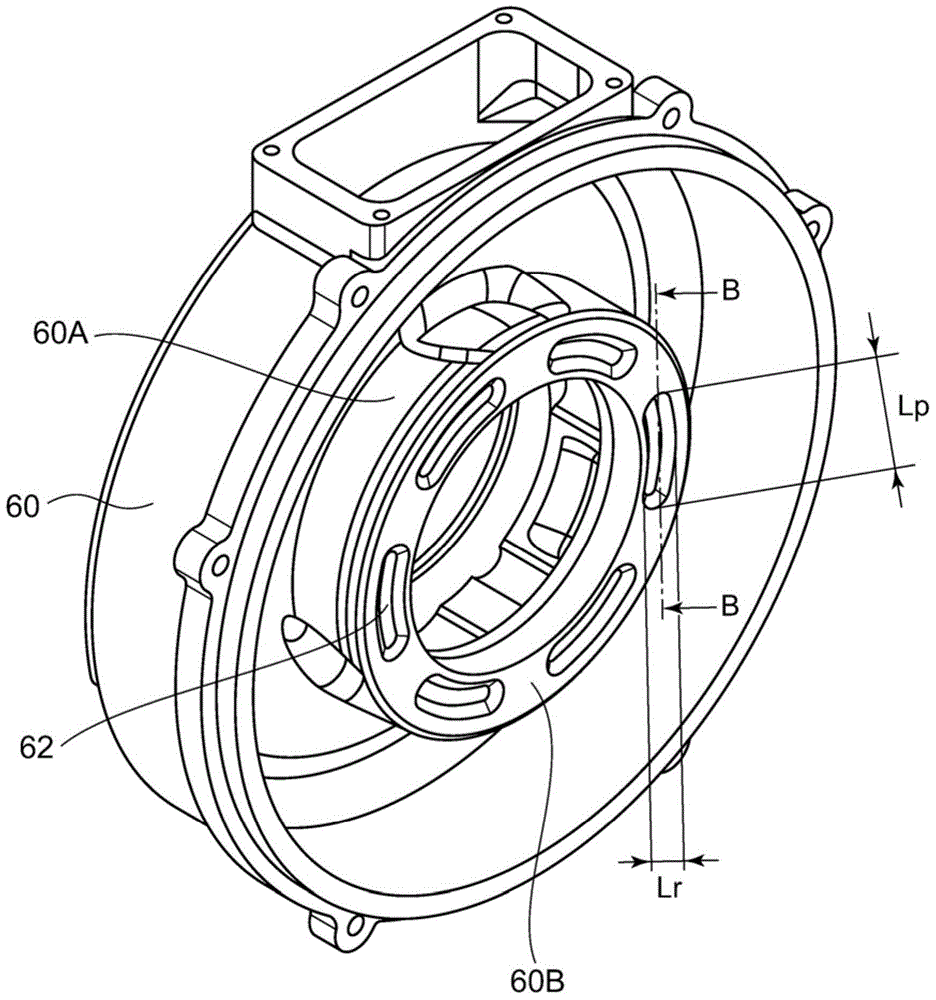

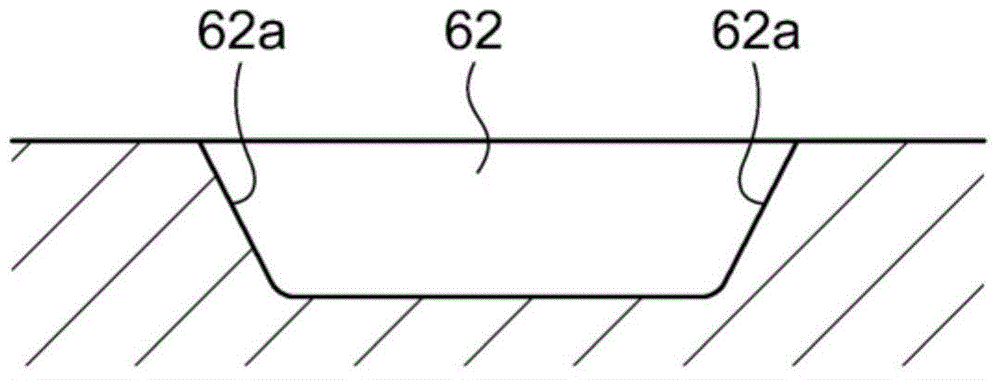

Motor, wet type brake and wet type clutch

To provide a motor, a wet type brake, or a wet type clutch in which liquid coolant is sealed and viscous resistance in a gap between a casing and a rotor is reduced. Provided is a motor (10) which includes a casing (60), and a rotor shaft (70) which rotates relative to the casing (60), in which liquid coolant is sealed in the casing (60), and a concave portion (62) is formed on a facing surface (60B) of the casing (60), which faces a rotor (66).

