Axial flow fan ternary impeller with vein-shaped structure and nonuniform empennage

An axial flow fan and ternary impeller technology, applied in pump components, mechanical equipment, non-variable-capacity pumps, etc., to suppress secondary flow, reduce eddy current noise, and improve boundary layer separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

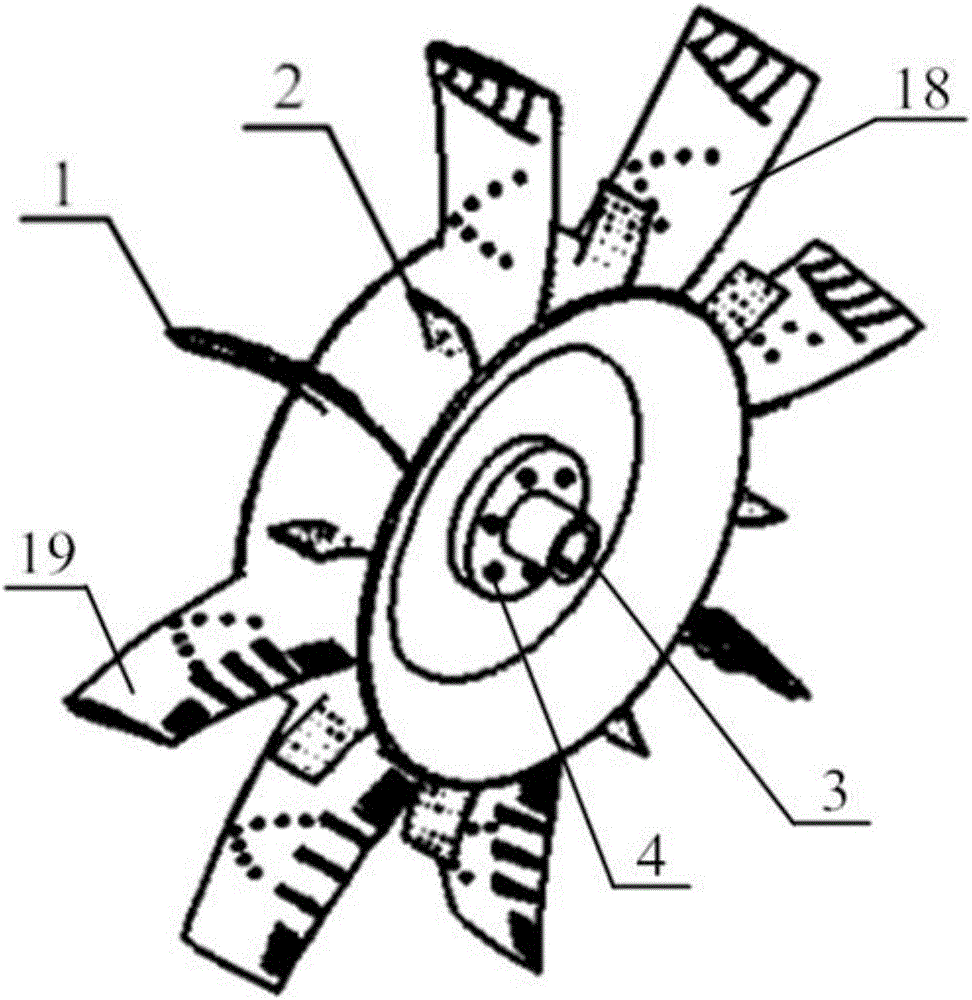

[0030] Embodiment 1. A new three-dimensional impeller for an axial flow fan with a vein-shaped structure and a non-uniform tail, as shown in the figure, includes a hub, a twisted blade 1 fixedly connected to the hub, a splitter blade 2, a bushing 3 and a connecting piece 4.

