Patents

Literature

30 results about "Spiral groove bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

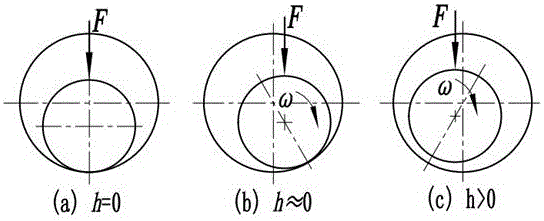

Spiral groove bearings (also known as Rifle bearings) are self-acting (journal and thrust), or hydrodynamic bearings used to reduce friction and wear without the use of pressurized lubricants. They have this ability due to special patterns of grooves. Spiral groove bearings are self-acting because their own rotation builds up the pressure needed to separate the bearing surfaces. For this reason, they are also contactless bearings.

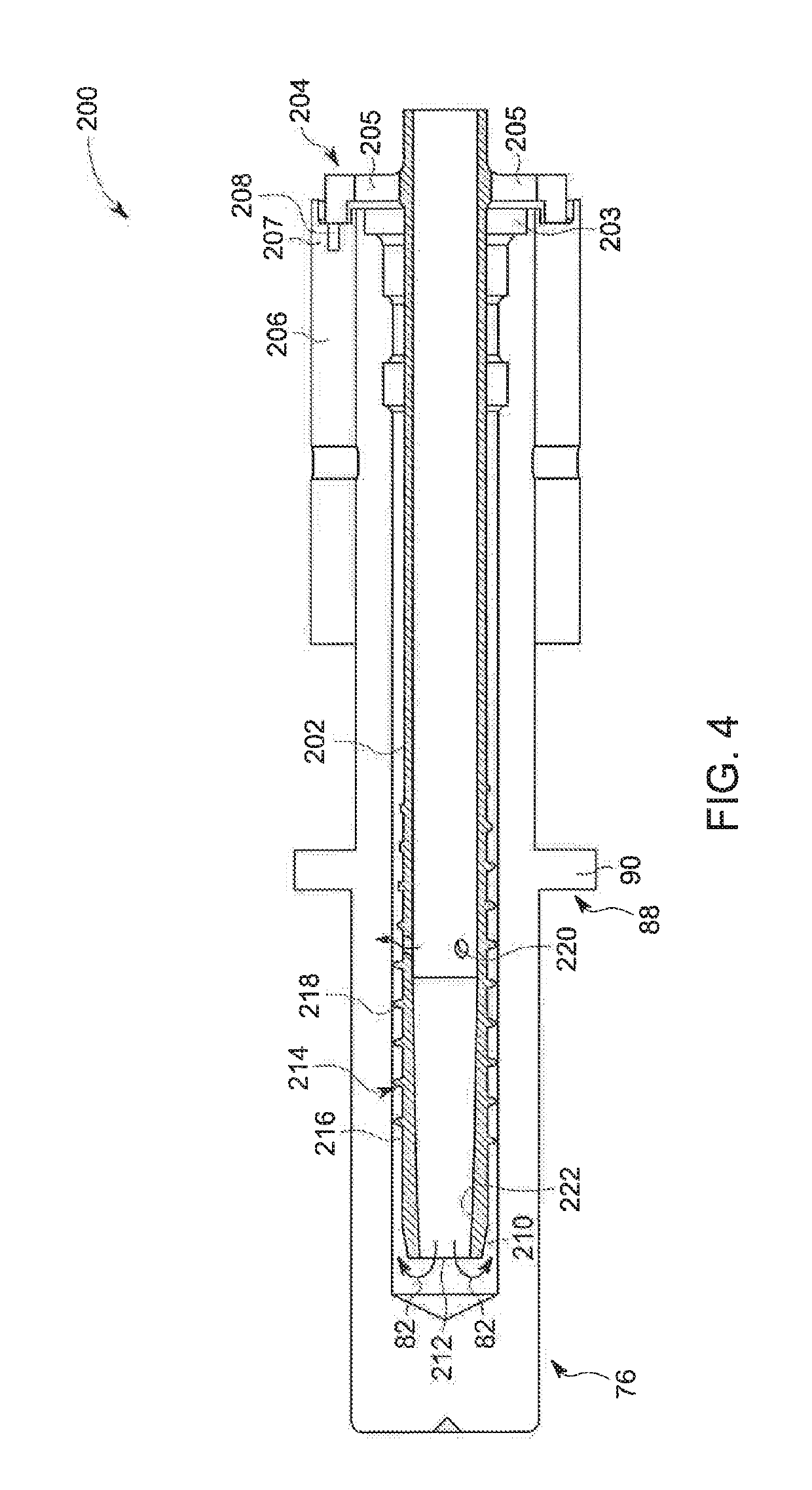

Welded Spiral Groove Bearing Assembly

ActiveUS20160133431A1Structure miniaturizationLow costBearing assemblyX-ray tube electrodesSpiral groove bearingEngineering

