Phase difference hydraulic tightening and loosening type clamp device

A fixture device and phase difference technology, applied in workpiece clamping devices, fluid pressure actuation devices, manufacturing tools, etc., can solve the problems of high pulling frequency, low work efficiency, and tired operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

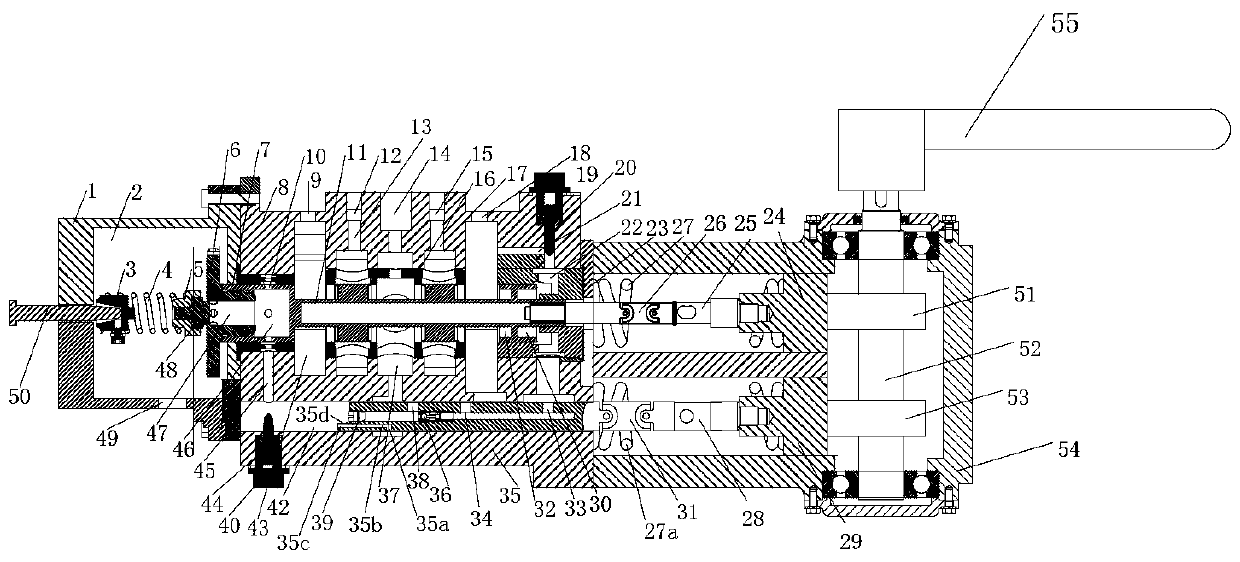

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

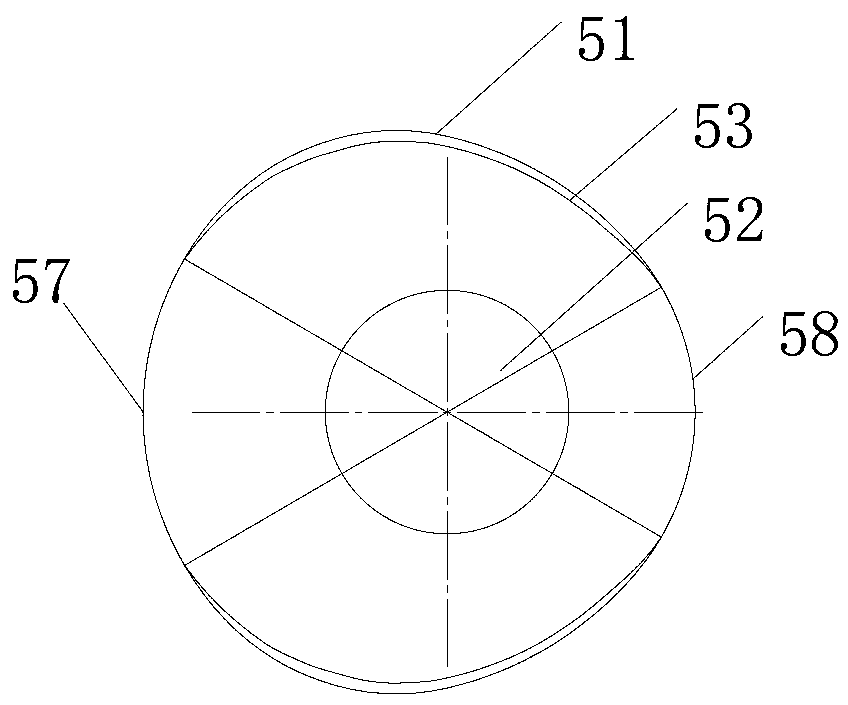

[0026] As shown in the figure, the phase-difference hydraulic elastic clamp device includes a handle 55 and a rotating shaft 52 connected with it. On the rotating shaft 52, a cam 51 and a cam 2 53 are coaxially arranged, and a phase difference is set between the cam 51 and the cam 2 53. , the cam one 51 and the cam two 53 are also simultaneously provided with a stable pressure holding area 57 at the port A and a stable pressure holding area 58 at the port B;

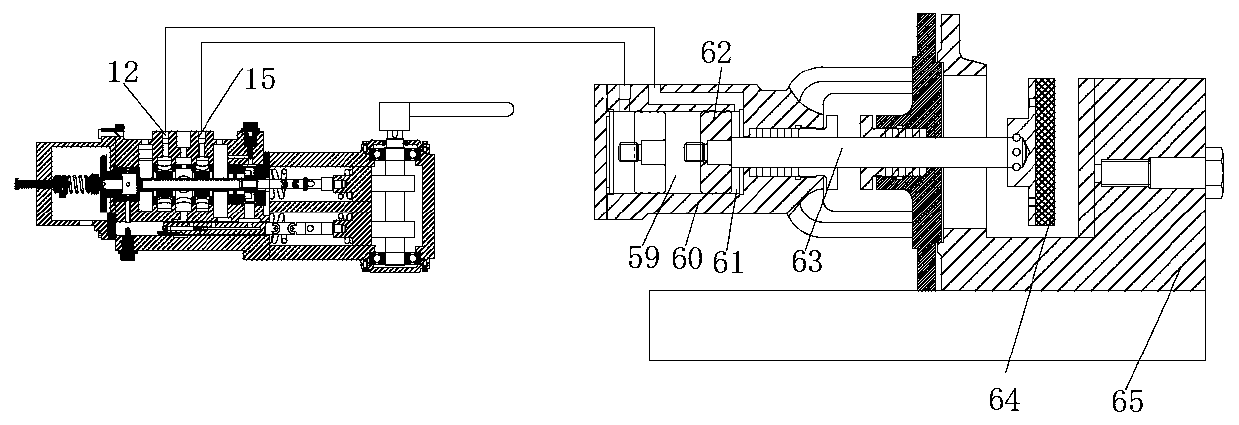

[0027]It also includes a reversing valve. The reversing valve is a valve body composed of housing one 1, housing two 8, and housing three 23. The housing one 1 is provided with an oil return chamber 2 and a return port three 49. The main valve core 11 is arranged in the housing two 8, and the middle part of the main valve core 11 is equipped with a reversing valve sleeve 16. The main valve core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com