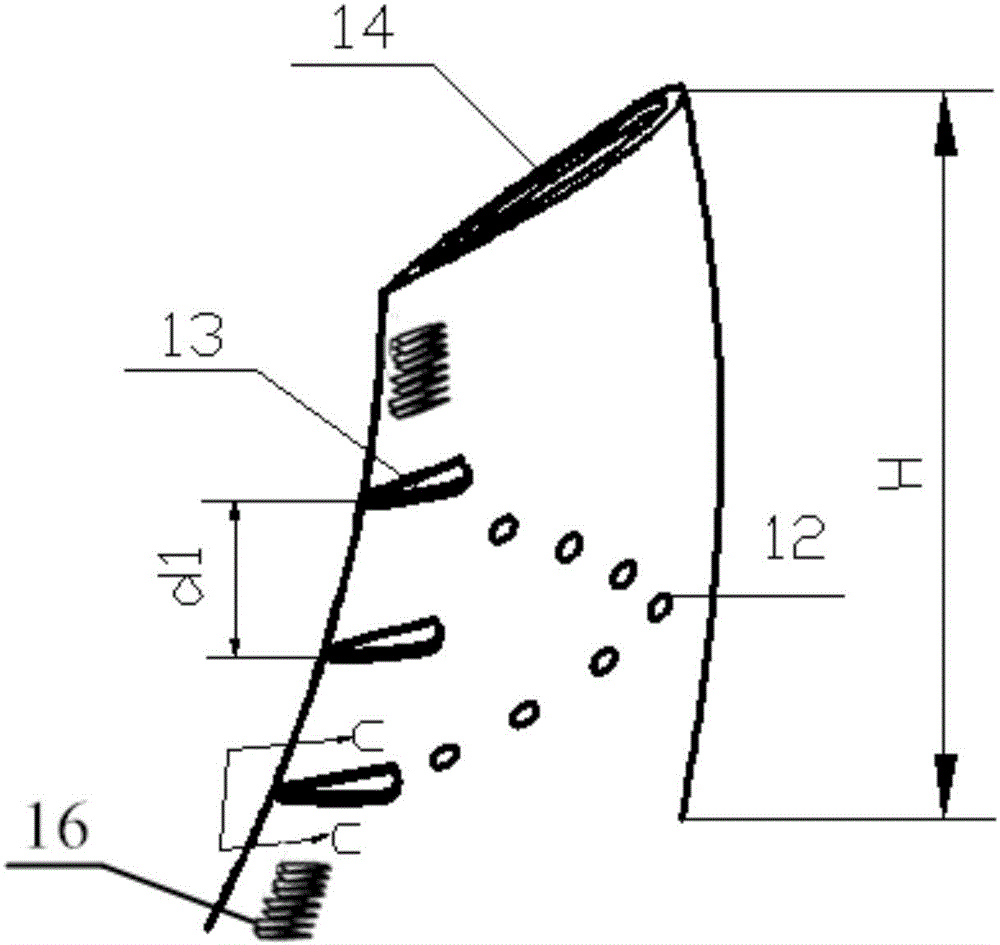

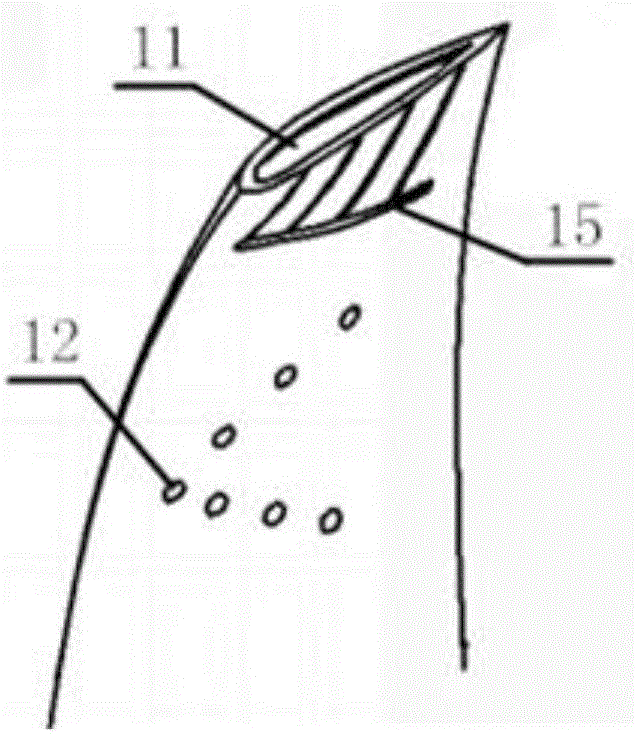

[0031] The curved and twisted blade 1 includes a suction surface 18 and a pressure surface 19. The top of the suction surface 18 of the curved and twisted blade 1 is provided with a vein-shaped groove 15, and the rear end of the curved and twisted blade 1 is provided with a small wing protrusion 13 and a dense small wing 16. The groove 15 includes at least two veins, the installation angle at the root of the curved and twisted blade 1 is large, and the installation angle at the top is small (the installation angle is the angle between the plane of rotation at the radius r of the curved and twisted blade 1 and the chord length of the airfoil. The angle is represented by β1 and β2 in the figure), to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com