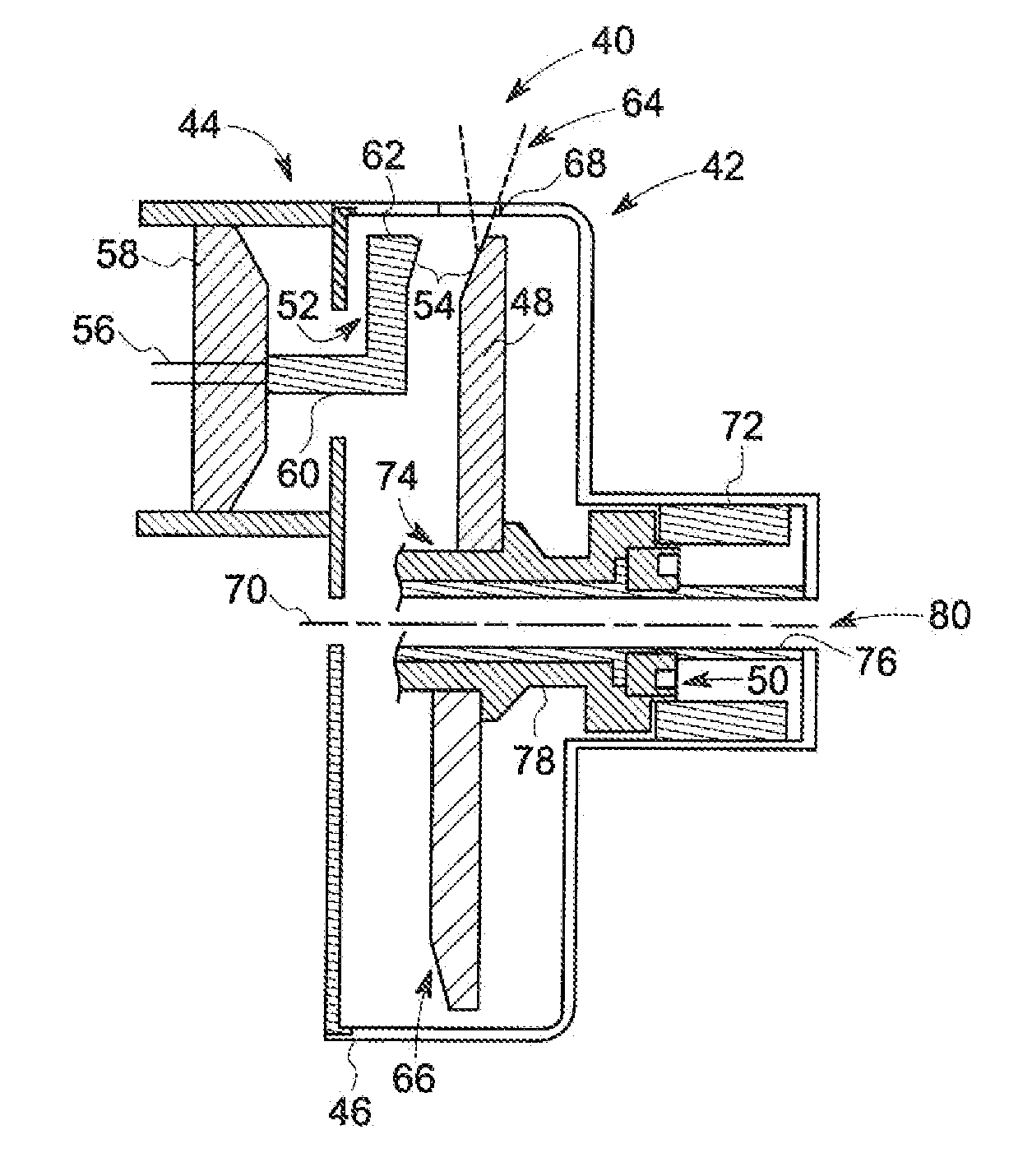

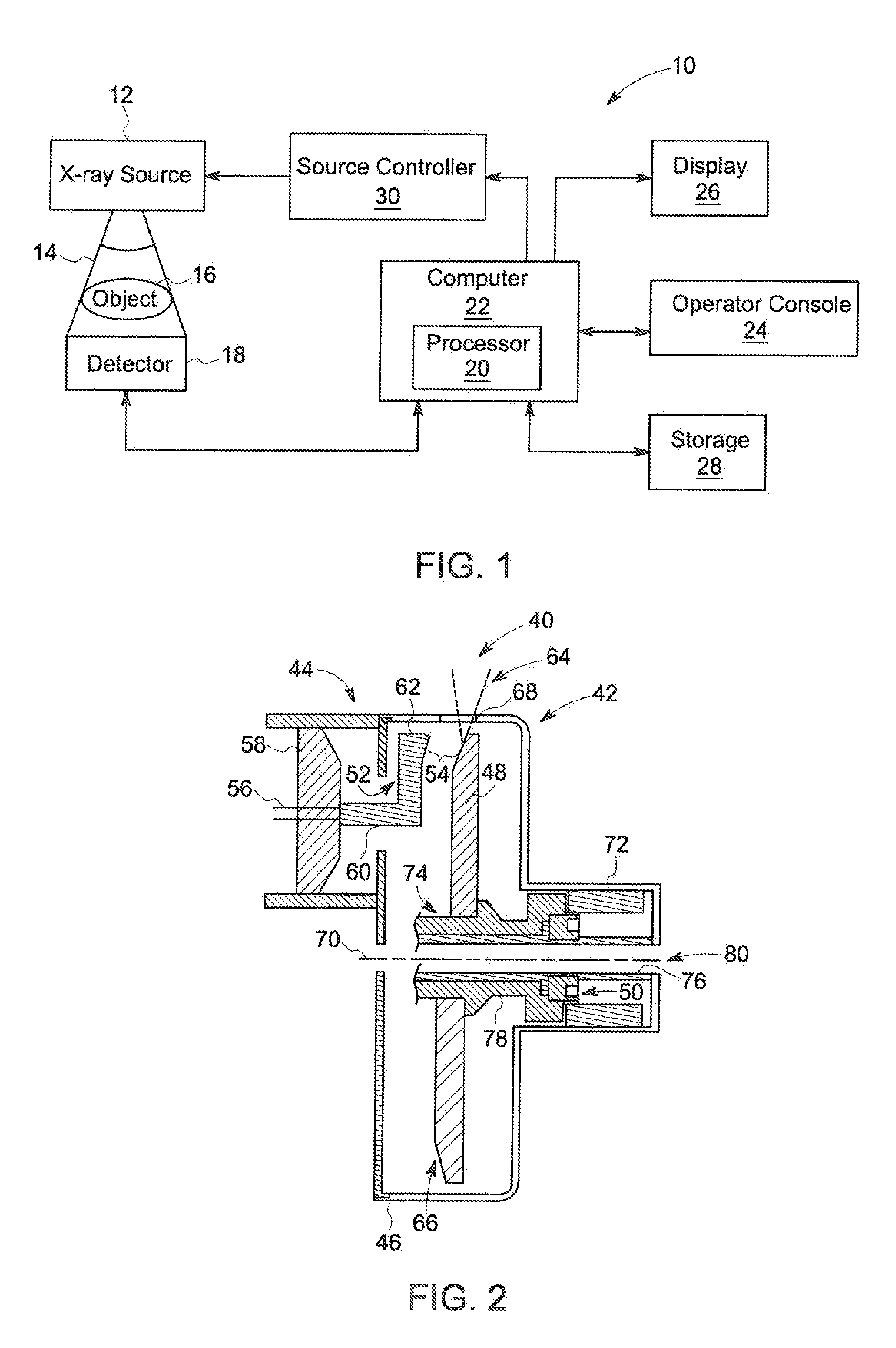

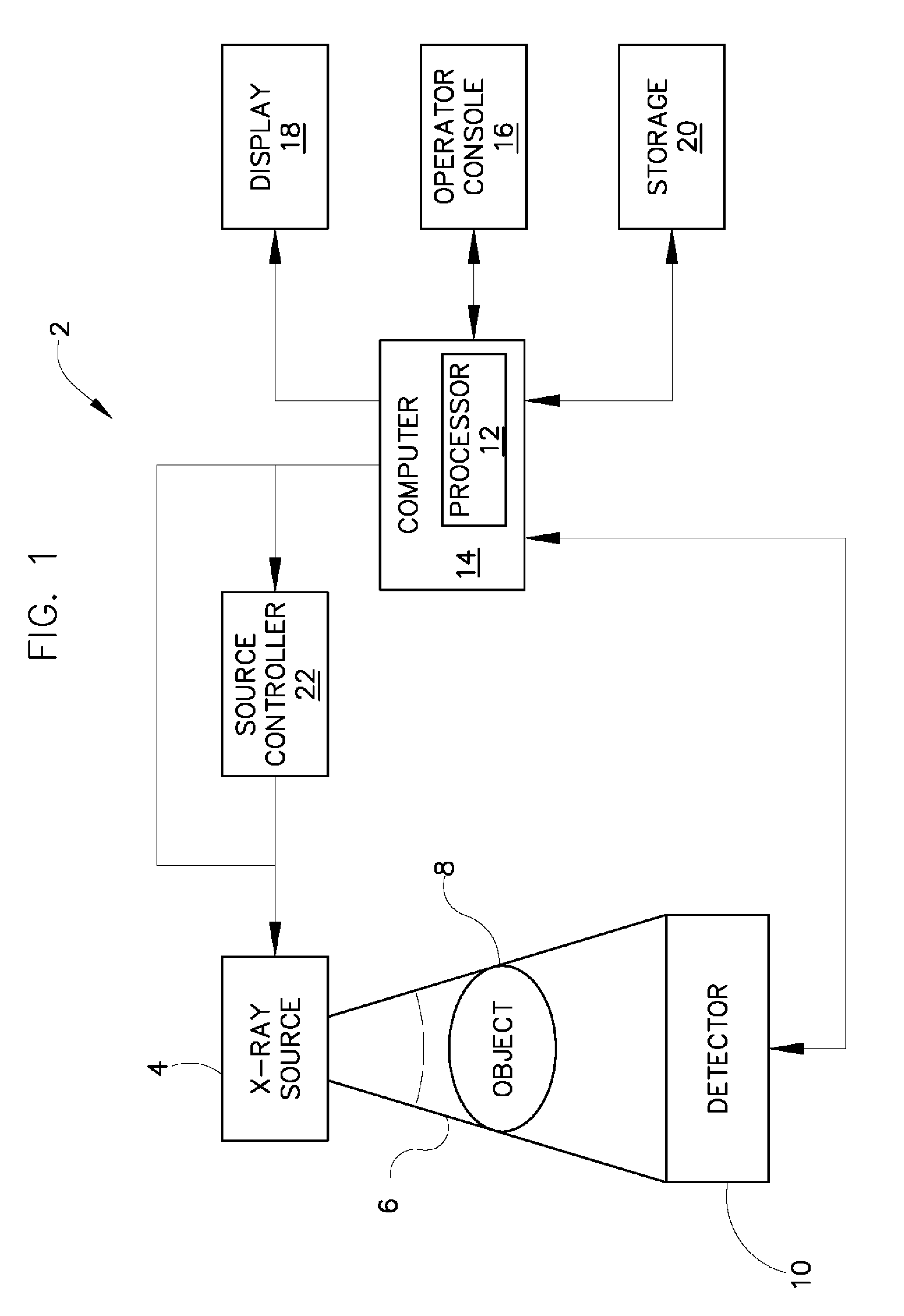

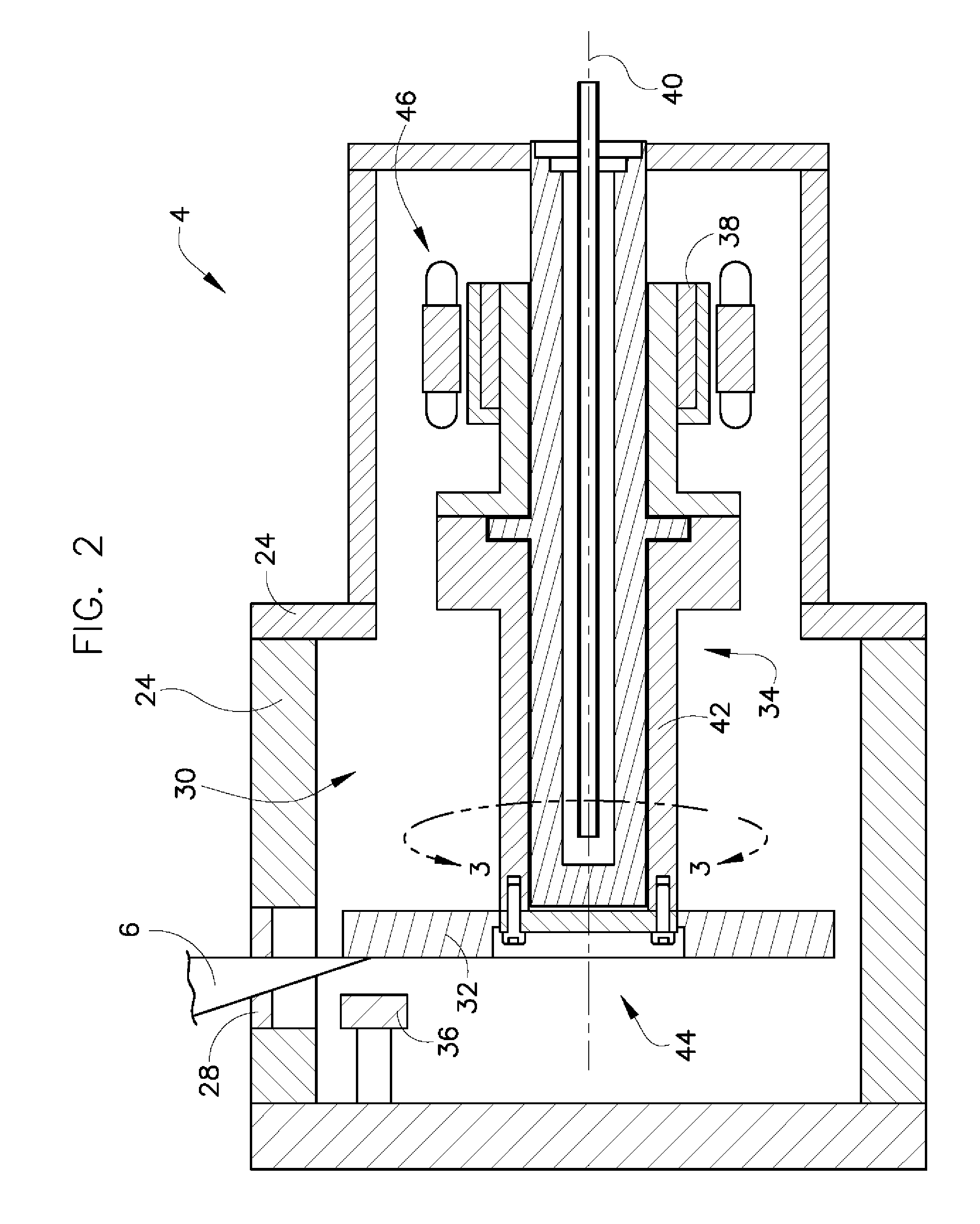

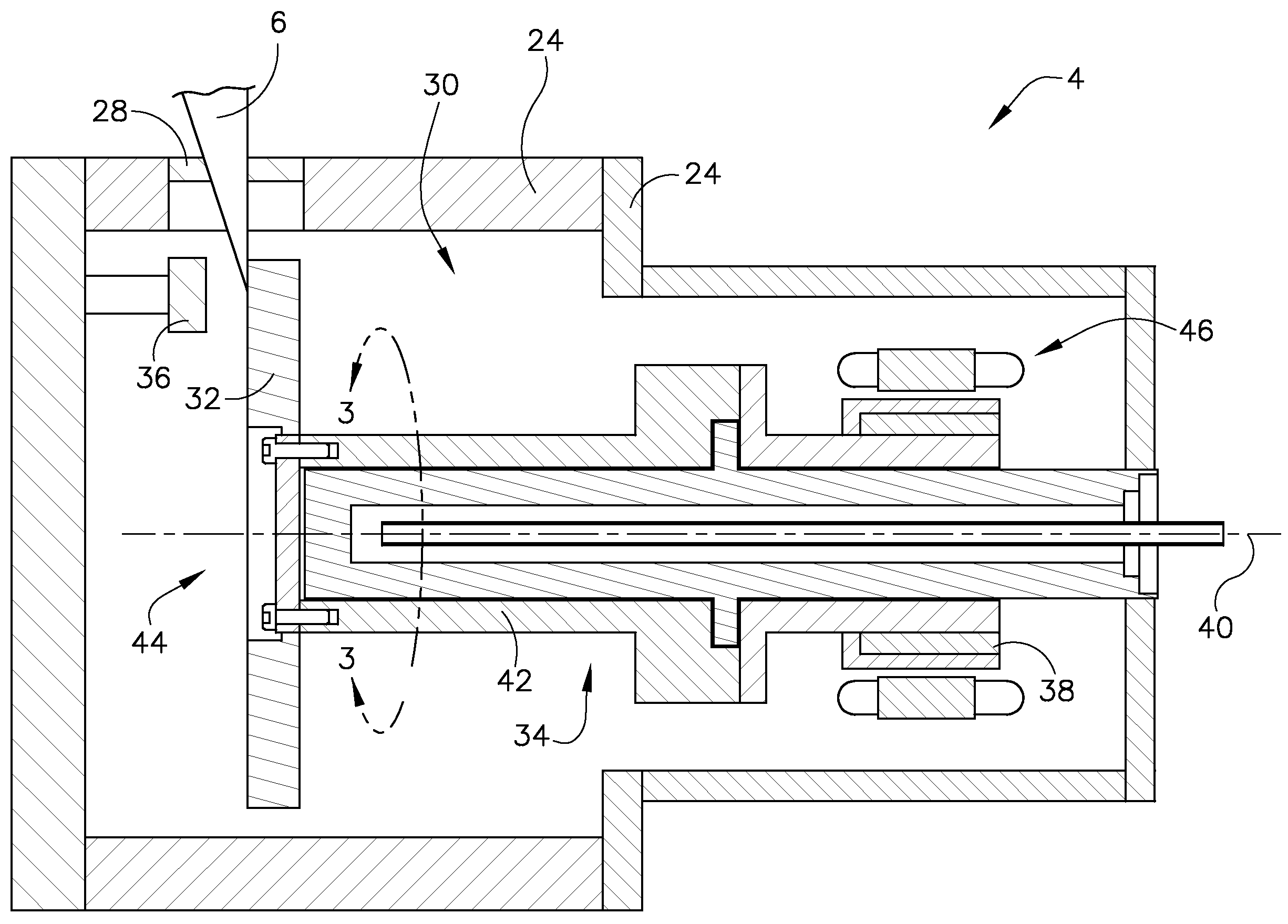

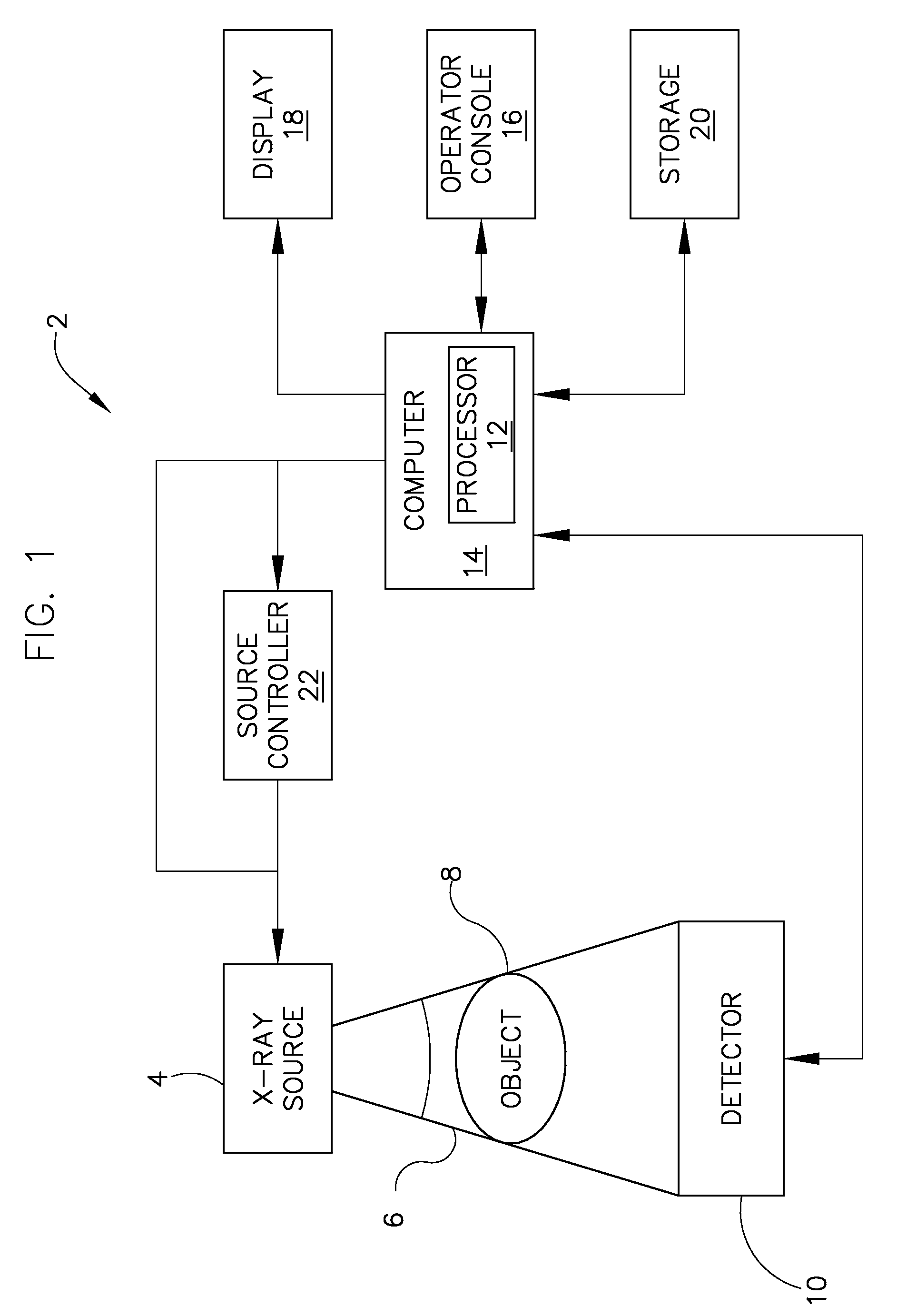

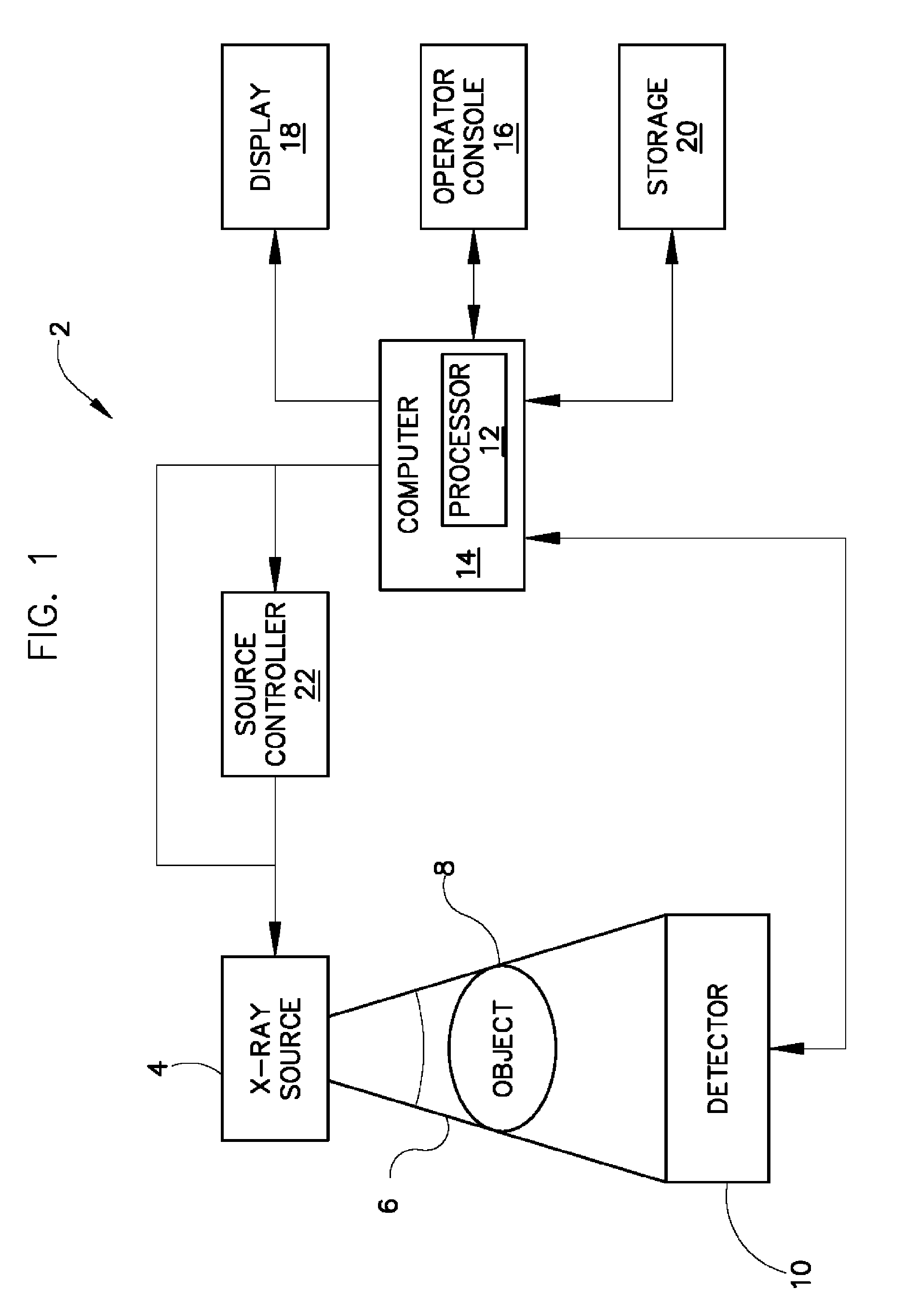

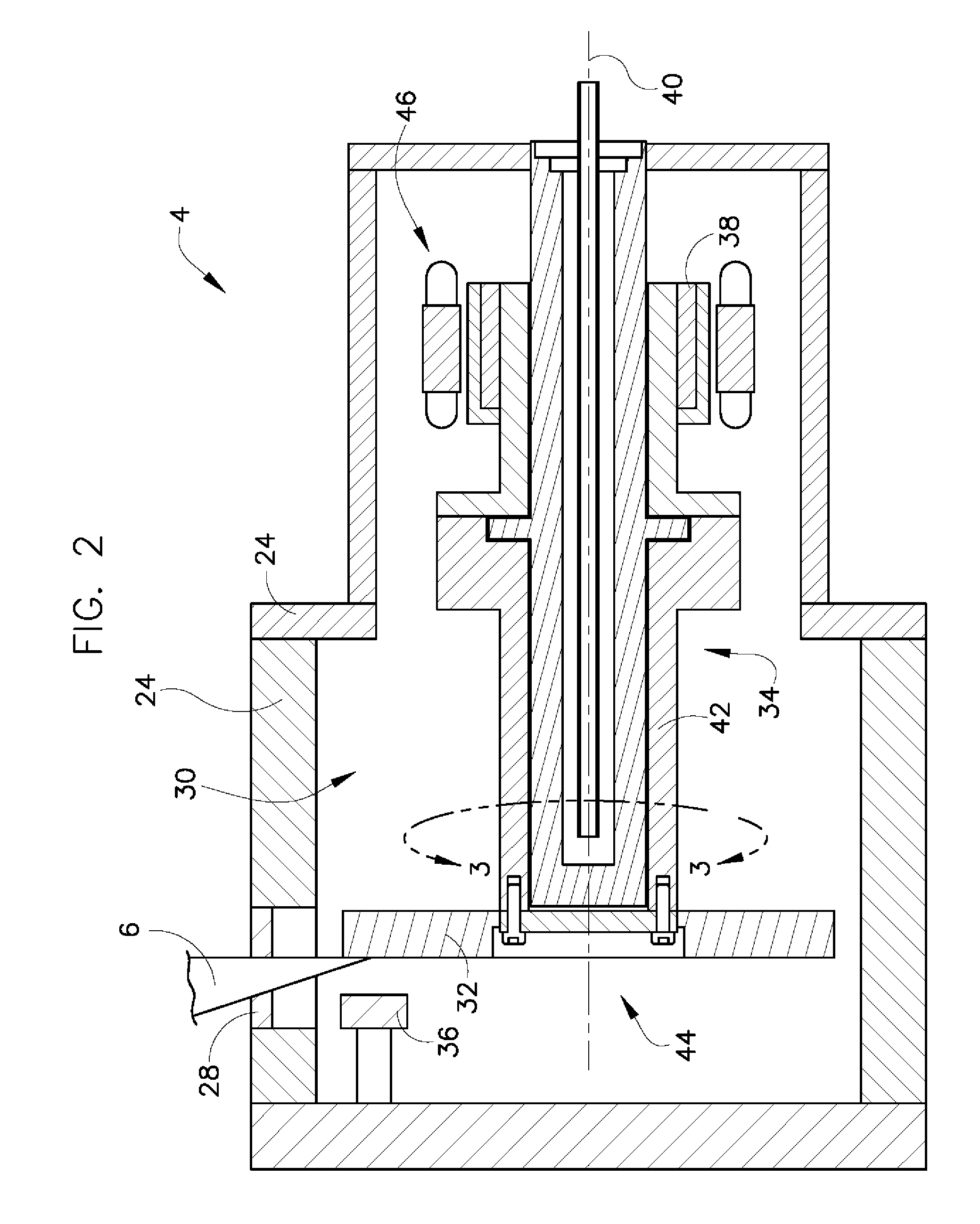

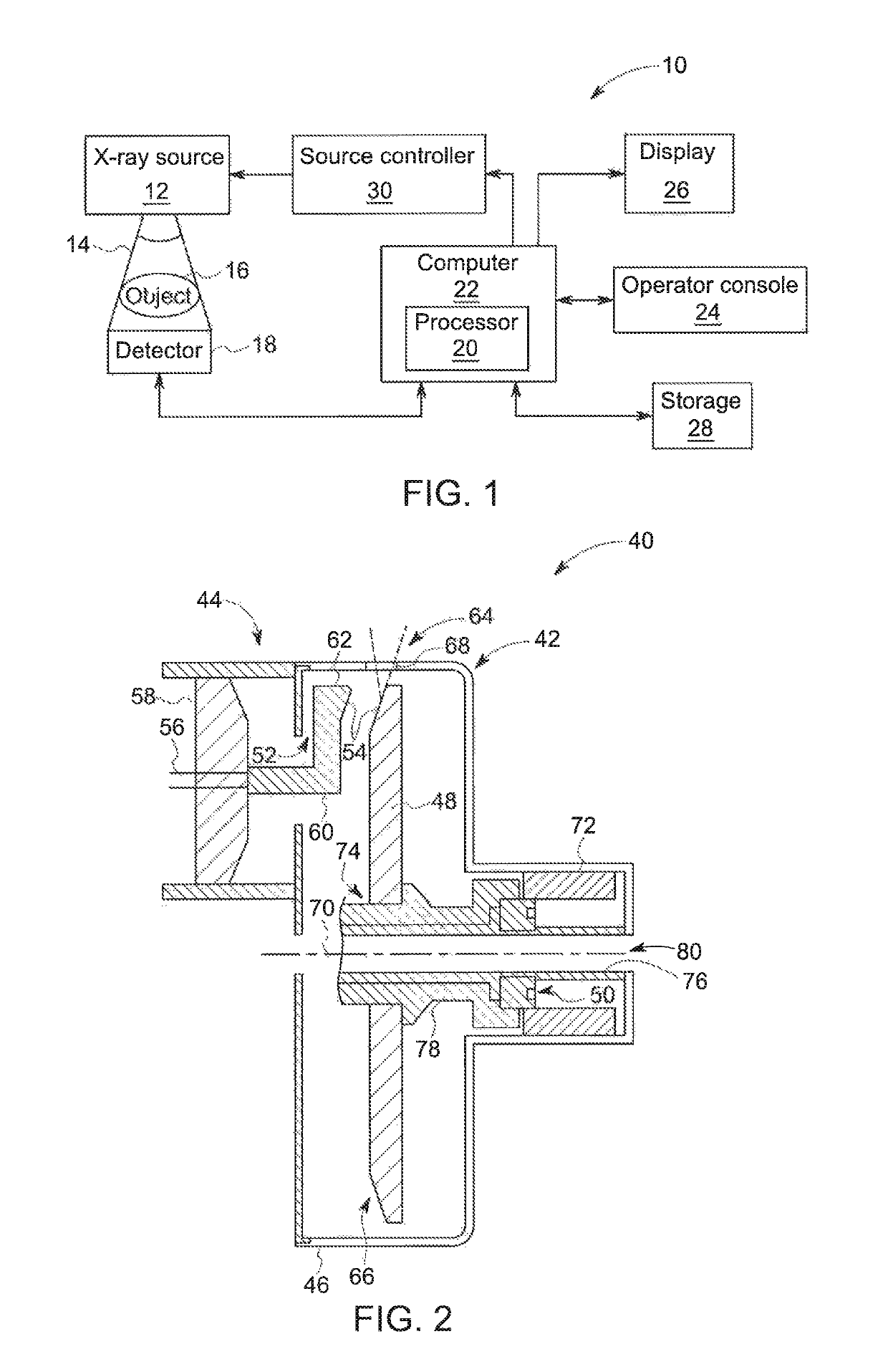

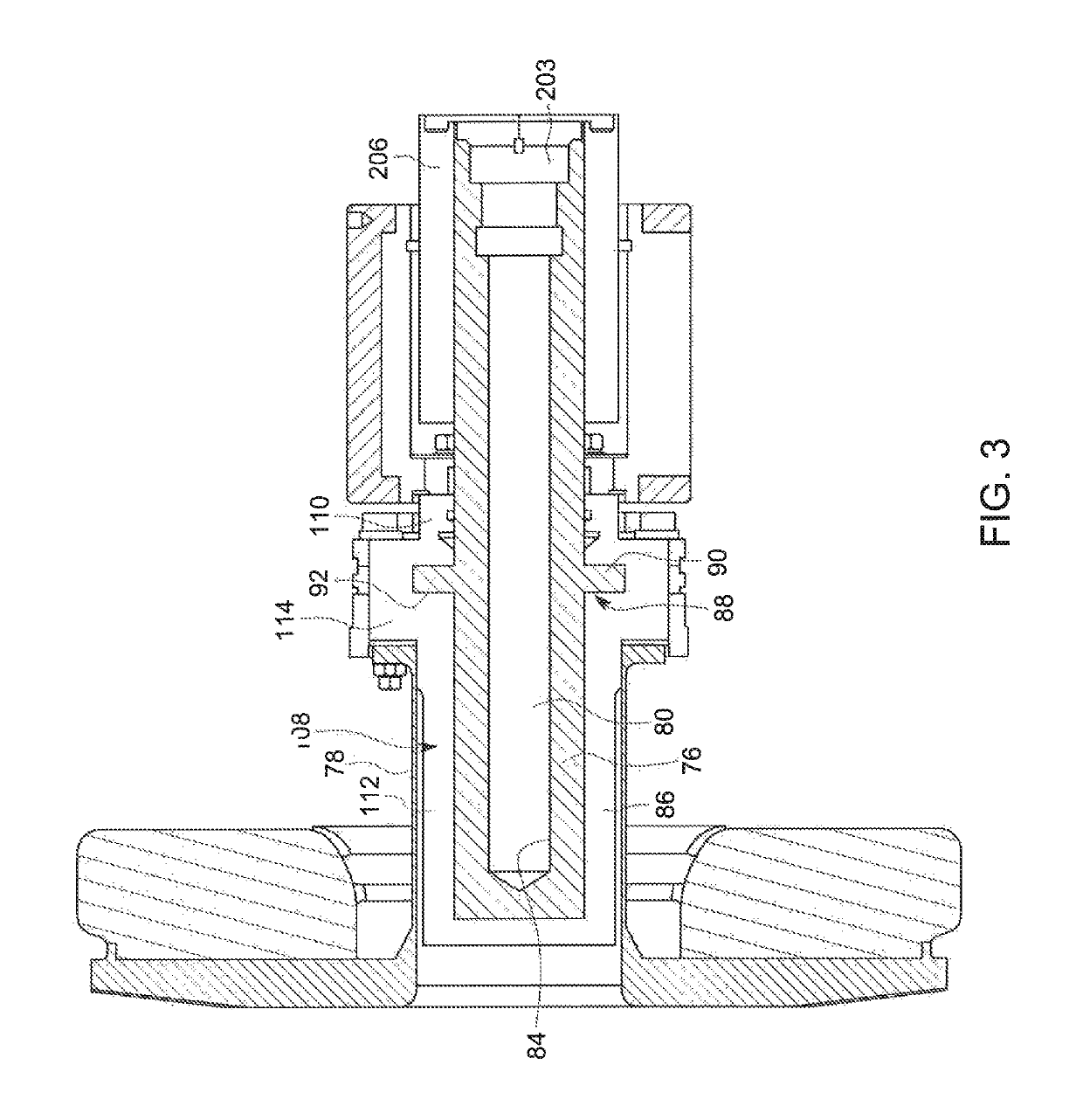

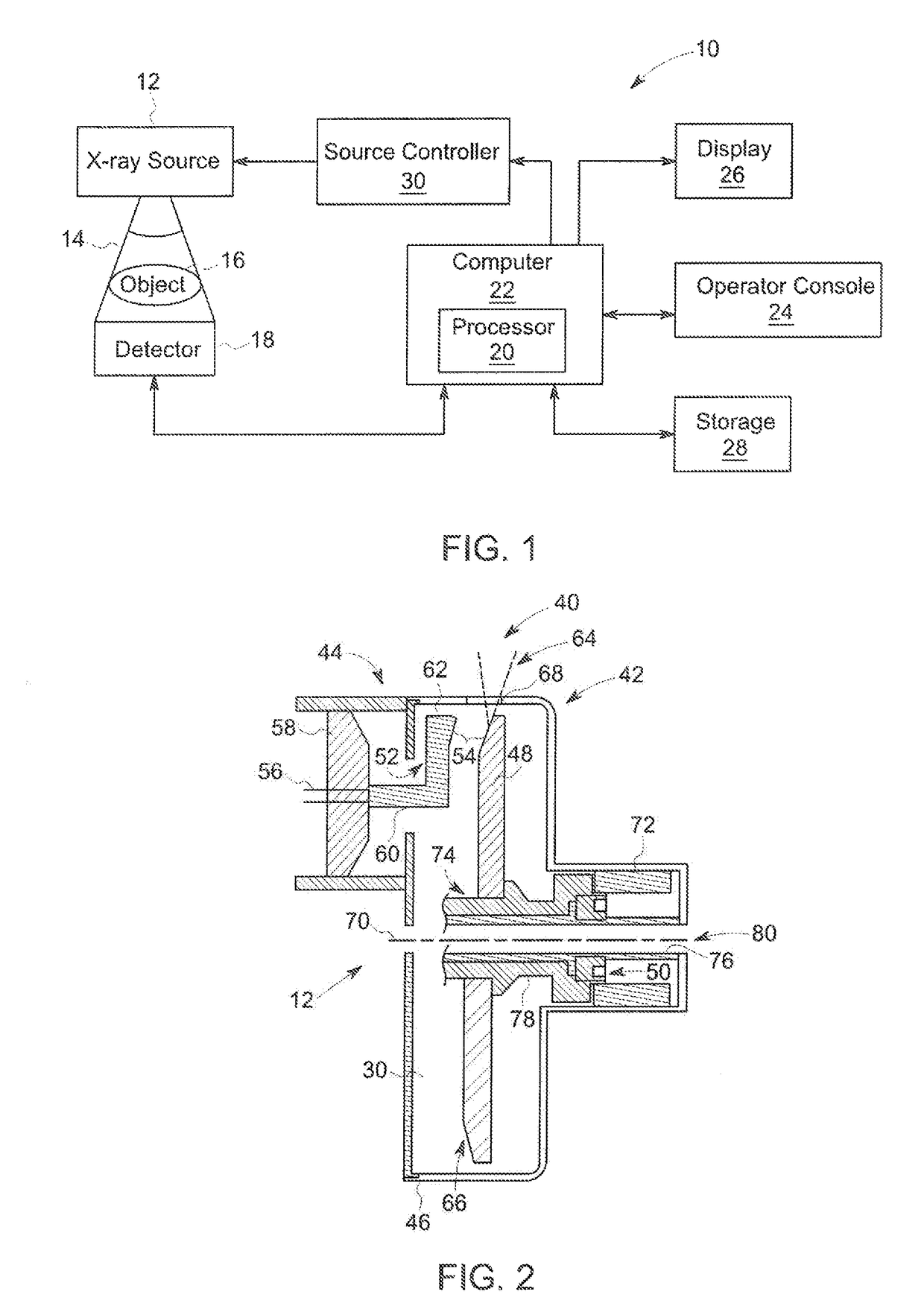

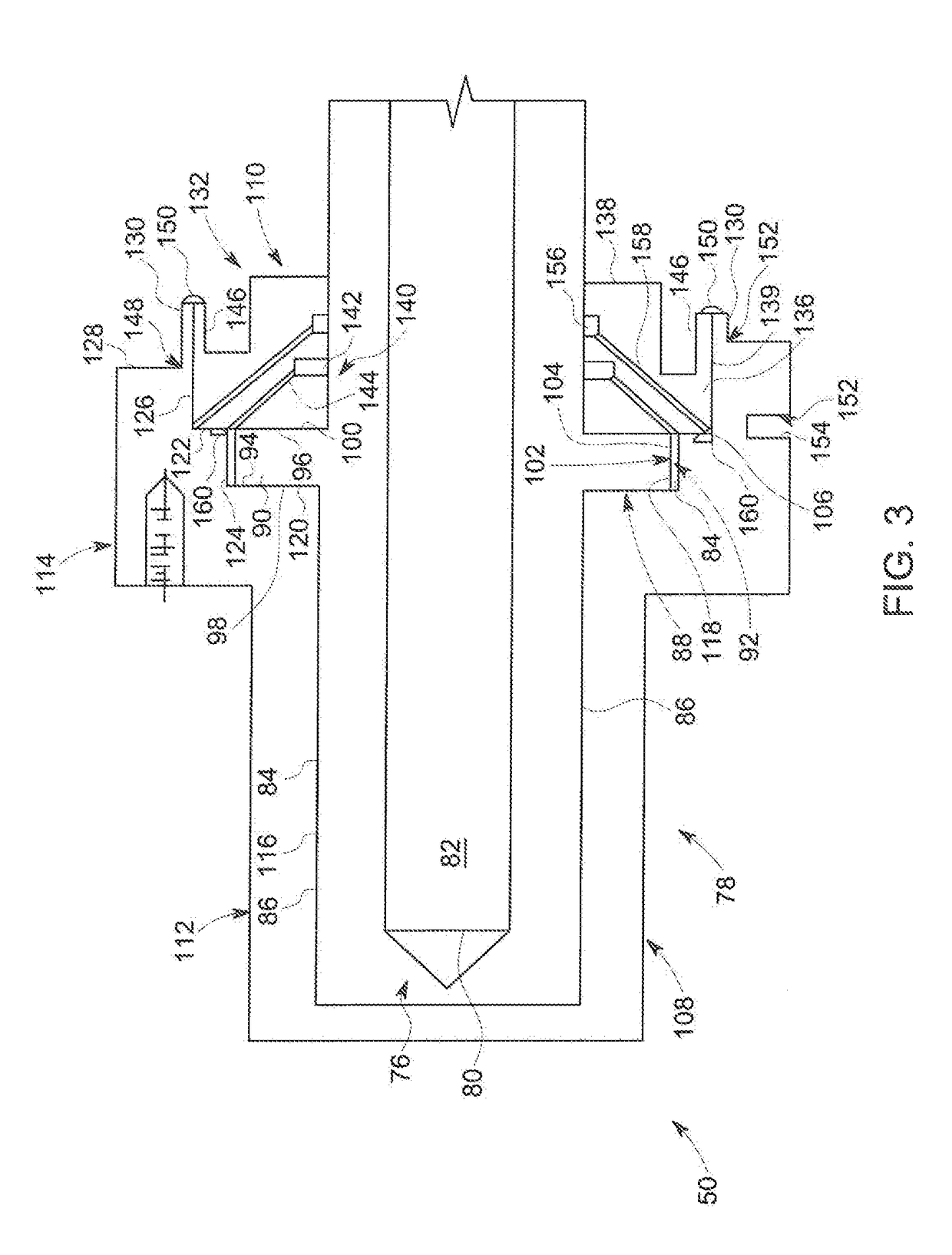

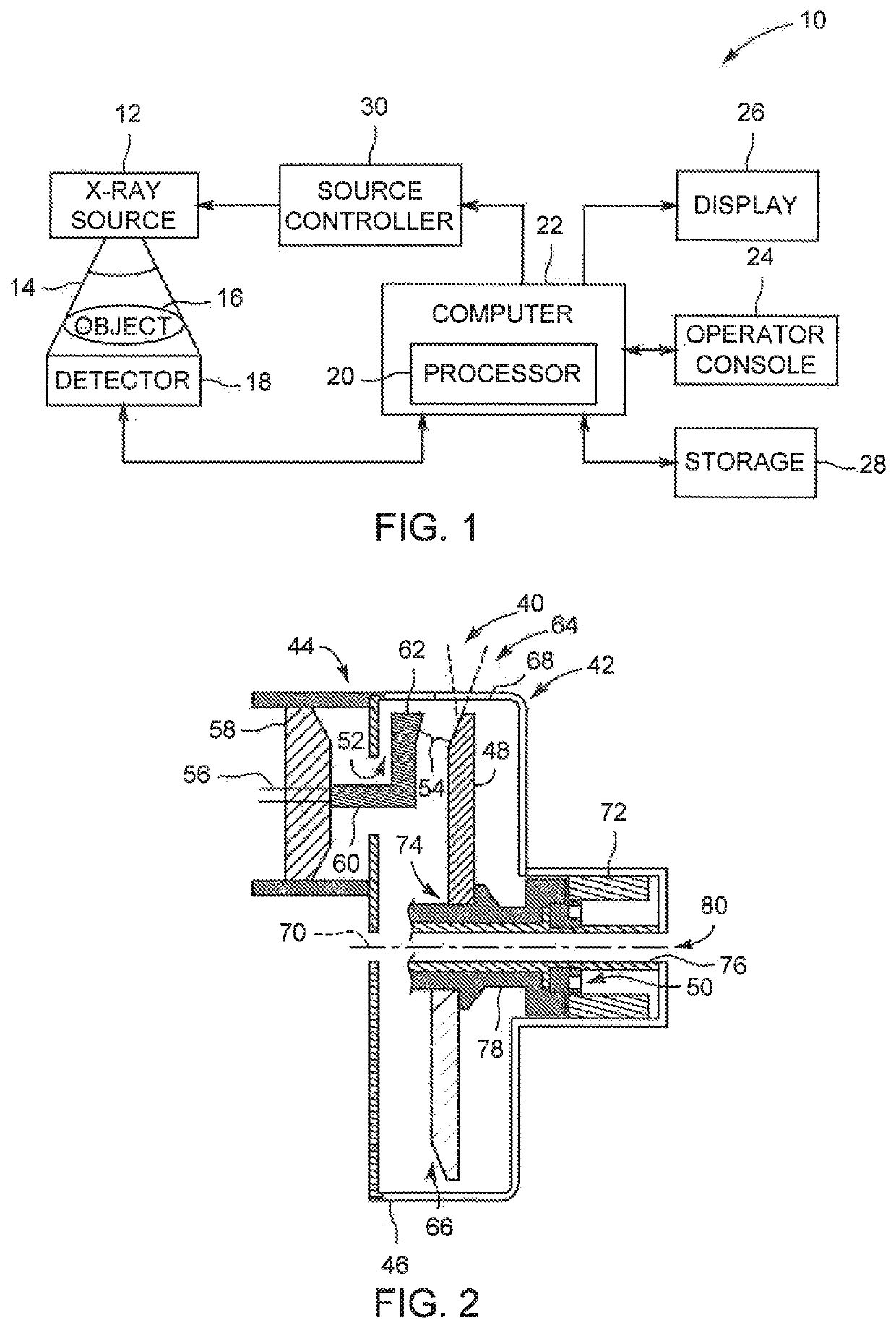

A structure and associated method for forming a liquid metal or spiral groove bearing assembly for an x-ray tube is illustrated that utilizes a unitary sleeve and a thrust ring or seal each formed of a weldable, non-refractory material. The sleeve and the thrust seal are welded to one another to provide an improved construction for minimizing leaks of the liquid metal bearing fluid. The structure of the sleeve and the thrust seal are formed with deformation restricting features that maintain the integrity of the bearing surfaces of the assembly when the thrust seal is secured within the sleeve and welded thereto to form the bearing assembly.

Owner:GENERAL ELECTRIC CO

Interface for liquid metal bearing and method of making same

InactiveUS20100246774A1Low costX-ray tube electrodesX-ray tube vessels/containerSpiral groove bearingLiquid state

An x-ray tube includes a cathode and a target assembly positioned to receive electrons emitted from the cathode. The target assembly includes a target, and a spiral groove bearing (SGB) configured to support the target. The SGB includes a rotatable component having a first surface and a first material attached to the first surface, a stationary component having a second surface and a second material attached to the second surface, the stationary component positioned such that a gap is formed between the first material and the second material, and a liquid metal positioned in the gap, wherein at least one of the first and second materials comprises tantalum.

Owner:GENERAL ELECTRIC CO

Interface for liquid metal bearing and method of making same

ActiveUS20100246773A1Reduces net costMetal rolling stand detailsMetal working apparatusSpiral groove bearingLiquid state

An x-ray tube includes a cathode and a target assembly positioned to receive electrons emitted from the cathode. The target assembly includes a target and a spiral groove bearing (SGB) configured to support the target. The SGB includes a rotatable component having a first surface and a first material attached to the first surface, a stationary component having a second surface and a second material attached to the second surface, the stationary component positioned such that a gap is formed between the first material and the second material, and a liquid metal positioned in the gap. At least one of the first and second materials has a thickness greater than 0.1 mm.

Owner:GENERAL ELECTRIC CO

Interface for liquid metal bearing and method of making same

An x-ray tube includes a cathode and a target assembly positioned to receive electrons emitted from the cathode. The target assembly includes a target and a spiral groove bearing (SGB) configured to support the target. The SGB includes a rotatable component having a first surface and a first material attached to the first surface, a stationary component having a second surface and a second material attached to the second surface, the stationary component positioned such that a gap is formed between the first material and the second material, and a liquid metal positioned in the gap. At least one of the first and second materials has a thickness greater than 0.1 mm.

Owner:GENERAL ELECTRIC CO

Interface for liquid metal bearing and method of making same

InactiveUS8363787B2X-ray tube electrodesX-ray tube vessels/containerSpiral groove bearingLiquid state

An x-ray tube includes a cathode and a target assembly positioned to receive electrons emitted from the cathode. The target assembly includes a target, and a spiral groove bearing (SGB) configured to support the target. The SGB includes a rotatable component having a first surface and a first material attached to the first surface, a stationary component having a second surface and a second material attached to the second surface, the stationary component positioned such that a gap is formed between the first material and the second material, and a liquid metal positioned in the gap, wherein at least one of the first and second materials comprises tantalum.

Owner:GENERAL ELECTRIC CO

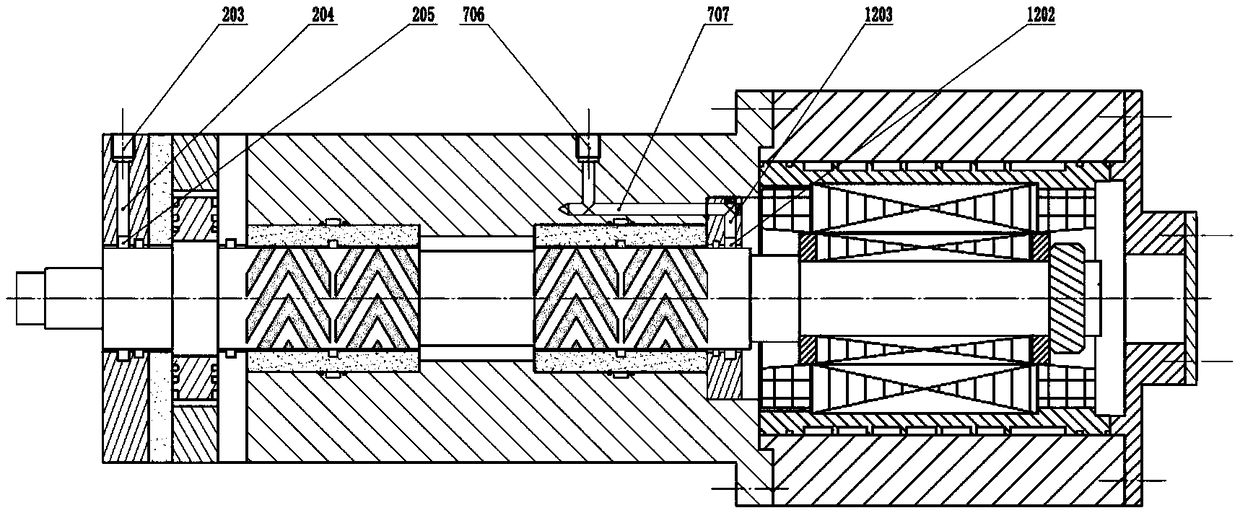

Low-loss and high-speed integrated flywheel energy storage motor

ActiveCN107482841AReduce lossHarmonic reductionMechanical energy handlingSpiral groove bearingFlywheel energy storage

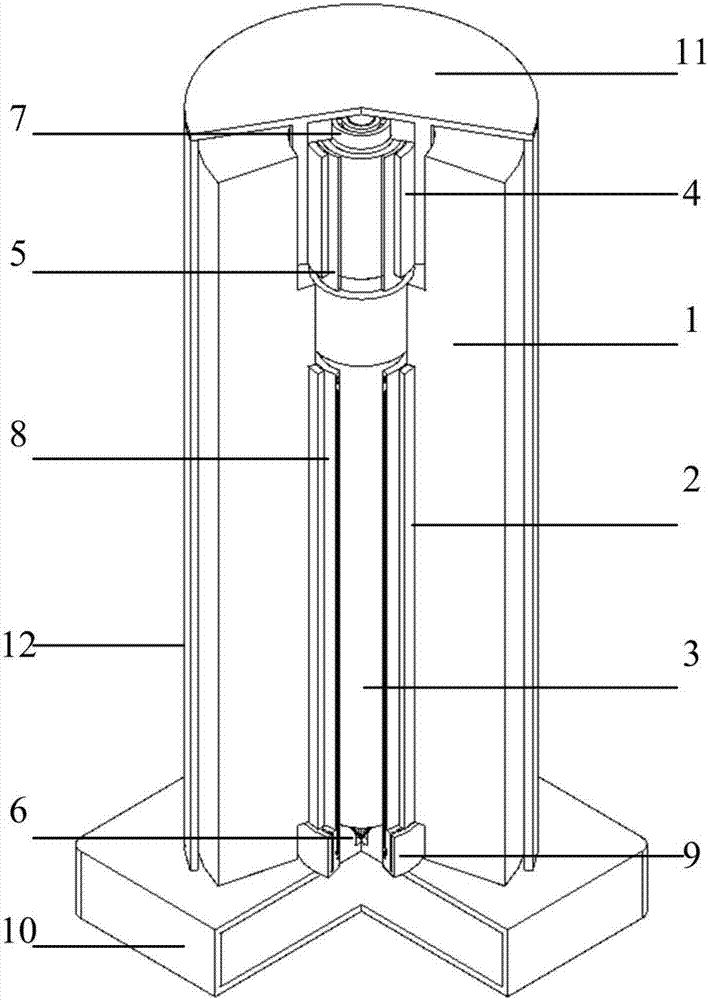

The present invention discloses a low-loss and high-speed integrated flywheel energy storage motor. The motor comprises a flywheel outer rotor, an excitation permanent magnet, an inner rotor, a motor bearing and a hollow core stator. The flywheel outer rotor is configured to store energy when rotation, the excitation permanent magnet is pasted at the surface of the inner side of the flywheel outer rotor to supply an excitation field for a motor; the hollow core stator is arranged between the inner rotor and the flywheel outer rotor, the air-gap winding in the hollow core stator is arranged along the direction of a rotation shaft, the motor bearing comprises a magnetic suspension bearing and a spiral groove bearing, the bottom of the inner rotor is connected with the rotation portion of the spiral groove bearing, and the upper portion of the boss of the inner rotor is connected with the rotation portion of the magnetic suspension bearing. The low-loss and high-speed integrated flywheel energy storage motor employs a mode of combination of an outer rotor structure, the excitation permanent magnet, the air-gap winding, the passive magnetic suspension bearing and the spiral groove bearing to allow the motor to reach low loss while high-speed operation and zero load energy storage maintenance.

