Shot blaster blades and impeller body assembly of shot blaster

A shot blasting machine and blade technology, used in impellers, rotor blades, metal processing equipment, etc., can solve the problems of shortening the service life of blades, increasing the cost of use, increasing energy consumption, etc., reducing the turbulent dissipation rate and weakening the burst strength. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

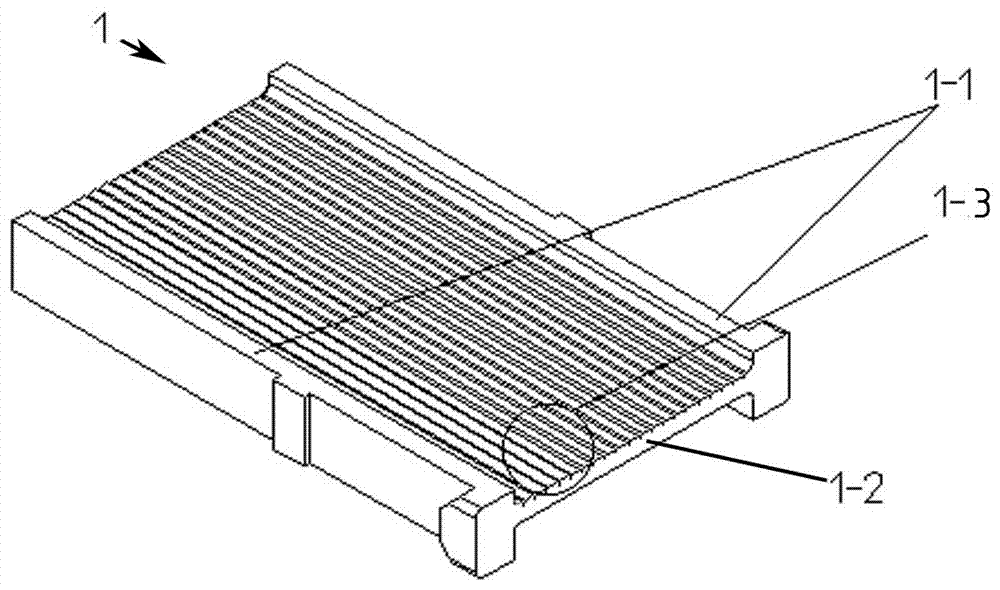

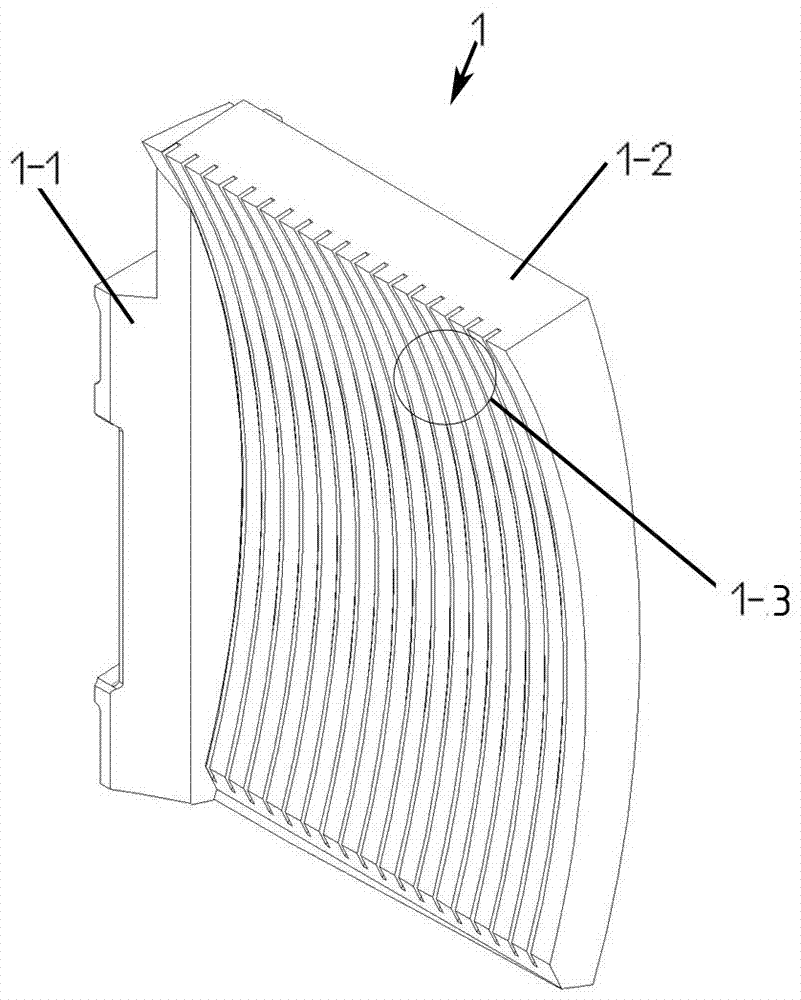

[0029] Such as figure 1 , 2 , 9, a blasting machine blade 1, including a base 1-1 and a sheet 1-2, the sheet 1-2 is provided with a surface texture 1-3, the sheet 1-2 