Owner:SUMITOMO HEAVY IND LTD

Axial flow fan three-dimensional impeller with leaf vein structures and arc cylindrical splitter blades

ActiveCN106762825AIncrease reaction rateImprove flow capacityPump componentsPumpsImpellerSuction surface

The invention discloses an axial flow fan three-dimensional impeller with leaf vein structures and arc cylindrical splitter blades. The axial flow fan three-dimensional impeller comprises a hub and further comprises curved-twisted blades and splitter blades, wherein a shaft sleeve is fixed on the hub by a connecting piece; the curved-twisted blades and splitter blades are fixedly connected onto the hub; the curved-twisted blades comprise suction surfaces and pressure surfaces; wing grooves are formed in the tops of the curved-twisted blades; leaf vein shaped grooves are formed in upper half parts of the pressure surfaces of the curved-twisted blades; the wing grooves are communicated with the leaf vein shaped grooves through air outlets; small wing protrusions are arranged at the tails of the suction surfaces of the curved-twisted blades; parabolic pinholes are formed in the curved-twisted blades; a splitter blade is arranged between every two adjacent curved-twisted blades; and the height of each splitter blade is smaller than one half of that of the curved-twisted blade.

Owner:ZHEJIANG SCI-TECH UNIV

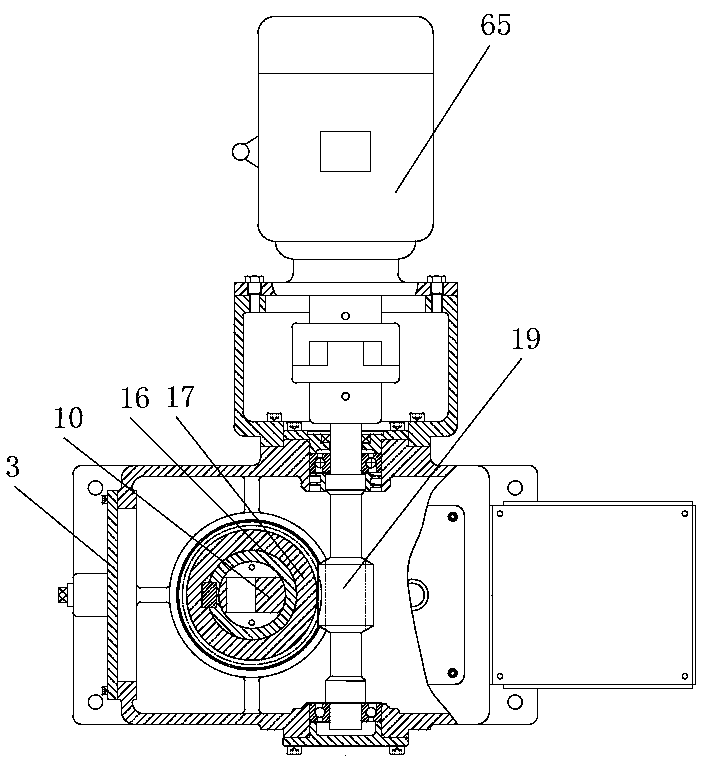

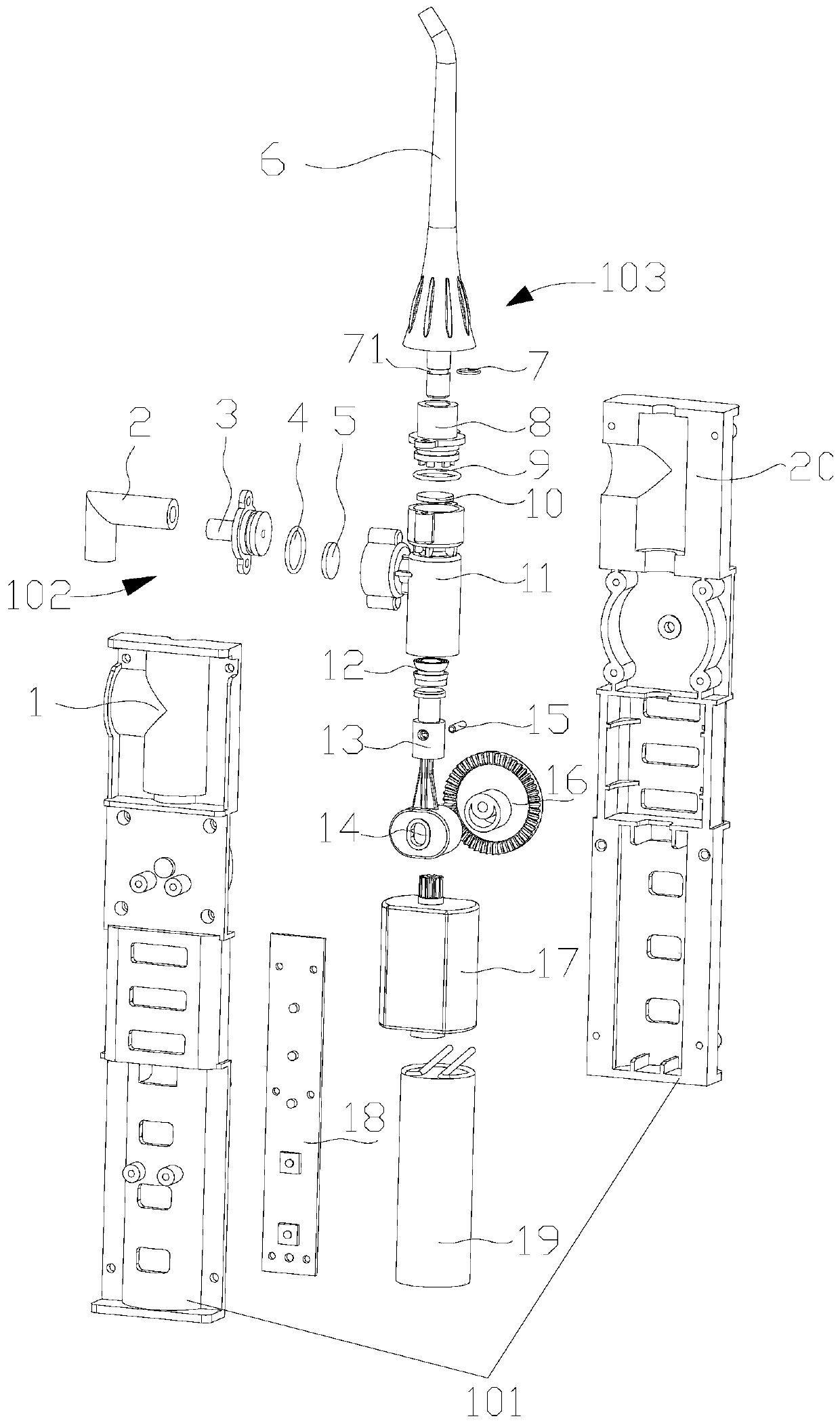

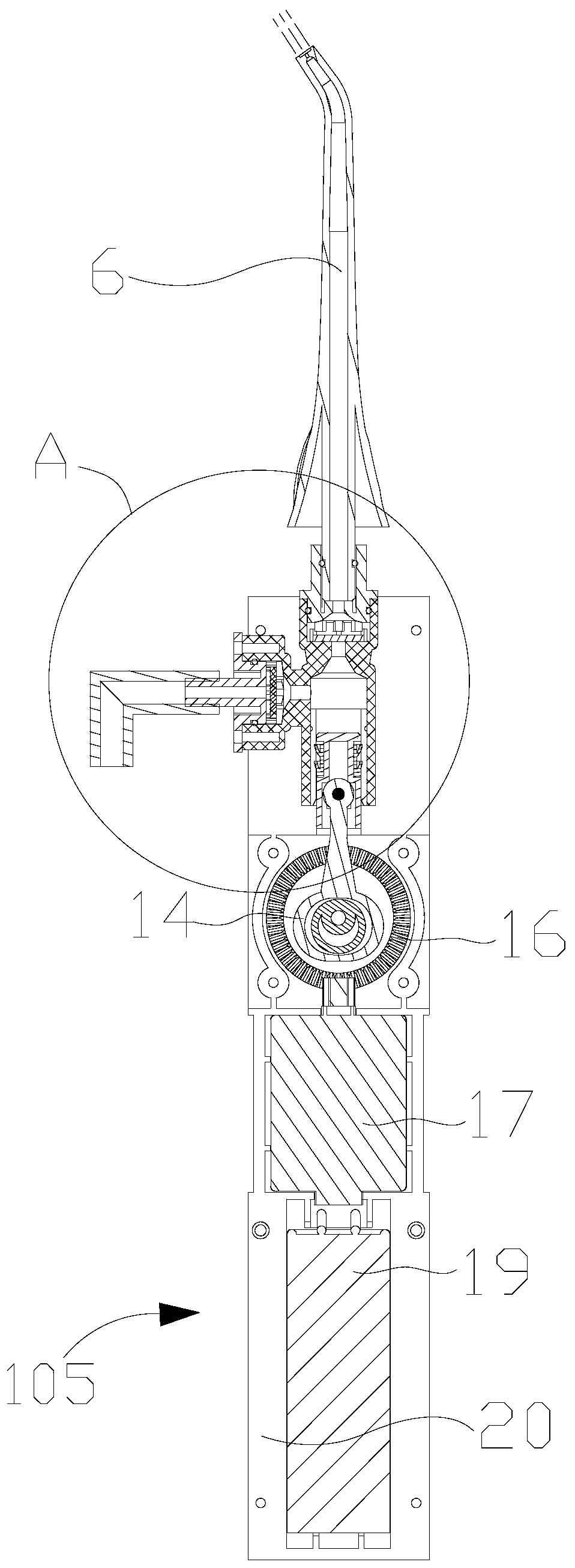

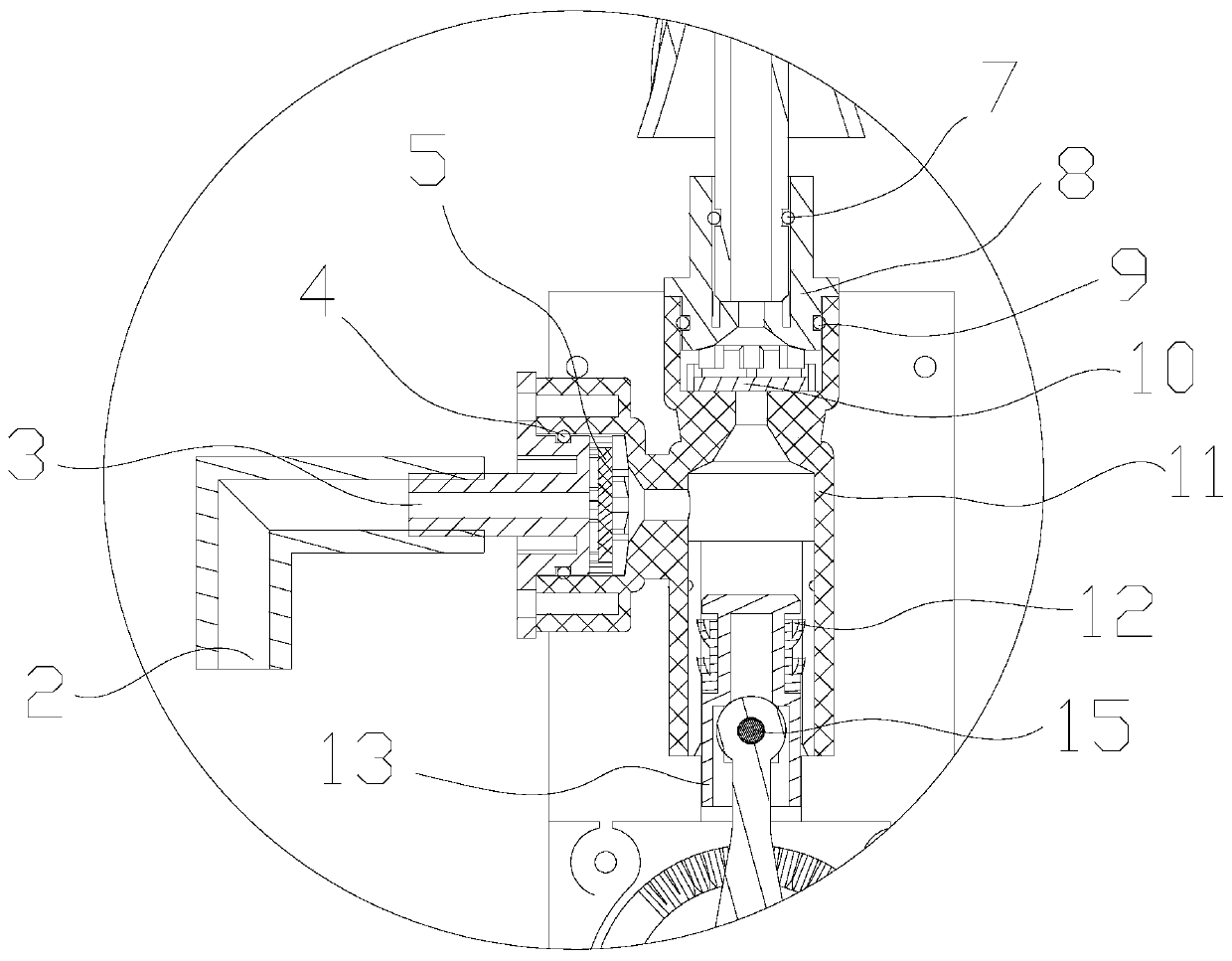

Oral irrigator

PendingCN110269707AReduce viscous dragAvoid lossPositive displacement pump componentsPumpsReciprocating motionWater flow