Owner:中能(深圳)能源科技发展有限公司

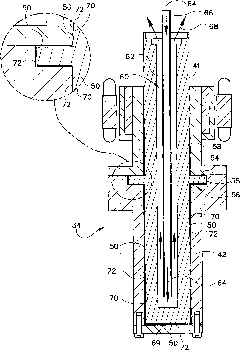

Interface for liquid metal bearing and manufacture method thereof

The invention relates to an interface for a liquid metal bearing and a manufacture method thereof. Specifically, an x-ray tube (4) comprises a cathode (36) and a target assembly located to receive electron emitted by the cathode. The target assembly comprises a target (32) and a spiral groove bearing (SGB) (34) configured to support the target (32). The SBG (34) comprises a fixed component (41) having a first surface and attached on first materials (72, 74, 76) on the first surface and having a second surface and attached on second materials (70, 78, 80) on the second surface, wherein the fixed component (41) is located to form clearances between the first materials (72, 74, 76) and the second materials (70, 78, 80); and liquid metals (50) located in the clearances, wherein at least one of the first and second materials (70, 72, 74, 76, 78, 80) contains tantalum.

Owner:GENERAL ELECTRIC CO

Separating elastic tube high-speed spinning spindle

InactiveCN101177808AImprove rigidityImprove carrying capacityTextiles and paperCushioningCarrying capacity

A separate elastic tube high-speed spinning spindle in a ring spinning frame, characterized in that the lower support tube in the spindle seat has a spiral groove, and the lower end is inserted into the lower support seat at the bottom of the spindle foot hole, and the bottom of the spindle is placed on the spiral In the upper hole of the lower support tube above the groove, the bottom end of the spindle rod is inserted into the bottom hole of the ingot, the positioning sleeve is sleeved outside the lower support tube above the lower support seat, and the damper is sleeved between the upper part of the lower support tube and the inner wall of the spindle foot. Between, the lower end is close to the top of the positioning sleeve. A spiral groove is added to the lower support tube, and the bottom of the ingot is moved above the spiral groove, so that the lower support has both radial and axial buffering and shock-absorbing functions. The shortening of the spindle rod enhances the rigidity and bearing capacity of the spindle rod, which can effectively reduce the spindle vibration amplitude, and the operation is stable and reliable.

Owner:HENGYANG TEXTILE MACHINERY MANUFACTORY

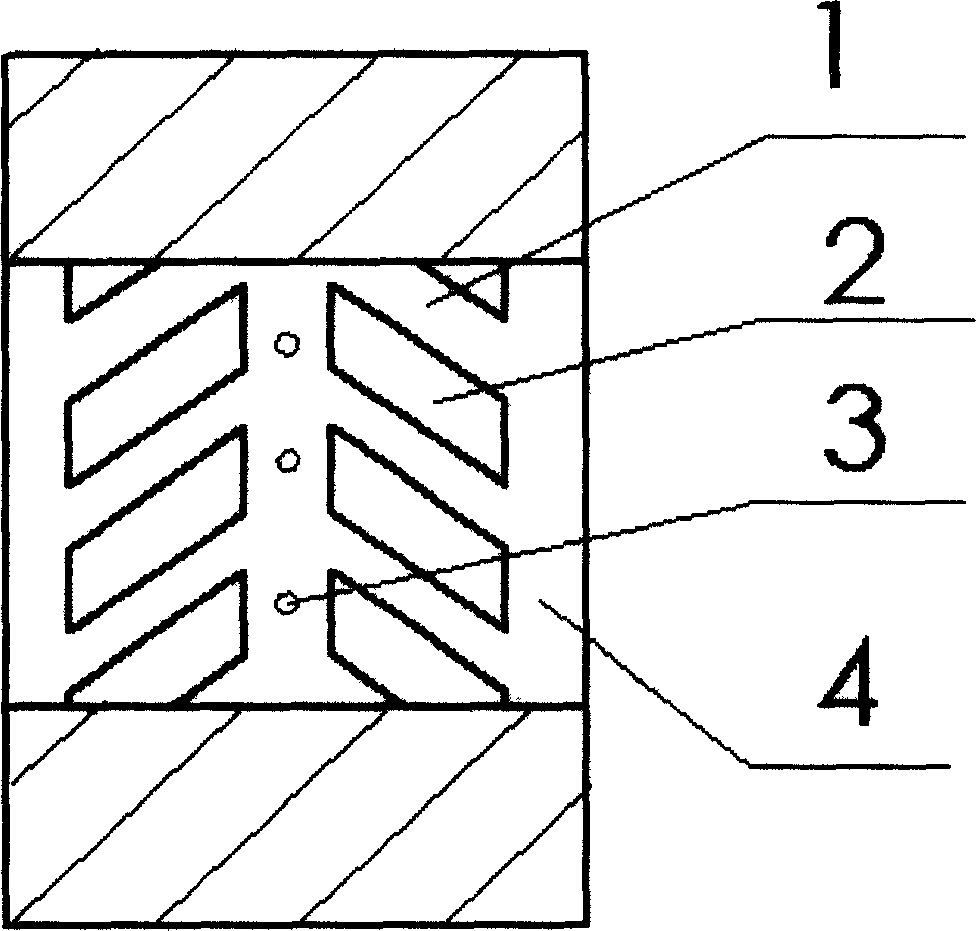

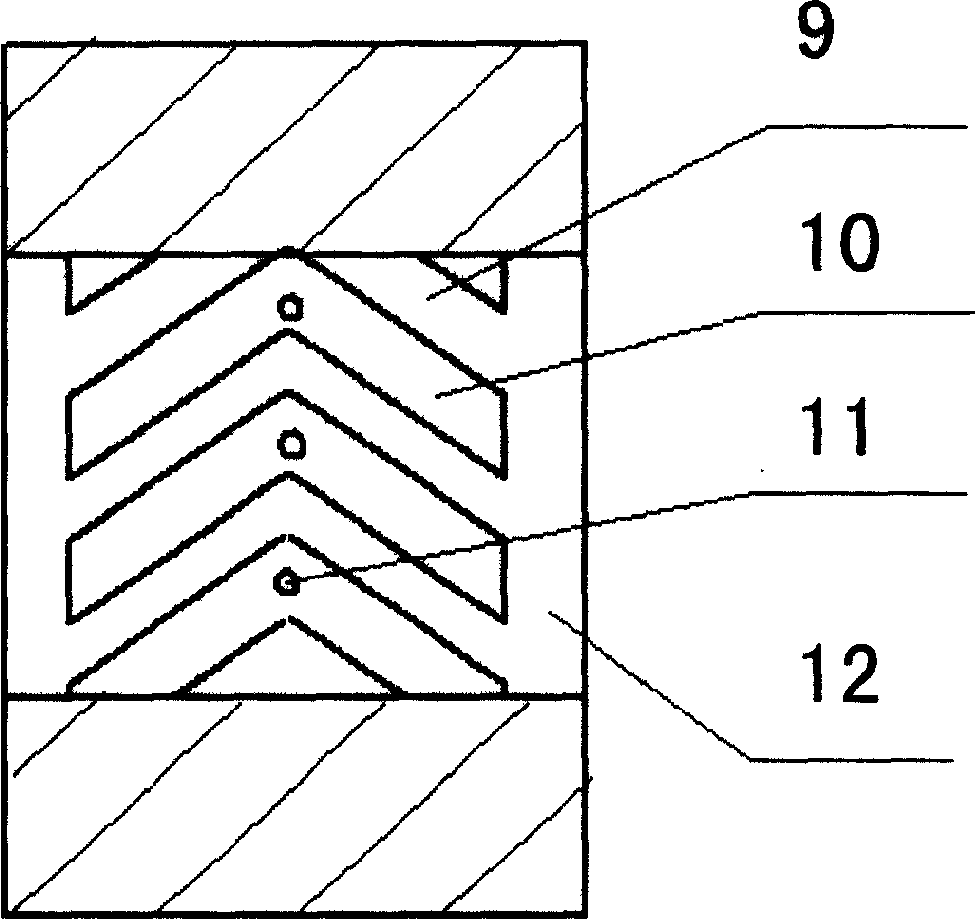

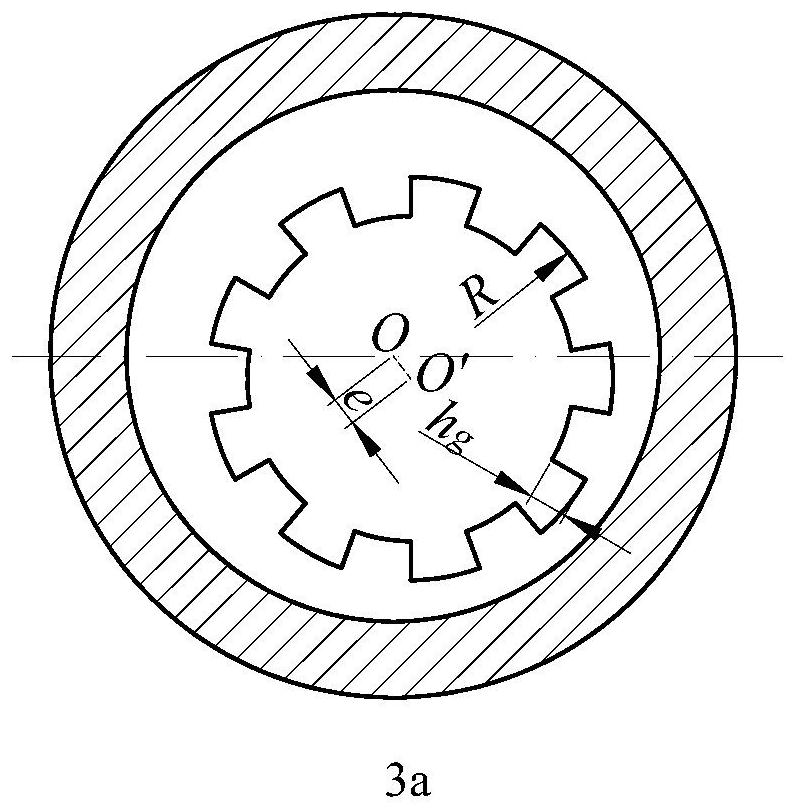

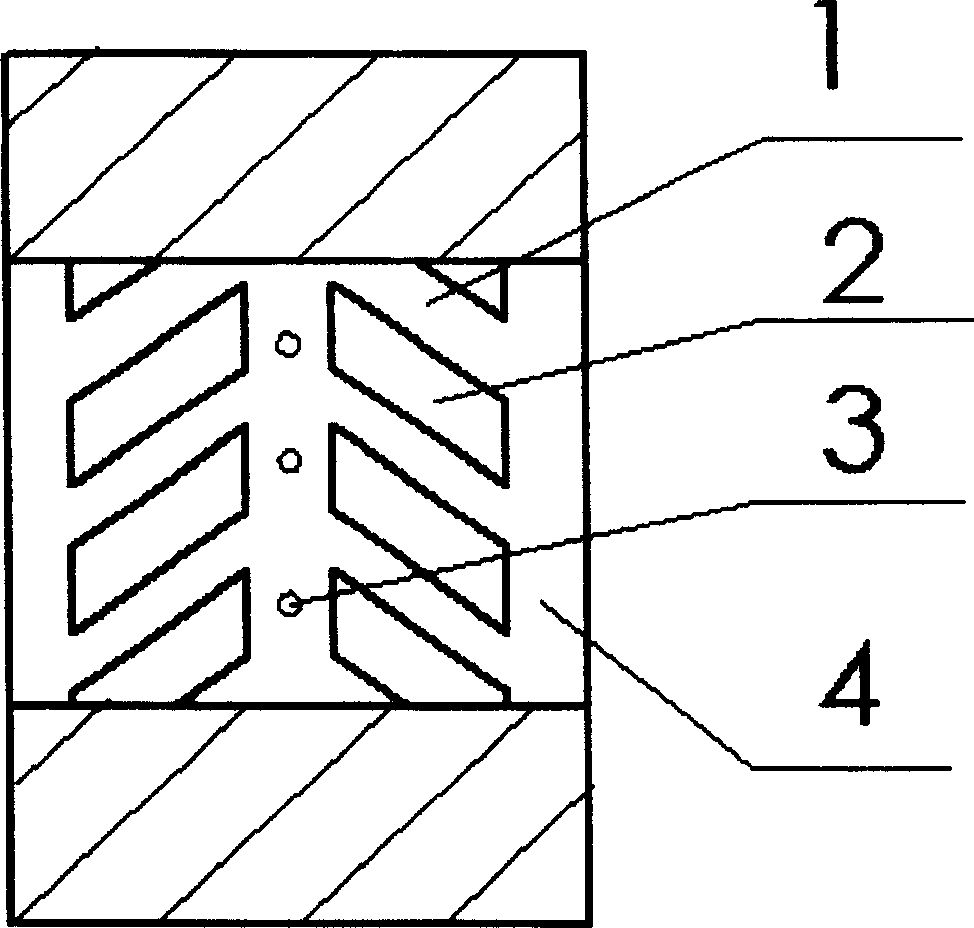

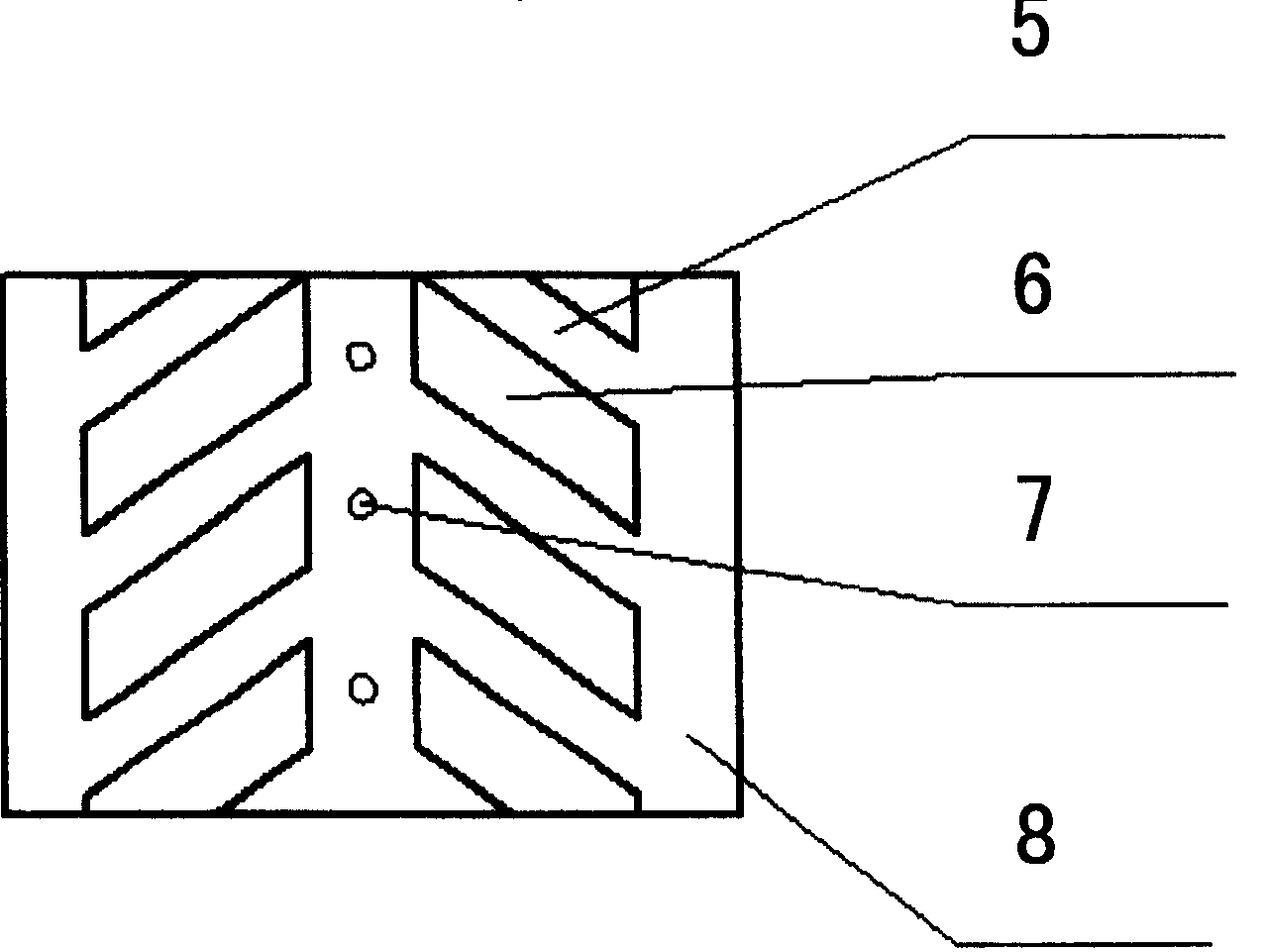

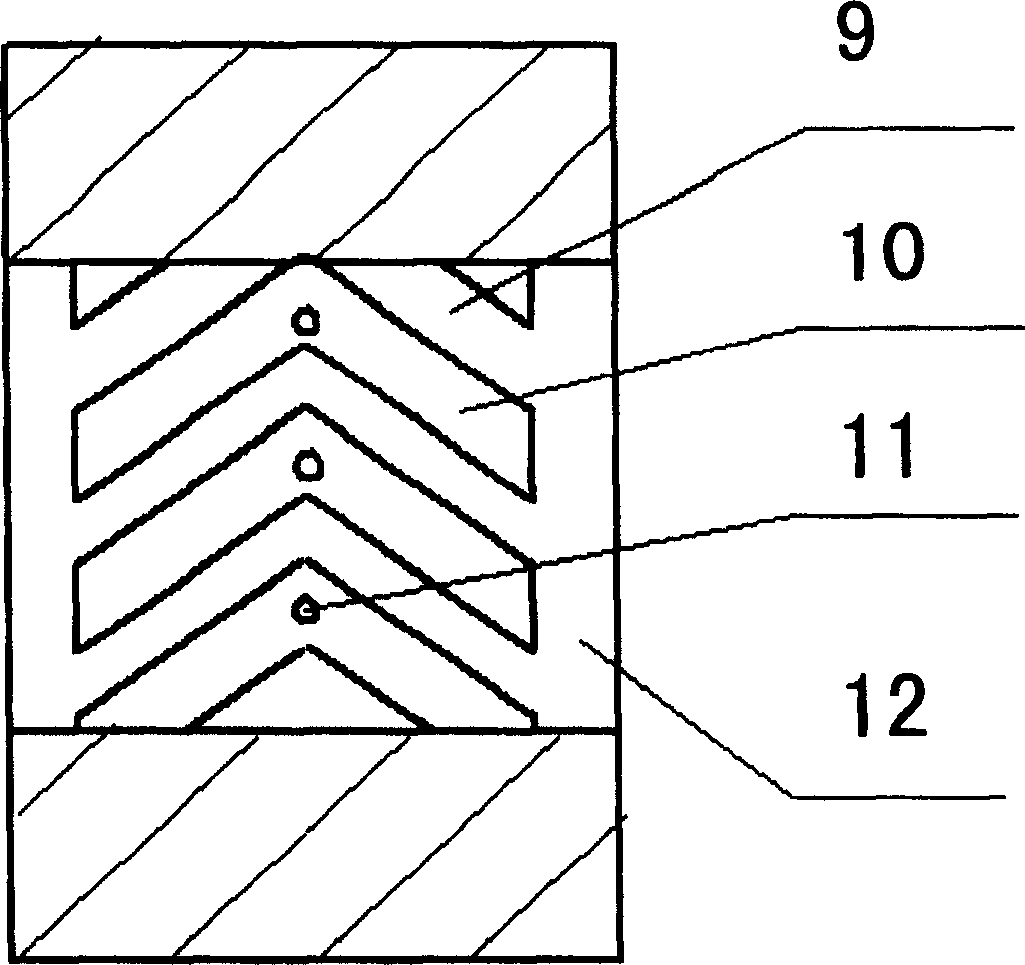

Mixed type helical groove dynamical and static pressure gas composite cylindrical bearing

The "hybrid spiral groove dynamic and static pressure gas composite cylindrical bearing" of the present invention relates to a high-speed, high rigidity, large load ultra-precision spiral groove dynamic and static pressure gas composite cylindrical bearing. On the working surface of the cylindrical bearing, the distribution of static pressure air flotation gas supply points There are herringbone dynamic pressure grooves on both sides of the circle. Without increasing the air consumption of the air bearing, the bearing capacity is increased by more than 30% compared with the traditional static pressure air bearing, and the bearing stiffness is 15% higher than that of the traditional static pressure air bearing. %above.

