Steam-turbine large hydraulic valve performance life test device

A life test, hydraulic valve technology, applied in the direction of mechanical valve testing, etc., can solve the problems of inability to rotate, low work efficiency, and tired operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

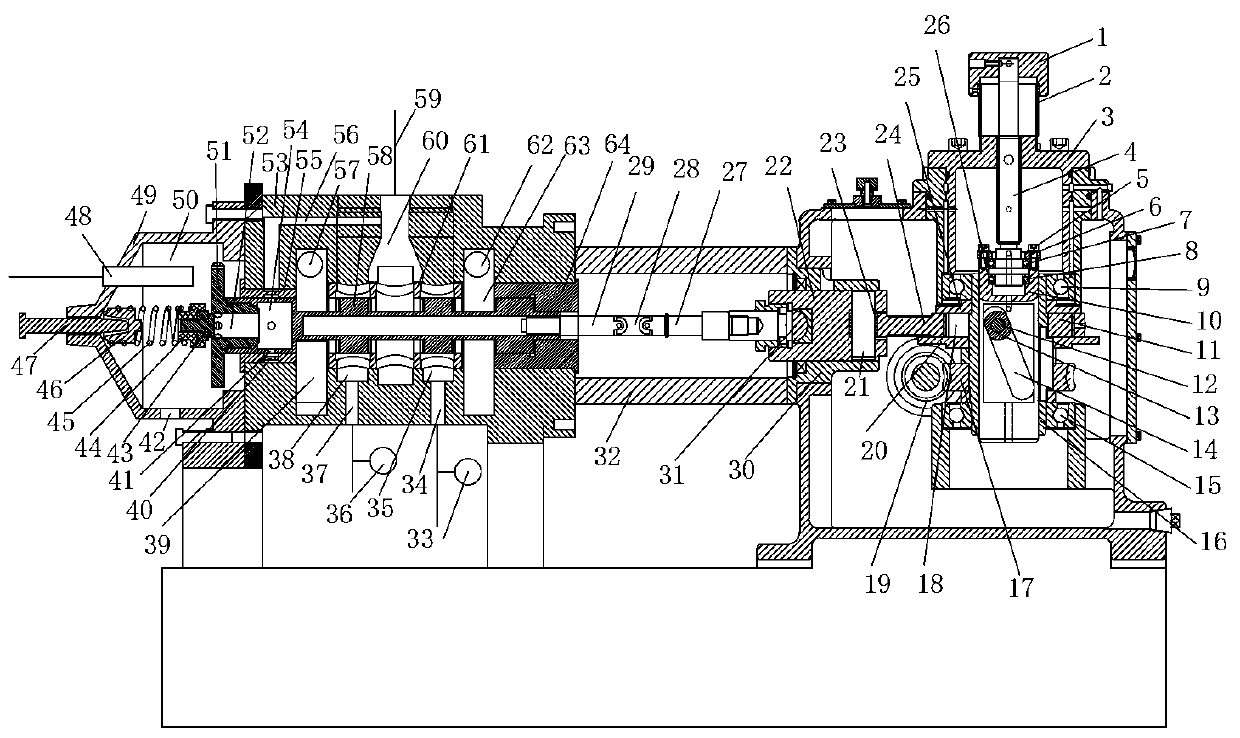

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

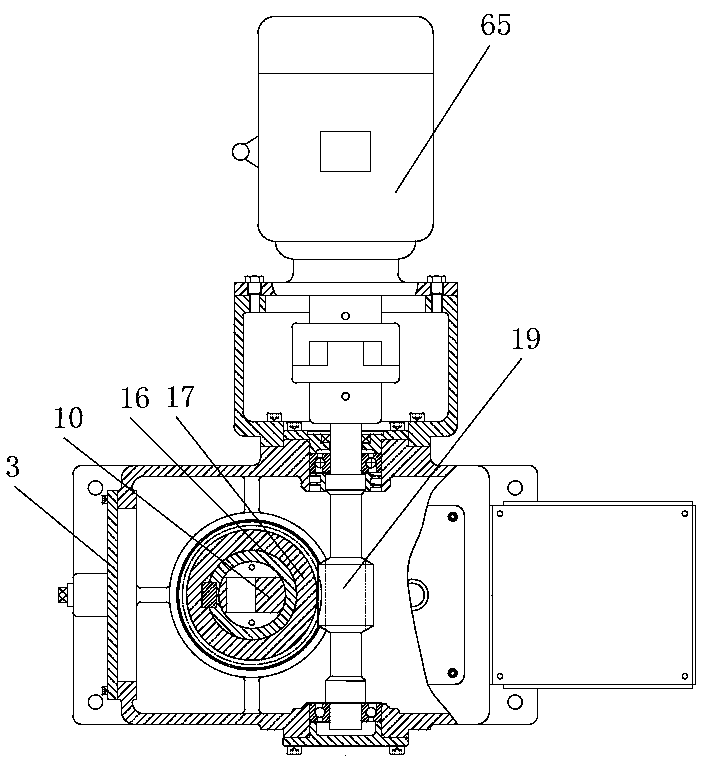

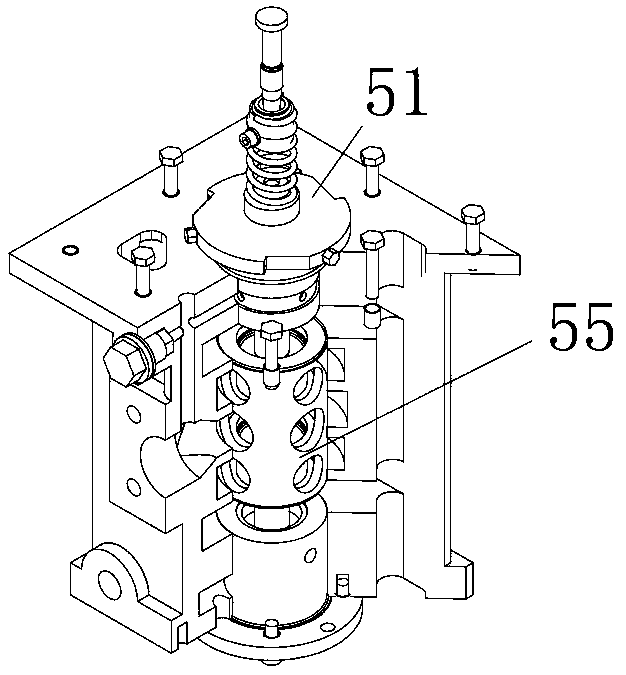

[0031] As shown in the figure, the steam turbine large-scale hydraulic valve performance life test device includes a reversing valve driven by a driving mechanism. The driving mechanism includes a body 3, and a worm 19, a worm wheel 17, and a worm 19 are arranged in the body 3 for mutual transmission and cooperation. Driven by the motor 65 installed on the body 3, the worm gear 17 is fixedly sleeved in the middle and lower part of the stroke adjustment sleeve 16, the stroke adjustment sleeve 16 and the body 3 are rotated and matched, and the upper part of the stroke adjustment sleeve 16 is engaged with a stroke adjustment block 11 which rotates integrally. The stroke adjustment block 11 is radially slidingly matched with the stroke adjustment sleeve 16, and the outside of the stroke adjustment block 11 is tightly fitted with a fixed concentric cam 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com