Motor, wet type brake and wet type clutch

A technology for motors and casings, which is applied in the direction of mechanically driven clutches, brakes, clutches, etc., can solve problems such as increased viscous resistance and decreased motor efficiency, and achieve the effect of reducing viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

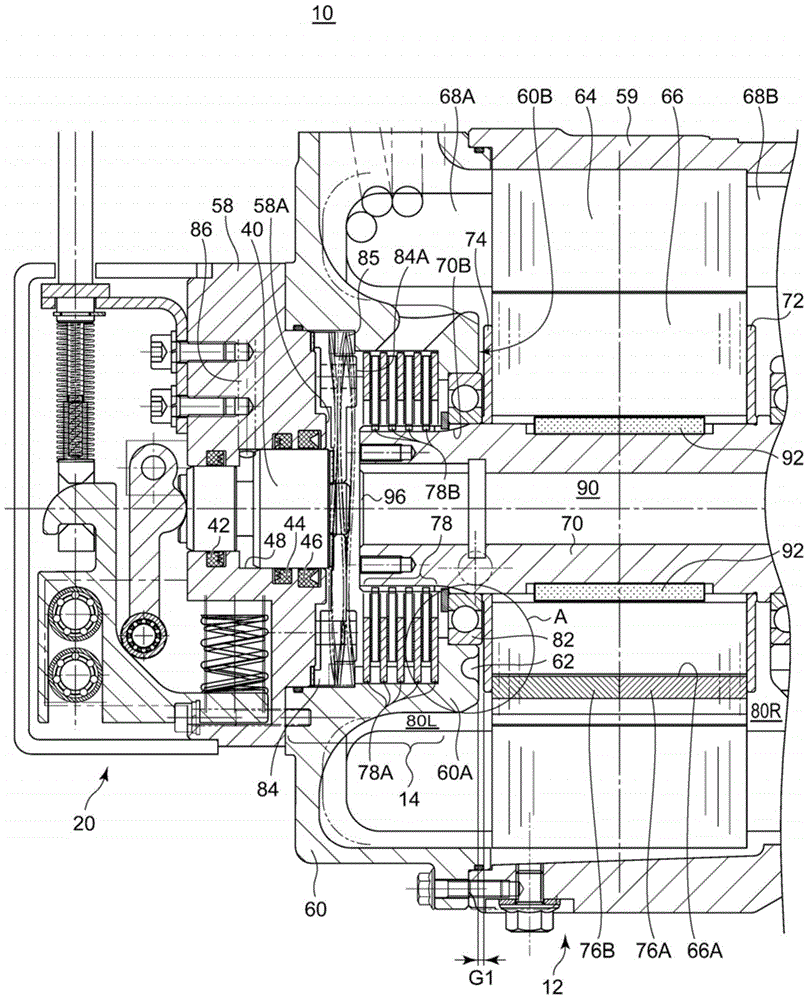

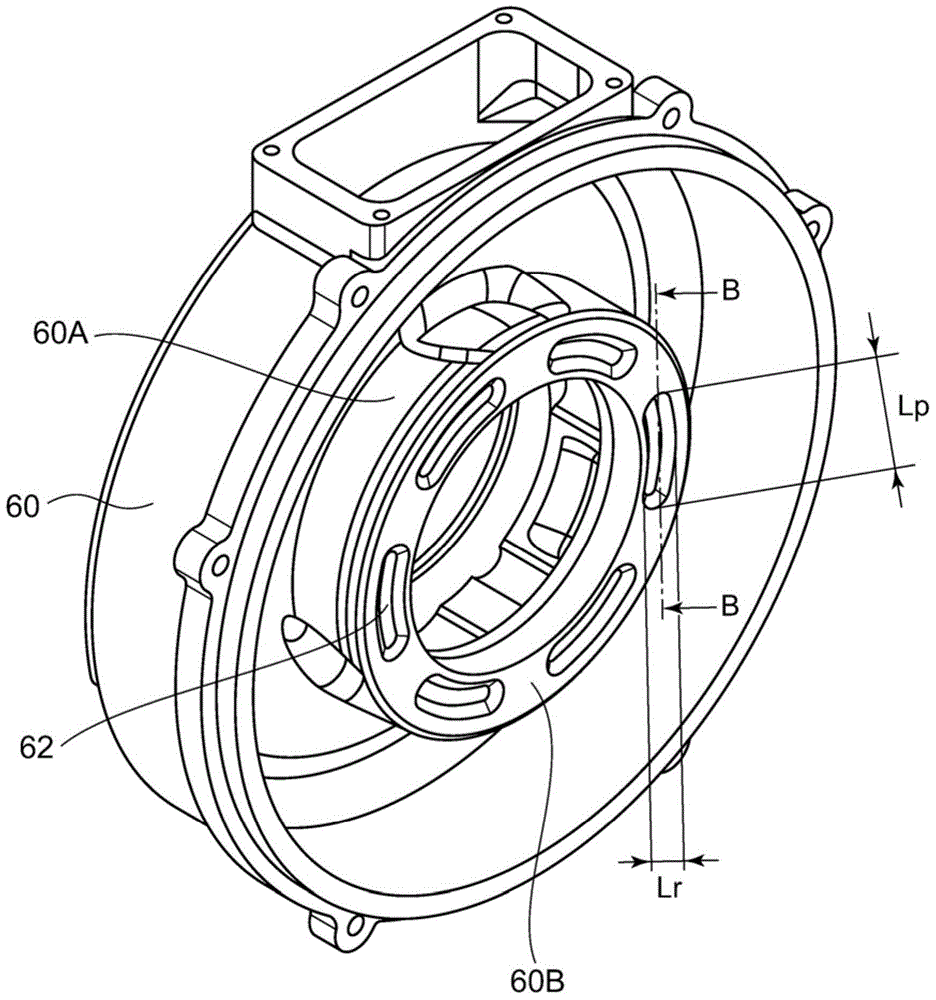

[0017] figure 1 It is a cross-sectional view of a part of the motor 10 according to one embodiment of the present invention taken along a vertical plane including the central axis.

[0018] The motor 10 is a device that integrates an IPM (Interior Permanent Magnet) motor 12 , a wet multi-disc brake mechanism 14 , and a parking brake device 20 .

[0019] The IPM motor 12 includes a stator 64 and a rotor 66 each made of laminated steel plates. The laminated steel plates of the rotor 66 are formed with a plurality of voids 66A extending in the axial direction, and permanent magnets 76A, 76B are embedded in the voids. IPM motors with permanent magnets embedded in the rotor are more efficient than SPM motors with permanent magnets attached to the rotor surface. The laminated steel plates constituting the rotor 66 are integrated with bolts (not shown), and are integrated with the rotor 70 via keys 92 . In addition, it can also be integrated by riveting and bonding without bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com