Patents

Literature

90results about How to "High torque output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

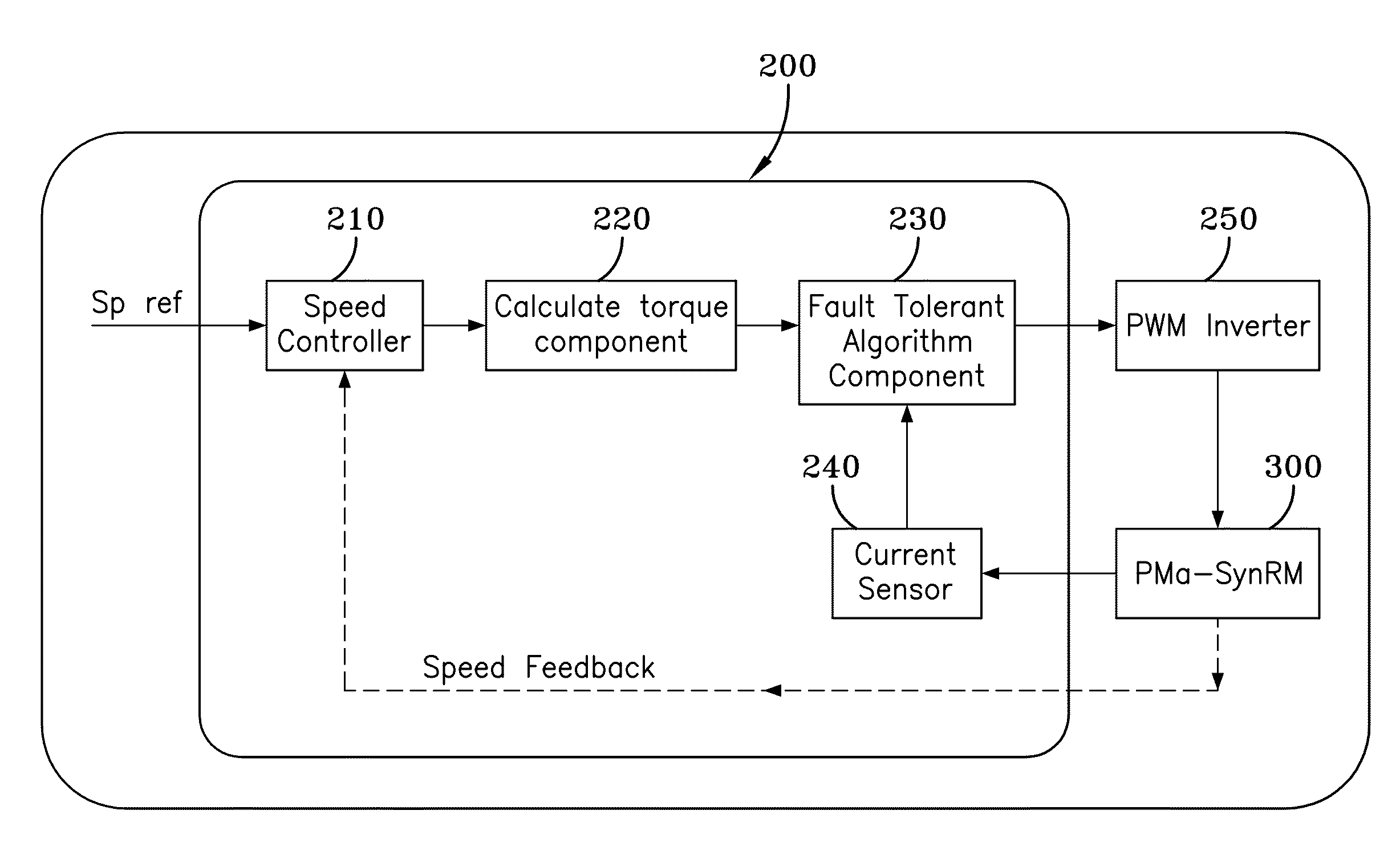

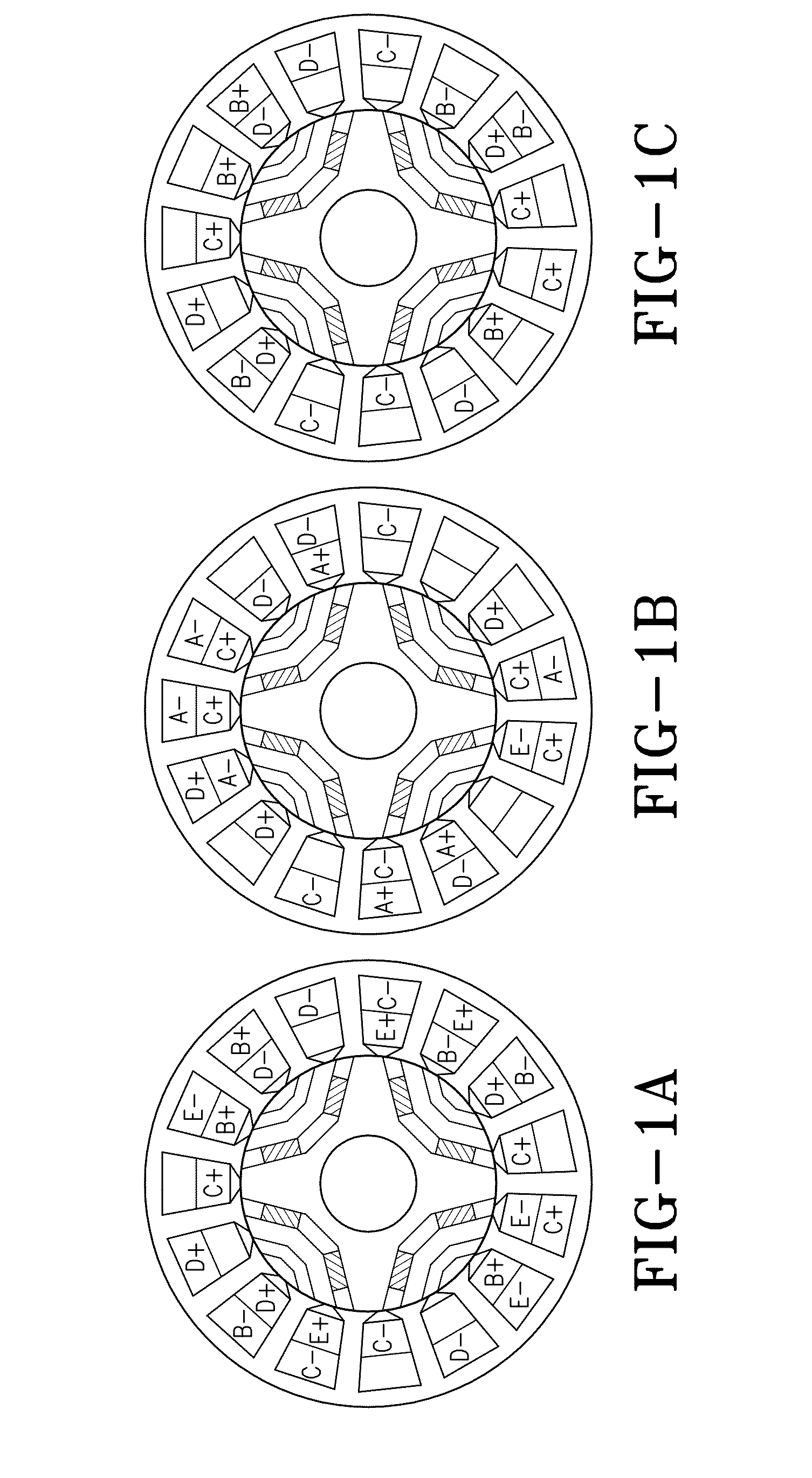

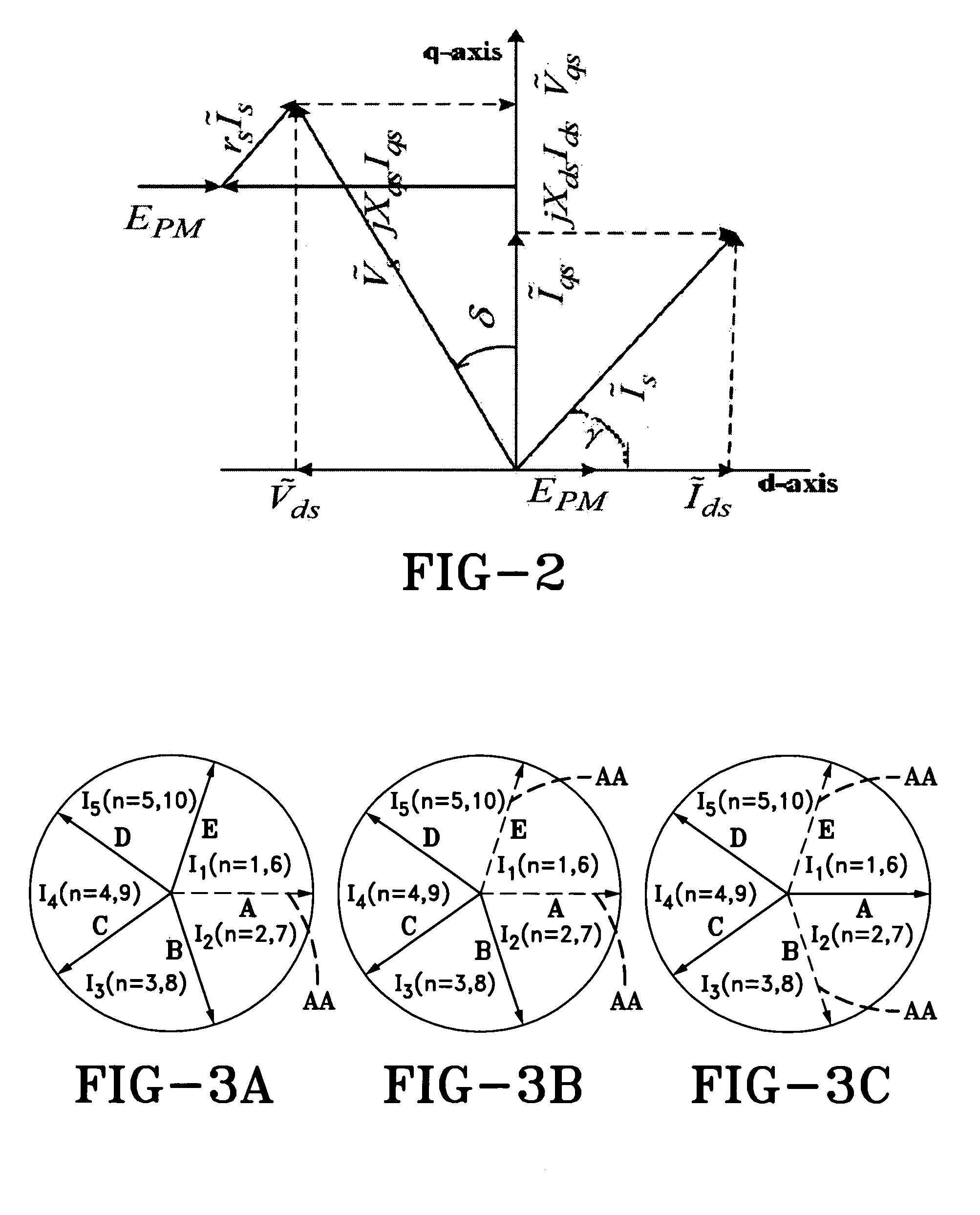

Fault tolerant control system for multi-phase permanent magnet assisted synchronous reluctance motors

ActiveUS20160028343A1High torque outputElectronic commutation motor controlMotor/generator/converter stoppersPhase currentsSynchronous reluctance motor

A fault tolerant control system for a multi-phase permanent magnet assisted synchronous reluctance motor utilizes vector control to provide safe operation under various phase loss fault conditions. Specifically, the vector control of the present invention utilizes a fault tolerant algorithm that receives a torque input and an electrical current feedback signal from the motor. Thus, in the presence of a fault condition, the vector control applies the optimal torque angle to the motor, while reducing the phase currents to an optimized value to lessen the saturation effect in the motor, so as to ensure that the motor delivers maximum torque output in the presence of such faults. As such, the control system allows the motor to operate safely with high reliability, which is highly desirable, such as in electric vehicles and the aerospace industry.

