Water-lubricated spiral groove bearing heating power calculation method and electric spindle thermal design method

A technology of heating power and calculation method, applied in the direction of computer-aided design, calculation, design optimization/simulation, etc., can solve the problems of heating power consumption and temperature rise calculation difficulties of spiral groove bearings, so as to improve the success rate of one-time design and shorten the design cycle, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The thermodynamic modeling and thermal design technology of the high-speed water-lubricated dynamic pressure spiral groove bearing electric spindle of the present invention will be further described in detail below in conjunction with an embodiment.

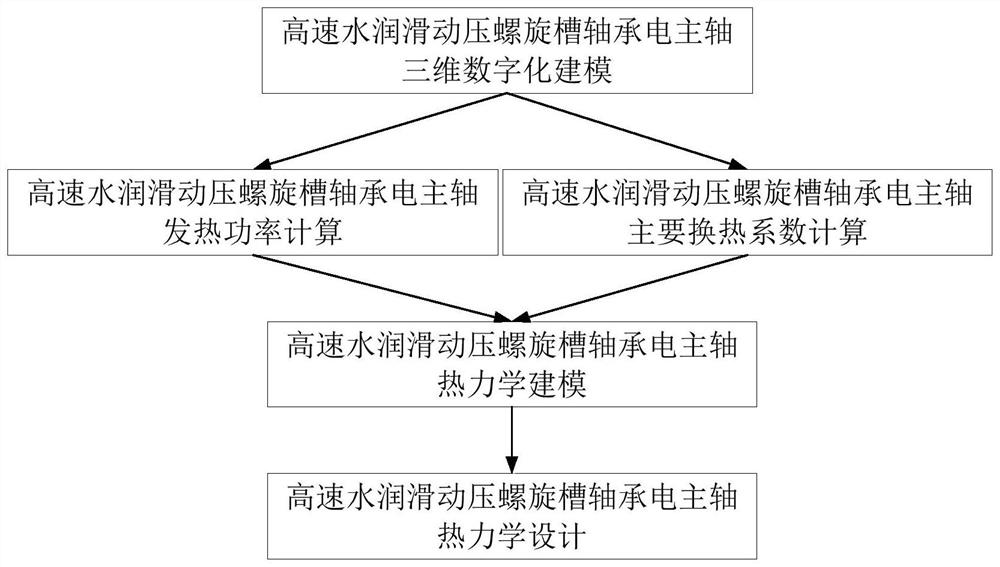

[0085] figure 1 The specific content of the thermodynamic modeling and thermal design technology of the high-speed water-lubricated dynamic pressure spiral groove bearing electric spindle of the present invention is given, including the following steps:

[0086] Step 1: 3D digital modeling of high-speed water-lubricated dynamic pressure spiral groove bearing electric spindle:

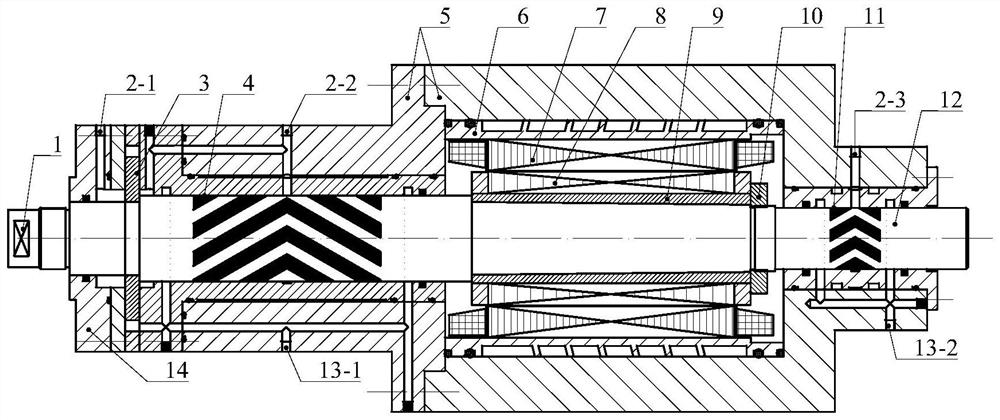

[0087] Use the 3D modeling software Solidworks to establish a 3D digital model of the high-speed water-lubricated dynamic pressure spiral groove bearing electric spindle. The structure of the electric spindle is as follows: figure 2 shown.

[0088] Electric spindle structure, including water-lubricated dynamic pressure spiral groove thrust bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com