Novel efficient hydrofoil

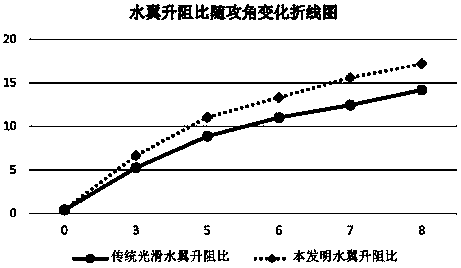

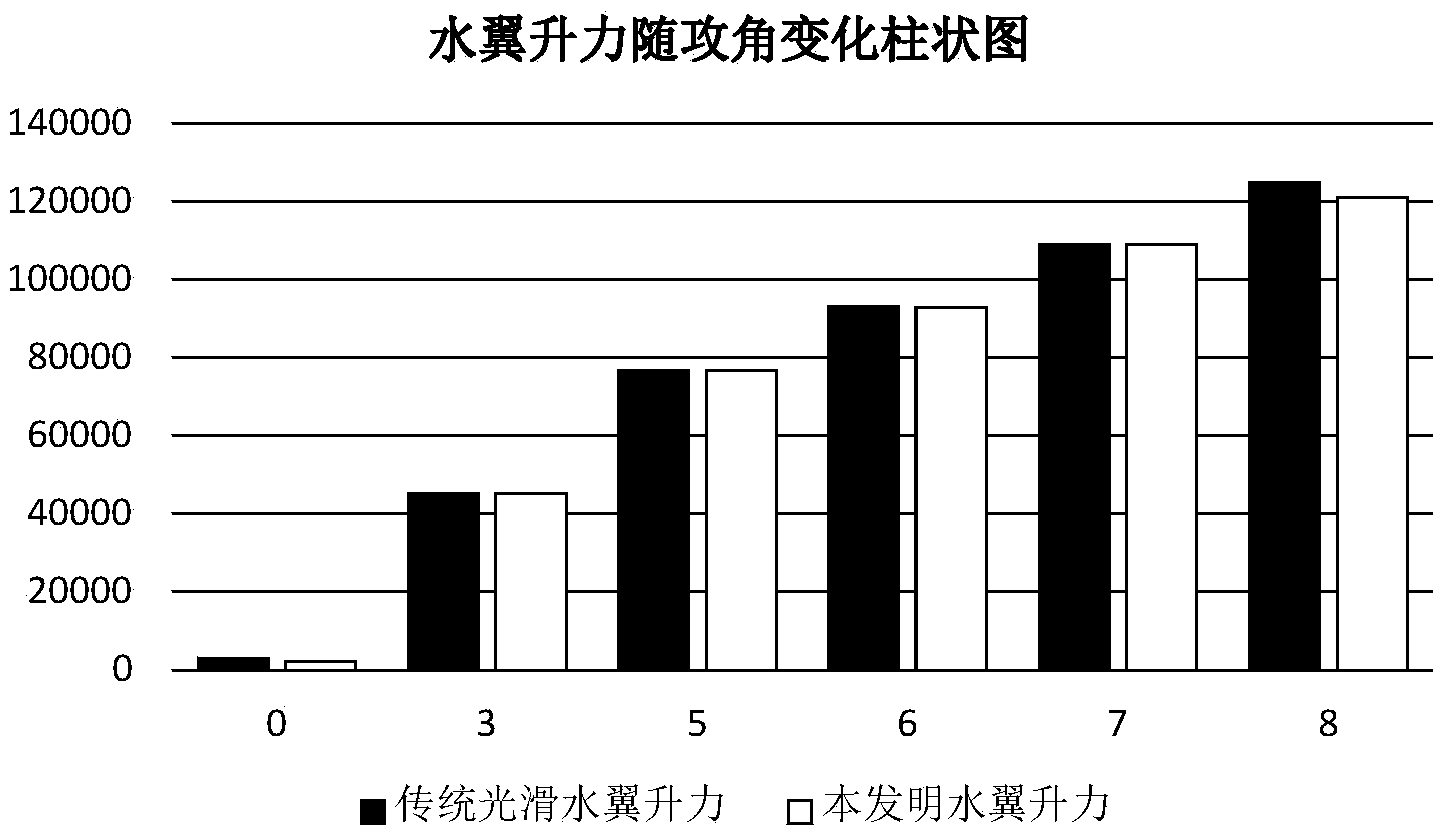

A hydrofoil and high-efficiency technology, applied to ships, hydrodynamic characteristics/hydrostatic characteristics, hulls, etc., can solve problems such as unstable lift, increased noise, increased resistance, etc., to increase the pressure of the flow field, reduce the Small resistance, the effect of reducing viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

