Mixed type helical groove dynamical and static pressure gas composite cylindrical bearing

A cylindrical bearing, dynamic and static pressure technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low load capacity, static pressure gas cylinder bearings do not fully utilize the load capacity and stiffness, reduce static pressure performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

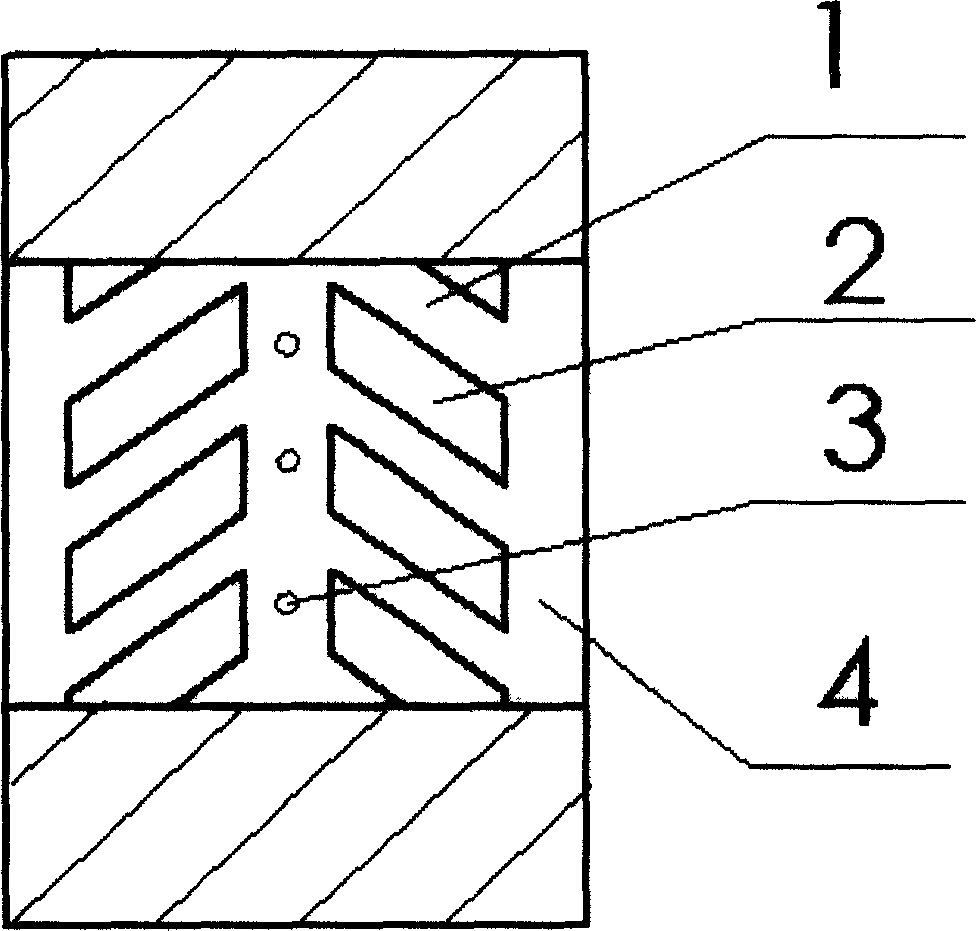

[0050] as attached figure 1 As shown, on the working face 1 of the cylindrical bearing, there are disjoint spiral dynamic pressure grooves 2 on both sides of the distribution circle of the static pressure air flotation air supply point 3, and the outer side of the spiral dynamic pressure groove 2 has an air sealing edge 4 The inner cylindrical surface is matched with a smooth outer cylindrical surface.

