Platform Moon Pool Drag Reduction Device

A drag reduction device and platform technology, which are used in devices to reduce the influence of resistance of marine engineering structures, devices for sloshing and eddies, and in the field of reducing the liquid level oscillation of the moonpool of the drilling platform under different working conditions, and can solve the problem of increasing the tightness. requirements, inconvenience of operation, environmental impact of offshore work and rest, etc., to achieve the effect of curbing vortex reaction, reducing viscous resistance, and reducing sloshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

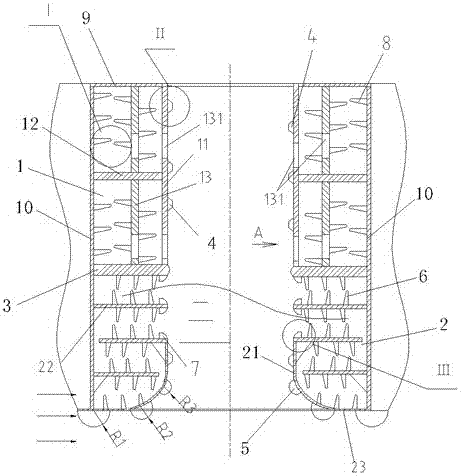

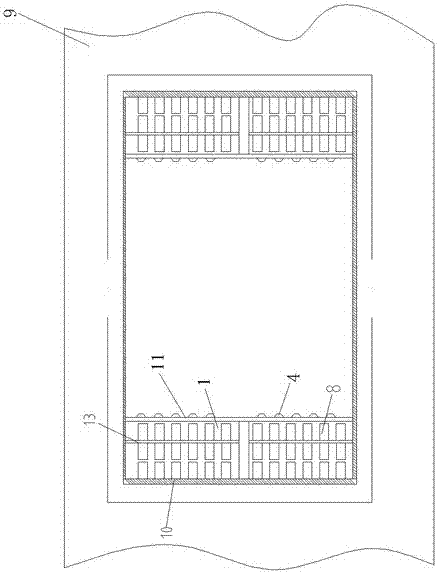

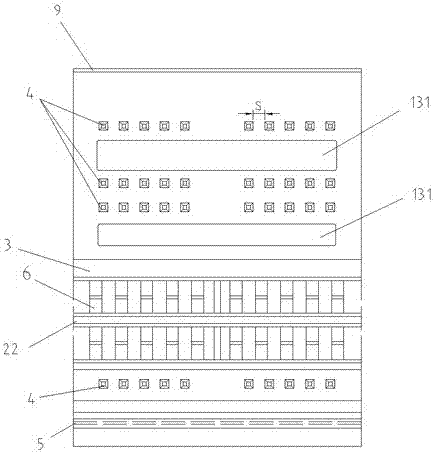

[0023] Such as Figure 1 to Figure 6 As shown, this embodiment includes a vibration damping cabin 1 and a sloshing cabin 2 arranged vertically on the lateral inner walls 10 at both ends of the moon pool. The vibration damping cabin 1 and the sloshing cabin 2 are separated by a watertight partition 3 . The outer wall 11 of the damping cabin and the lower outer wall 21 of the sloshing cabin are respectively horizontally placed with several rows of staggered damping blocks 4, the outer wall 21 of the lower part of the sloshing cabin is fixedly connected with four wave-blocking columns 5 with the same width as the moon pool, above the middle of the sloshing cabin There is no vertical outer wall, and three-layer partitions 22 are arranged up and down in the sloshing reduction cabin 2. Eight rows of vertical wave-dissipating blocks 6 are placed horizontally on the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com