Owner:HARBIN INST OF TECH

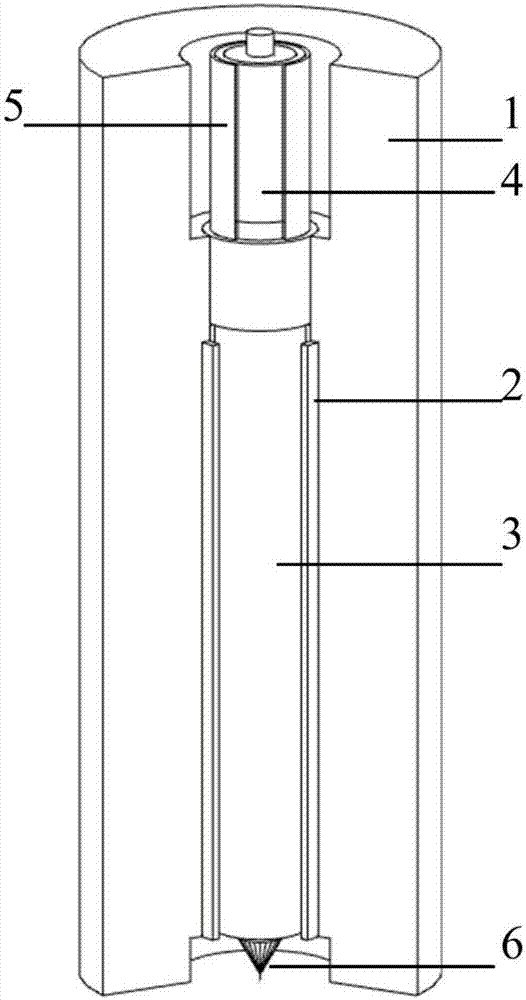

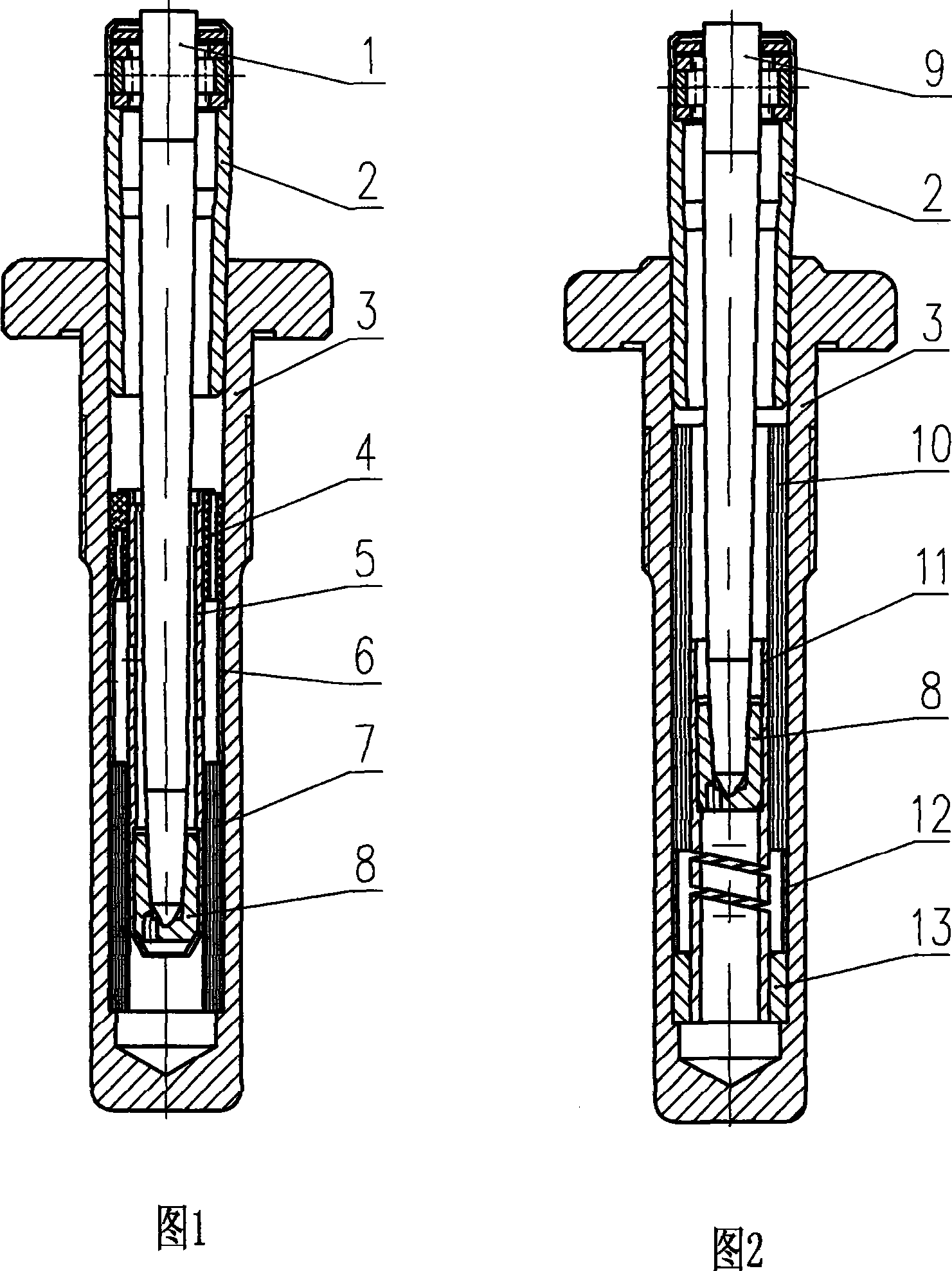

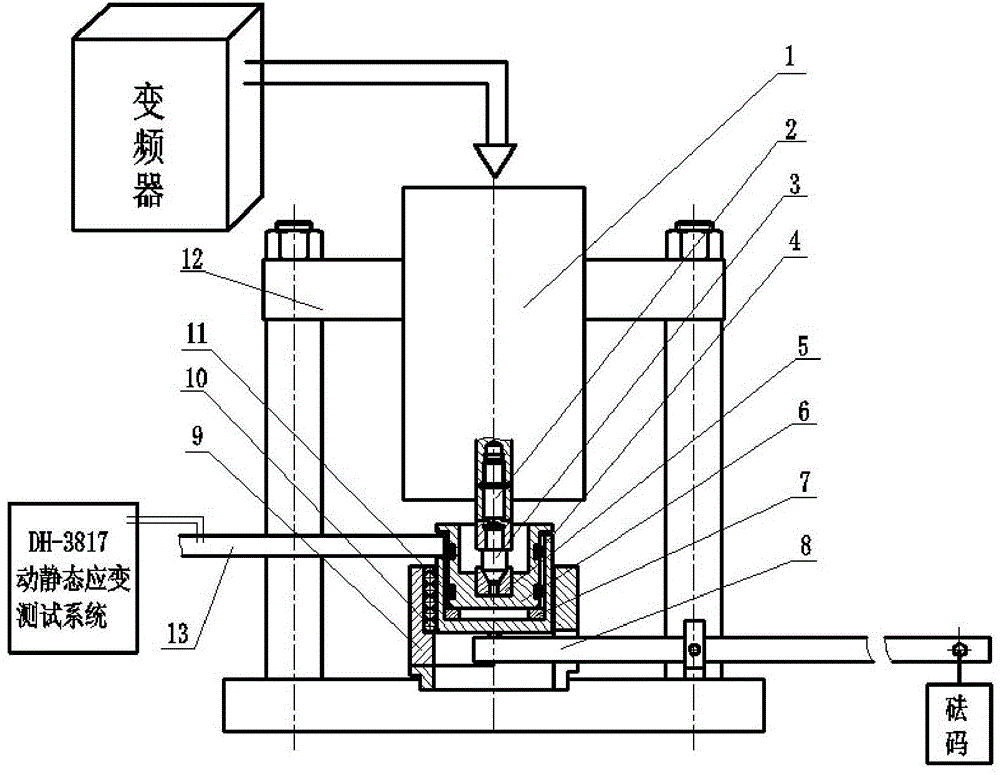

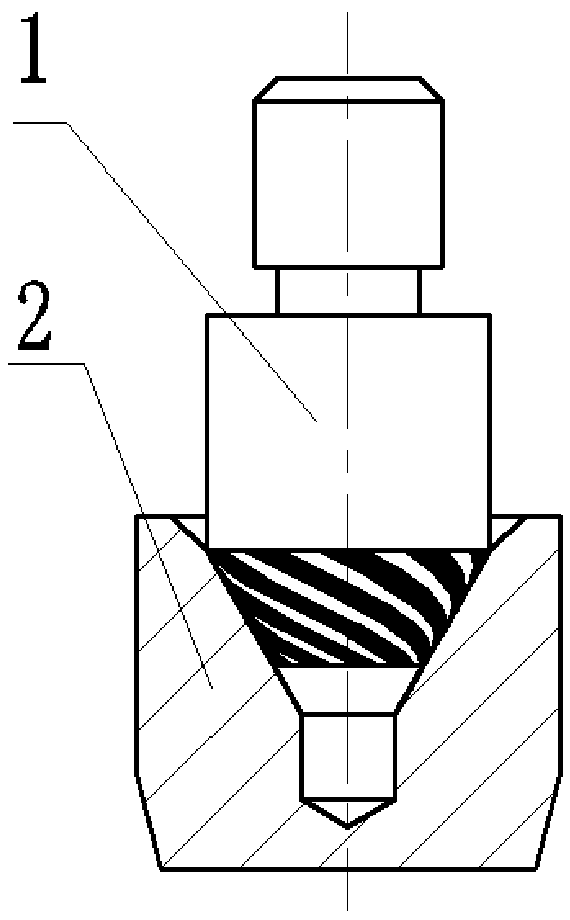

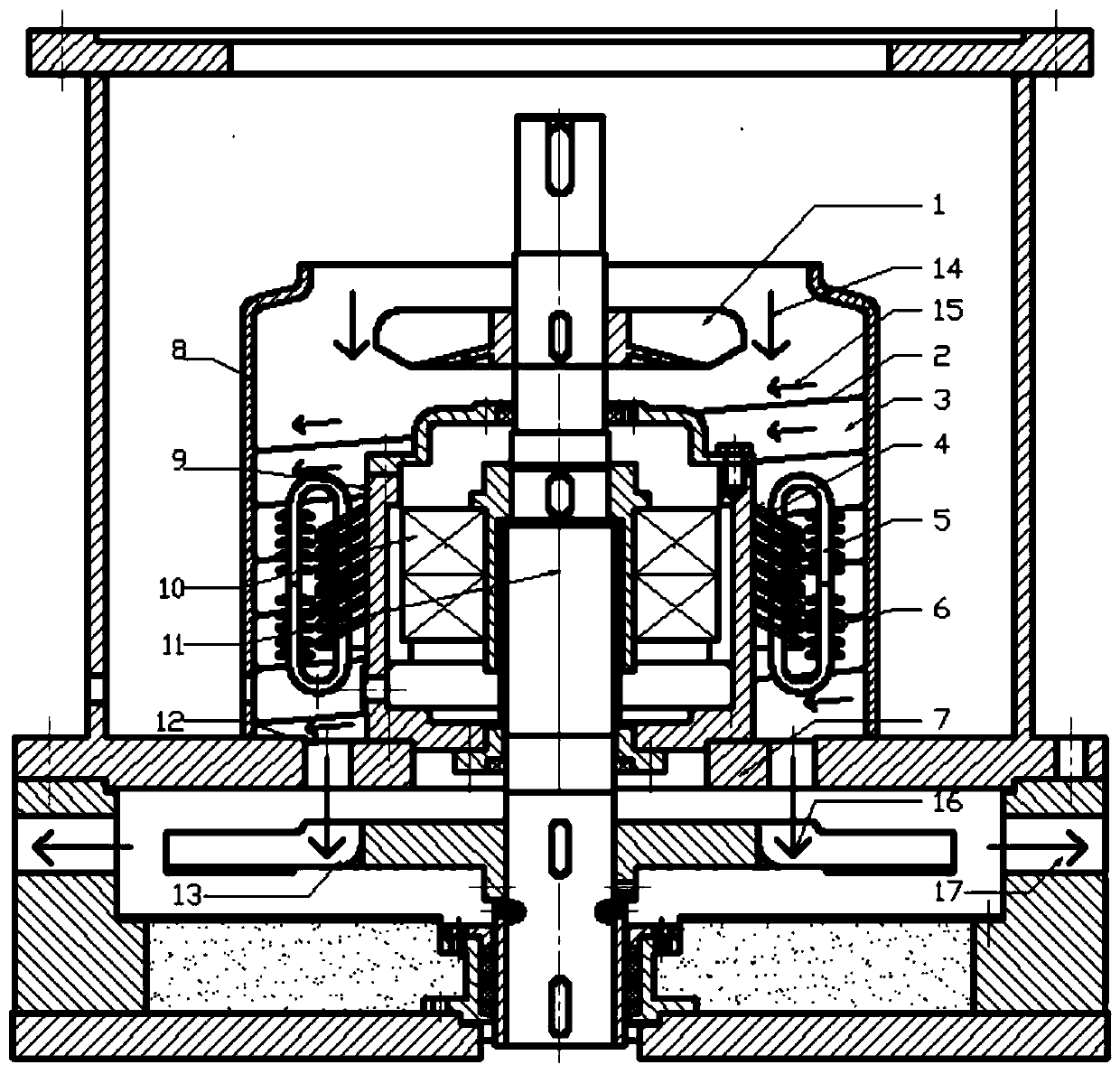

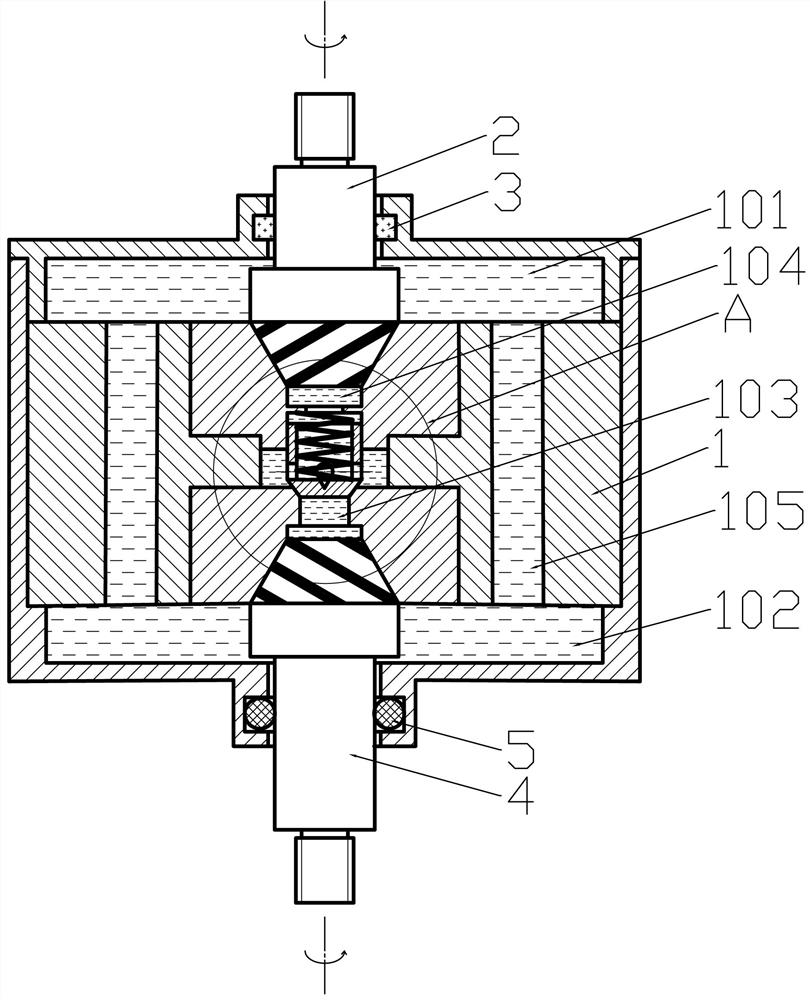

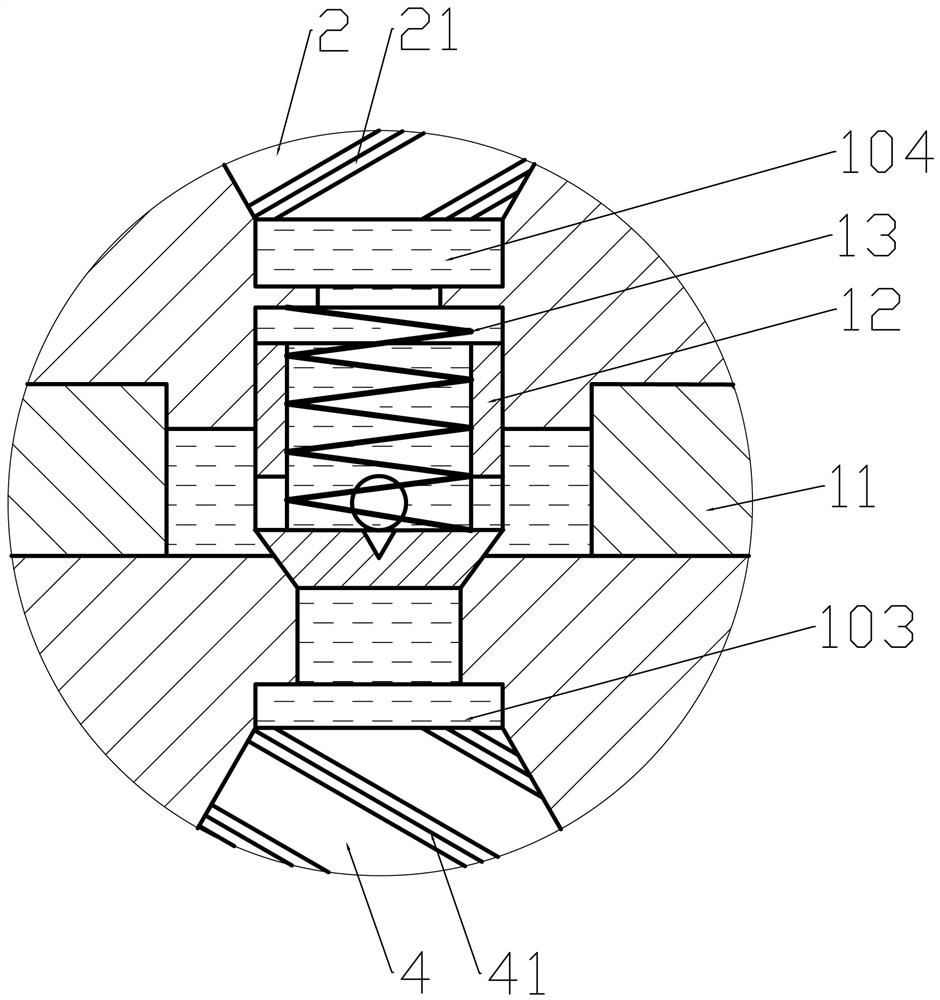

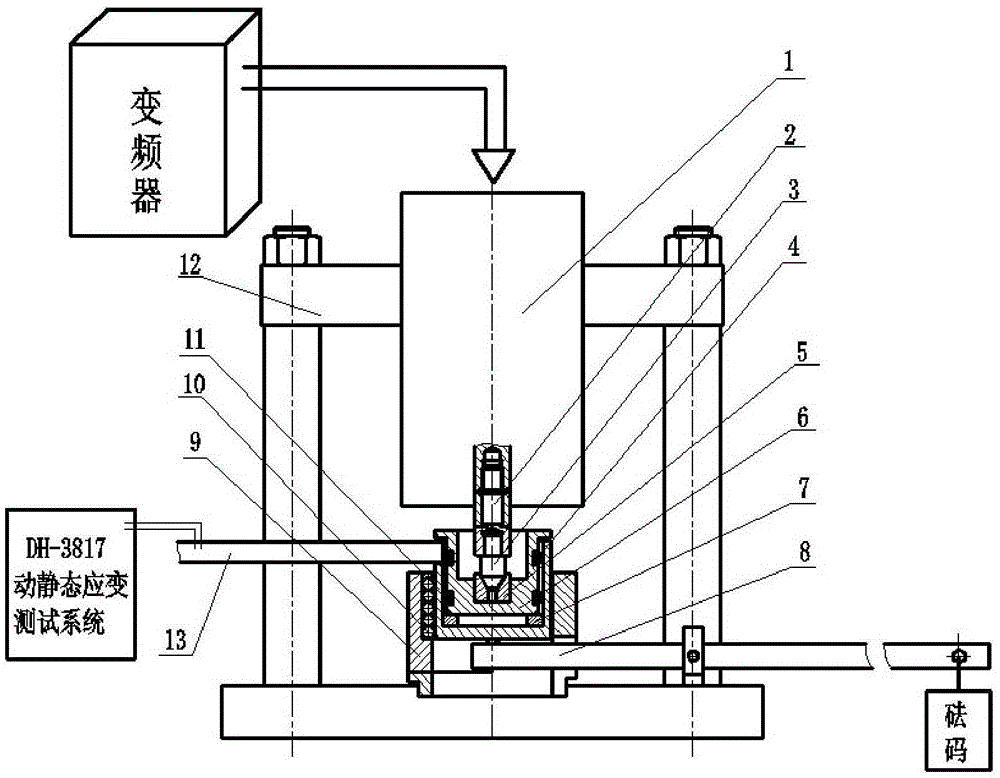

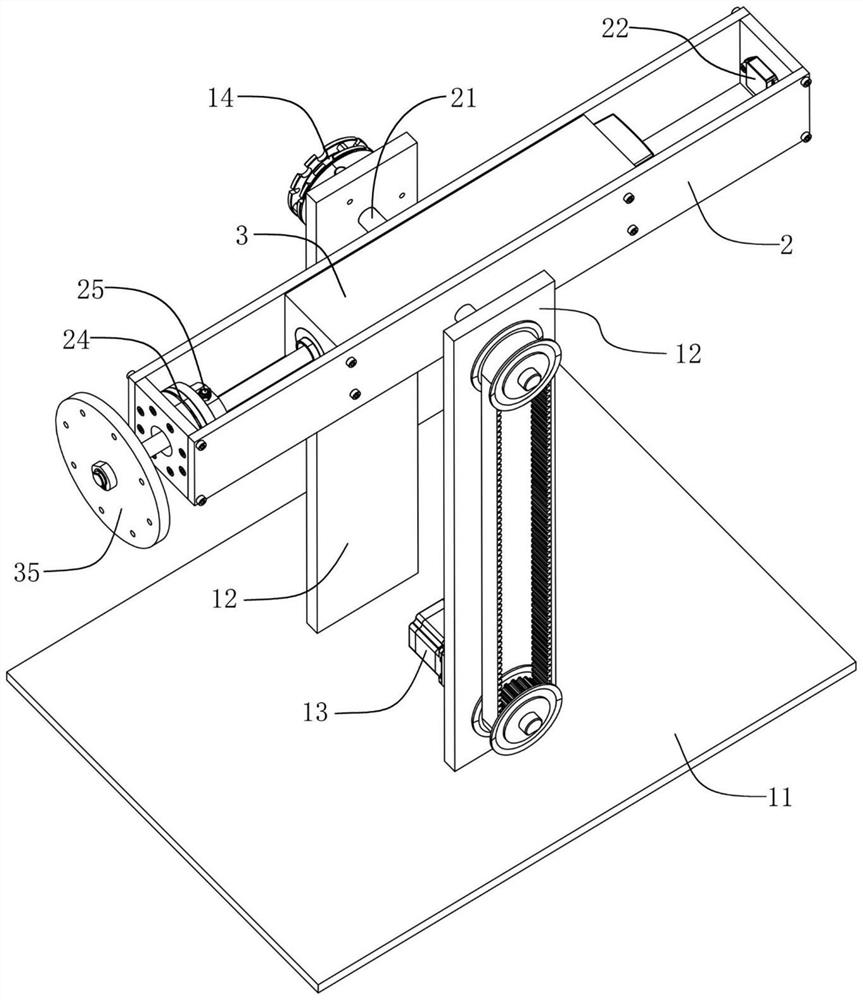

Device for testing axial bearing capacity of conical dynamic-pressure spiral groove bearing

ActiveCN103335845AEasy to testAvoid shock loadsMachine bearings testingSpiral groove bearingDrive shaft

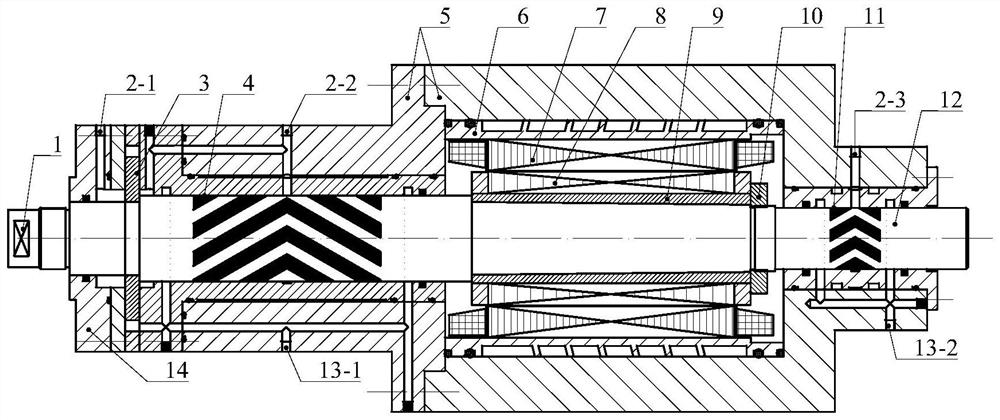

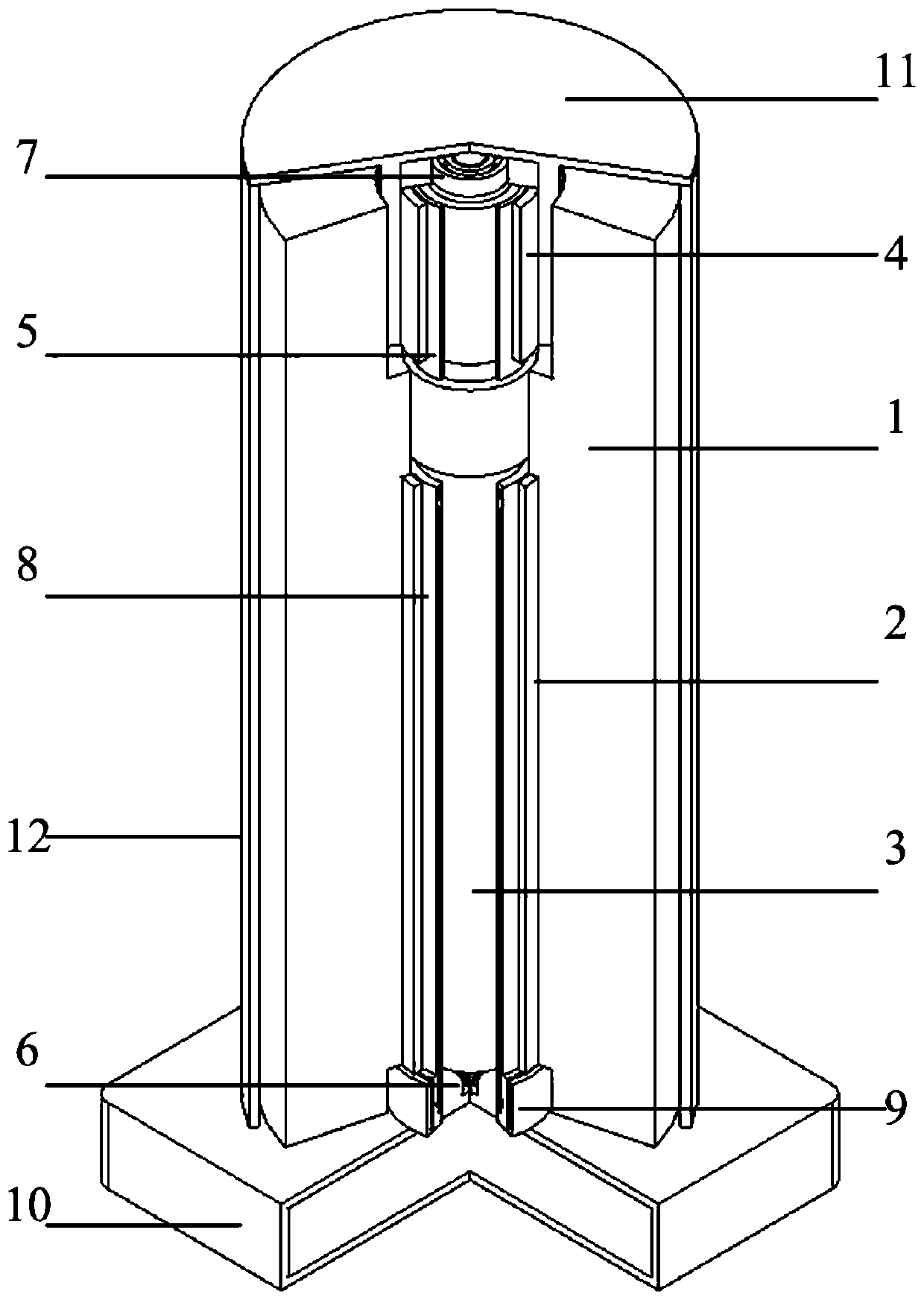

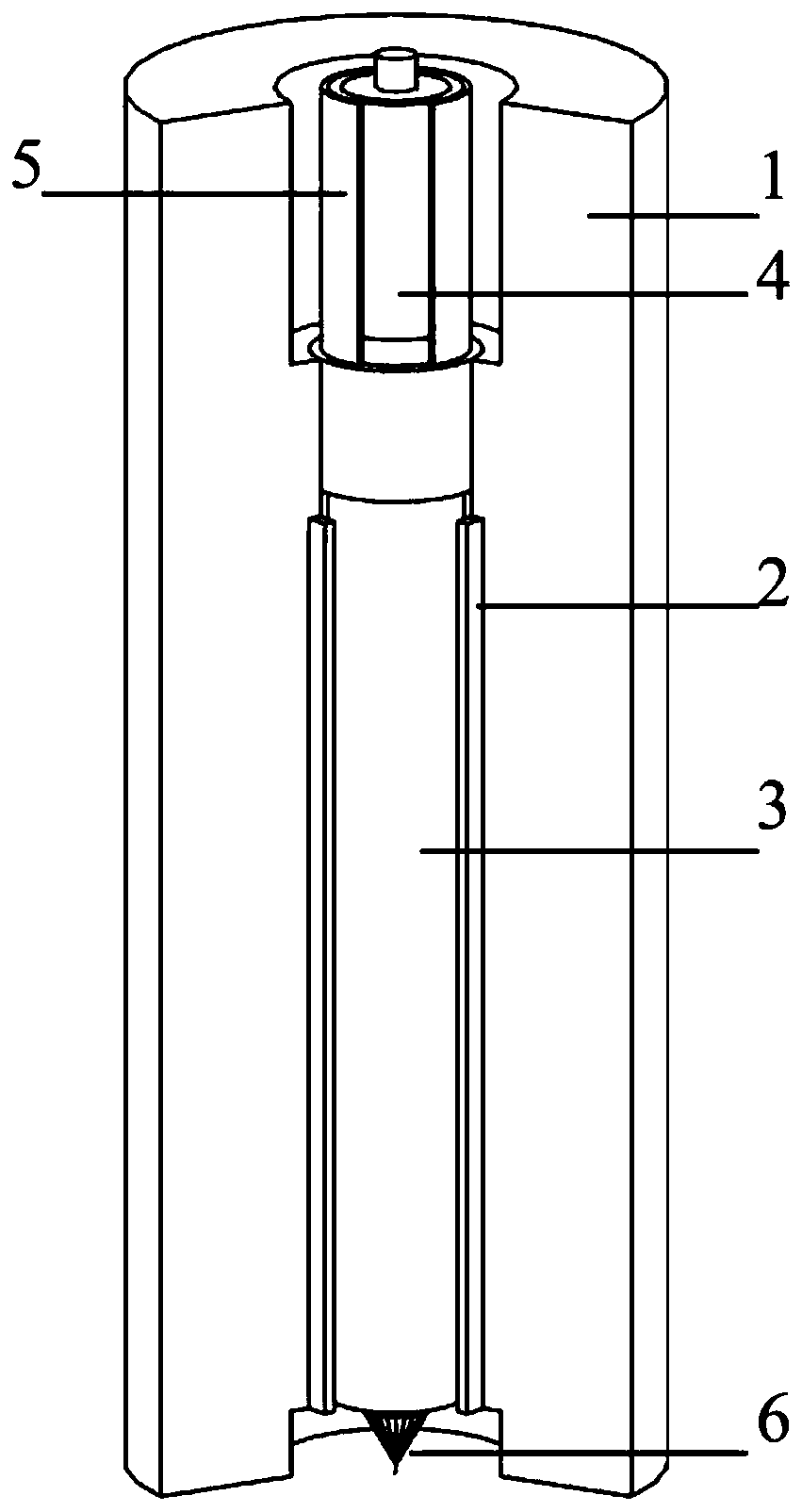

The invention discloses a device for testing axial bearing capacity of a conical dynamic-pressure spiral groove bearing. The device for testing the axial bearing capacity of the conical dynamic-pressure spiral groove bearing consists of a mechanical part and an electrical control part; a high-frequency motor (1) is mounted at the upper part of a test device frame (12); a transmission shaft (2) is mounted at the lower part of the high-frequency motor; a tested bearing (3) is mounted below the transmission shaft; a bearing base (5) is mounted inside a bearing race (6); the bearing race is positioned inside a loading sleeve (11) at the upper part of a gasket (4); the loading sleeve is mounted inside a split positioning ring (9); a ball (10) is mounted inside a rectilinear runner of the split positioning ring; the split positioning ring is mounted at the bottom of the test device frame (12); a loading lever (8) is mounted at the bottom of the test device frame (12); a weight is arranged at the outer end of the loading lever; the inner end of the loading lever is arranged below the loading sleeve; the inner end of a strain beam (13) is embedded into a U-shaped groove of the loading sleeve; the outer end of the strain beam is connected with a dynamic and static strain testing system of the electrical control part.

Owner:SOUTHEAST UNIV

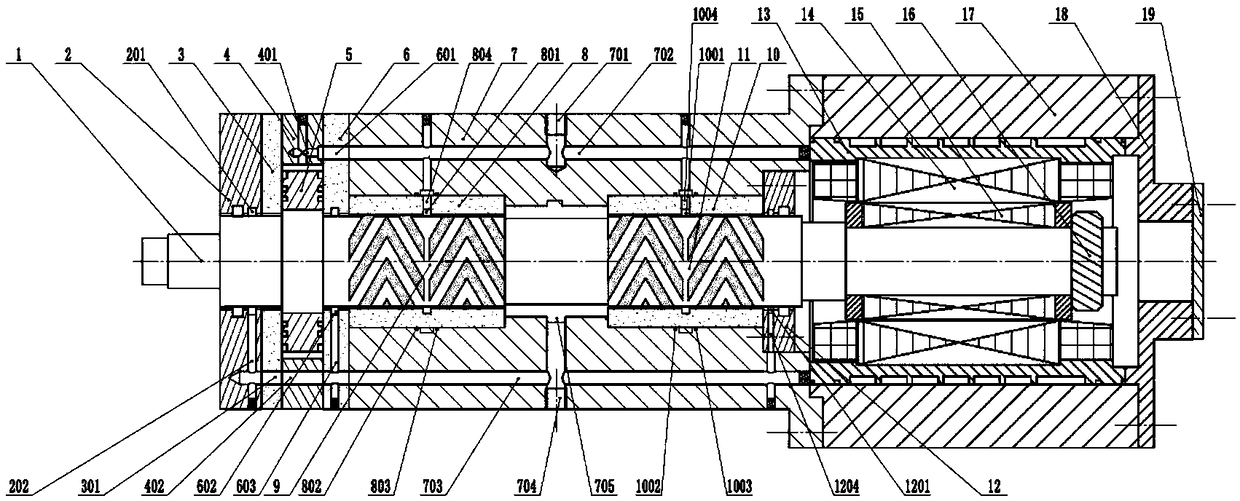

High-speed water lubrication dynamic pressure spiral groove bearing electric spindle

InactiveCN109128224ALow running costReduce frictionLarge fixed membersMaintainance and safety accessoriesRare earthCarbon graphite

The invention discloses a high-speed water lubrication dynamic pressure spiral groove bearing electric spindle. The spindle comprises a shaft neck, a radial bearing bush, a thrust disc, a thrust bearing bush, a spindle body, a gas injection sealing ring, a motor stator, a motor rotor, a cooling water jacket, a shell and peripheral equipment. Water serves as lubricant of a radial (thrust) bearing,spiral grooves are engraved in the shaft neck and in the thrust disc, and an anti-drag micro-textures are machined in a table area; the radial (thrust) bearing bush is made of special carbon graphite,and a Ta-Si-based nano composite coating is prepared on the surface of the neck shaft (thrust disc); the spindle body adopts dynamic pressure spiral groove radial supporting and thrust bearing mixingsupporting, the special non-contact gas injection sealing ring is designed at the ends of the bearings, and the spindle body is driven by a rare earth permanent magnet brushless direct current motor;and the motor stator is cooled through the cooling water jacket. The spindle has the advantages that the temperature rise of the bearings is low, the friction power consumption is low, the rotation precision is high, the stability is good, the cavitation erosion resistance is high, pollution is avoided, and the spindle is particularly suitable for a high-speed precision machining machine tool.

