Hull structure

A hull and stern technology, applied in the direction of hull, hull design, ship propulsion, etc., can solve the problems of low propulsion performance, inability to sufficiently reduce downflow, failure to achieve propulsion performance, etc., to improve propulsion performance and reduce viscous resistance. , the effect of flow field stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the following description, "front", "rear", "left", "right", "upper", and "lower" correspond to the front-back direction, left-right (width) direction, and up-down direction of the hull, respectively.

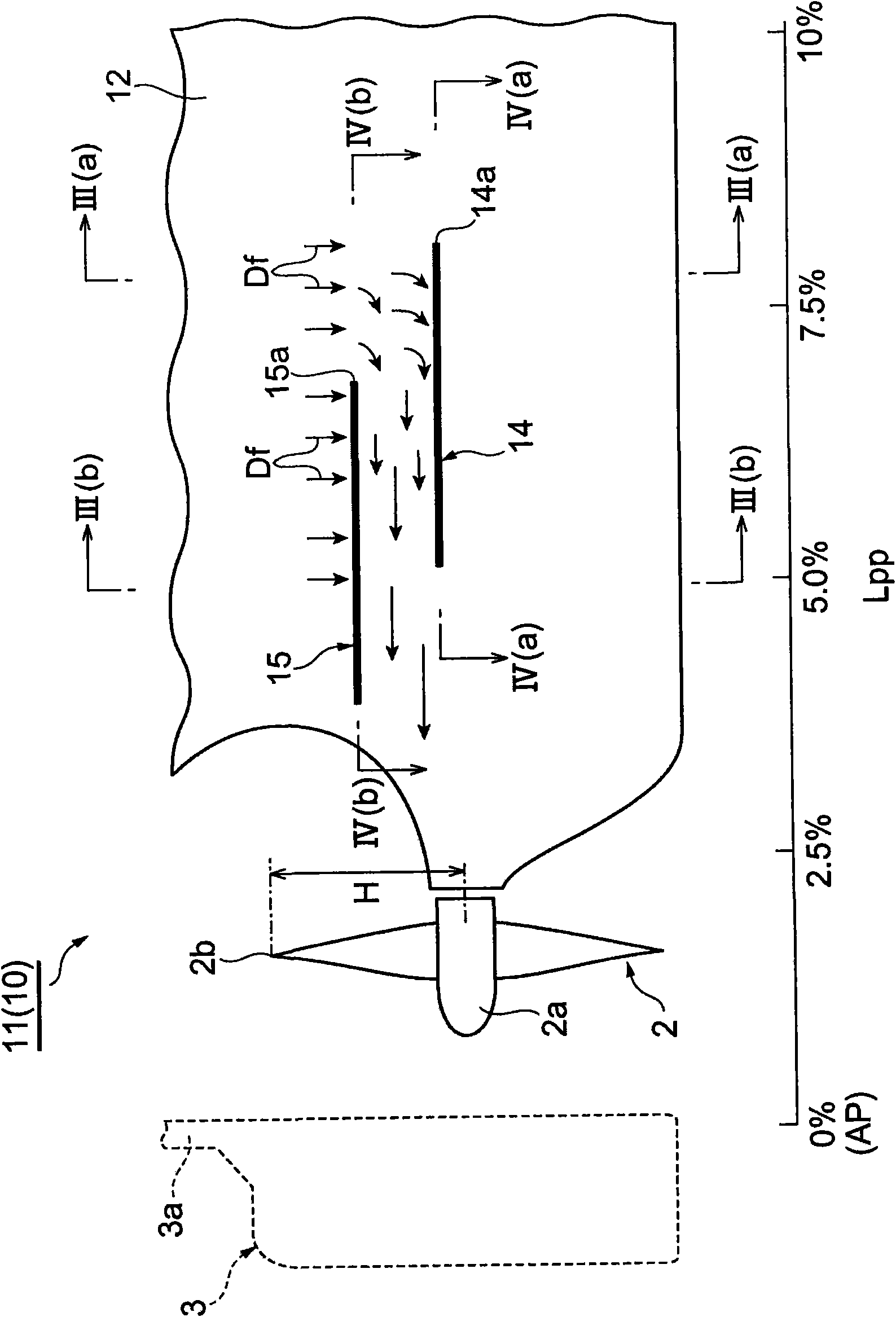

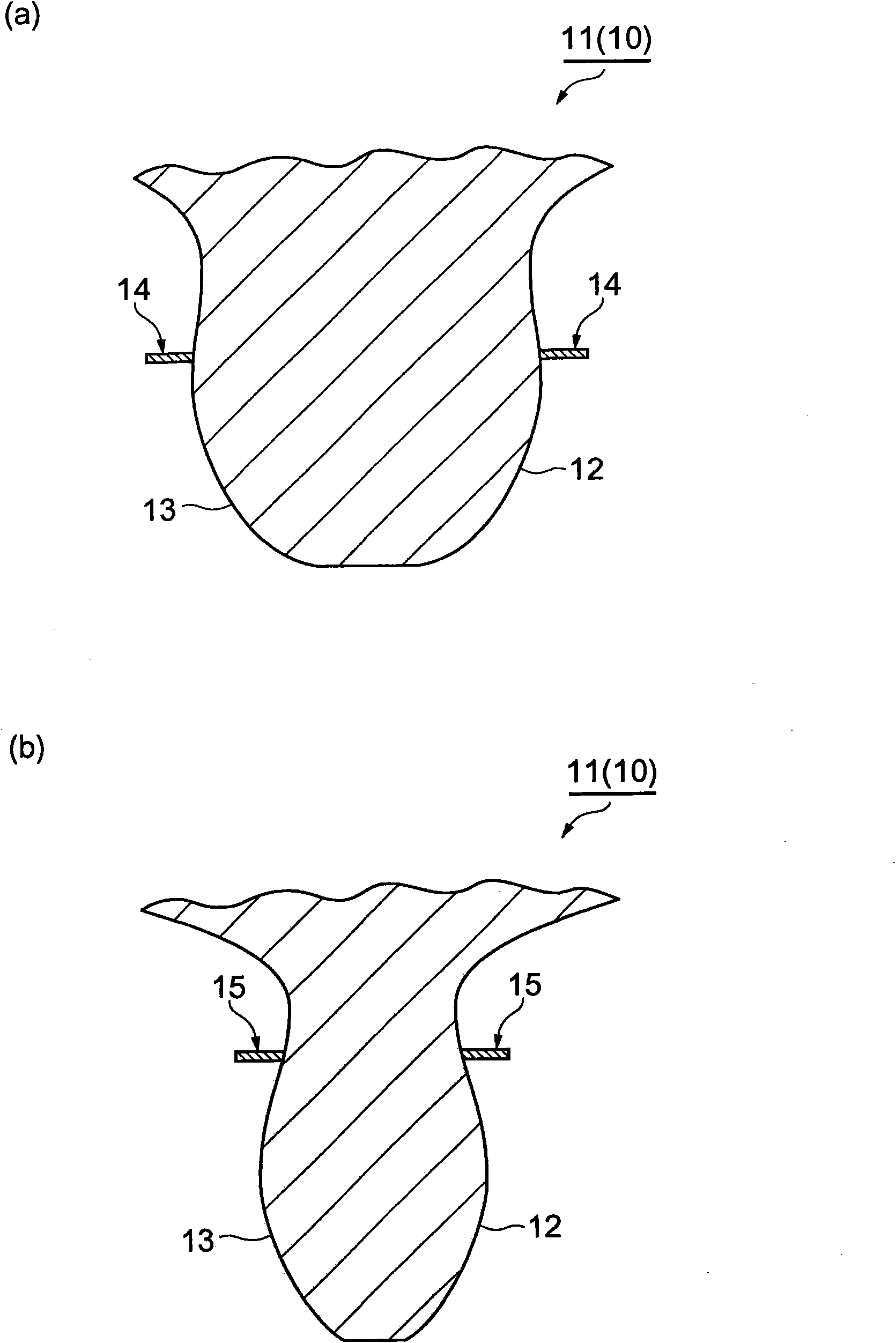

[0020] figure 1 It is a schematic side view showing the ship including the hull structure of the first embodiment of the present invention, figure 2 yes means figure 1 Enlarged side view of the stern portion of the ship, image 3 is along figure 2 Sectional view of line III-III, Figure 4 is along figure 2 Sectional drawing of the port side of the line IV-IV. Such as figure 1 , 2 As shown, the ship 1 of this embodiment is a large ship such as an oil tanker, and includes a hull 10 , propulsion propellers 2 and rudders 3 .

[0021] Such as image 3 As shown, the stern portion 11 of the hull 10 is a left-right symmetrical struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com