The invention provides an oral irrigator. The oral irrigator comprises a shell body, a water inlet assembly, a water outlet assembly and a pump body assembly, the pump body assembly comprises a valve pump body, a piston and a driving device, the valve pump body comprises a water inlet valve base, a water outlet valve base and a pump body, and a water outlet is formed in the water outlet valve base; a water outlet valve block is arranged on the outer side of the water outlet, the water outlet assembly comprises a water outlet pipe and a water outlet pipe joint, the outer end of the water outlet pipe joint is connected with the water outlet pipe, and the inner end of the water outlet pipe joint is connected with the water outlet valve base; a water outlet valve cavity is formed in the water outlet valve base, the water outlet is formed in the middle of the bottom surface of the water outlet valve cavity, a water outlet valve block supporting rib is arranged around the water outlet and located on the bottom surface of the water outlet valve cavity, and several water outlet valve block guiding ribs are arranged on the periphery of the water outlet valve block supporting rib; the driving device drives the piston to reciprocate in the pump body, and the water outlet valve block reciprocates between the water outlet pipe joint and the water outlet valve block guiding ribs to control opening and closing of the water outlet. According to the oral irrigator, the viscous resistance of water flow to the water outlet valve block is reduced, and the stability of water flow sprayed by the pump body is improved.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