Owner:SOUTHEAST UNIV

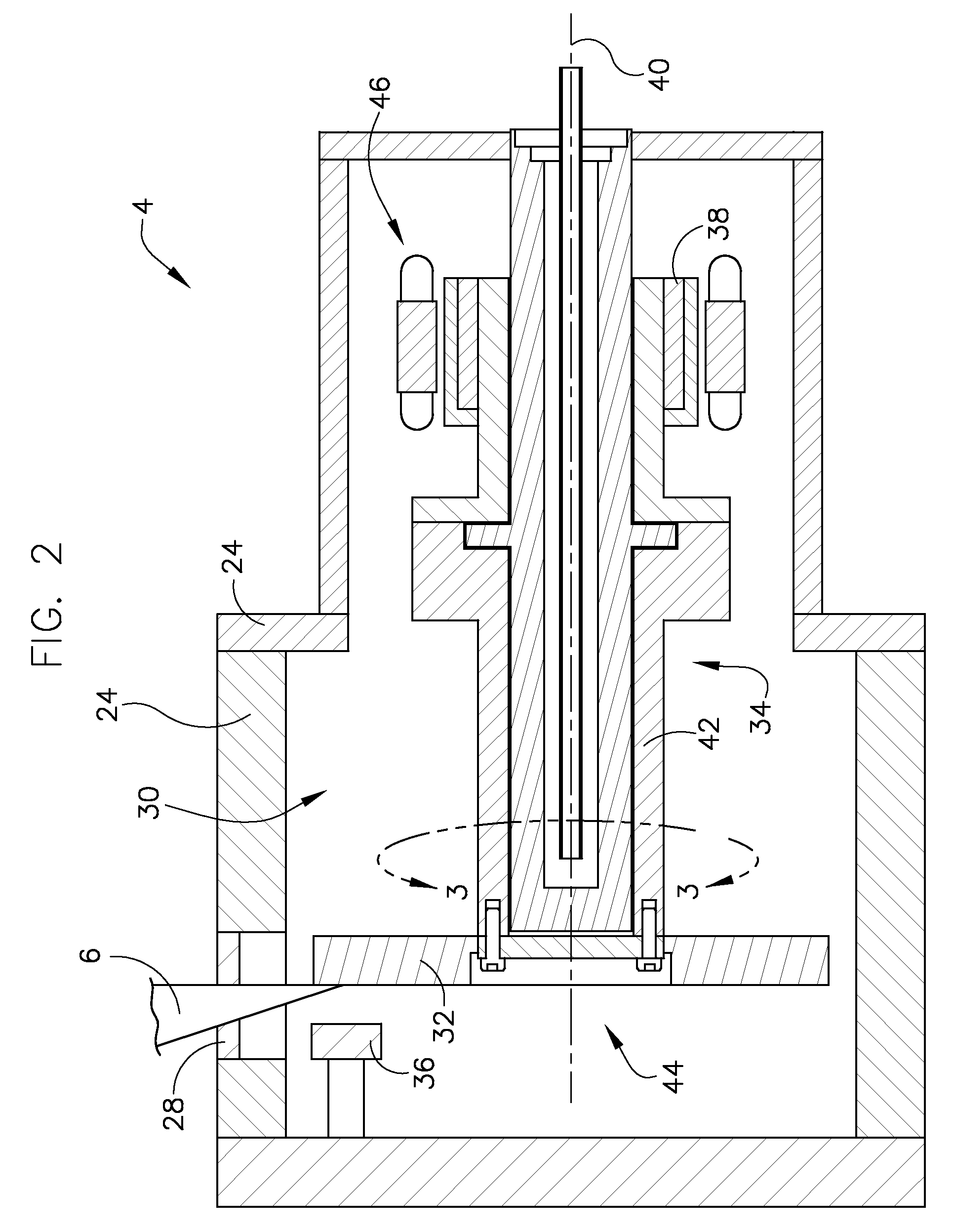

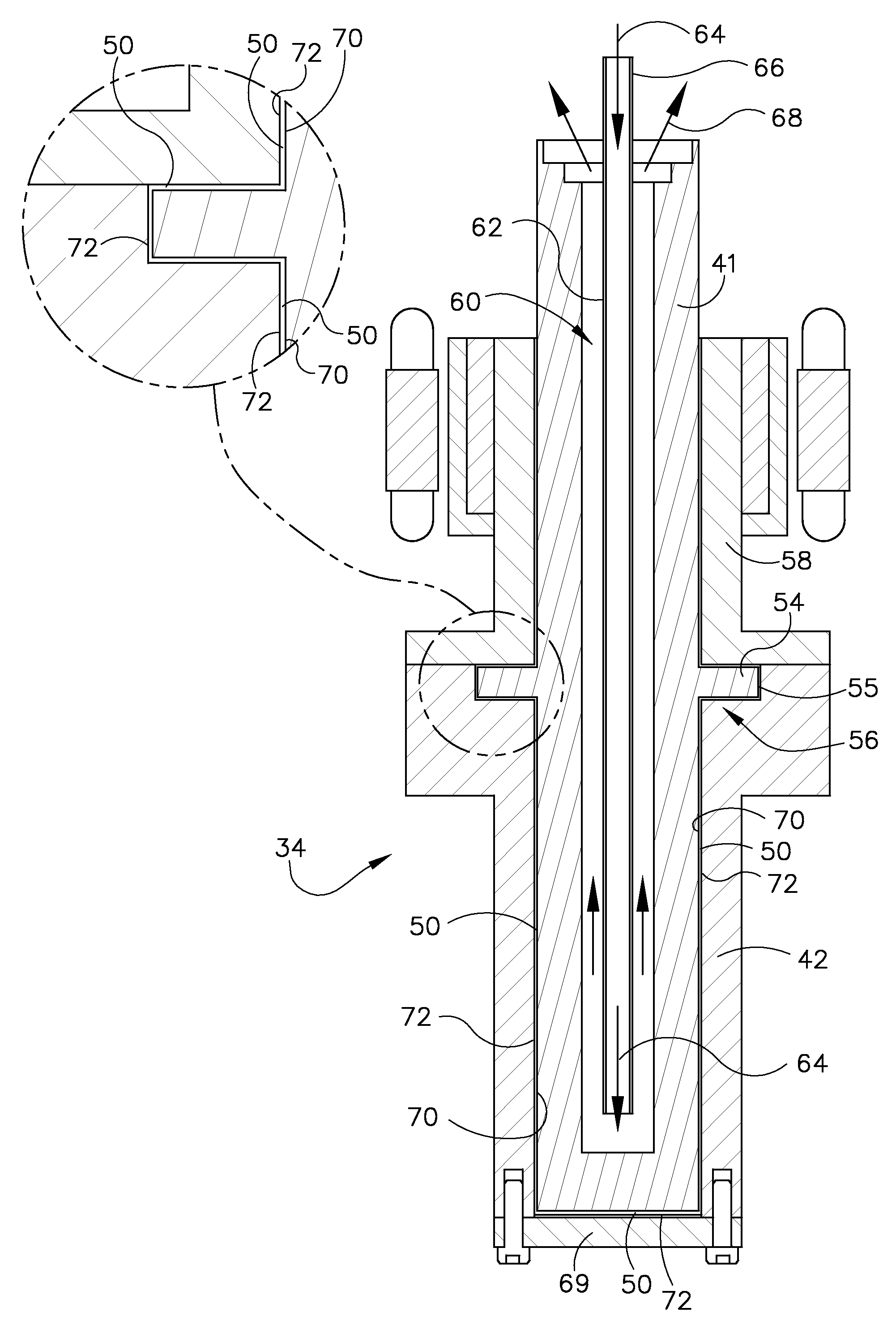

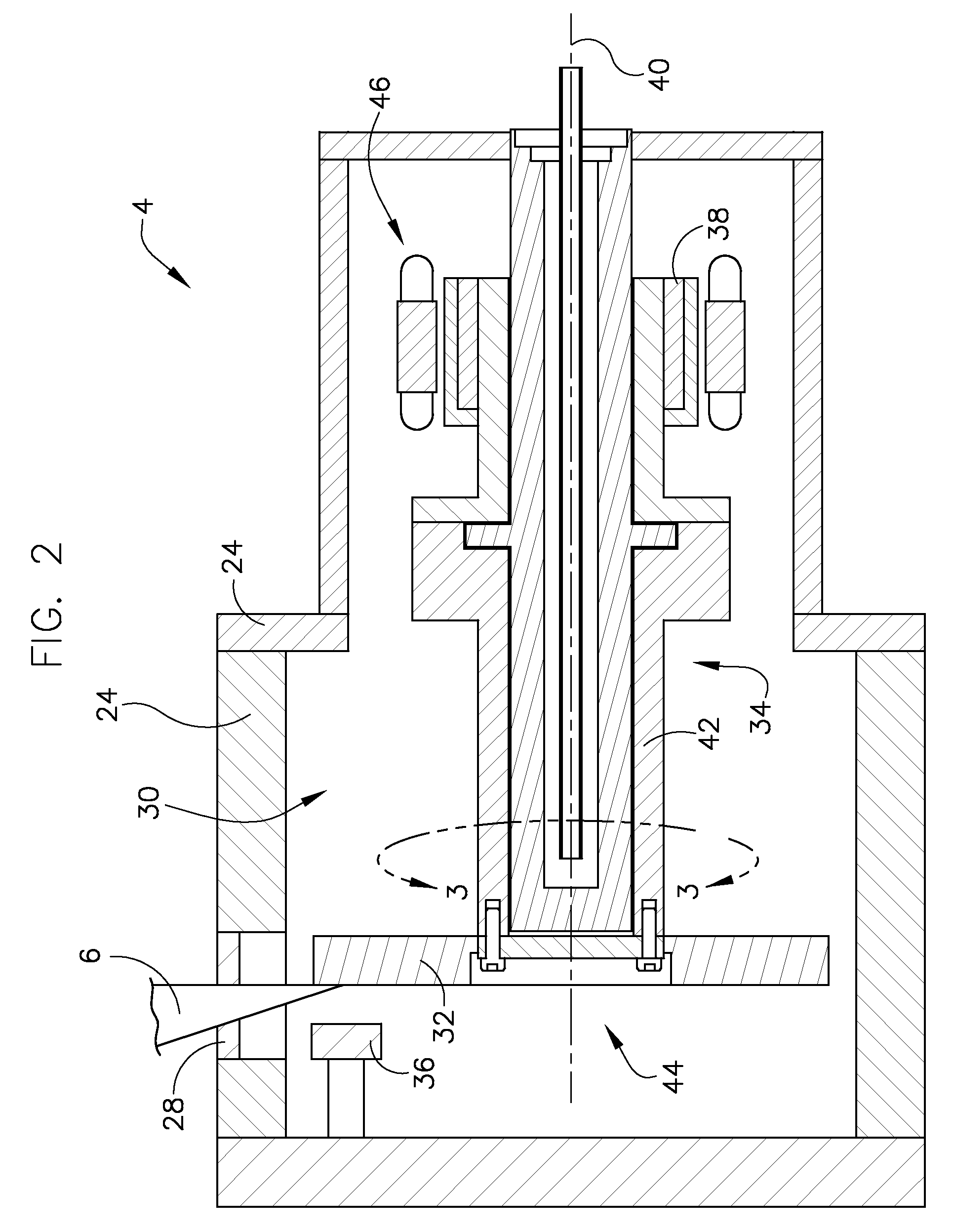

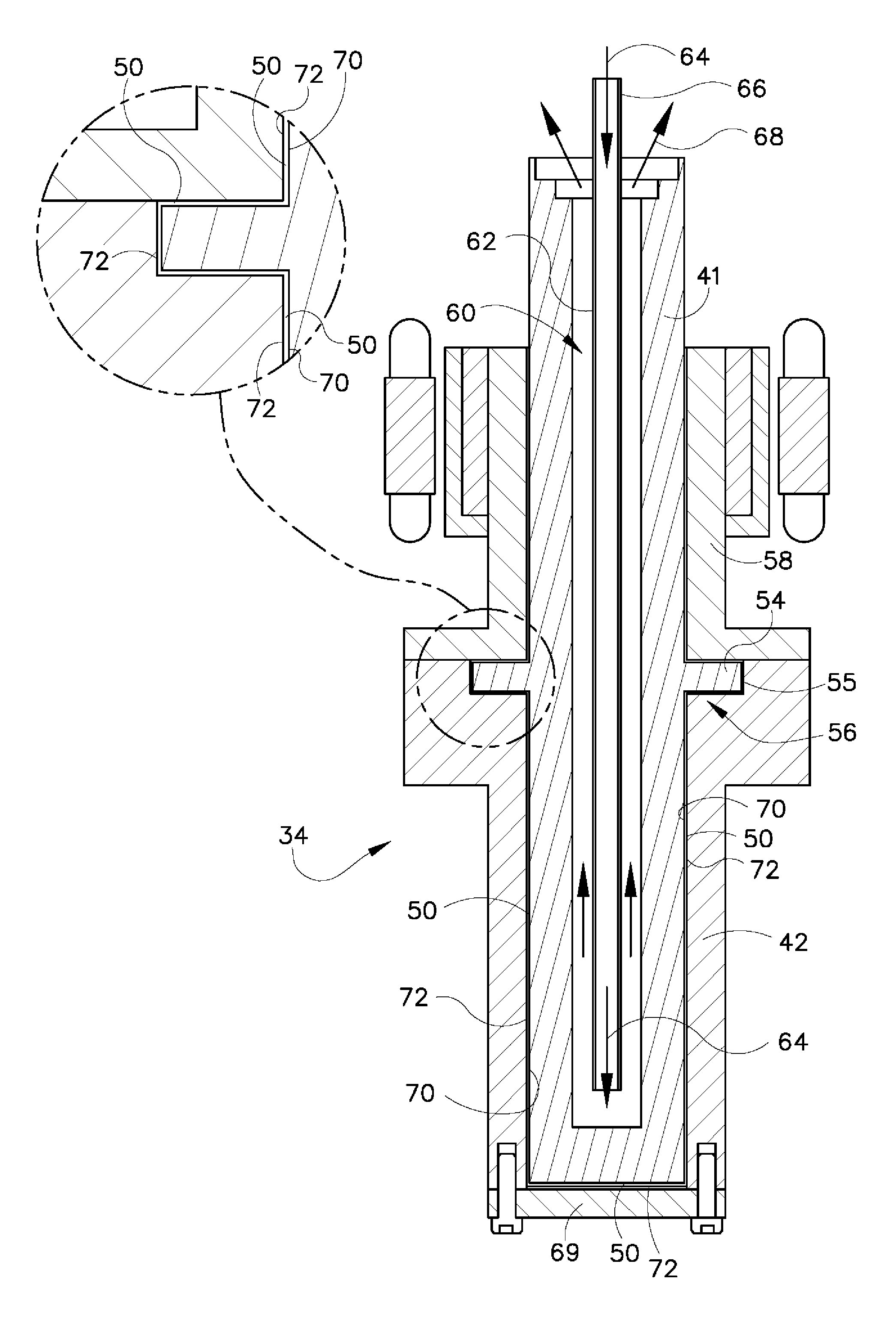

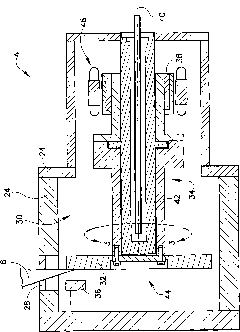

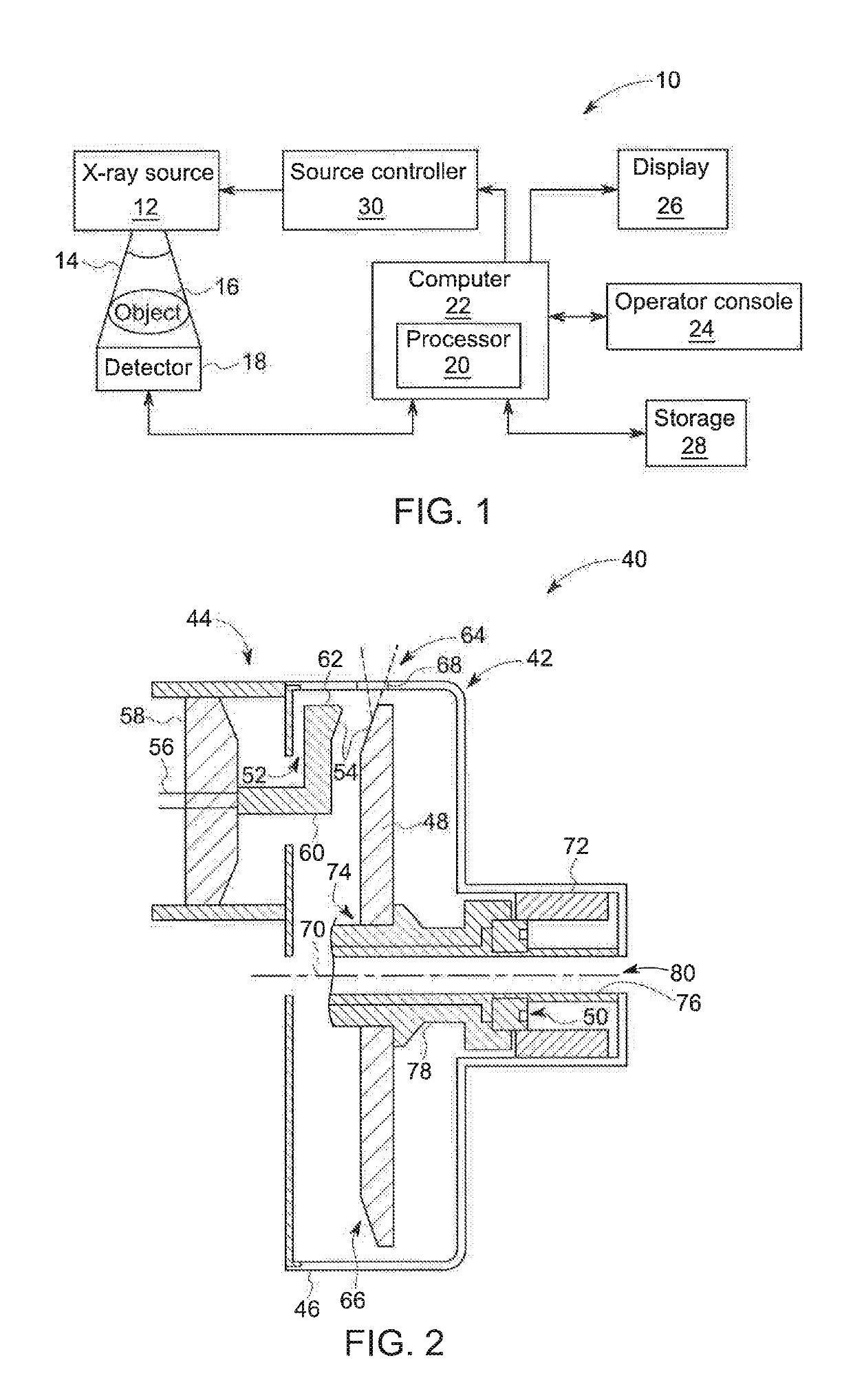

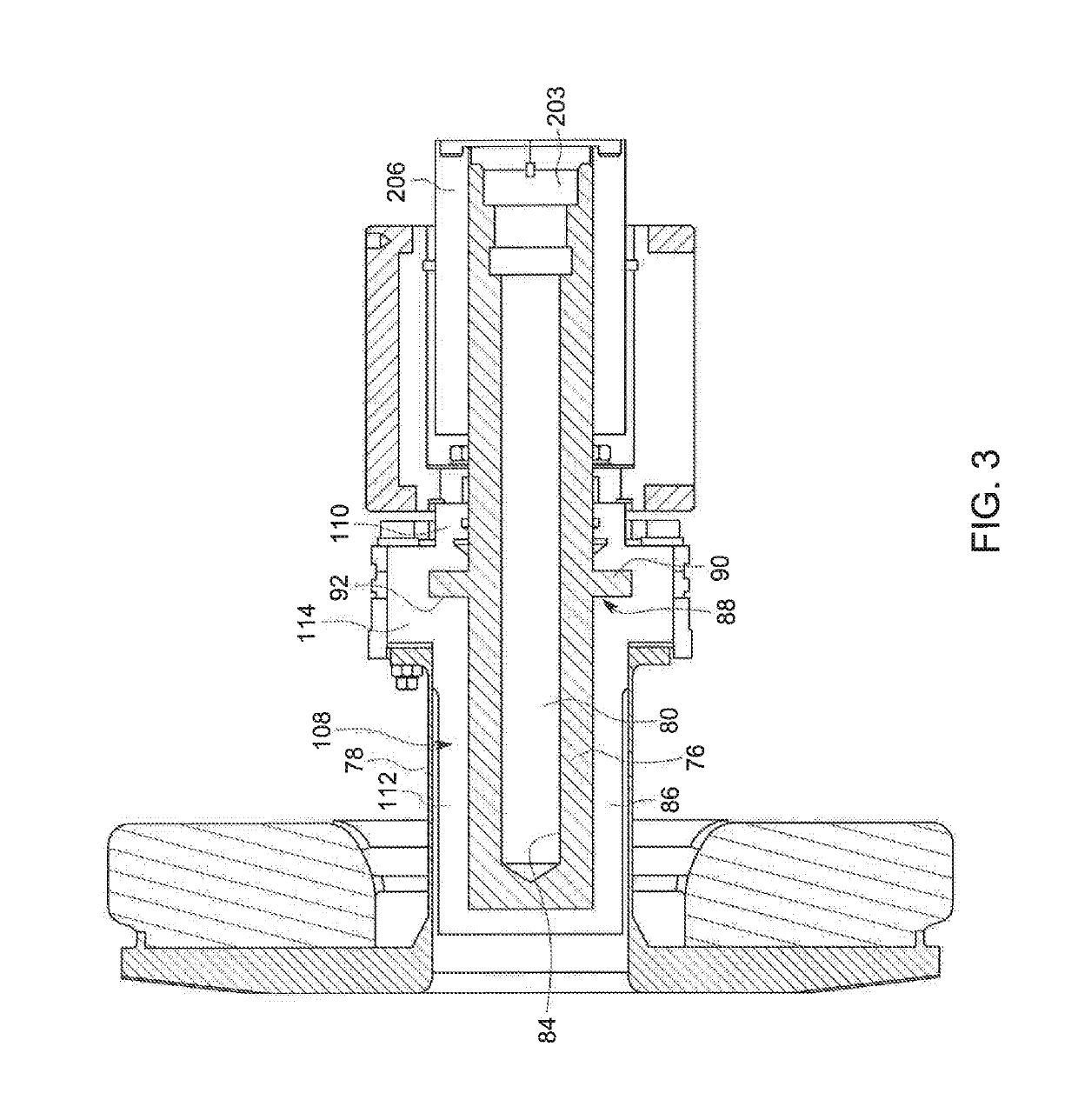

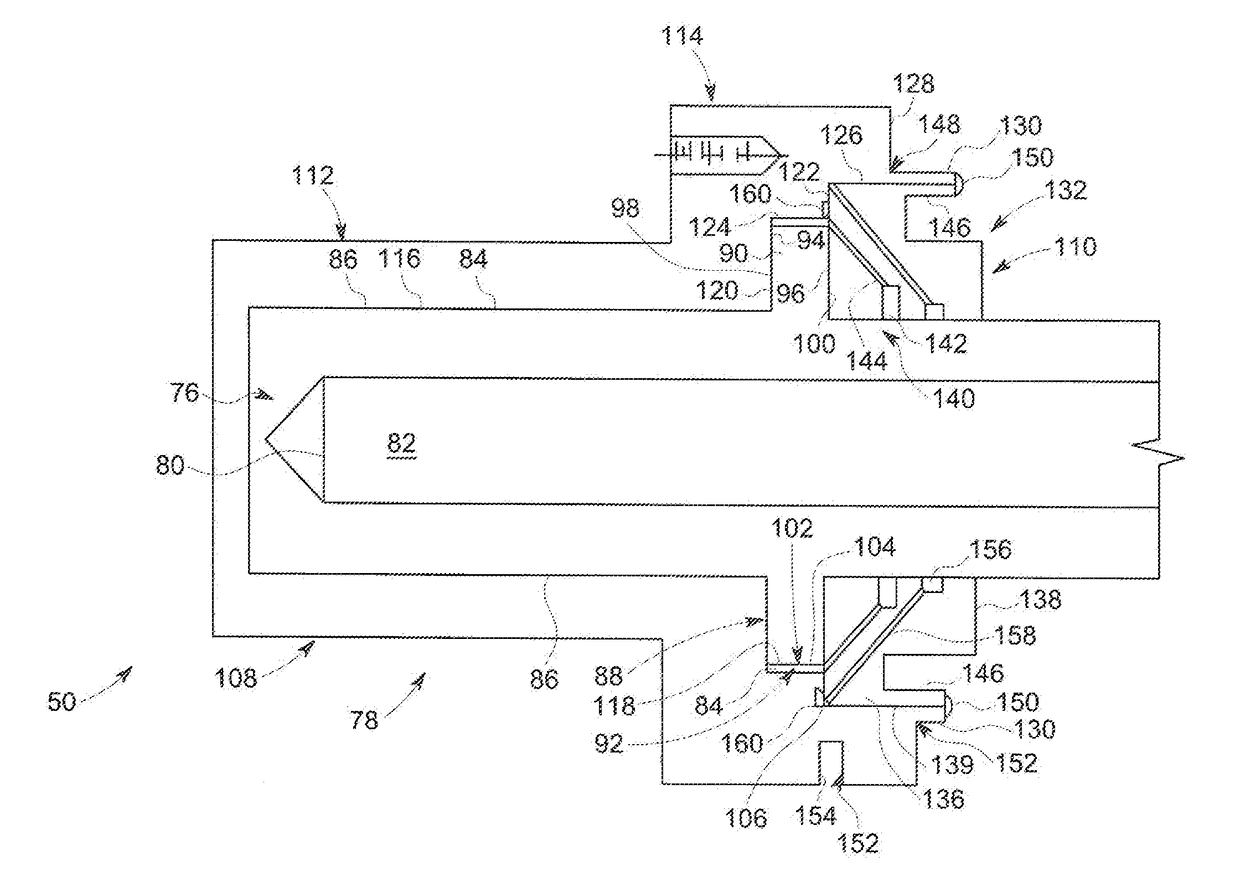

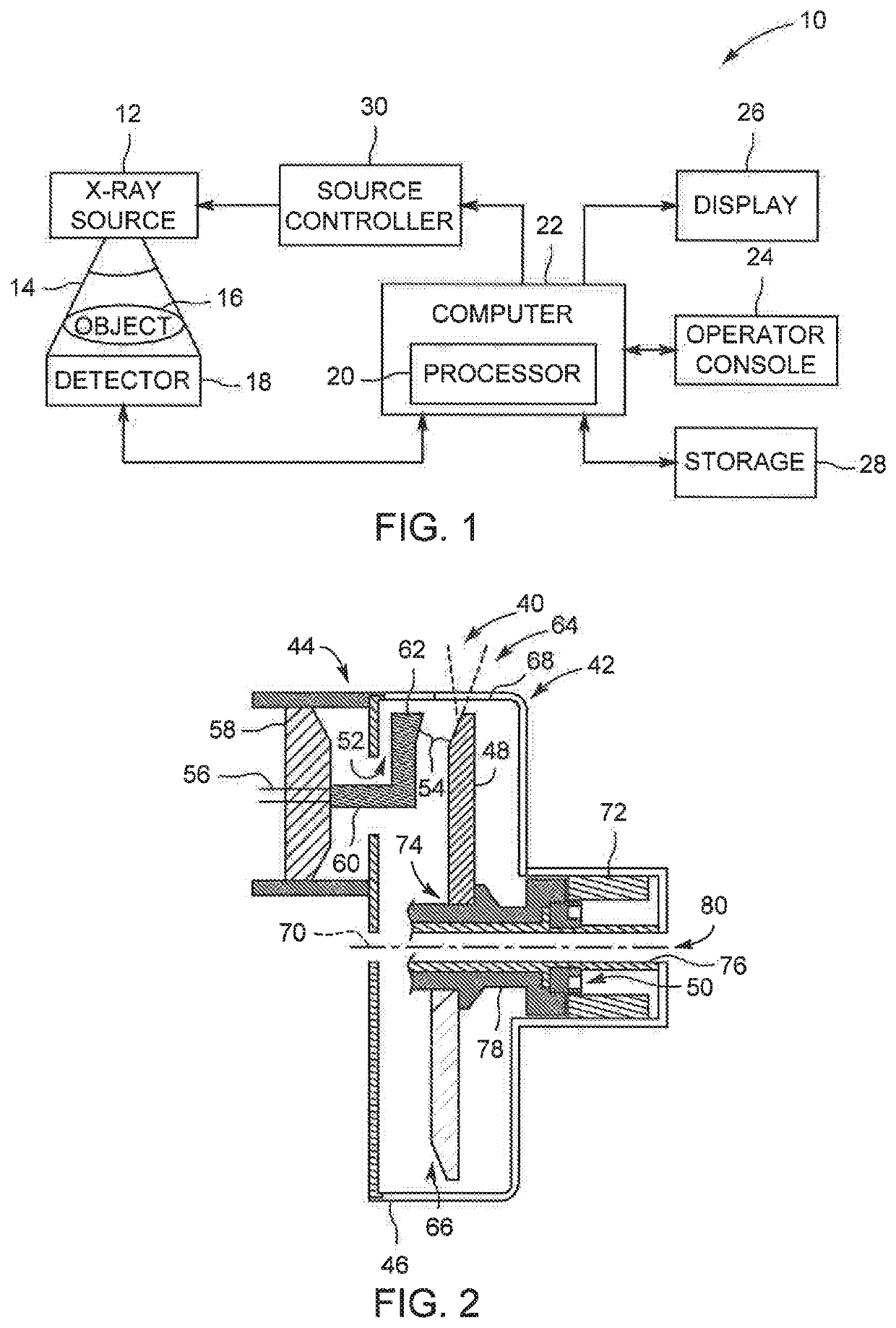

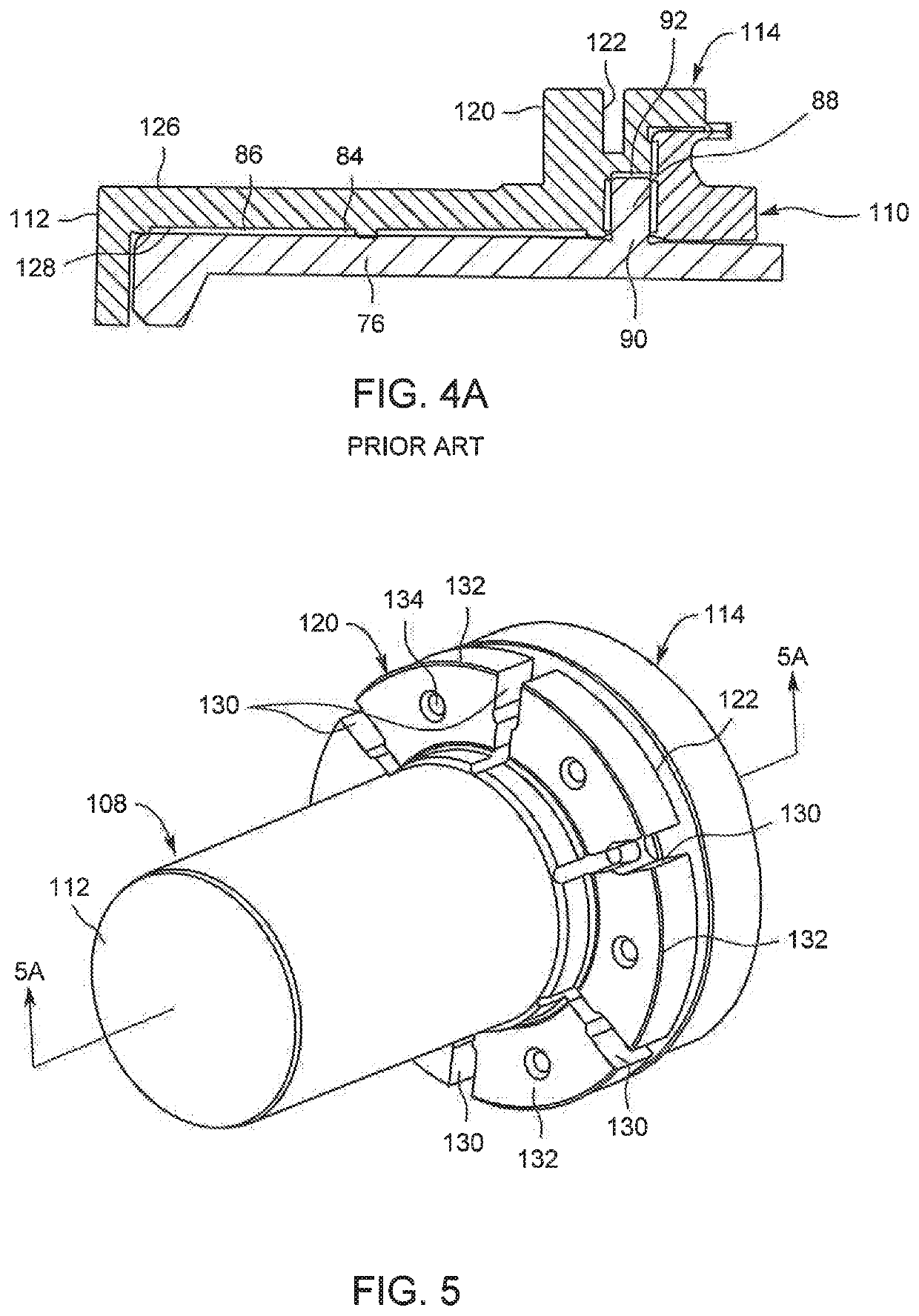

Cooling Spiral Groove Bearing Assembly

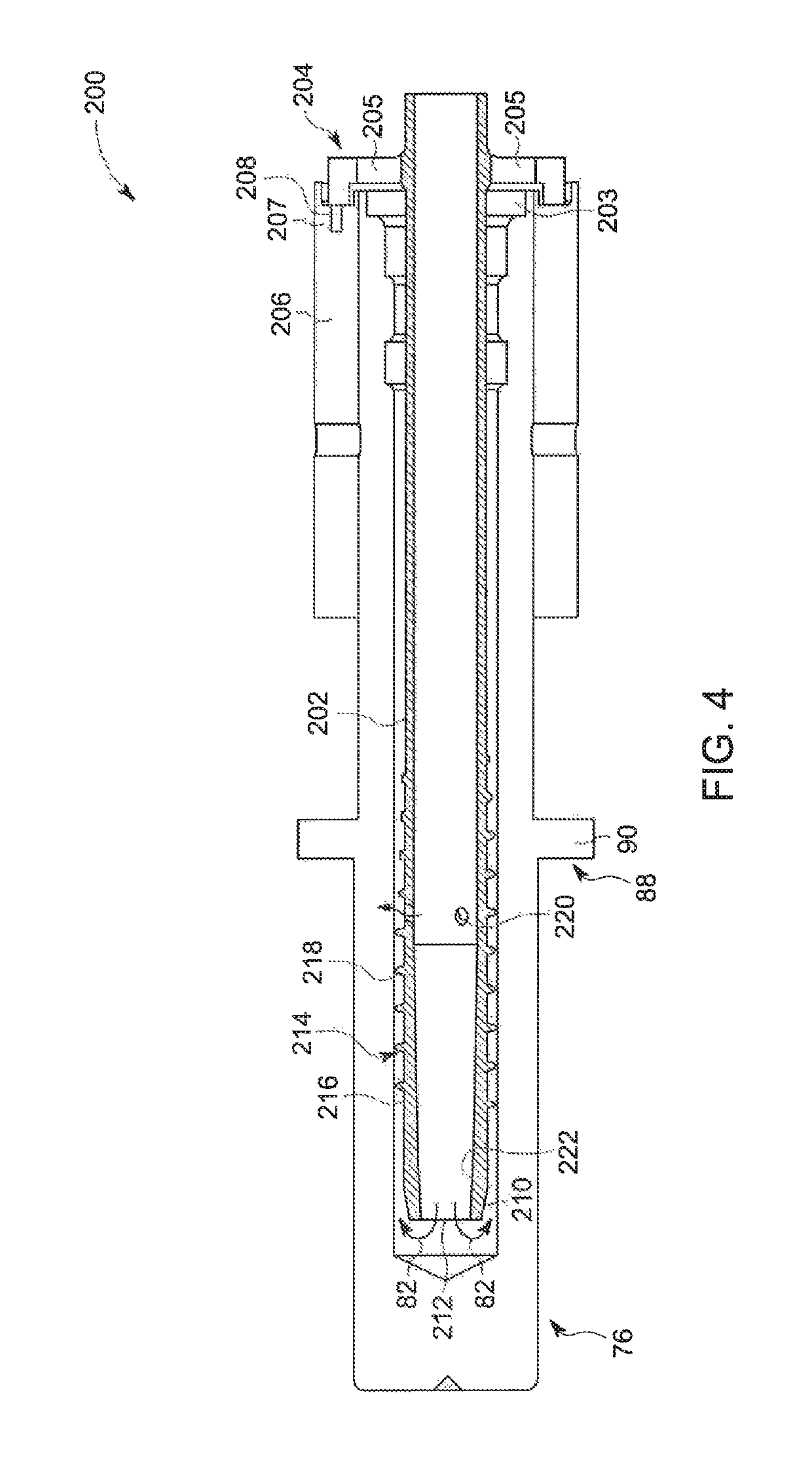

ActiveUS20190103244A1Increased turbulenceSpeed up heat exchangeX-ray tube anode coolingX-ray tube electrodesSpiral groove bearingEngineering

