Injection mold hot runner valve type vibration type nozzle device

A technology of nozzle device and hot runner, which is applied in the field of injection mold hot runner valve-type vibrating nozzle device, can solve the problems of difficult adjustment, high energy consumption, complex structure, etc., and achieve enhanced vibration effect, low energy consumption and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

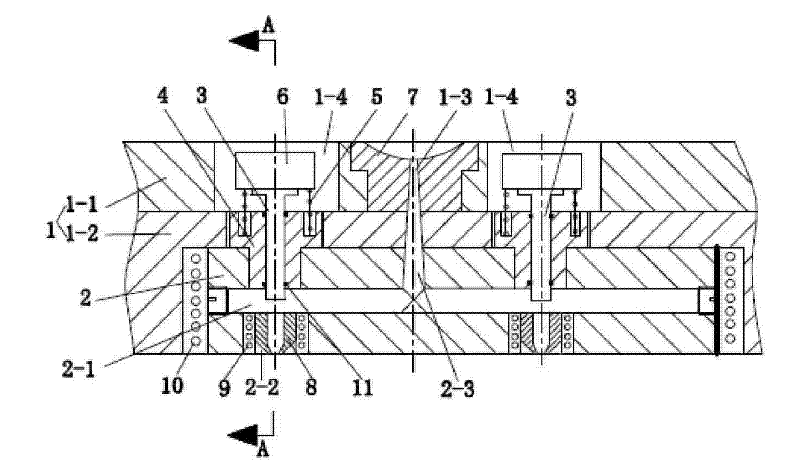

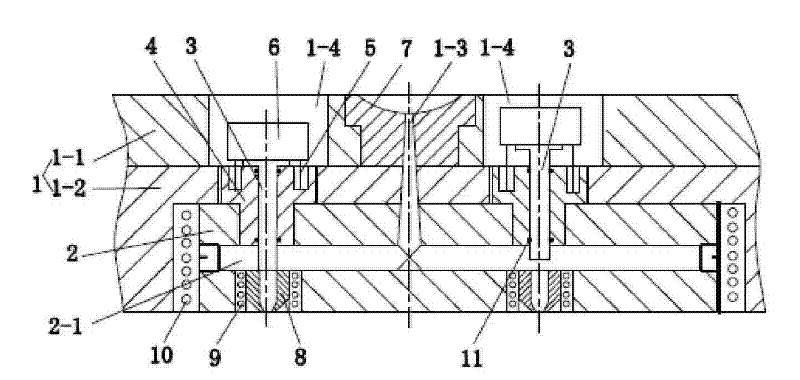

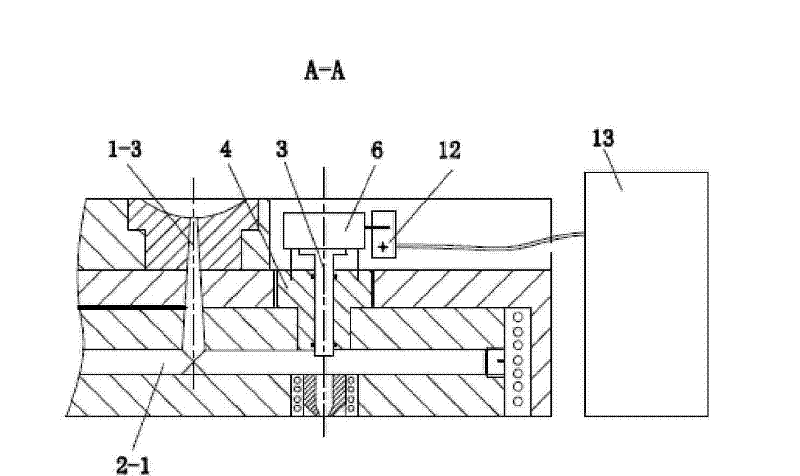

[0019] Embodiment 1 shown in the drawings has a mold body and a control cabinet 13, and the mold body includes a fixed template 1 and a splitter template 2 for realizing hot runner diversion. The fixed template 1 is composed of an upper fixed template 1-1 and a lower fixed template 1-2, the splitter template 2 is located in the cavity of the lower fixed template 1-2, and a heating ring 10 is arranged around the splitter template 2.

[0020] The middle part of the splitter template 2 is provided with a horizontal splitter channel 2-1, and the fixed template 1 is provided with a vertical fixed template main channel 1-3 and at least two vertical fixed template valve holes 1-4, and the fixed template valve hole 1 The number of -4 depends on the number of product mold cavity gates, and the figure shows two fixed template valve holes 1-4. In the embodiment, a bushing 7 is provided at the position of the sprue 1-3 of the fixed template, and the central hole of the bush 7 is the sprue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com