Conical dynamic pressure spiral groove bearing containing self-lubricating material

A self-lubricating material, self-lubricating bearing technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing parts, etc., can solve problems such as adhesive wear, improve lubrication conditions, solve large friction power consumption, and improve load-carrying performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

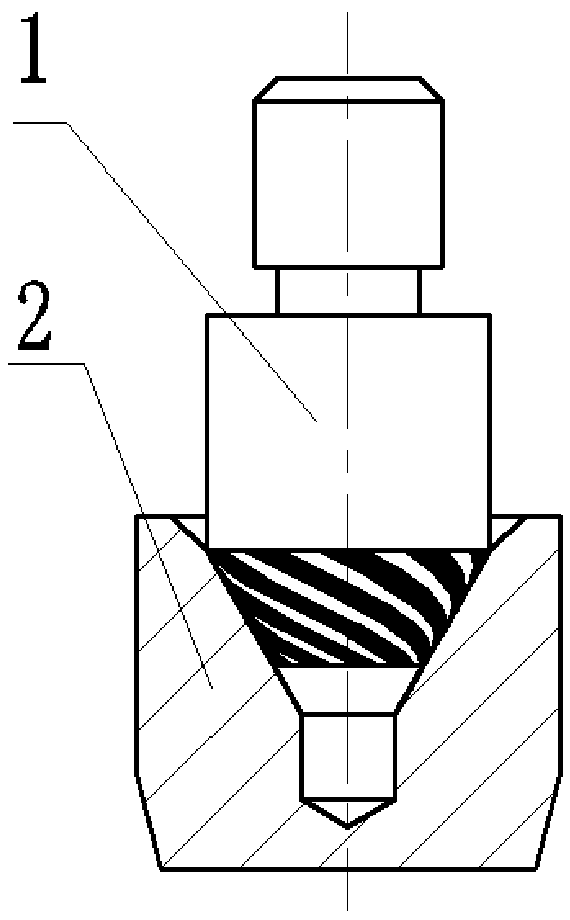

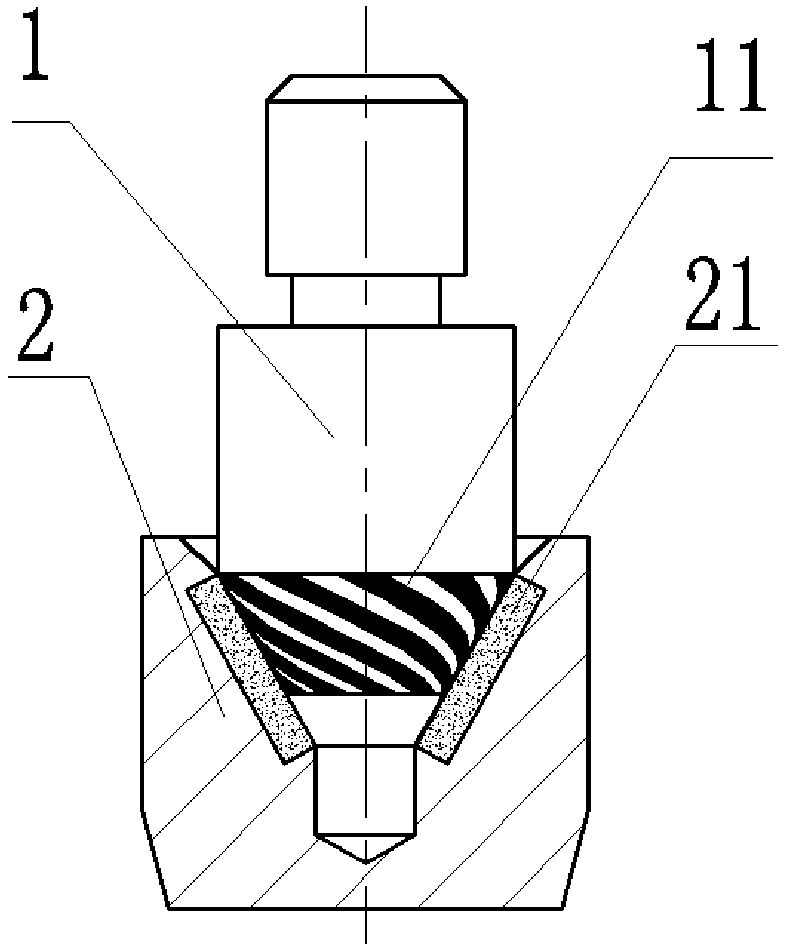

[0012] A tapered dynamic pressure spiral groove bearing of the present invention is a new type of tapered dynamic pressure spiral groove bearing in which the bearing seat is made of self-lubricating material; structurally, the contact surface between the self-lubricating bearing seat 2 and the bearing main shaft 1 is a cone The contact surface between the bearing main shaft 1 and the self-lubricating bearing seat 2 is a cone that matches the self-lubricating bearing seat 2, and a spiral groove 11 is provided on the surface of the cone of the bearing main shaft 1, and the self-lubricating bearing seat 2 Self-lubricating materials are adopted; the self-lubricating bearing seat 2 adopts self-lubricating materials such as graphite, polytetrafluoroethylene, and oil-containing porous materials. The self-lubricating bearing seat 2 adopts a self-lubricating material coating 21 prepared on the conical contact surface of the bearing seat; the self-lubricating material coating is a diamon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com