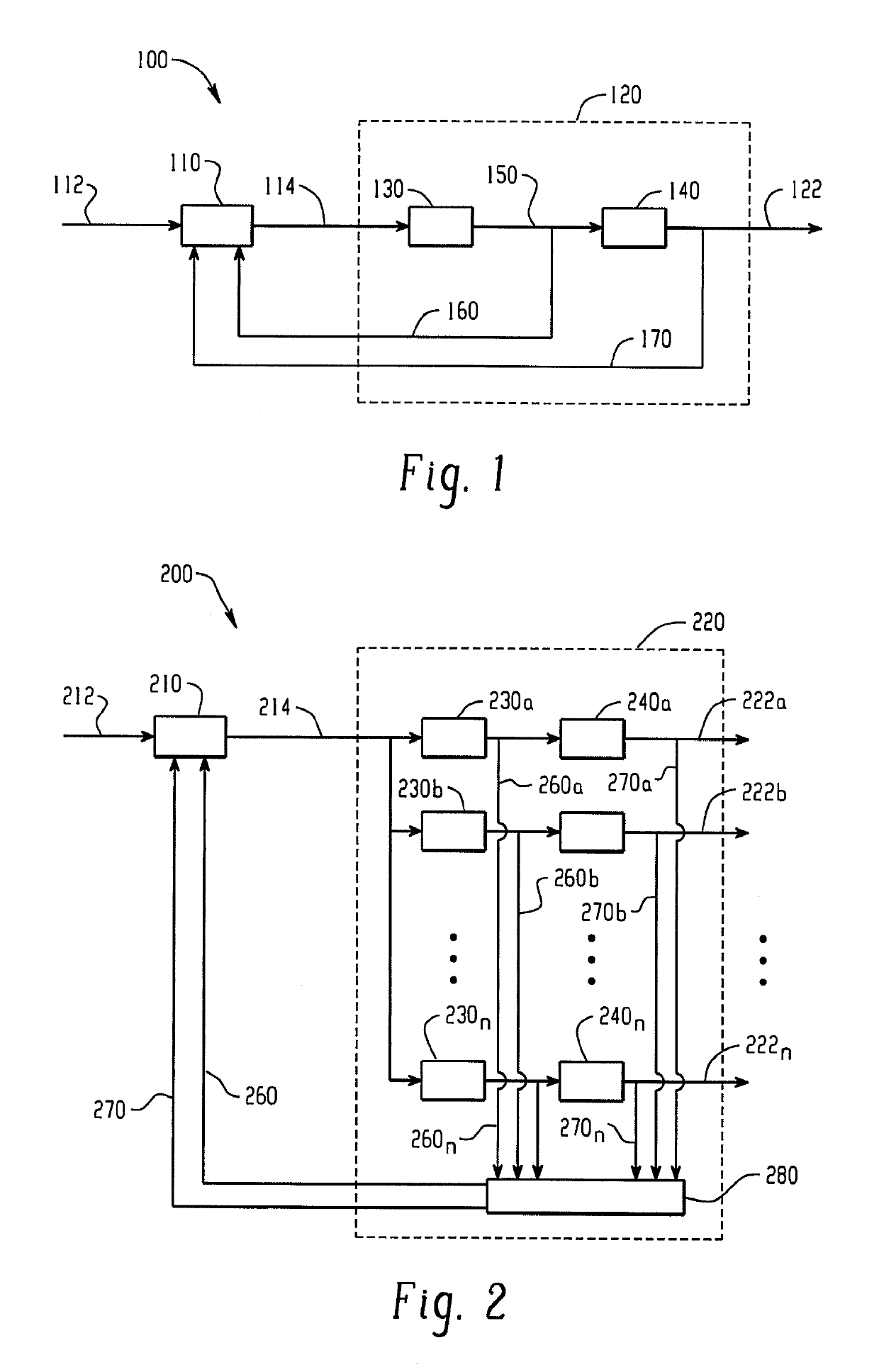

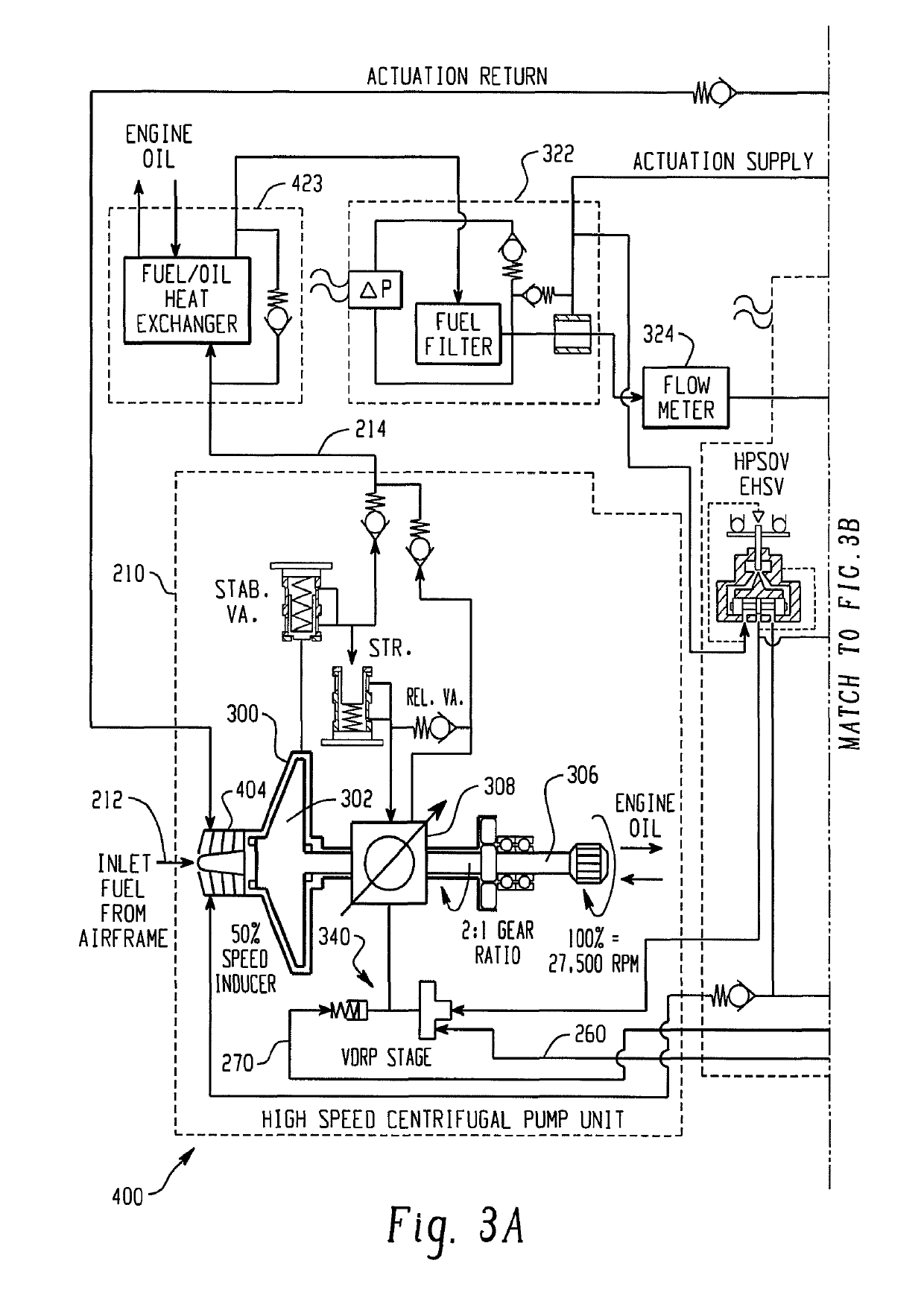

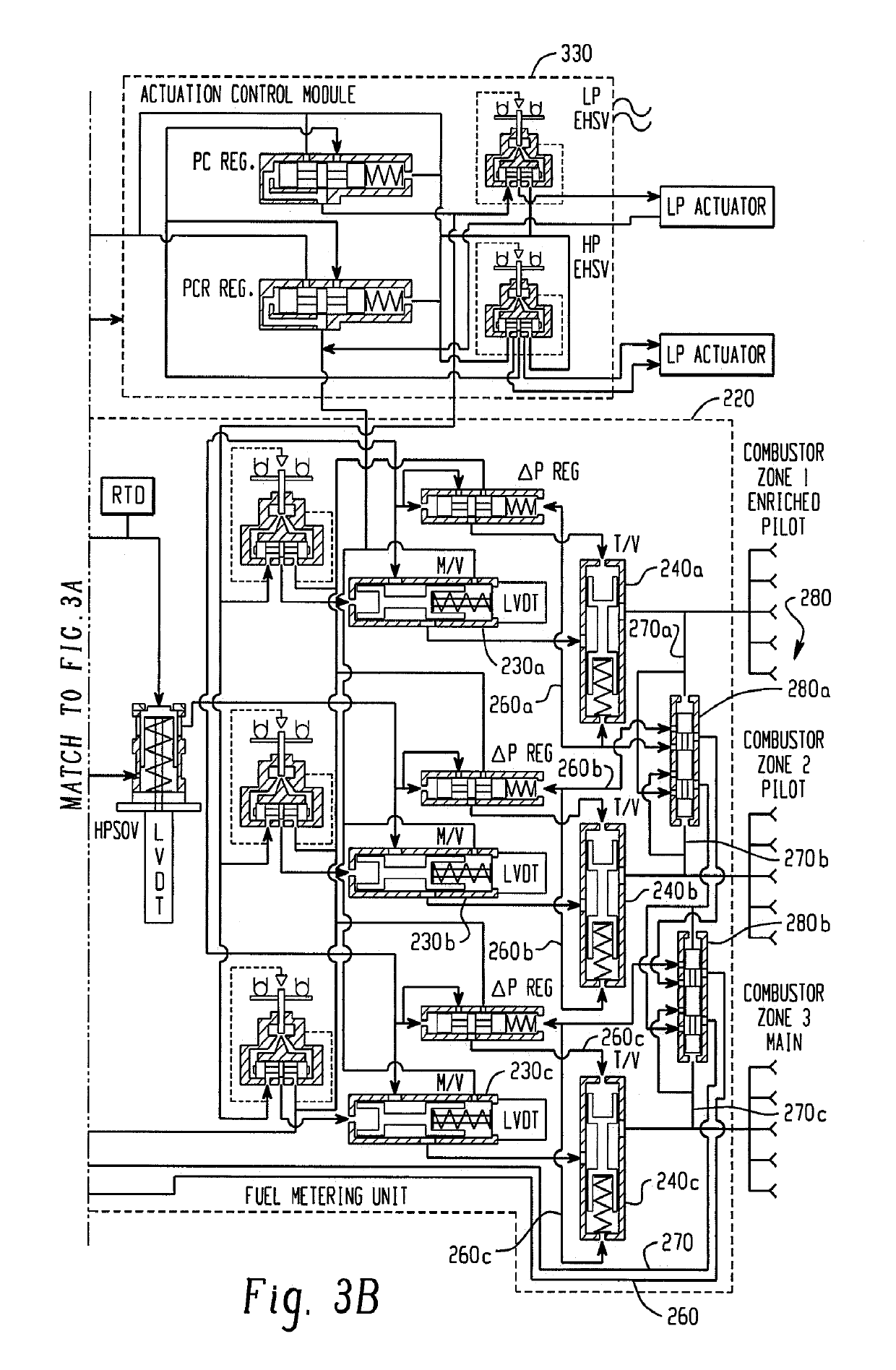

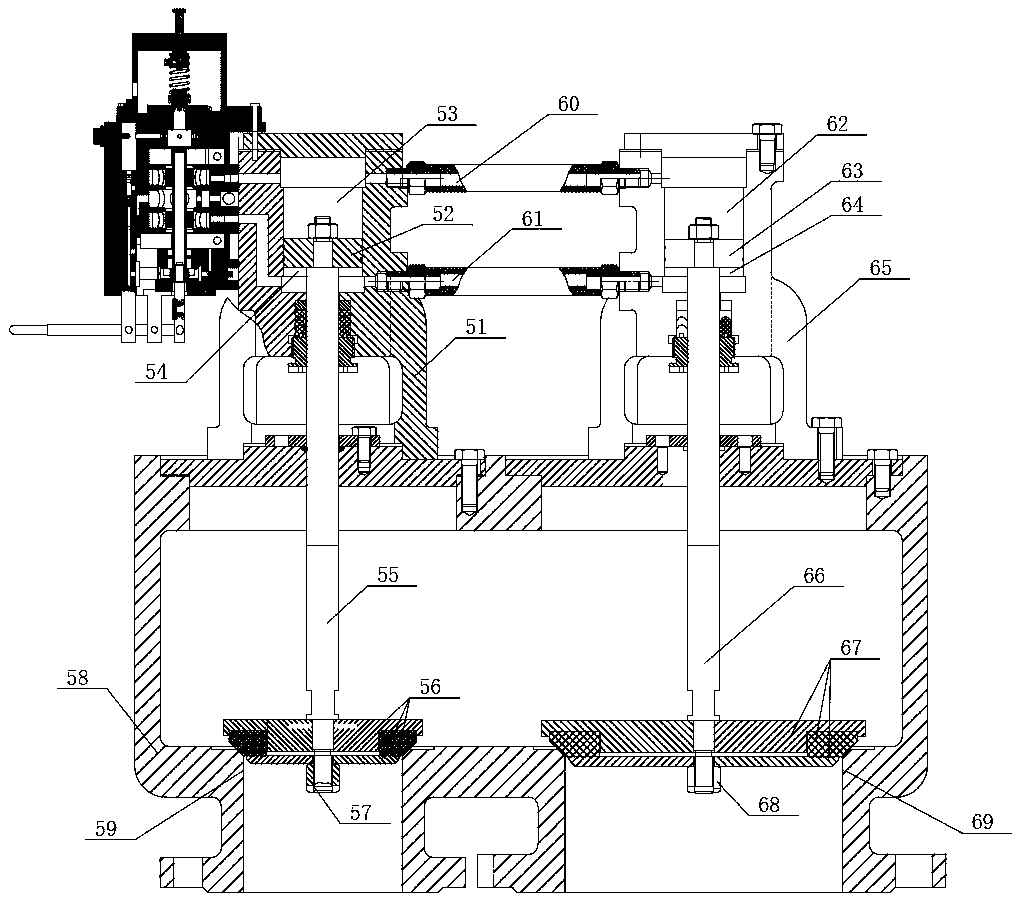

Hydromechanical pressure compensation control of a variable displacement pump in a centrifugal pumping and metering system and associated method

ActiveUS10451053B2Improve inlet performance characteristicReduce rotationFluid pressure control with auxillary non-electric powerPump controlHydraulic machineryPressure difference

A pump assembly includes a pump unit having a centrifugal pump and a variable pump supplying pressurized flow. A fuel control assembly receives flow from the pump unit and includes at least one metering valve and at least one throttling valve. A control for the variable pump receives first and second pressure signals indicative of a pressure differential across the throttling valve, or across the metering valve / throttling valve combination, for altering operation of the variable pump in response to the pressure differential.