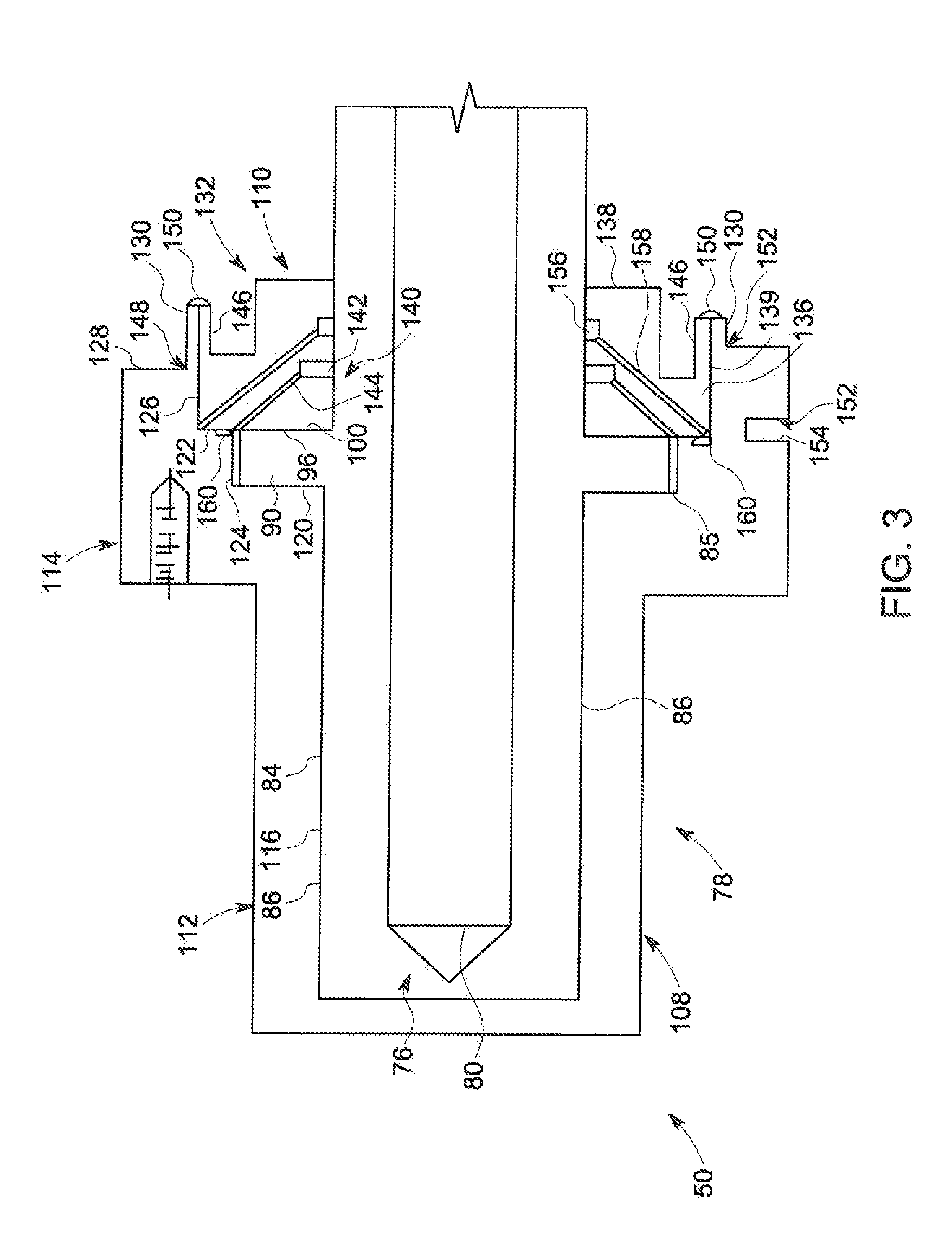

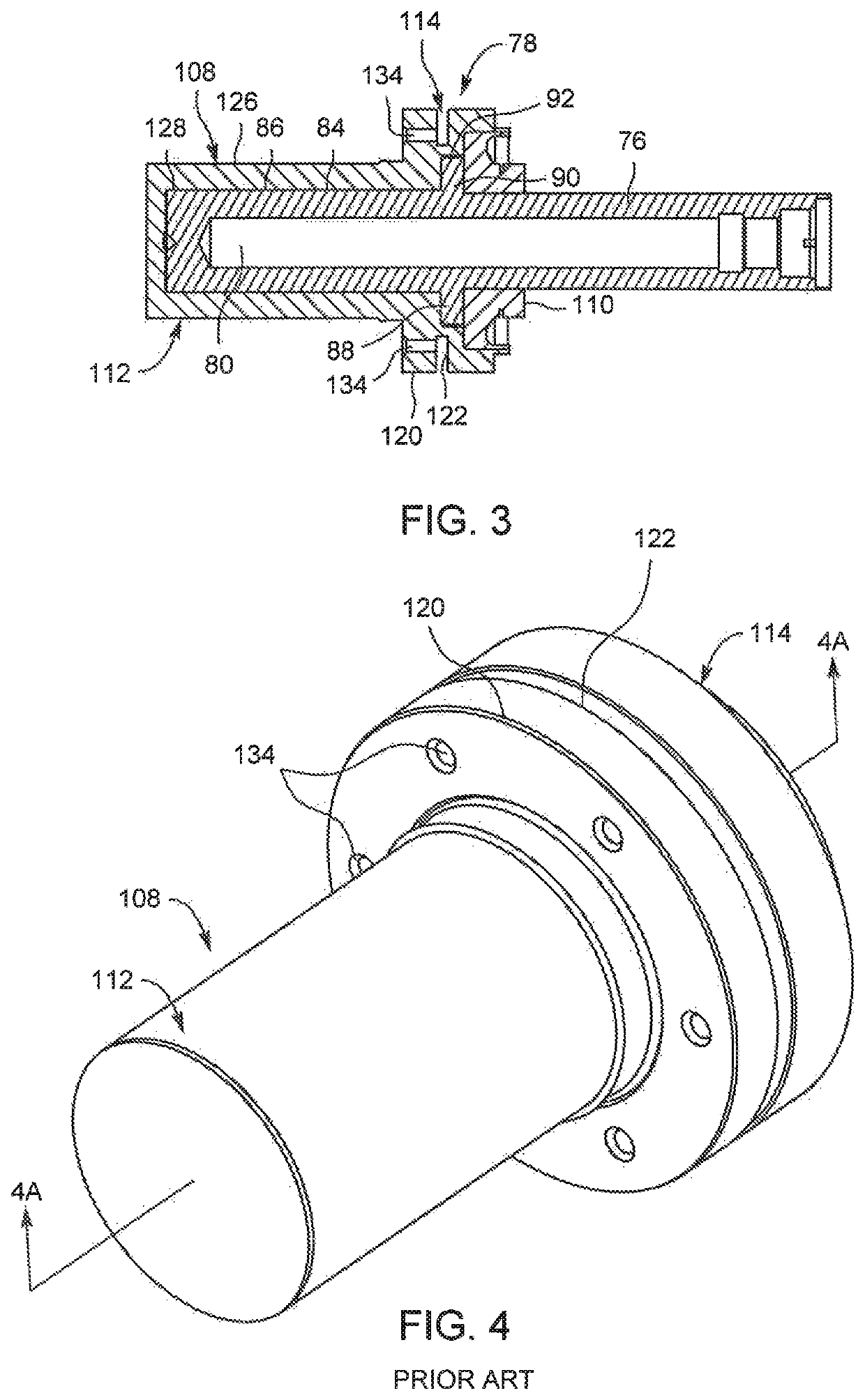

A liquid metal or spiral groove bearing structure for an x-ray tube and associated process for manufacturing the bearing structure is provided that includes a bearing shaft rotatably disposed in a bearing housing or shell. The shell includes a thrust seal engaged with a sleeve to maintain co-axiality for the rotating liquid metal seal formed in the shell about the shaft. The shaft has a bore for the introduction of a cooling fluid into the bearing assembly in which is disposed a cooling tube. The cooling tube includes turbulence-inducing features to increase the turbulence of the cooling fluid flowing through the cooling tube, consequently enhancing the heat exchange between the cooling fluid and the shaft. This maximizes the heat transfer from the shaft to the oil, allowing materials with lower thermal conductivities, such as non-refractory materials, to be used to form the bearing shaft and shell.

Owner:GENERAL ELECTRIC CO

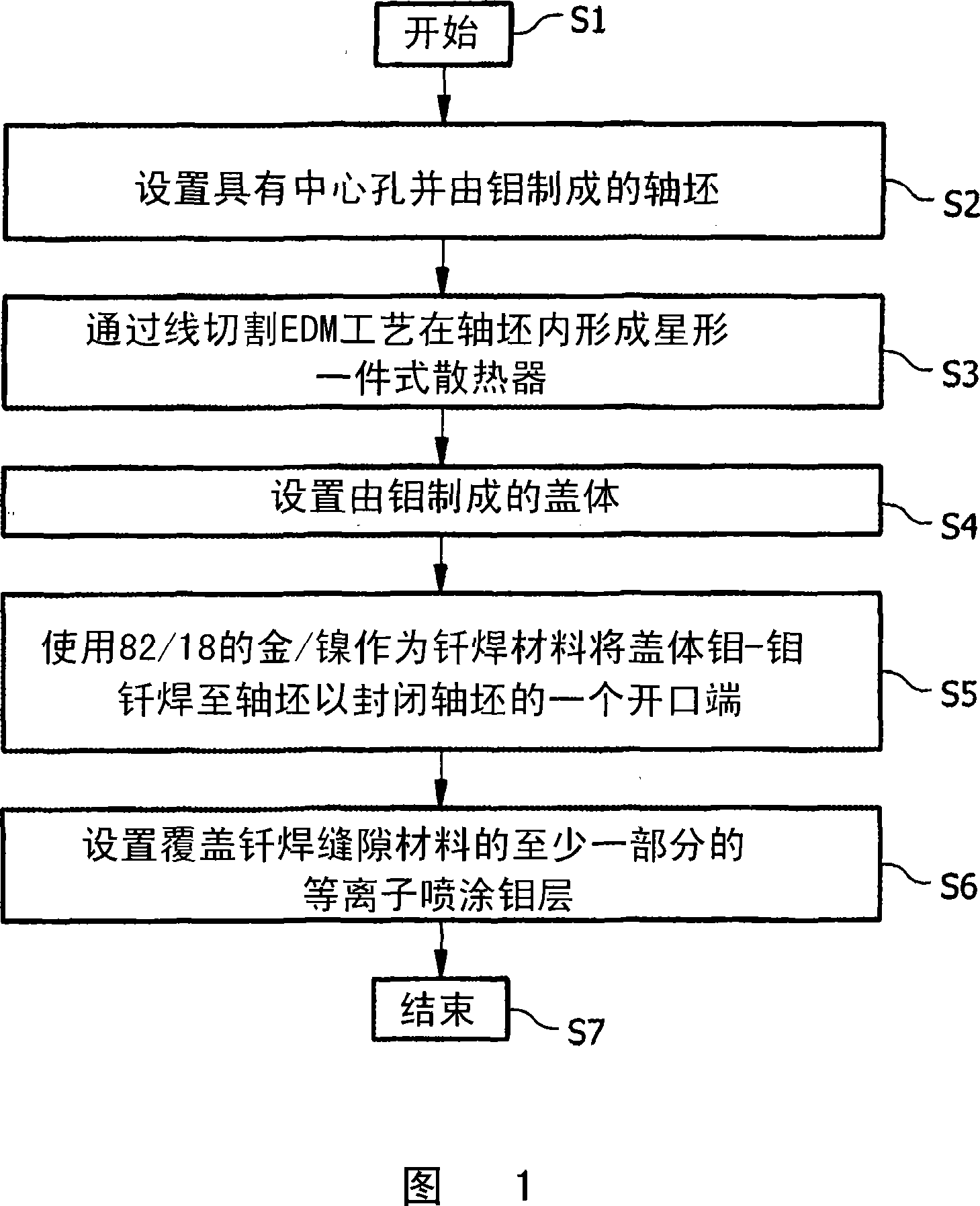

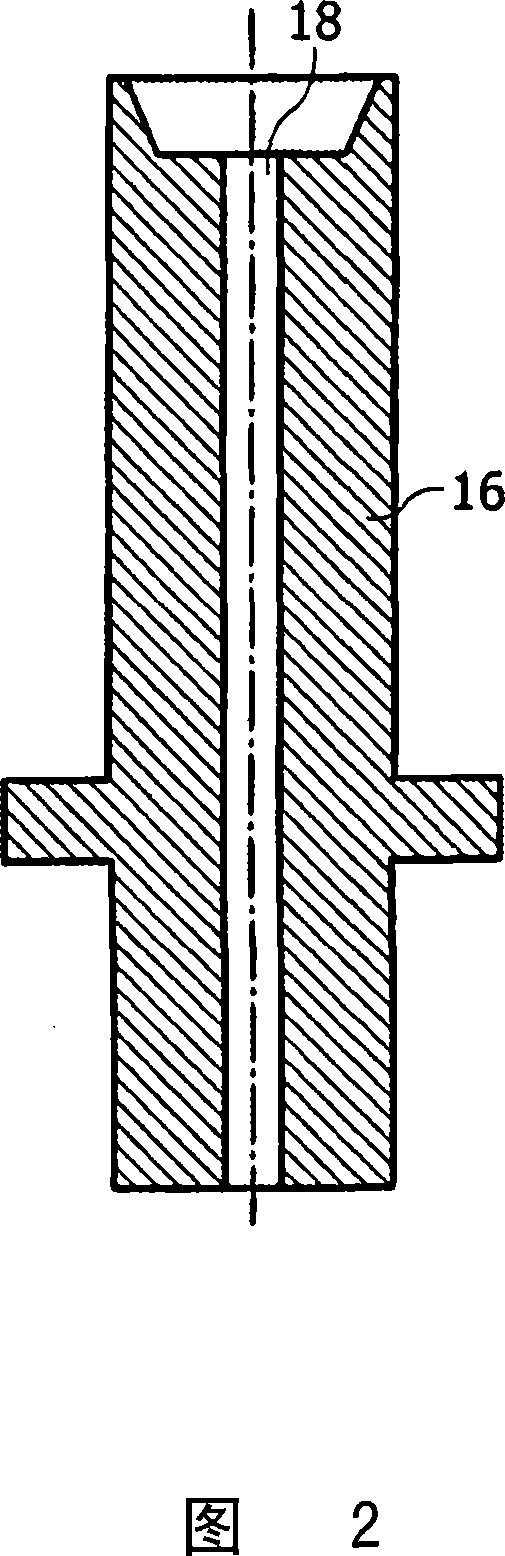

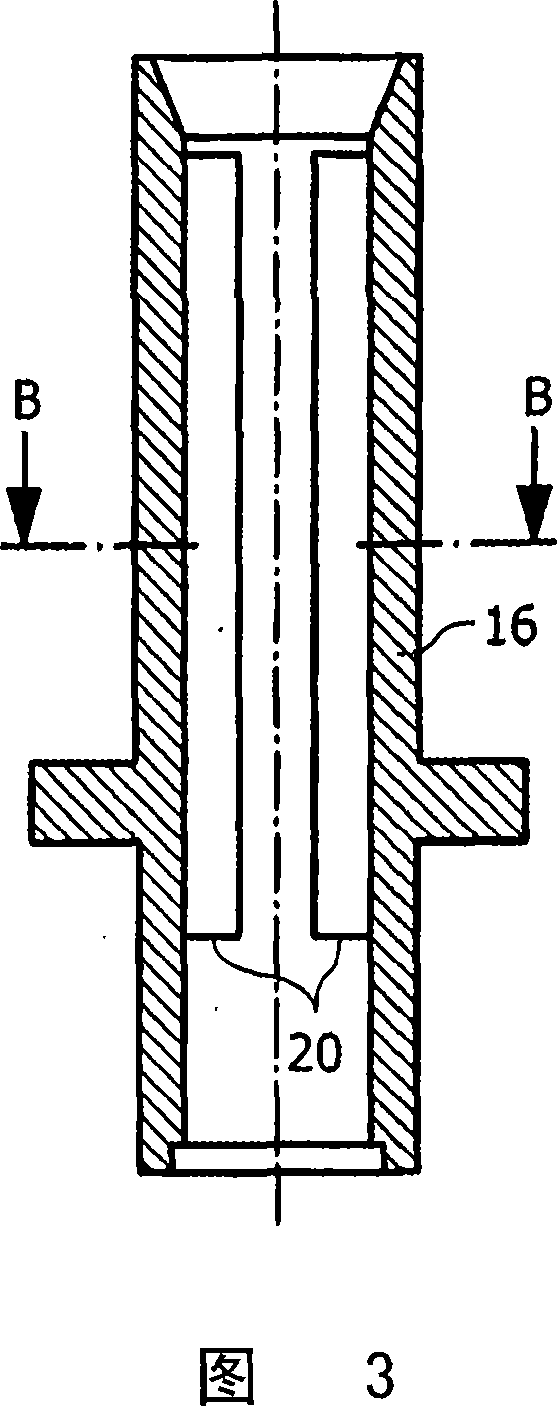

Molybdenum-molybdenum brazing and rotary-anode x-ray tube comprising such a brazing

The present invention relates to a method for providing a molybdenum-molybdenum or molybdenum aaloy-molybdenum alloy brazing. In accordance with the invention this method comprises the following steps: - providing at least two parts (16, 22) made of molybdenum or a molybdenum alloy; - brazing together said two parts (16, 22) using a brazing material (26); and - providing a plasma-sprayed molybdenum of molybdenum alloy layer (28) at least on a portion of the brazing material (26) that would be accessible otherwise. Furthermore, the present invention is directed to a rotary-anode X-ray tube (14) which is equipped with a spiral groove bearing (12) comprising, as a first part (16), an axle blank (16) having a center bore (18) and being made of molybdenum or a molybdenum alloy and, as a second part (22), a cap (22) made of molybdenum or an molybdenum alloy, wherein, for closing one open axial end (24) of said axle blank (16), said axle blank (16) and said cap (22) are brazed together using the method in accordance with the invention.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

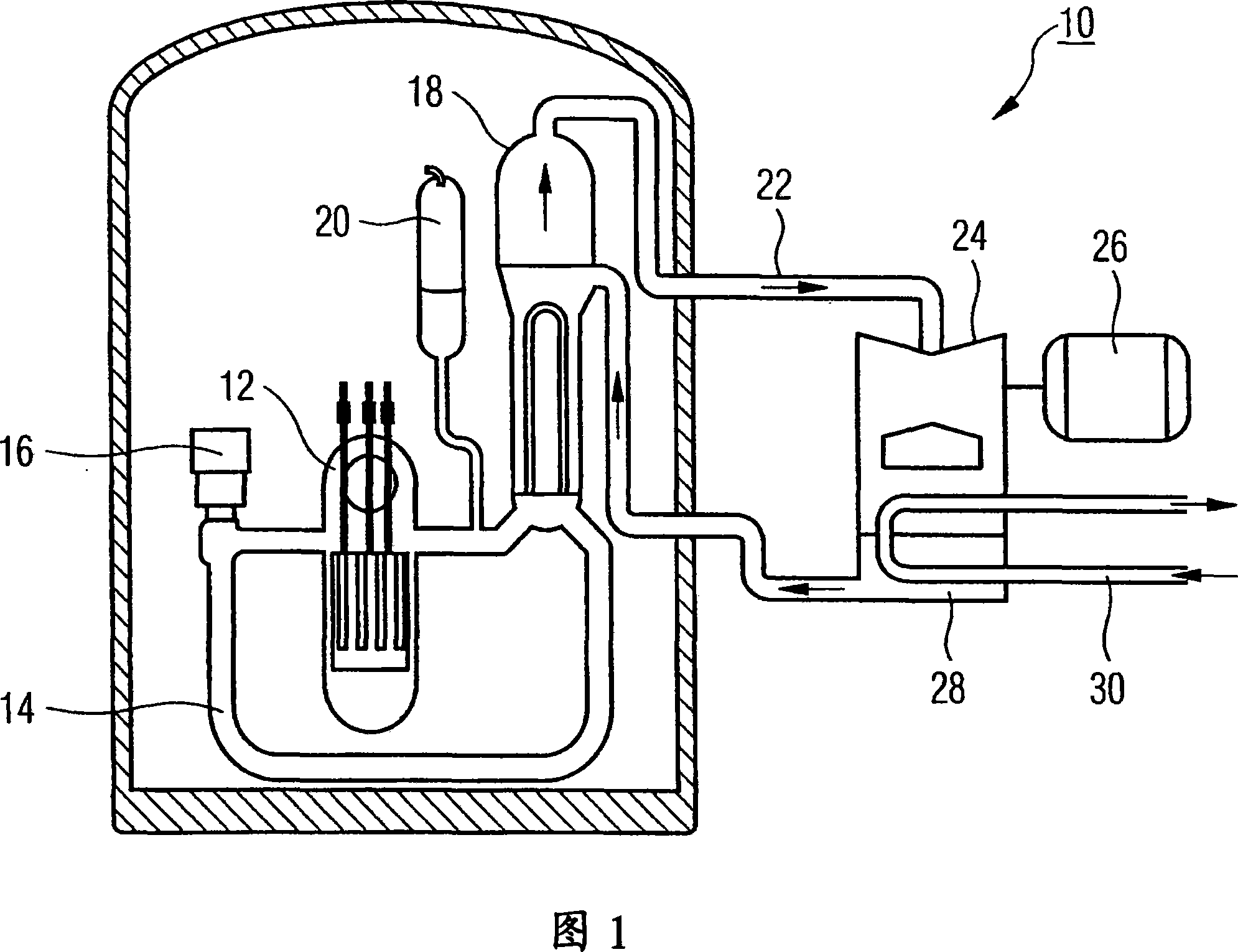

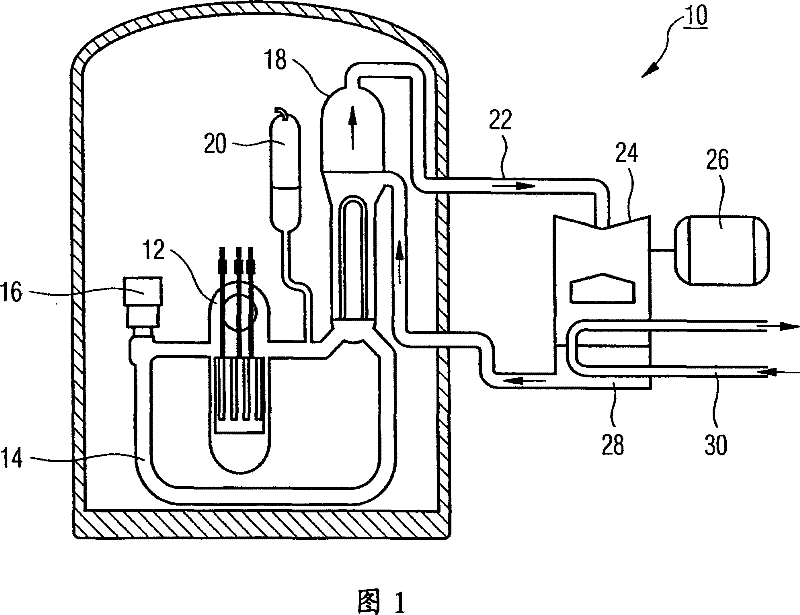

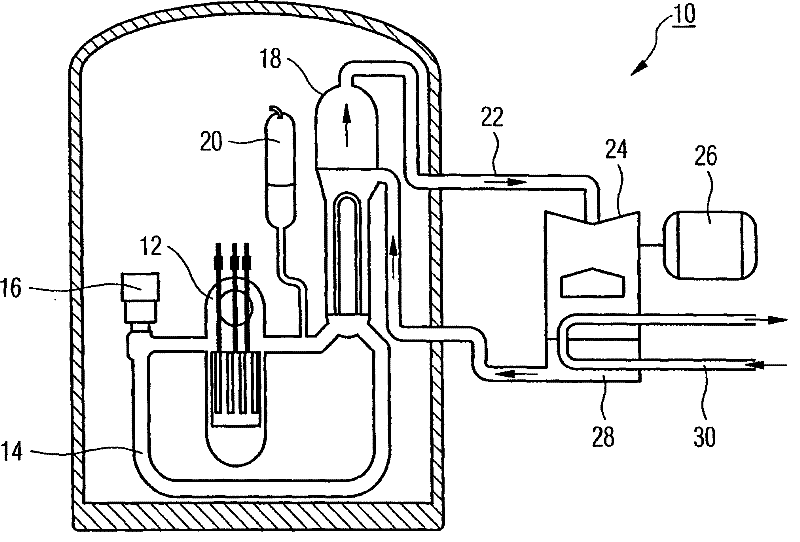

Pump unit for nuclear installations

InactiveCN101213615AAvoid half-frequency whirlAvoid contactPump componentsNuclear energy generationSpiral groove bearingPressurized water reactor

A pump unit for a nuclear installation, for example a pressurized water reactor, contains a vertical shaft, which is guided through at least one journal bearing. The journal bearing or bearings is or are configured as a spiral groove bearing or bearings, to prevent shaft vibration caused by the bearings and to increase the service life of the pump unit. Preferred uses of the pump units include, for example, the coolant pump of a pressurized water reactor and the circulating pump of a boiling water reactor.

