Aerofoil blade of ridged surface drag reduction

An airfoil blade, ridged technology, applied in the field of drag reduction and energy saving of pumps and fans, can solve the problems of affecting the stable operation of pumps and fans, rough processing technology, and large influence of fluid viscosity, so as to reduce shear stress. , the effect of reducing energy consumption and reducing viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment

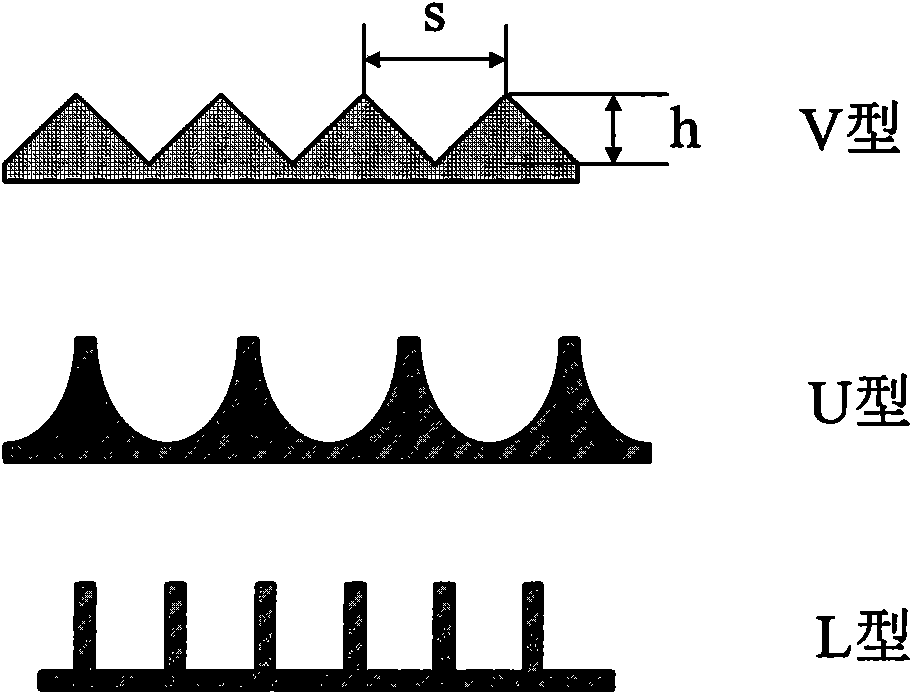

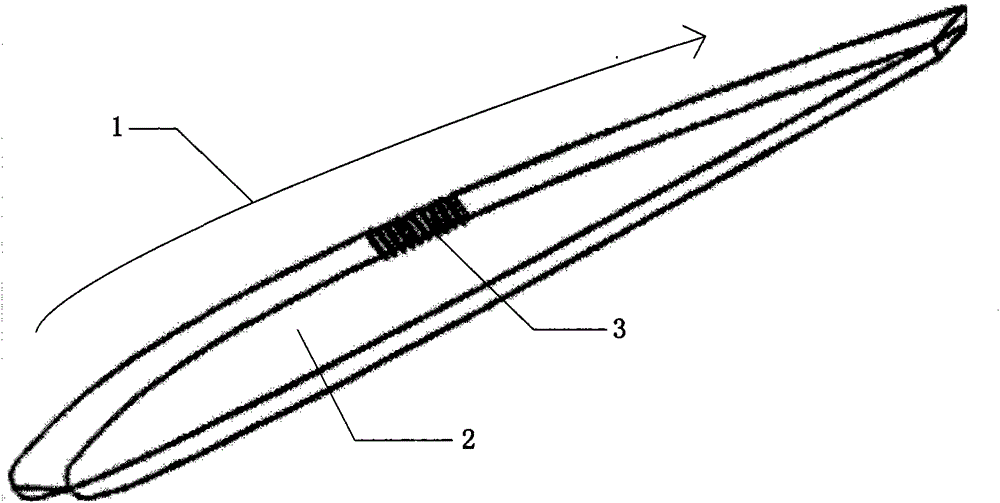

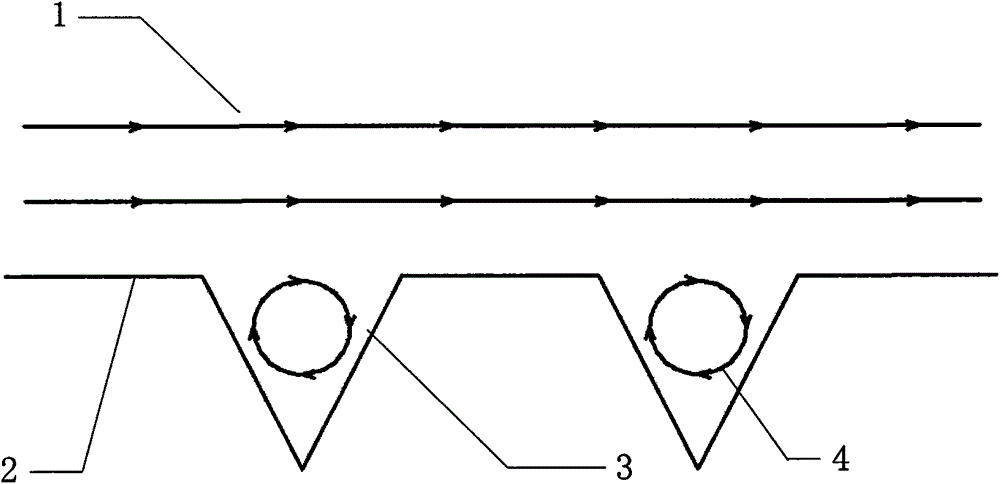

[0022] like Figure 1 to Figure 7 , an airfoil blade with a ridged surface drag reduction. A "V-shaped" ridge structure 3 is arranged on the surface of the blade 2. The direction of the grooves of the ridge structure 3 is perpendicular to the moving direction 1 of the fluid relative to the blade. The groove size characteristics Determined by the groove depth h, groove width s and groove spacing a, since this drag reduction technology is only applicable to the turbulent flow state, the ridge structure needs to be arranged on the middle and rear of the blade on the blade surface, that is, when the fluid flows around the blade to achieve turbulence. fully developed part of the flow. At the same time, in order to make the arrangement of the ridge structure better adapt to the streamline shape of the blade itself and not have a great impact on the aerodyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com