Floating-assisted type bearing and using method thereof

A floating and bearing technology, used in lubricating parts, lubricating oil control valves, mechanical equipment, etc., can solve problems such as increased rotational speed, increased power consumption, and reduced life, and achieve the effect of reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

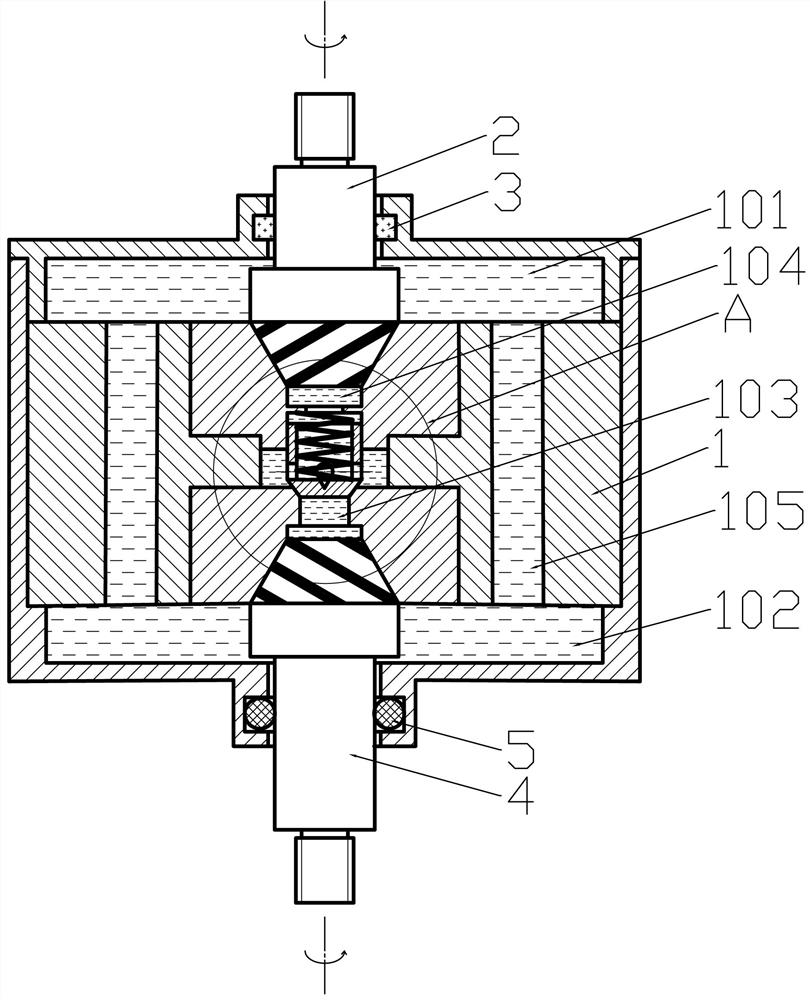

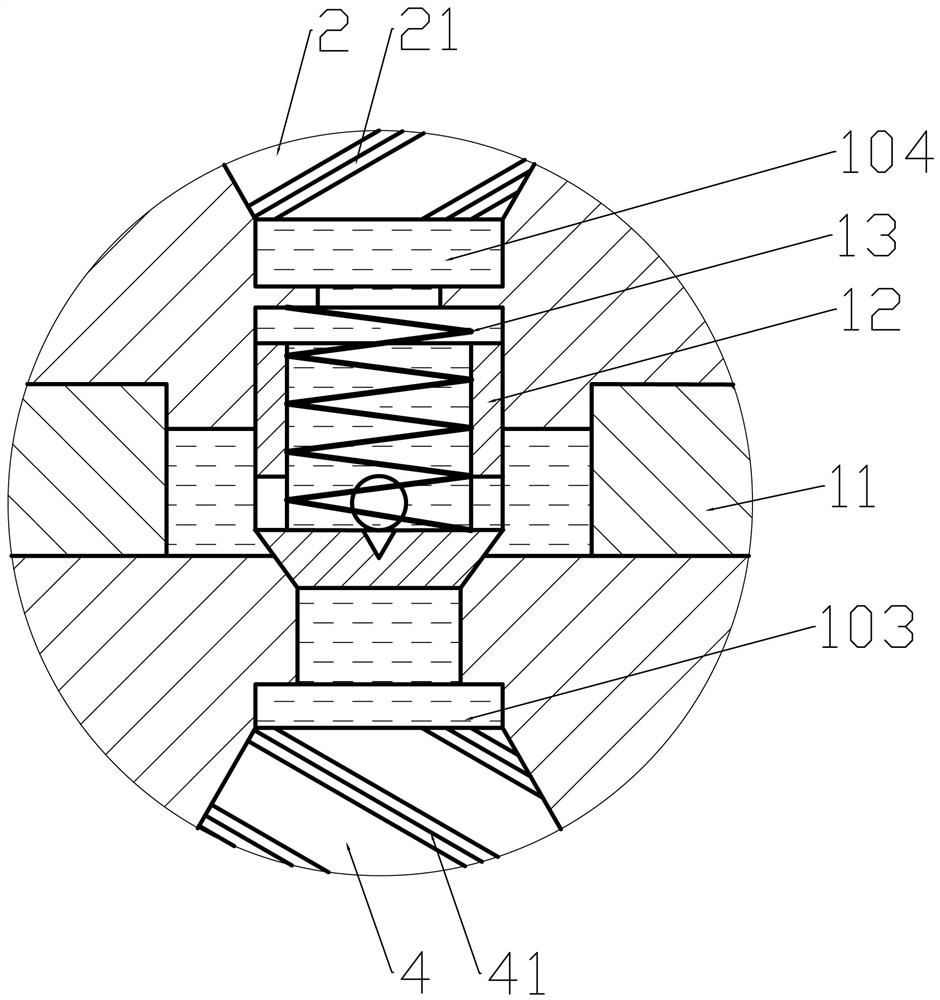

[0028] Embodiment 1: a kind of floating bearing, refer to Figure 1-2 , including main shaft 2, one-way valve 1 and auxiliary floating shaft 4.

[0029] The one-way valve 2 is provided with a first oil storage chamber 101, a second oil storage chamber 102, a valve front chamber 103 and a valve rear chamber 104. The one-way valve 1 includes a valve body 11, a valve core 12 and a compression spring 13. Normally ( That is, when the pressure difference between the valve front chamber 103 and the valve rear chamber 104 is not greater than the opening pressure of the check valve 1), the compression spring 13 pushes the valve core 12 to connect with the valve body 11, and the valve front chamber 103 is isolated from the valve rear chamber 104. Check valve 1 is closed. When the pressure difference between the valve front chamber 103 and the valve rear chamber 104 is greater than the opening pressure of the check valve 1, the lubricating oil in the valve front chamber 103 pushes the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com