Both the upper surface and the lower surface are provided with a surface texture 1-3, the direction of the surface texture 1-3 is along the direction of projectile movement, and the blades of the blasting machine are curved blades or plane straight blades, and the plane straight blades are The inclination angle at the inlet of the water pill mixture is α, and the inclination angle α is 10°-22°.

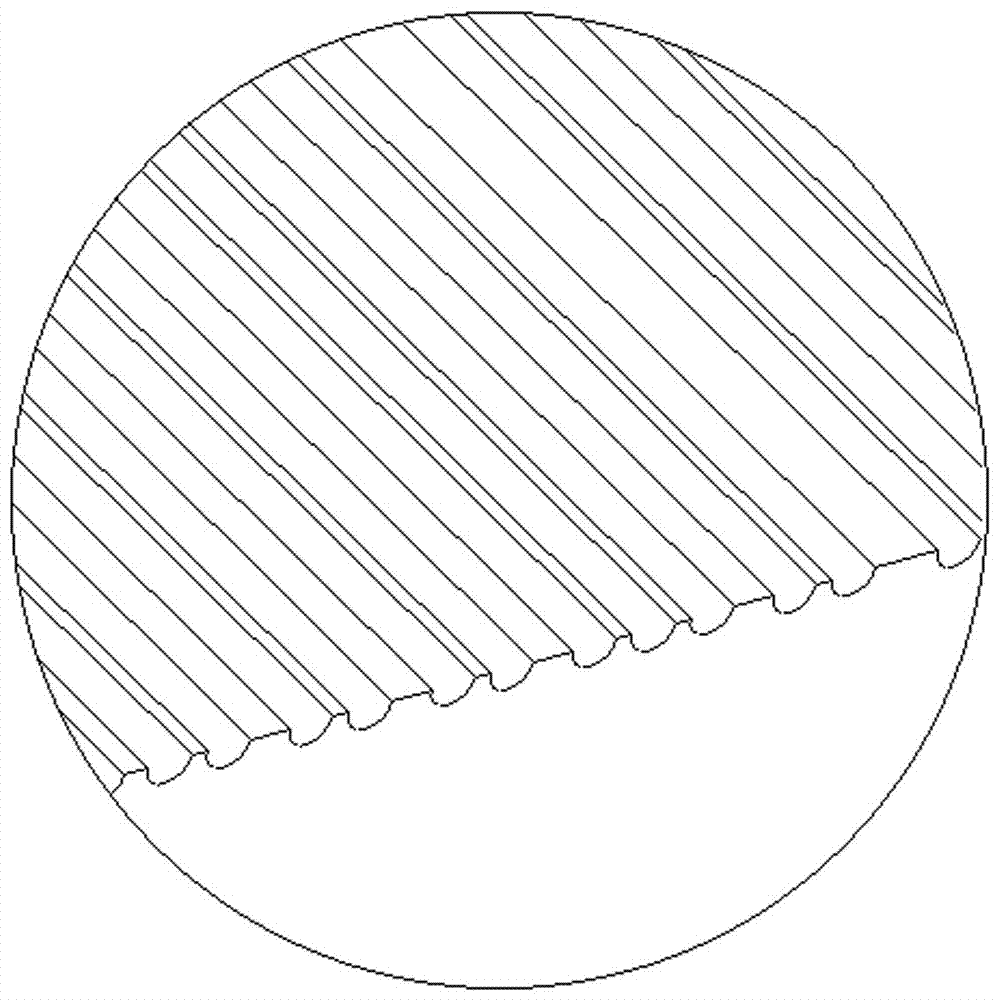

[0030] Such as image 3 , 4 As shown, the surface texture is a U-shaped groove, the groove width of the U-shaped groove is W, the long distance of the U-shaped groove is L, and the short distance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com