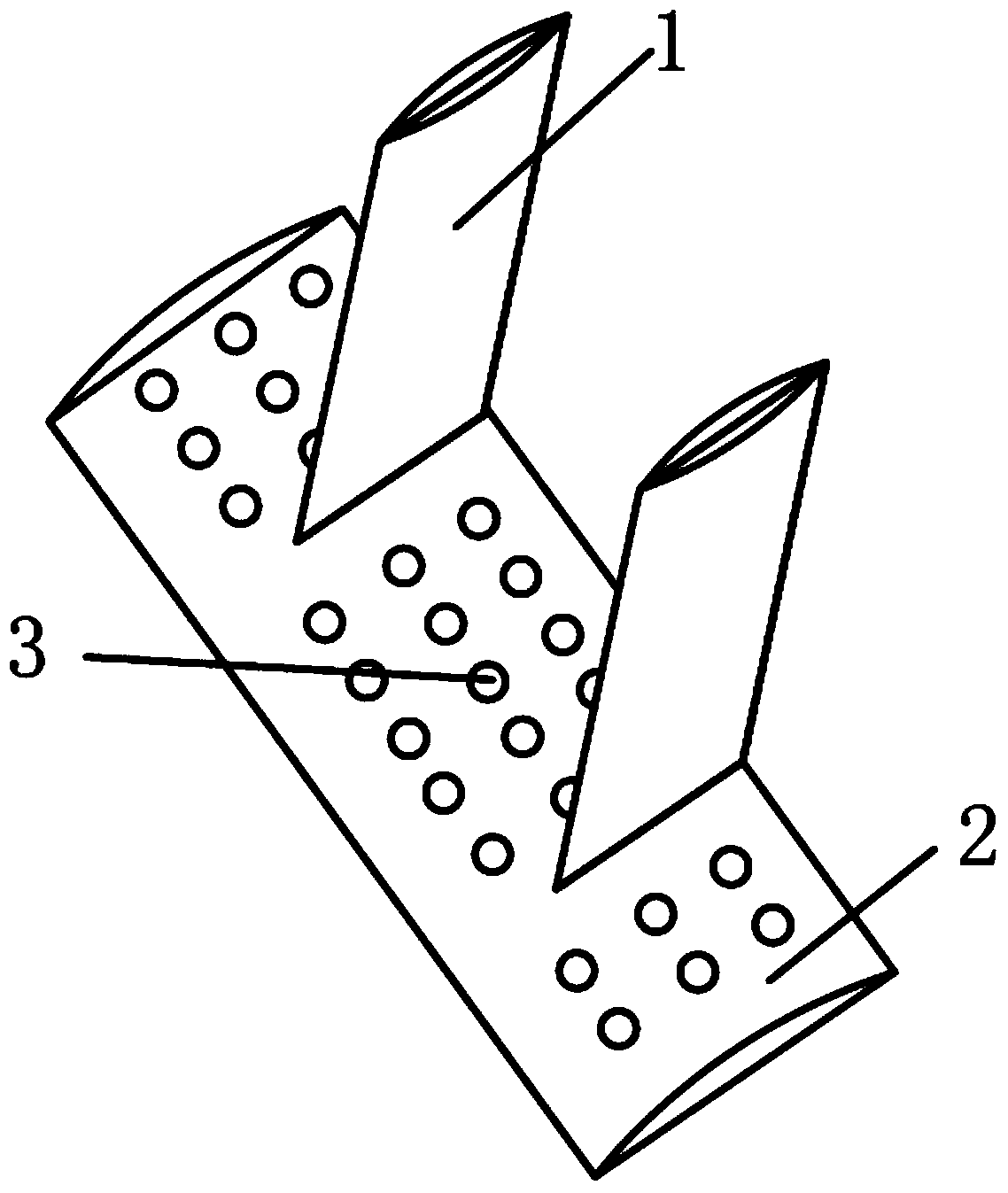

[0024] The present invention will be further described below based on specific embodiments and drawings.

[0025] Such as figure 1 with figure 2 The low drag hydrofoil shown includes a hydrofoil pillar 1 and a hydrofoil plate 2. The cross-sectional shape of the hydrofoil plate 2 is an airfoil. The hydrofoil has a wingspan of 15m and a chord length of 3m. On the surface of 2, circular pits 3 are aligned vertically and horizontally. The depth of the pits 3 is 30 mm, and the area ratio of the pits 3 on the surface of the hydrofoil plate 2 is 50%.

[0026] Due to traditional habits, people think that the smoother the surface, the lower the frictional resistance, and the better materials such as titanium alloy materials will have better anti-cavitation effects. Therefore, the traditional research and development directions are mostly focused on improving the shape of the hydrofoil to reduce For the resistance it receives, better materials are used to combat the cavitation effect, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com