Owner:FRAMATOME ANP

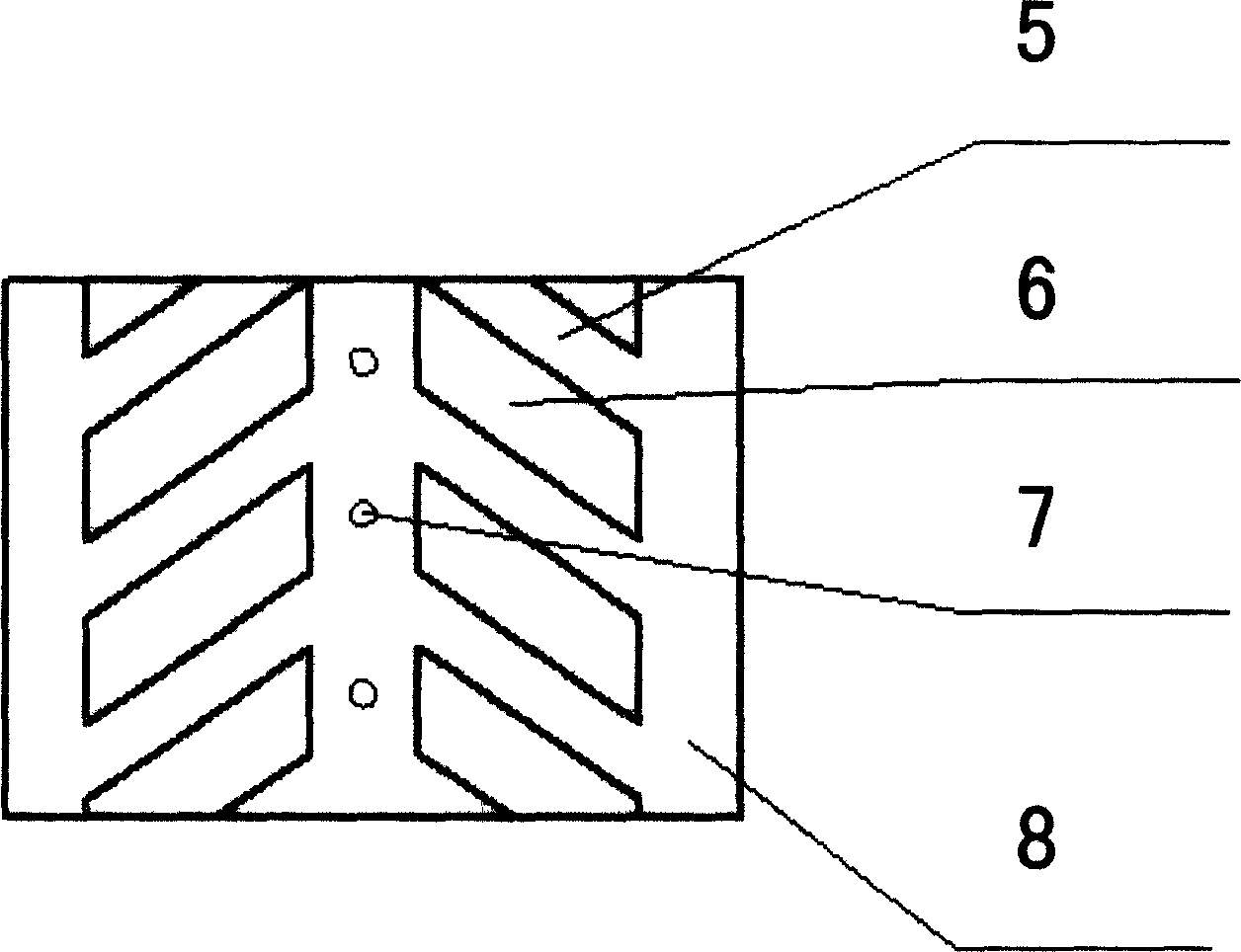

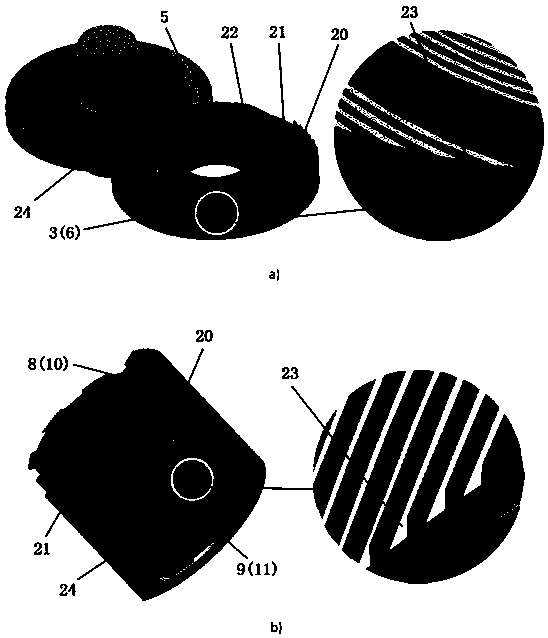

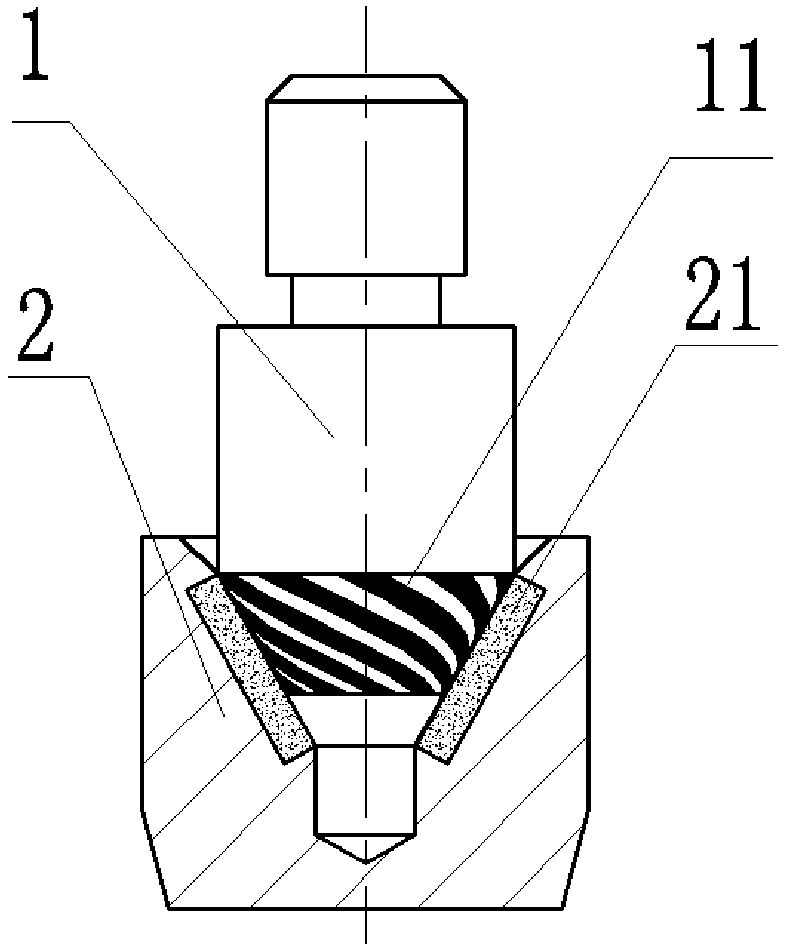

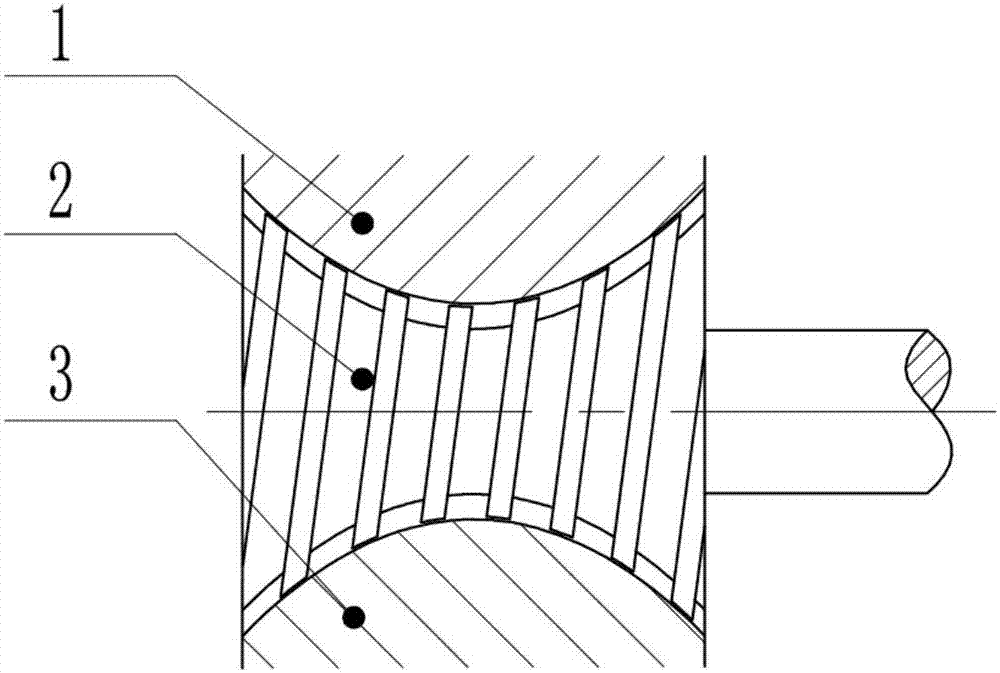

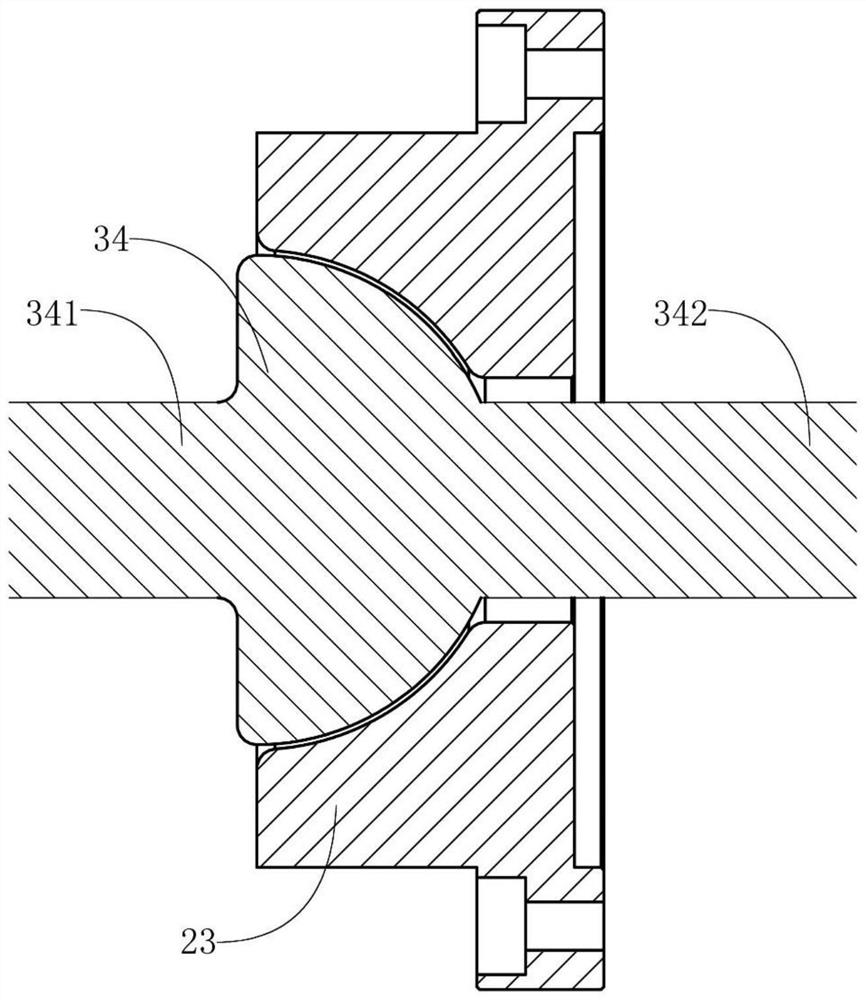

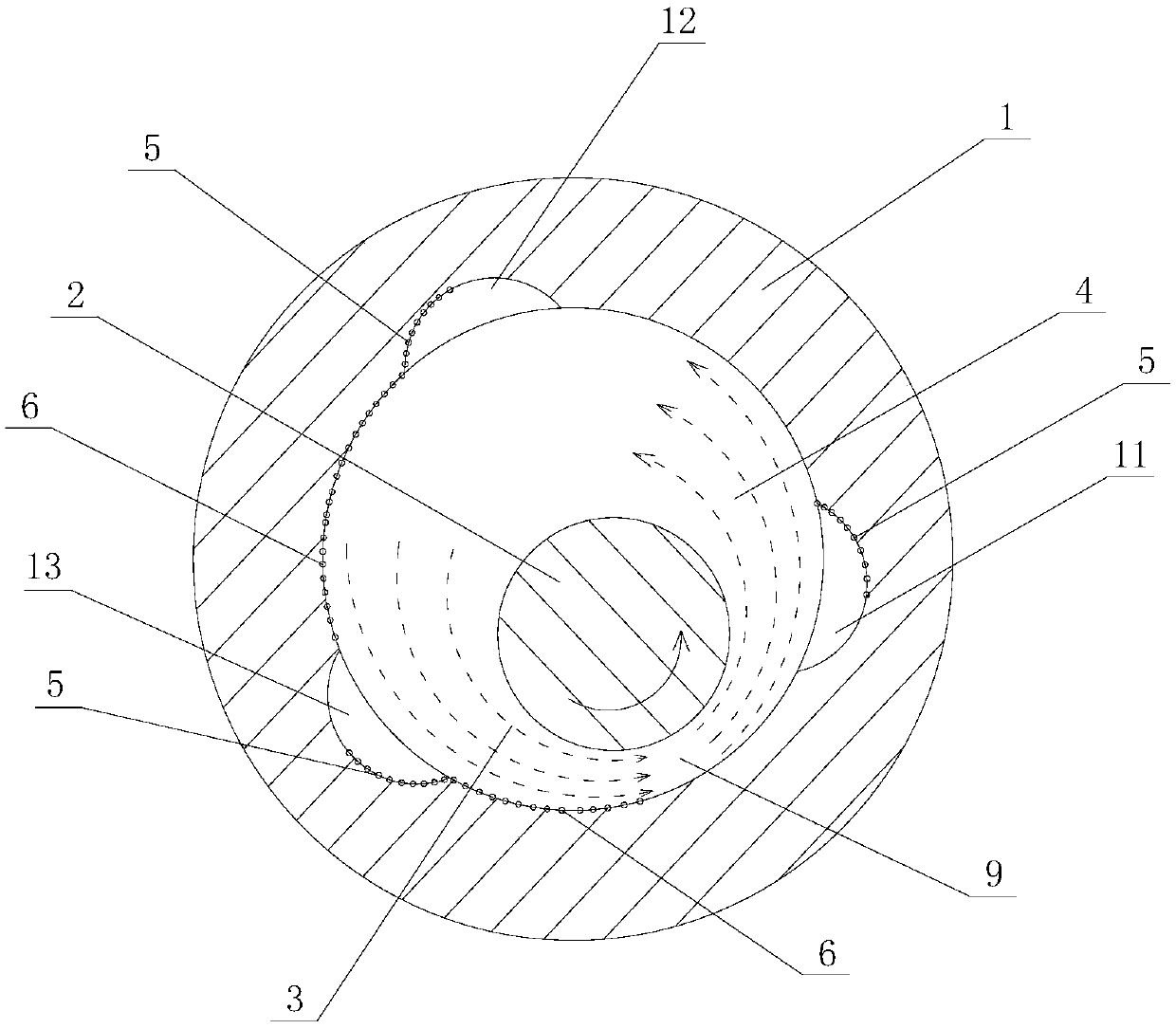

Conical dynamic pressure spiral groove bearing containing self-lubricating material

InactiveCN103322067AImprove carrying capacityImprove lubrication conditionsBearing unit rigid supportSpiral groove bearingLow speed

The invention discloses a conical dynamic pressure spiral groove bearing containing self-lubricating material, aiming at solving the problem of adhesive wear of a conical dynamic pressure spiral groove bearing at present. According to the invention, the lubrication condition of the conical dynamic pressure spiral groove bearing is improved at the low-speed and heavy-load working conditions, and the bearing performance of the conical dynamic pressure spiral groove bearing is further improved. The surface, which is in contact with a bearing main shaft (1), of a self-lubrication bearing seat (2) is provided with a conical concave pit, and the surface, which is in contact with the self-lubrication bearing seat (2), of the bearing main shaft (1) is provided with a conical body meshed with the self-lubrication bearing seat (2); the surface of the conical body of the bearing main shaft (1) is provided with a spiral groove (11); the self-lubrication material is adopted by the self-lubrication bearing seat (2), or a self-lubrication material coating (21) is prepared on the conical contact surface of the bearing seat.

Owner:SOUTHEAST UNIV

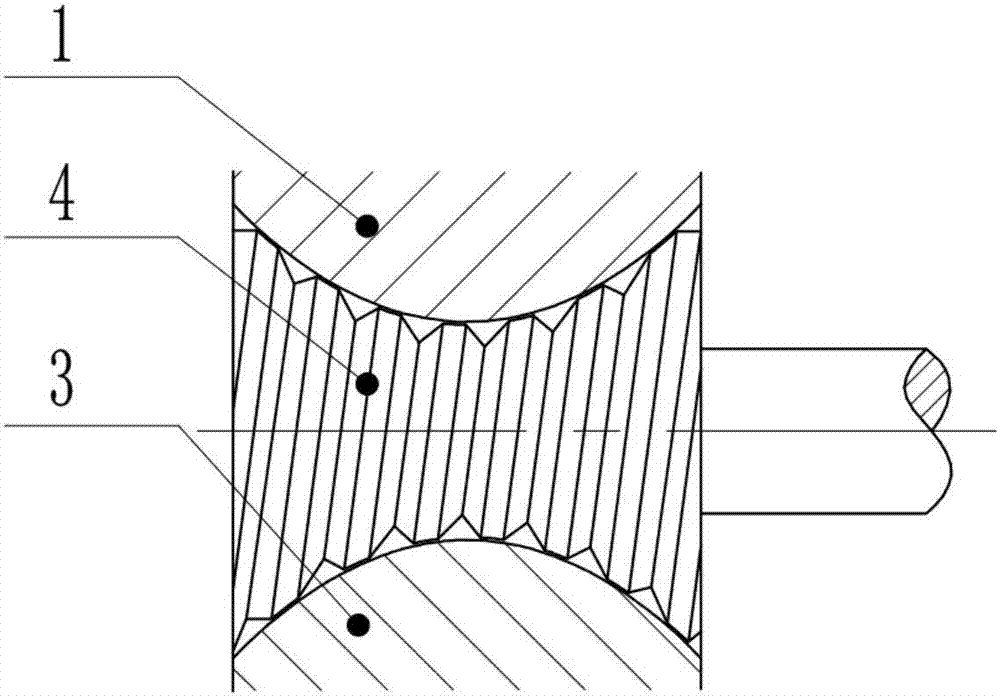

Bionic variable-structure cone spiral groove bearing

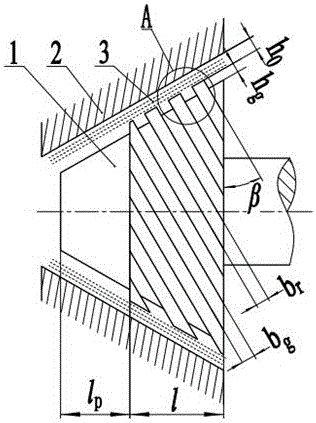

PendingCN106763150AResolve frictionSolve problems such as serious wear and teShaftsRotary machine partsGroove widthSpiral groove bearing

The invention discloses a bionic variable-structure cone spiral groove bearing comprising a bearing main shaft and a bearing pedestal. The end, matched with the bearing pedestal, of the bearing main shaft is a cone. Multiple variable-structure spiral grooves are formed in the conical face close to the large end face side of the cone. The space between the bearing pedestal and the bearing main shaft is full filled with a lubricating agent. The multiple variable-structure spiral grooves are variable-groove-depth spiral grooves or variable-spiral-angle spiral grooves or variable-groove-width spiral grooves or a combination with the spiral groove depth, the spiral angle and the spiral groove width each linearly changing. By means of the special distribution rule of the spiral grooves, dynamic pressure lubrication and hydrostatic lubrication both exist when the bearing works, the fluid lubrication performance is improved, the lubrication effect is enhanced, and the problems that a traditional cone spiral groove bearing is poor in dynamic pressure lubrication performance, large in friction torque and severe in abrasion when the speed is low are solved. Direct contact of the bearing main shaft and the bearing pedestal during work is reduced, precision can be kept for a long time, and the service life of the bearing is prolonged.

Owner:ZHEJIANG UNIV

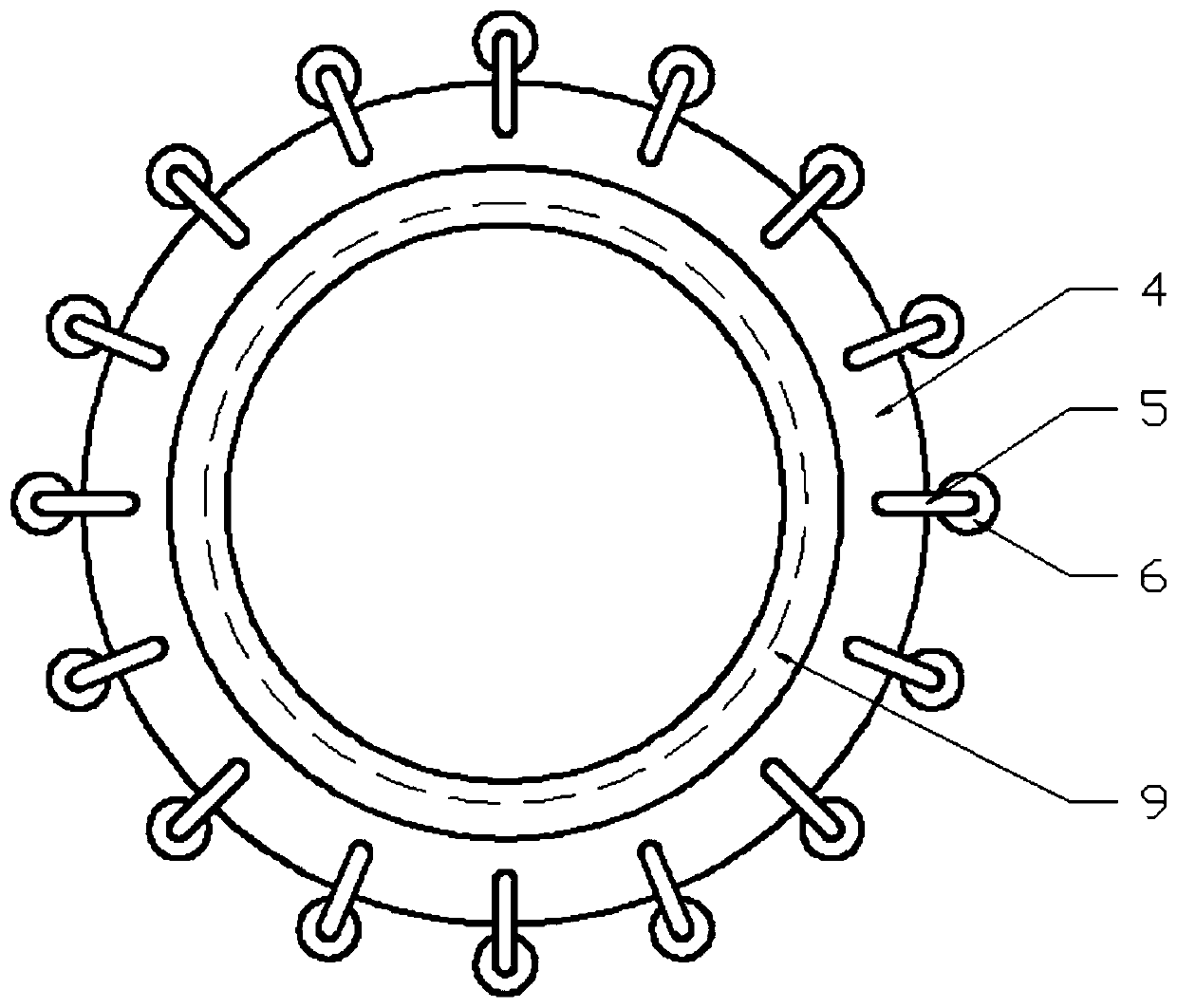

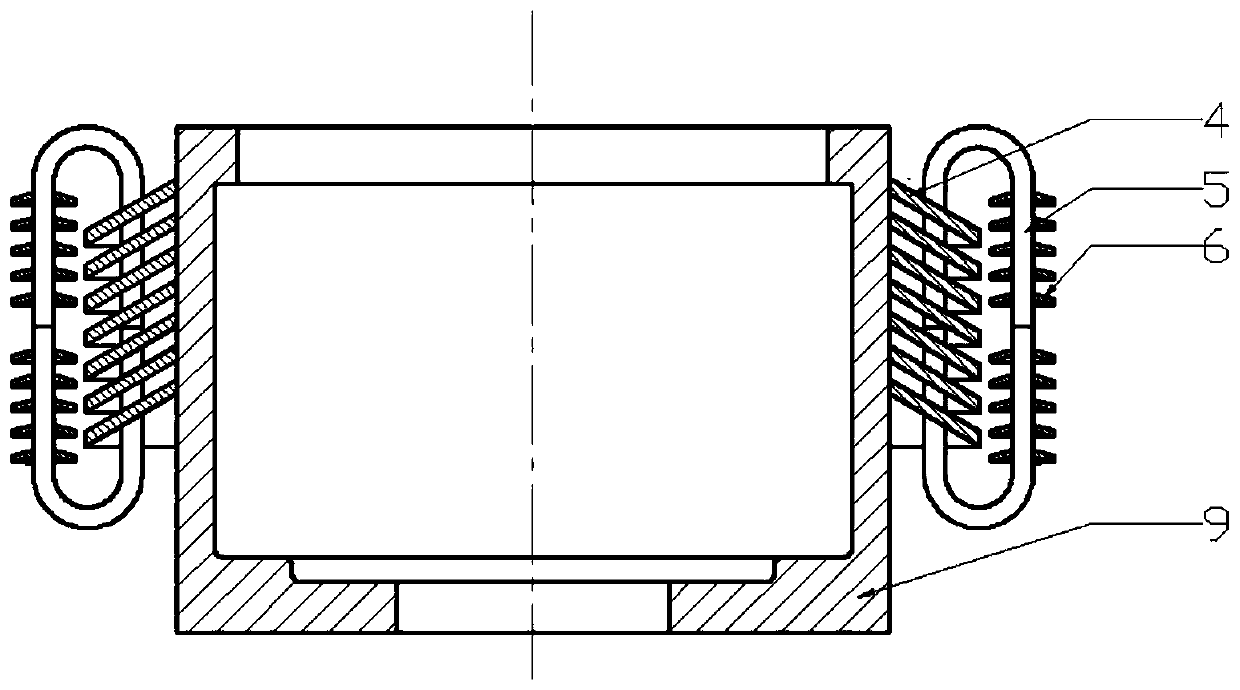

Heat pipe auxiliary type heat dissipation system for cooling bearing on high-temperature molten salt pump

PendingCN111288022AImprove cooling effectImprove heat transfer efficiencyPump componentsPumpsSpiral groove bearingMolten salt

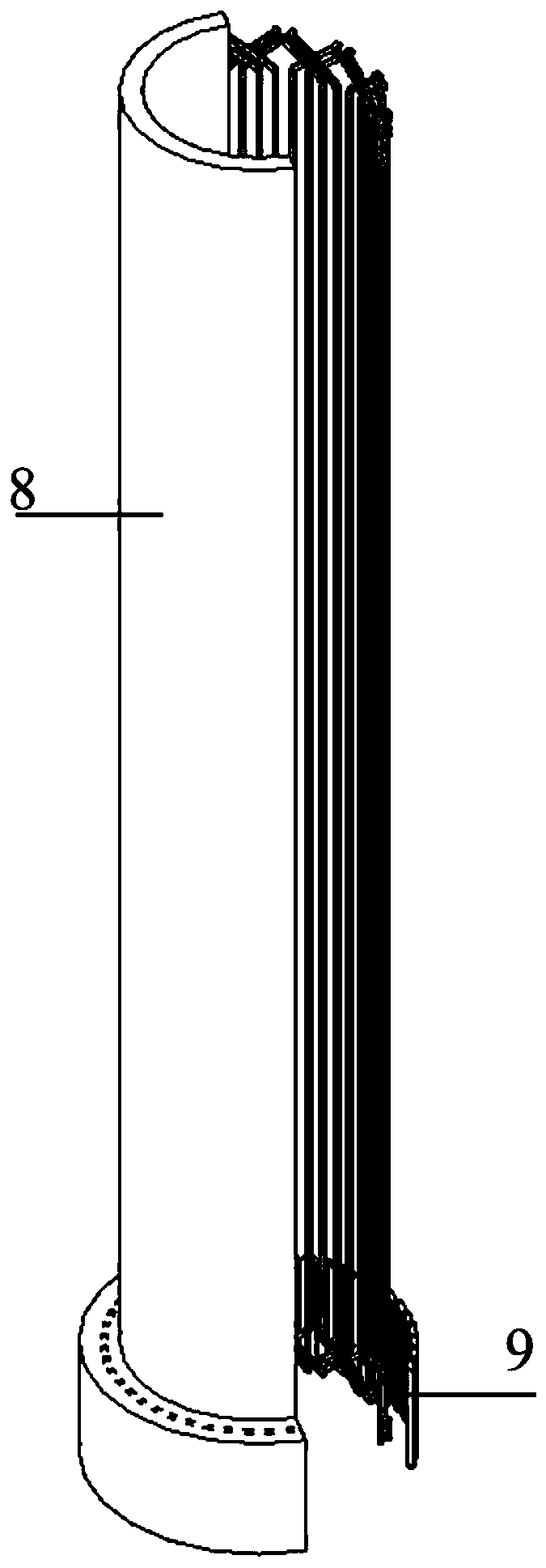

The invention relates to a high-temperature molten salt pump, in particular to a heat pipe auxiliary type heat dissipation system for cooling a bearing on the high-temperature molten salt pump. The heat pipe auxiliary type heat dissipation system comprises a bearing box, a heat exchange system and an air cooling system, wherein the heat exchange system is formed by welding a main radiating fin, aU-shaped heat pipe and an umbrella-shaped radiating fin; the air cooling system comprises an upper wind wheel, a lower wind wheel, a cover cylinder, a spiral flow deflector and a continuous spiral groove. A bearing is installed in the bearing box, main radiating fins are arranged on the outer wall of the bearing box, the main radiating fins are vertically provided with holes to be installed into apair of U-shaped heat pipes, and the umbrella-shaped radiating fins are evenly arranged on the periphery of the condensation end; the upper wind wheel is arranged at the upper end of the pump shaft,and the lower wind wheel is arranged at the lower end of the pump shaft; the spiral flow deflectors are arranged on the inner wall of the cover cylinder to form the continuous spiral groove; air holes are formed in the motor base, and airflow can be discharged from the air holes and is further discharged out of the system through the lower wind wheel. The heat pipe is used for assisting the finsto dissipate heat, the spiral flow deflector is additionally arranged to be matched with the cover cylinder to form a controllable air duct, heat in the system is discharged, and therefore the servicelife of the bearing is guaranteed.

Owner:JIANGSU UNIV

Floating-assisted type bearing and using method thereof

The invention discloses a floating-assisted type bearing and a using method thereof. The bearing comprises a main shaft, a one-way valve and a pressurizing floating-assisted device. A first oil storage cavity, a valve front cavity and a valve rear cavity are formed in the one-way valve, and a valve element of the one-way valve is used for enabling lubricating oil in the valve front cavity to enter the valve rear cavity in a one-way mode. The main shaft and the one-way valve are rotatably connected to form a conical surface bearing, a first pumping type groove is formed in the connecting conical surface of the main shaft and the one-way valve, and when the main shaft rotates, the lubricating oil in the first oil storage cavity is pumped into the valve rear cavity. And an output port of the pressurizing floating-assisted device is communicated with the valve front cavity through a pipeline and is used for opening the one-way valve. In the starting or halting stage of the main shaft, the pressurizing floating-assisted device is started, so that an oil film is formed on the connecting conical surface of the main shaft and the one-way valve, and the friction force of the conical surface spiral groove bearing in the starting or halting stage is reduced.

Owner:NANYANG INST OF TECH

Hyperboloid spiral groove bearing

PendingCN106870563AImprove carrying capacityGood symmetryBearing coolingBearing unit rigid supportSpiral groove bearingEngineering

The invention discloses a hyperboloid spiral groove bearing which comprises an upper bearing pedestal, a bearing main shaft and a lower bearing pedestal. The outer surface, matched with the upper bearing pedestal and the lower bearing pedestal, of the bearing main shaft is a rotary uniparted hyperboloid, and the rotary uniparted hyperboloid is provided with spiral grooves, and therefore the hyperboloid spiral groove bearing is formed. Compared with a common spiral groove bearing, the hyperboloid spiral groove bearing has the better stability and heat dissipation ability, the using requirements for a lubricating agent are lowered, the bearing can bear both the radial load and the axial load of two ends, and the bearing capacity of the bearing is improved.

