Separating elastic tube high-speed spinning spindle

The technology of spinning spindle and elastic tube is applied in the field of high-speed spinning spindle with separate elastic tube, which can solve the problem of no axial buffer and shock absorption function, and achieve the effects of stable and reliable operation, enhanced rigidity and bearing capacity, and reduced amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

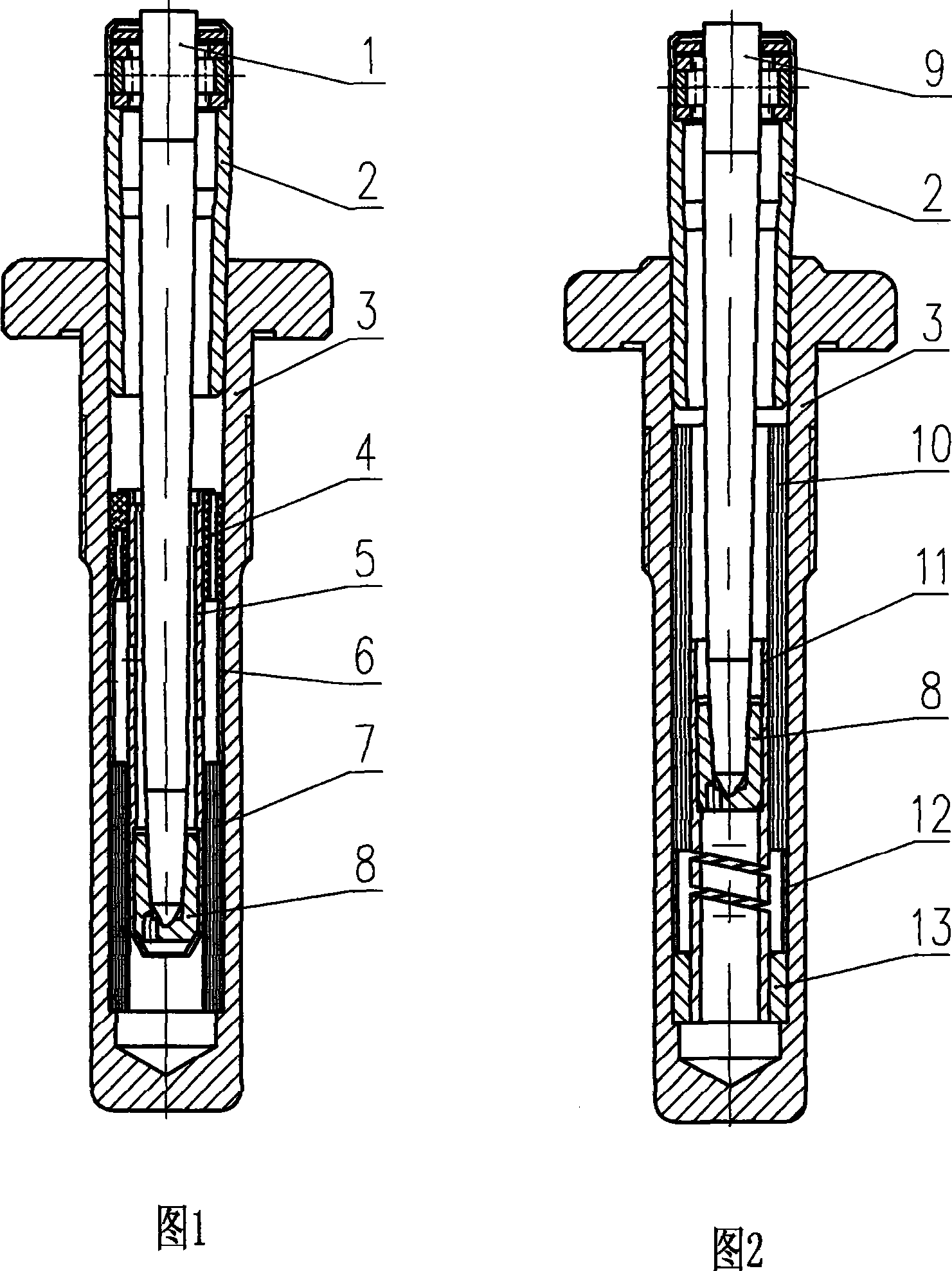

[0008] Among Fig. 1: 1. spindle rod, 2. upper support, 3. spindle foot, 4. elastic ring, 5. lower support tube, 6. positioning sleeve, 7. damper, 8 spindle bottoms.

[0009] The present invention will now be described in detail in conjunction with the embodiment shown in FIG. 2 .

[0010] The separated elastic tube high-speed spinning spindle includes a spindle base and a rod disc. The lower support tube 11 in the spindle base is made of metal tube material, and two spiral grooves are milled on the top to make it have good elasticity. The lower end is clipped into the spindle foot 3 In the lower support seat 13 at the bottom of the hole, the lower support seat 13 mainly plays a role in positioning and fixing the lower support. It can be made of metal, plastic, powder metallurgy, etc. into a cylindrical shape, and the ingot bottom 8 is placed on the lower support of the spiral groove. In the upper hole of the tube 11, the bottom end of the ingot rod 9 is inserted into the 8 hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com