Embodiment 2

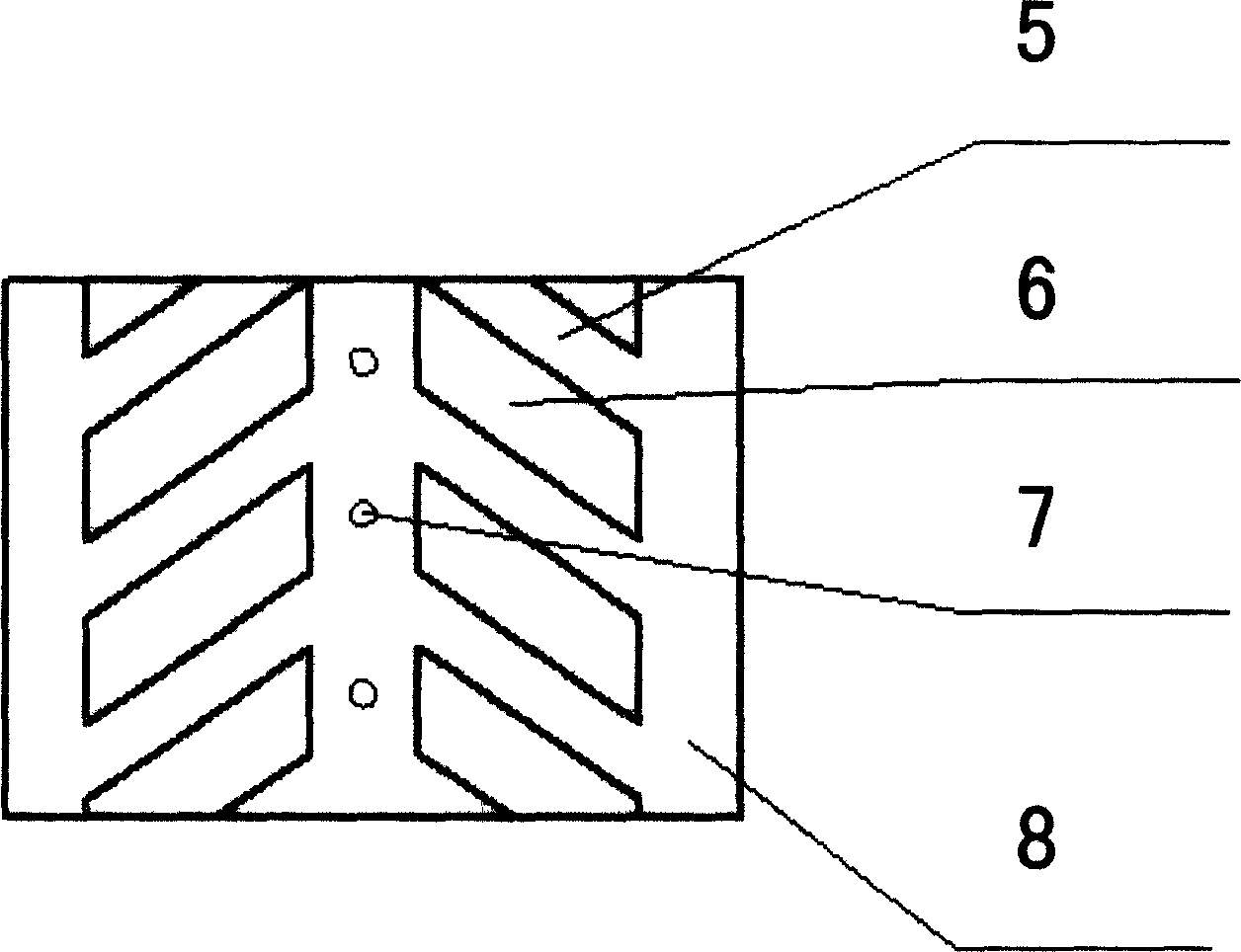

[0052] as attached figure 2 As shown, on the cylindrical bearing working surface 5, the static pressure air flotation air supply points 7 are distributed on both sides of the circle, and there are respectively unconnected helical dynamic pressure grooves 6, and the outer sides of the helical dynamic pressure grooves 6 have air sealing edges 8 The outer cylindrical surface is matched with a smooth inner cylindrical surface.

Embodiment 3

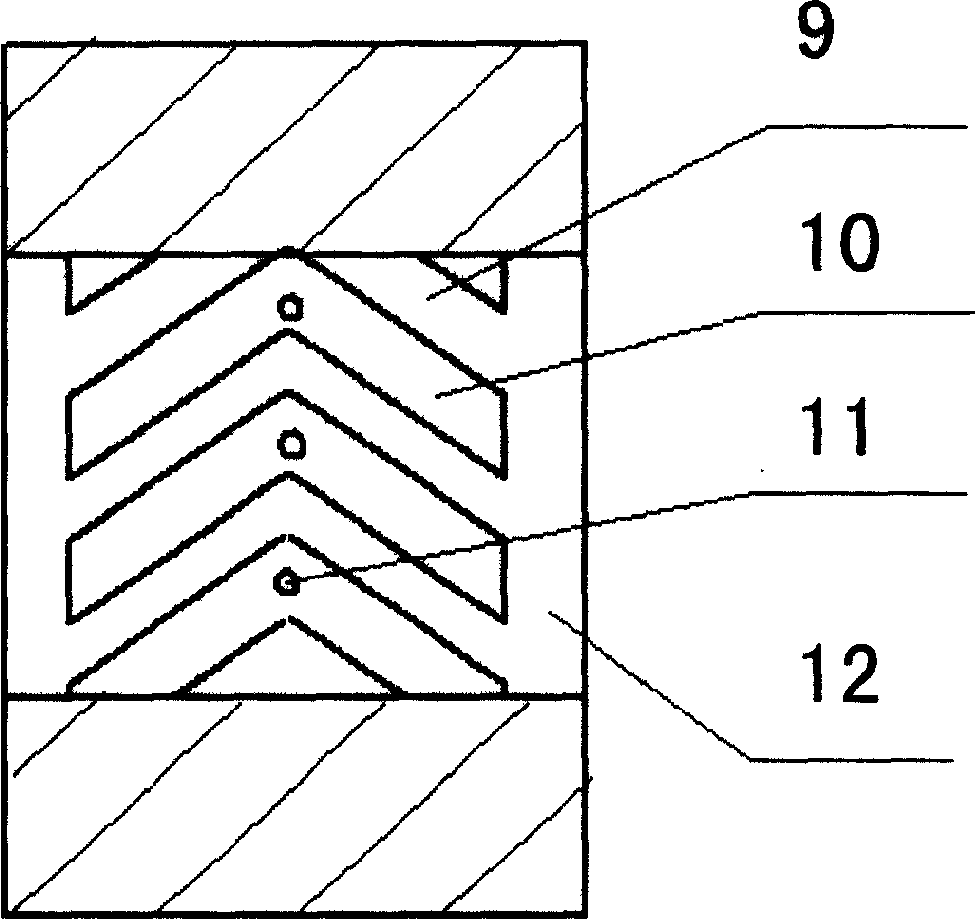

[0054] as attached image 3 As shown, there are connected spiral dynamic pressure grooves 10 on both sides of the distribution circle of the static pressure air flotation gas supply point 11 on the cylindrical bearing working surface 9, and the outer side of the spiral dynamic pressure groove 10 has a sealing edge 12. Inner cylindrical surface with smooth outer cylindrical surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com