Pump unit for nuclear installations

A technology for pumping devices and nuclear facilities, which is applied to the components of pumping devices, pumping devices, pumps, etc. for elastic fluids, can solve problems such as inability to eliminate, and achieve the effect of avoiding material contact and minimizing half-frequency whirl.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

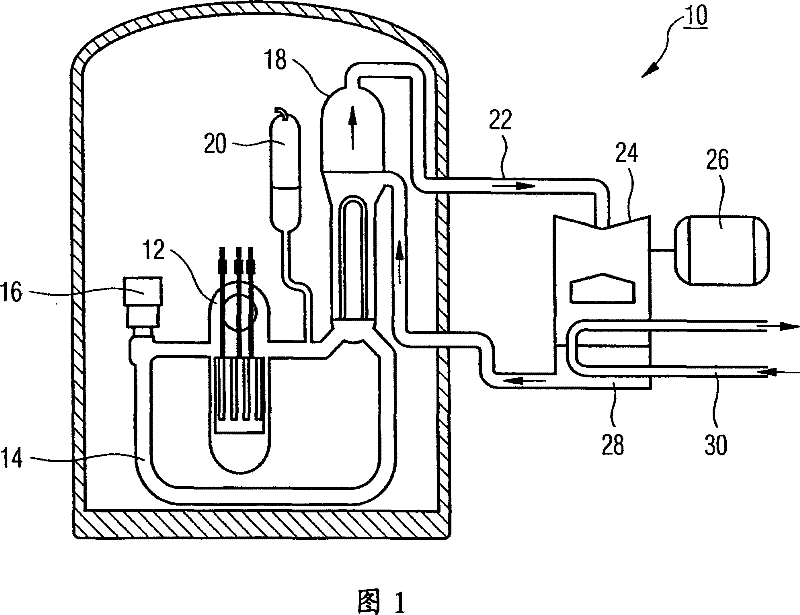

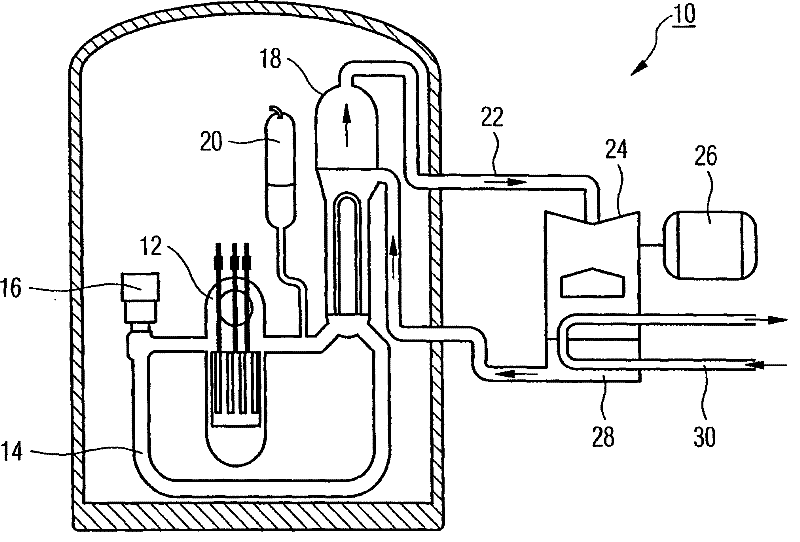

[0013] In the pressurized water reactor 10, generally "light" water is used as both moderator and coolant. Therefore, the pressurized water reactor is of the type of light water reactor.

[0014] The pressurized water reactor 10 has two main cooling circuits, a primary cooling circuit and a secondary cooling circuit. The primary cooling circuit 14 is composed of a reactor pressure vessel 12 including a reactor core, a main coolant pump 16 , a steam generator 18 , and piping for connection. Furthermore, a pressure vessel 20 is provided in a known manner.

[0015] The main coolant pump 16 delivers the coolant (purified water, approximately 290° C.) into the thick-walled reactor pressure vessel 12 made of steel, where it flows initially downwards in an annular channel. The coolant is diverted at the bottom of the vessel and then flows from the bottom up around the fuel rods in the reactor pressure vessel 12 . Here, the coolant cools the fuel rods, whereby the coolant is heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com