Owner:EATON INTELLIGENT POWER LTD

Two-dimensional primary and secondary compensation spray rotation steam pipe fast-switching device

PendingCN110319247AComplete closureImprove reliabilityMultiple way valvesValve housingsPetrochemicalEngineering

The invention discloses a two-dimensional primary and secondary compensation spray rotation steam pipe fast-switching device and belongs to the technical field of petrochemical equipment. The two-dimensional primary and secondary compensation spray rotation steam pipe fast-switching device comprises a first valve body. The first valve body is internally provided with a first valve rod, wherein thefirst valve rod is movably matched with the first valve body in a sealed manner. The rear portion of the first valve rod is provided with a first rear valve plate. A valve body cavity is divided intoa first valve cavity A and a first valve cavity B through the first rear valve plate. A second valve body of the same structure is arranged at the outer side of the first valve body in a matched manner. The device further comprises a reversing valve connected with the first valve body and the second valve body. The front end of the first valve rod is provided with a first valve disc. The first valve disc extends into a pipe cavity and is matched with or separated from a first pipe opening in a sealed manner. The two-dimensional primary and secondary compensation spray rotation steam pipe fast-switching device is provided with bidirectional parallel valves and achieves synchronous driving, and fluid in the pipe can be thoroughly intercepted; and the device is good in reliability, high in stability and safe and convenient to use. Under the combined action of a main valve element and a rotary push small valve, the labor intensity is remarkably lowered, and the work efficiency is improved.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com