Low-Reynolds-number lower wing with oblique grooves

A low Reynolds number and groove technology, applied in the direction of wings, aircraft parts, aircraft control, etc., can solve the problems of reducing wall friction, inability to effectively suppress negative layer separation, and failure to achieve drag reduction. Small viscous resistance, strong reverse pressure gradient, good effect of reducing drag and increasing lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

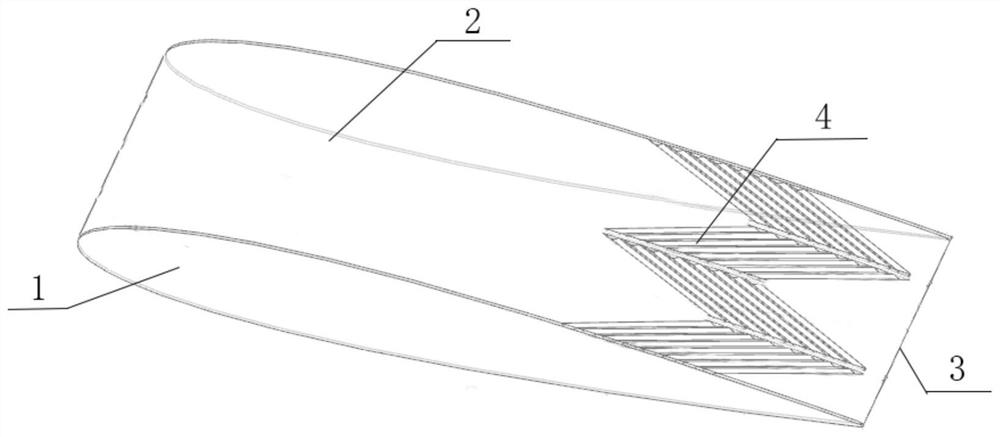

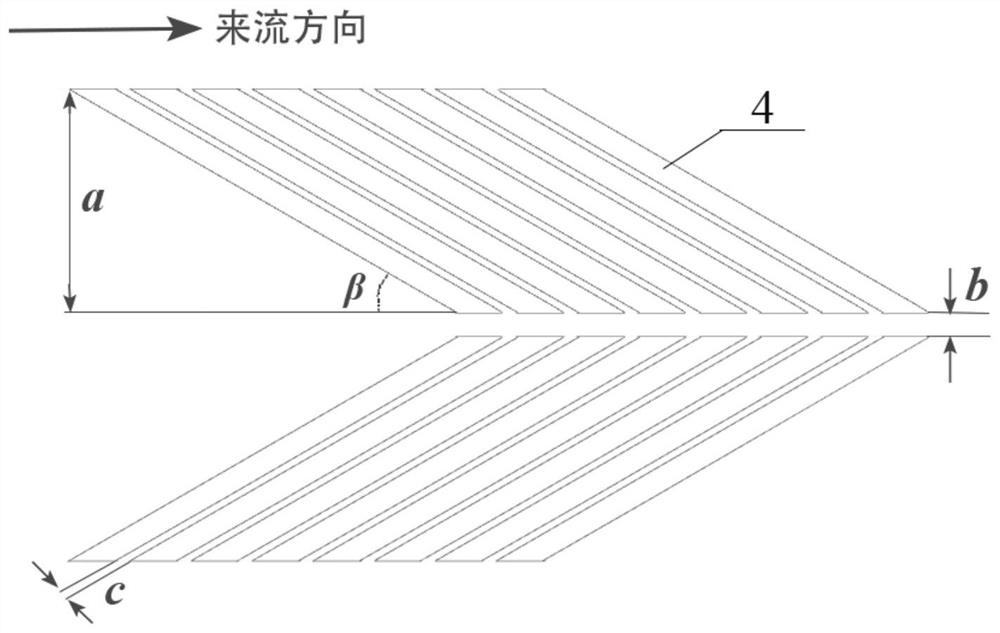

[0021] Such as figure 1 As shown, the low Reynolds number lower wing 1 with oblique grooves provided by the present invention is provided with a plurality of "left-inclined" and "right-inclined" groups of oblique grooves alternately distributed near the trailing edge 3 of the upper surface 2; Each oblique groove group is composed of a plurality of oblique grooves 4 arranged in parallel at intervals along the chord direction, thus forming a spanwise array; adjacent oblique groove groups are arranged at intervals, so a plurality of oblique grooves The overall shape of the group is zigzag.

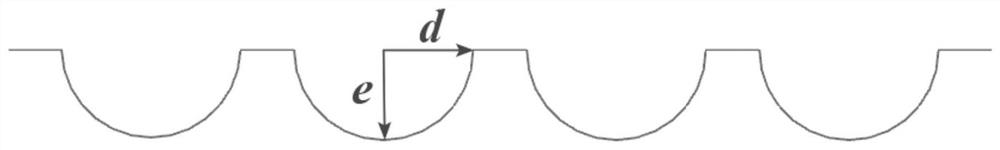

[0022] Such as figure 2 shown, for a Reynolds number of 5×10 5 In the working condition of the wing 1, as the angle of attack of the wing 1 increases, the separation of the boundary layer will develop from the trailing edge 3 to the leading edge. The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com