Owner:ZHEJIANG UNIV

Cooling spiral groove bearing assembly

ActiveUS10460901B2Increased turbulenceSpeed up heat exchangeX-ray tube anode coolingX-ray tube electrodesSpiral groove bearingLiquid metal

A liquid metal or spiral groove bearing structure for an x-ray tube and associated process for manufacturing the bearing structure is provided that includes a bearing shaft rotatably disposed in a bearing housing or shell. The shell includes a thrust seal engaged with a sleeve to maintain co-axiality for the rotating liquid metal seal formed in the shell about the shaft. The shaft has a bore for the introduction of a cooling fluid into the bearing assembly in which is disposed a cooling tube. The cooling tube includes turbulence-inducing features to increase the turbulence of the cooling fluid flowing through the cooling tube, consequently enhancing the heat exchange between the cooling fluid and the shaft. This maximizes the heat transfer from the shaft to the oil, allowing materials with lower thermal conductivities, such as non-refractory materials, to be used to form the bearing shaft and shell.

Owner:GENERAL ELECTRIC CO

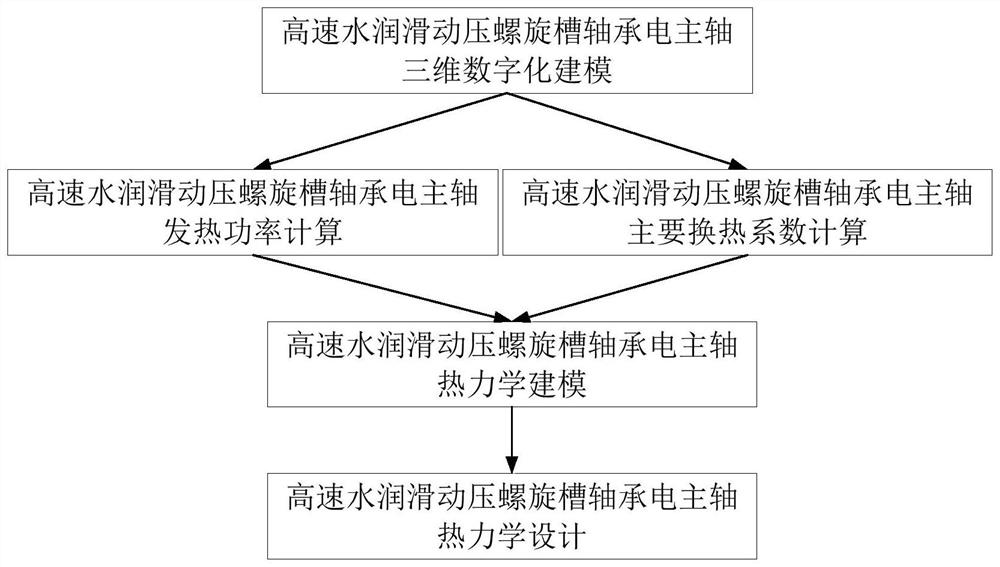

Water-lubricated spiral groove bearing heating power calculation method and electric spindle thermal design method

PendingCN114444221AImprove accuracyIncrease success rateGeometric CADDesign optimisation/simulationThermal stateSpiral groove bearing

The invention provides a thermal design method for a high-speed water-lubricated dynamic pressure spiral groove bearing motorized spindle. The thermal design method comprises the following steps that 1, the heating power of a main heat source of the high-speed water-lubricated dynamic pressure spiral groove bearing motorized spindle and the heat exchange coefficient of each heat exchange surface are calculated; step 2, establishing a thermodynamic model of the high-speed water-lubricated dynamic-pressure spiral groove bearing motorized spindle, and performing performance analysis; and 3, determining design parameters of the high-speed water-lubricated dynamic-pressure spiral groove bearing electric spindle according to a performance analysis result in the step 2. According to the thermodynamic modeling and thermal design method for the high-speed water-lubricated dynamic pressure spiral groove bearing motorized spindle structure, an effective means is provided for thermodynamic modeling and thermal state design of the high-speed water-lubricated dynamic pressure spiral groove bearing motorized spindle structure, forward design of the motorized spindle is facilitated, the one-time design success rate is increased, and the design efficiency is improved. The design period is shortened.

Owner:SOUTHEAST UNIV

A low-loss high-speed integrated flywheel energy storage motor

ActiveCN107482841BReduce lossHarmonic reductionMechanical energy handlingSpiral groove bearingFlywheel energy storage

The present invention discloses a low-loss and high-speed integrated flywheel energy storage motor. The motor comprises a flywheel outer rotor, an excitation permanent magnet, an inner rotor, a motor bearing and a hollow core stator. The flywheel outer rotor is configured to store energy when rotation, the excitation permanent magnet is pasted at the surface of the inner side of the flywheel outer rotor to supply an excitation field for a motor; the hollow core stator is arranged between the inner rotor and the flywheel outer rotor, the air-gap winding in the hollow core stator is arranged along the direction of a rotation shaft, the motor bearing comprises a magnetic suspension bearing and a spiral groove bearing, the bottom of the inner rotor is connected with the rotation portion of the spiral groove bearing, and the upper portion of the boss of the inner rotor is connected with the rotation portion of the magnetic suspension bearing. The low-loss and high-speed integrated flywheel energy storage motor employs a mode of combination of an outer rotor structure, the excitation permanent magnet, the air-gap winding, the passive magnetic suspension bearing and the spiral groove bearing to allow the motor to reach low loss while high-speed operation and zero load energy storage maintenance.

Owner:中能(深圳)能源科技发展有限公司

Test device for axial load capacity of conical dynamic pressure spiral groove bearing

ActiveCN103335845BEasy to testAvoid shock loadsMachine bearings testingSpiral groove bearingDrive shaft

The invention discloses a device for testing axial bearing capacity of a conical dynamic-pressure spiral groove bearing. The device for testing the axial bearing capacity of the conical dynamic-pressure spiral groove bearing consists of a mechanical part and an electrical control part; a high-frequency motor (1) is mounted at the upper part of a test device frame (12); a transmission shaft (2) is mounted at the lower part of the high-frequency motor; a tested bearing (3) is mounted below the transmission shaft; a bearing base (5) is mounted inside a bearing race (6); the bearing race is positioned inside a loading sleeve (11) at the upper part of a gasket (4); the loading sleeve is mounted inside a split positioning ring (9); a ball (10) is mounted inside a rectilinear runner of the split positioning ring; the split positioning ring is mounted at the bottom of the test device frame (12); a loading lever (8) is mounted at the bottom of the test device frame (12); a weight is arranged at the outer end of the loading lever; the inner end of the loading lever is arranged below the loading sleeve; the inner end of a strain beam (13) is embedded into a U-shaped groove of the loading sleeve; the outer end of the strain beam is connected with a dynamic and static strain testing system of the electrical control part.

Owner:SOUTHEAST UNIV

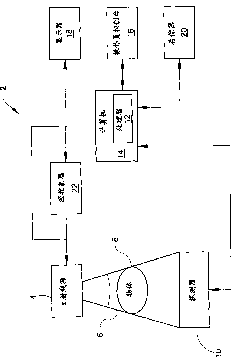

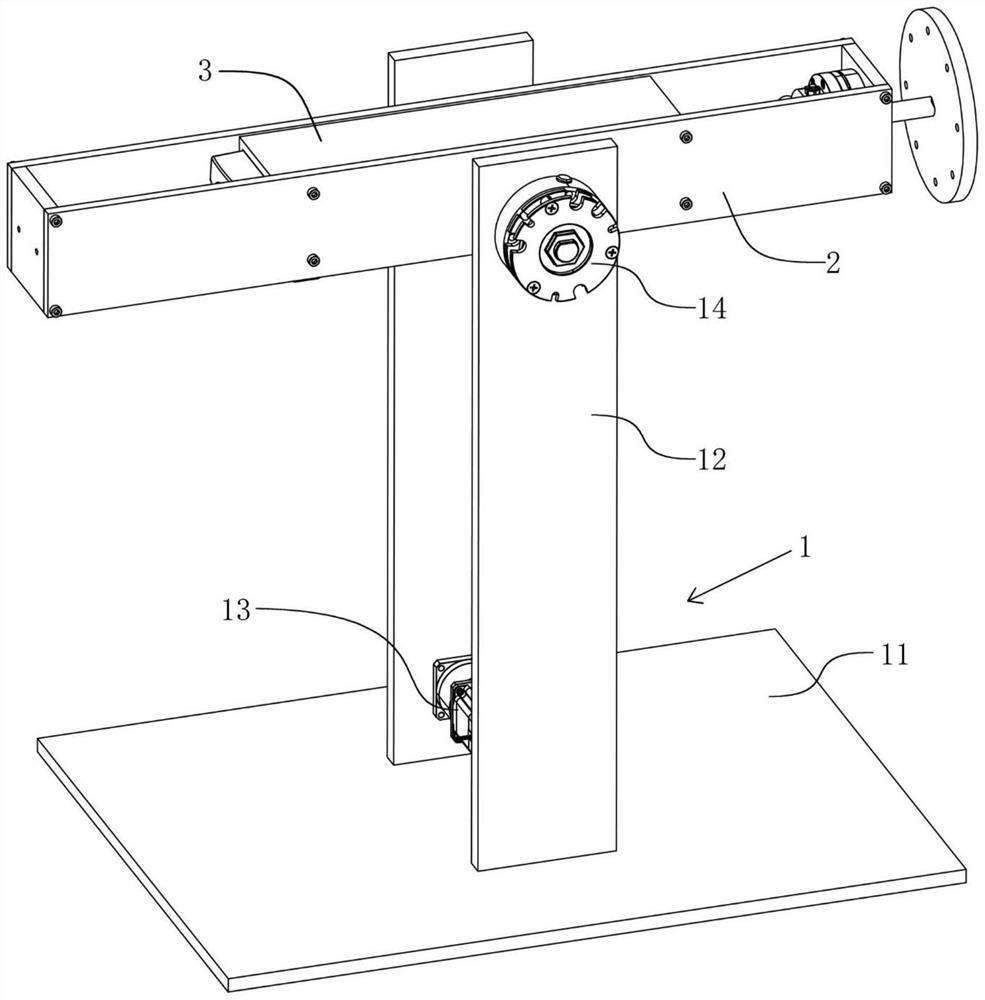

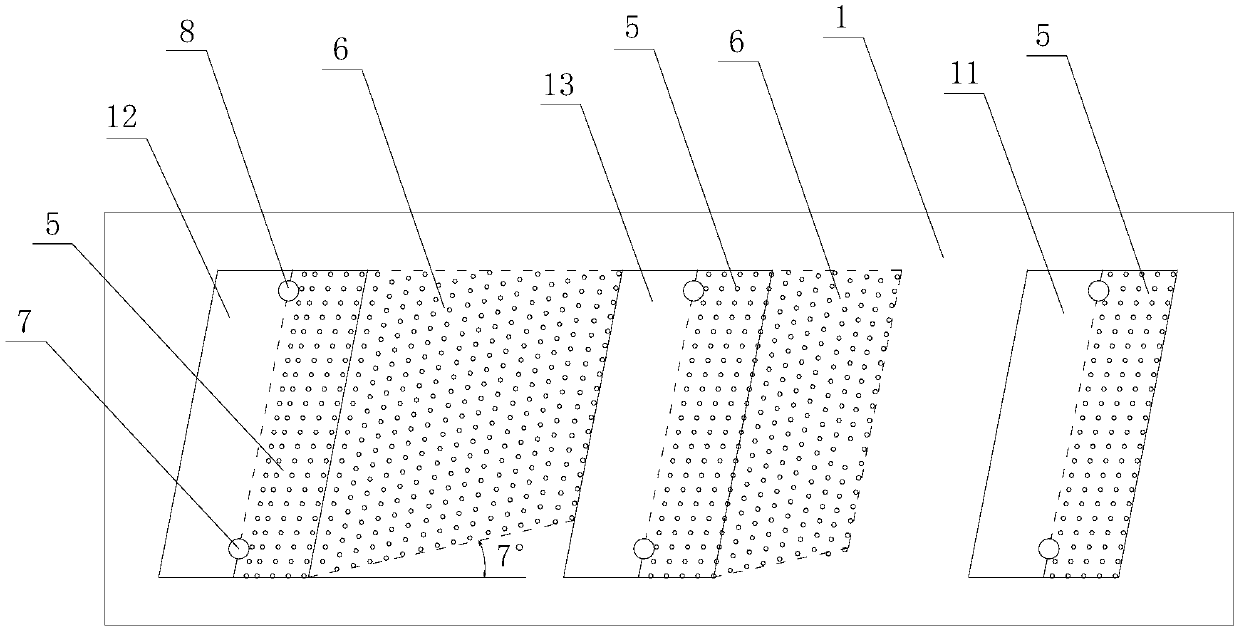

Spiral groove gas dynamic pressure bearing test device

The invention provides a spiral groove gas dynamic pressure bearing test device, and belongs to the technical field of spiral groove bearing detection. The spiral groove gas dynamic pressure bearing testing device comprises a spiral groove gas dynamic pressure bearing to be tested, the spiral groove gas dynamic pressure bearing comprises a stator and a rotor which are arranged in a matched mode, and a driving shaft is coaxially arranged on the side, away from the stator, of the rotor; the device further comprises a rack unit, a positioning unit, a driving unit and a control analysis unit, the rack unit comprises a supporting base, a rotating support and a bearing support, the positioning unit is used for controlling the inclination angle of the rotating support, and the driving unit is used for driving the rotor to rotate. The control analysis unit comprises a control mechanism, a torque sensor and a vibration sensor. The friction performance and the stability performance of the spiral groove gas dynamic pressure bearing can be tested and displayed, the gas lubrication characteristic, the dynamic stability and other characteristics of the bearing can be visually displayed to students, and a simulation verification test can also be carried out.

Owner:XINYANG VOCATIONAL & TECHN COLLEGE

Combined sliding surface spiral groove bearing

PendingCN109681523AReduce frictional resistanceReduce frictional power consumptionShaftsRotary machine partsSpiral groove bearingMechanical engineering

The invention discloses a combined sliding surface spiral groove bearing. A bearing bush and a rotation shaft are included. The rotation shaft is arranged in the bearing bush and is in clearance fit with the bearing bush. In the usage state, the axis of the rotation shaft is located below one side of the axis of the bearing bush, and an oil convergence area and an oil divergence area are formed bythe gap between the bearing bush and the rotation shaft in the rotation direction of the rotation shaft. A plurality of oil cavities are sequentially formed in the inner wall of the bearing bush at intervals in the circumference direction. Each oil cavity is internally provided with an oil inlet and an oil outlet. Sliding coating areas are arranged in all the oil cavities, the sliding coating areas located in the oil cavities in the convergence area extend in the rotation direction of the rotation shaft, and a sliding coating extension area is formed in the inner wall of the bearing bush. Coatings of the sliding coating areas and the sliding coating extension area are fluorocarbon coatings. The sliding character of the fluorocarbon coatings is utilized in the combined sliding surface spiral groove bearing, friction resistance is reduced, oil film inner friction power consumption is reduced, the oil film pressure and the end release amount are increased, heat is rapidly brought away, temperature rise of the bearing in the high-speed rotation process is restrained, and the bearing force for high-speed bearing rotation is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Welded spiral groove bearing assembly

ActiveUS9972472B2Structure miniaturizationLow costBearing assemblyX-ray tube electrodesSpiral groove bearingEngineering

A structure and associated method for forming a liquid metal or spiral groove bearing assembly for an x-ray tube is illustrated that utilizes a unitary sleeve and a thrust ring or seal each formed of a weldable, non-refractory material. The sleeve and the thrust seal are welded to one another to provide an improved construction for minimizing leaks of the liquid metal bearing fluid. The structure of the sleeve and the thrust seal are formed with deformation restricting features that maintain the integrity of the bearing surfaces of the assembly when the thrust seal is secured within the sleeve and welded thereto to form the bearing assembly.

Owner:GENERAL ELECTRIC CO

Pump unit for nuclear installations

InactiveCN101213615BAvoid half-frequency whirlAvoid contactPump componentsNuclear energy generationSpiral groove bearingPressurized water reactor

The invention relates to a pump device (16) for a nuclear equipment (10) (such as water pressing reaction pile). The pump device is provided with a vertical axle (standing axle) which is guided through a sliding bearing. In the pump device, at least one sliding bearing is designed to helix groove bearing to avoid the axle vibration caused by the bearing and improve the service life of the pump device. For instance, the pump device (16) is preferably used as the cooling agent pump of the water pressing reaction pile and the cycle of the boiling water reaction pile.

Owner:FRAMATOME ANP

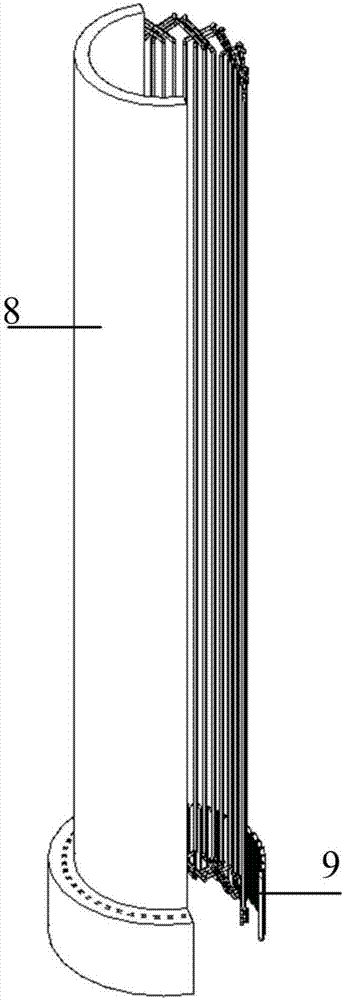

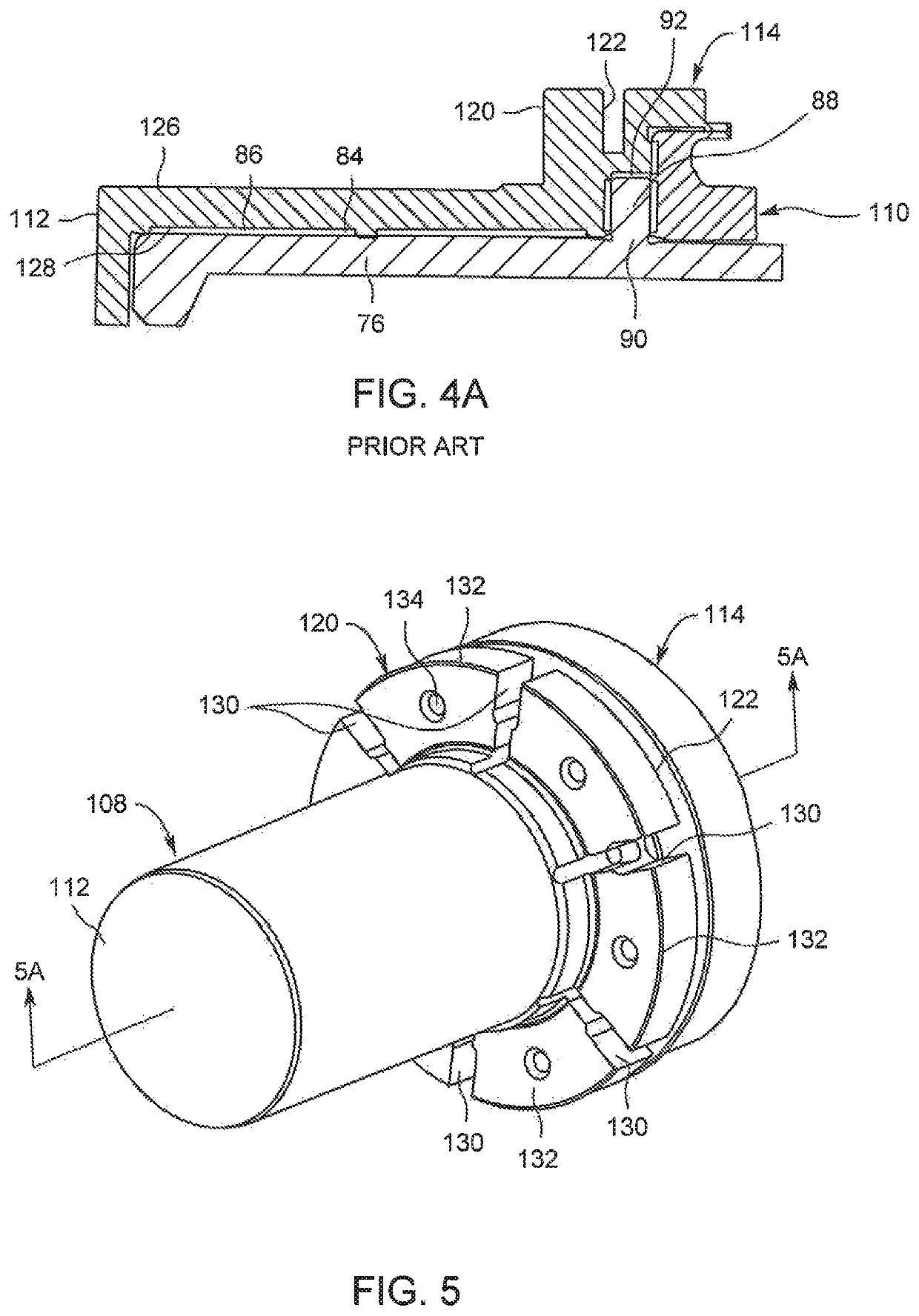

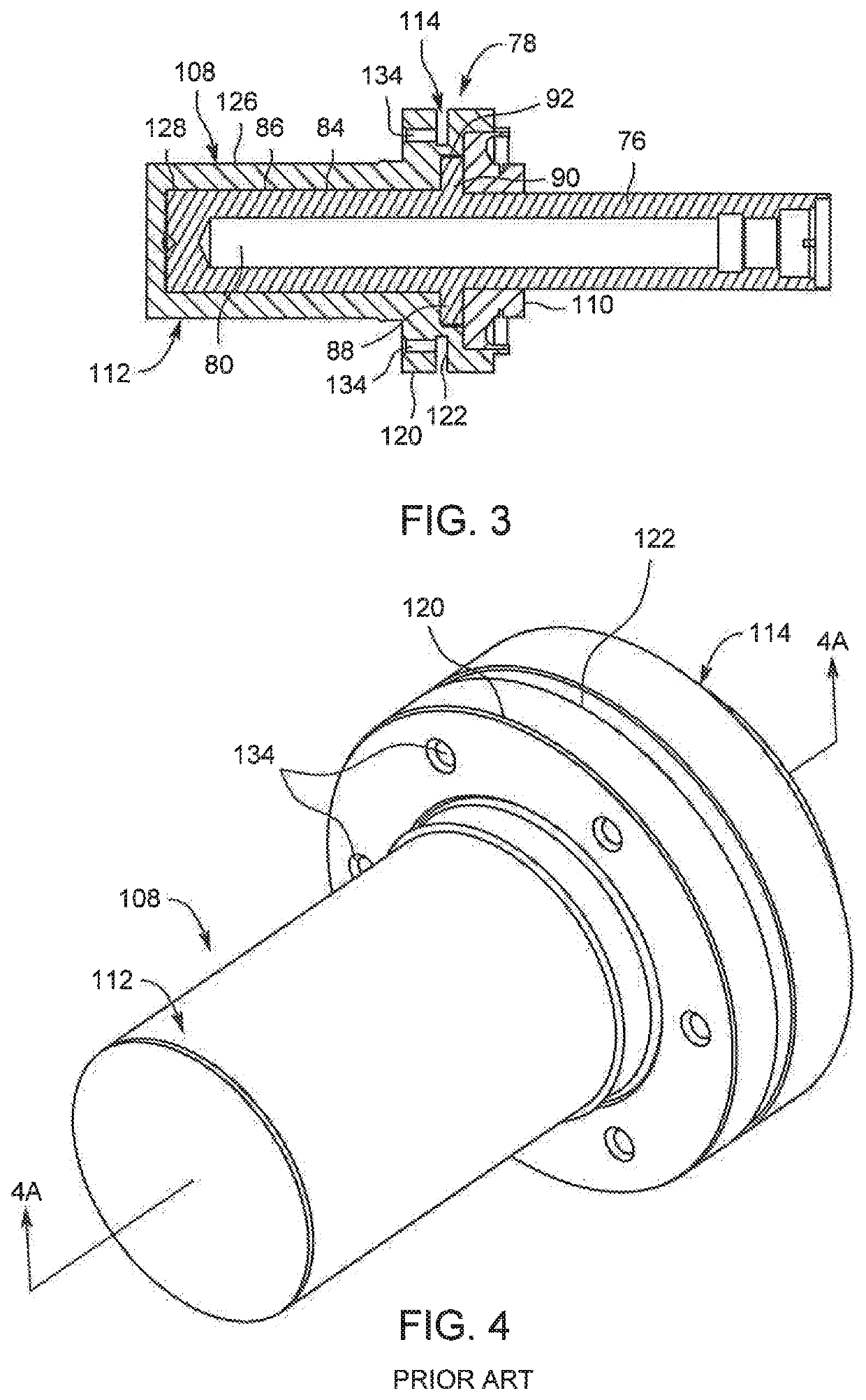

Spiral groove bearing assembly with minimized deflection

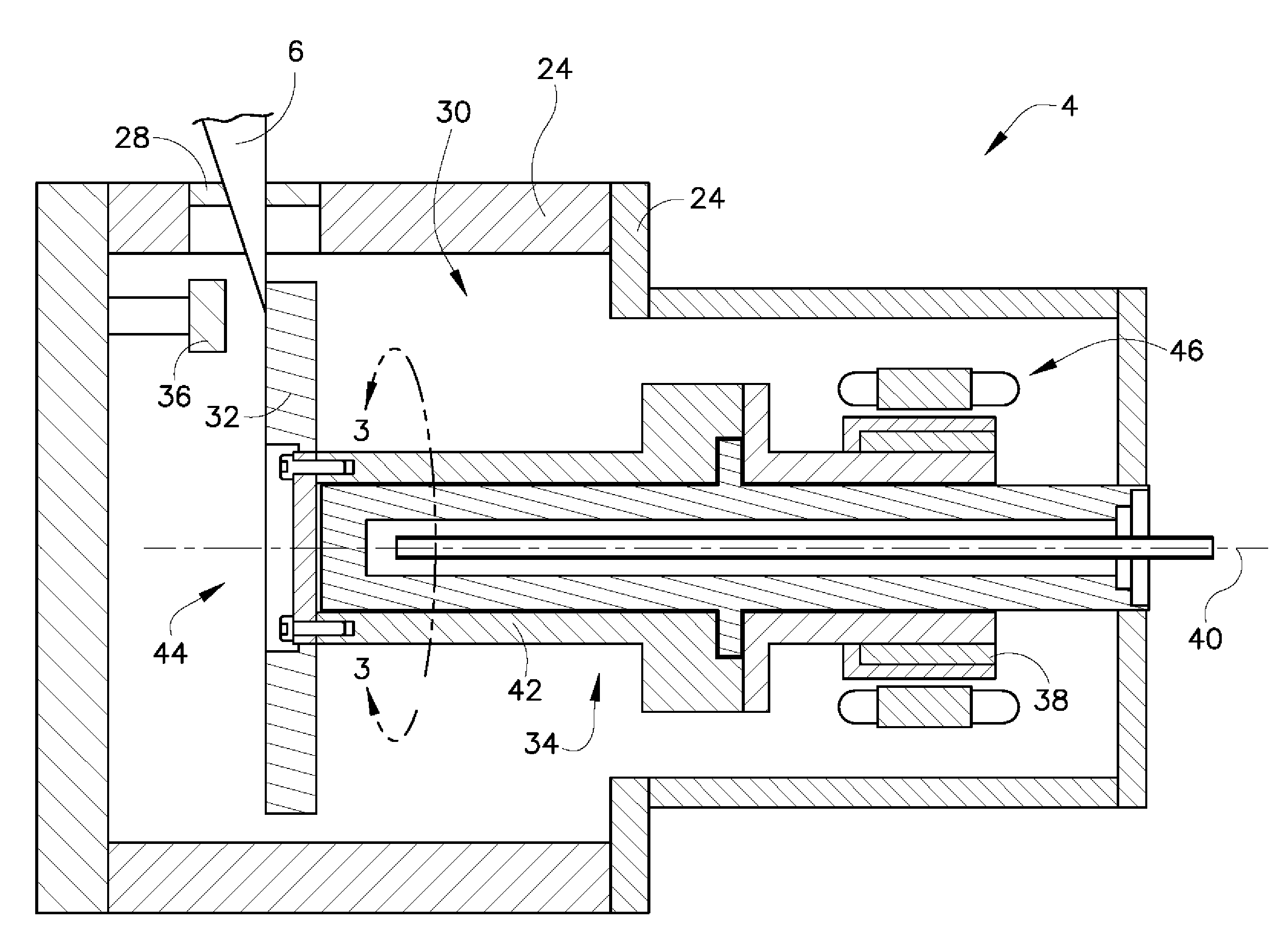

ActiveUS10714297B2Minimized thermal deformationMinimizing gap size alterationX-ray tube electrodesX-ray tube bearing assembly coolingSpiral groove bearingThermal deformation

A liquid metal or spiral groove bearing structure for an x-ray tube and associated process for manufacturing the bearing structure is provided in which journal bearing sleeve is formed with a number of structures thereon that function to dissipate heat transmitted to the sleeve during operation of the bearing assembly within the x-ray tube to minimize thermal deformation of the sleeve, thereby minimizing gap size alteration within the bearing assembly. The structures formed within the sleeve are slots disposed within the section of the sleeve in which the highest temperature gradients develop. The slots enable an increase in thermal conductance away from the sleeve while minimizing the stresses created from the deformation of the portion(s) of the sleeve between the slots.

Owner:GENERAL ELECTRIC CO

Mixed type helical groove dynamical and static pressure gas composite cylindrical bearing

InactiveCN1282829CImprove carrying capacityIncrease stiffnessBearingsAir bearingSpiral groove bearing

Owner:HARBIN INST OF TECH

Spiral Groove Bearing Assembly With Minimized Deflection

ActiveUS20200013577A1Minimized thermal deformationMinimizing gap size alterationX-ray tube bearing assembly coolingX-ray tube electrodesSpiral groove bearingThermal deformation

A liquid metal or spiral groove bearing structure for an x-ray tube and associated process for manufacturing the bearing structure is provided in which journal bearing sleeve is formed with a number of structures thereon that function to dissipate heat transmitted to the sleeve during operation of the bearing assembly within the x-ray tube to minimize thermal deformation of the sleeve, thereby minimizing gap size alteration within the bearing assembly. The structures formed within the sleeve are slots disposed within the section of the sleeve in which the highest temperature gradients develop. The slots enable an increase in thermal conductance away from the sleeve while minimizing the stresses created from the deformation of the portion(s) of the sleeve between the slots.

Owner:GENERAL ELECTRIC CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com