Owner:THE UNIVERSITY OF AKRON

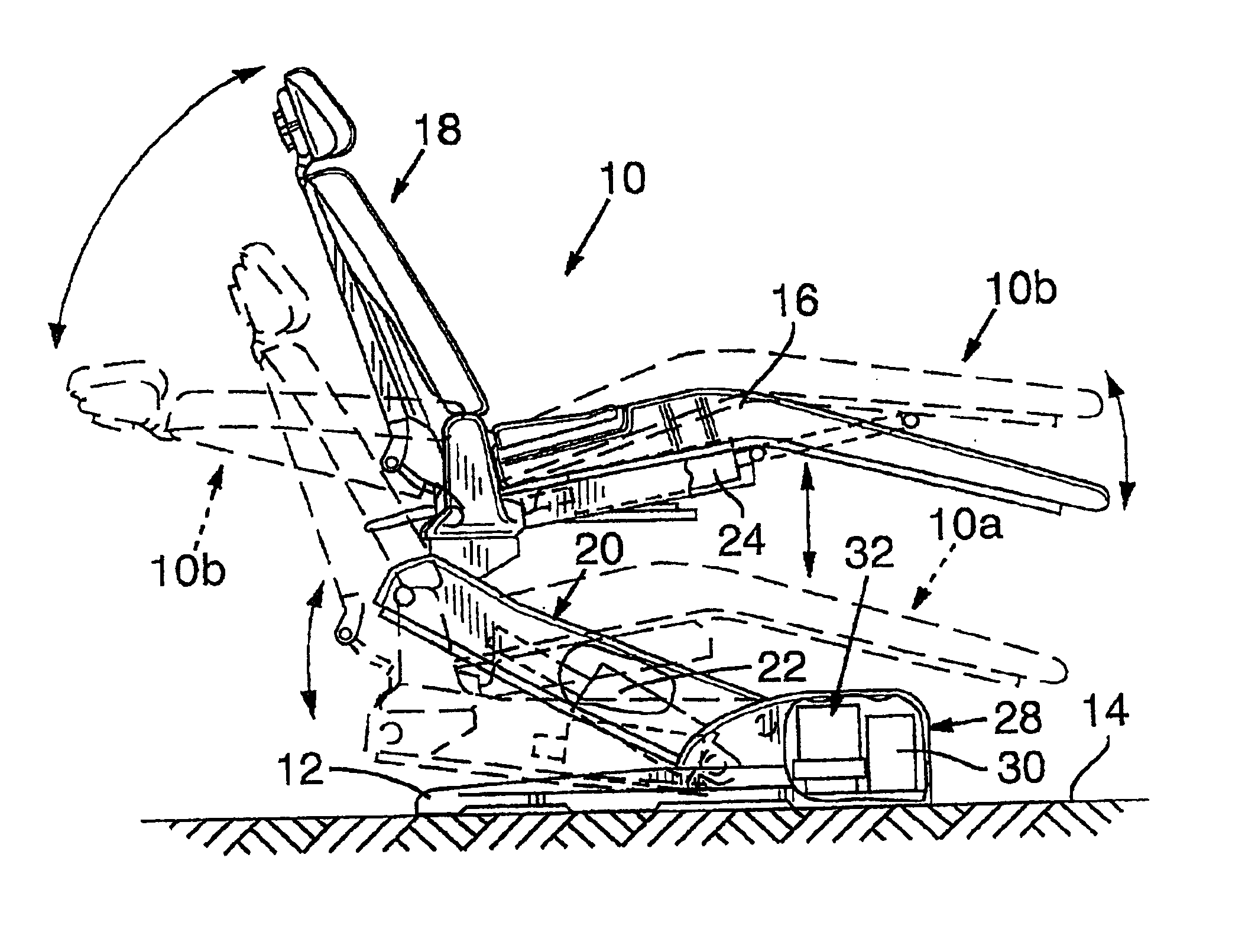

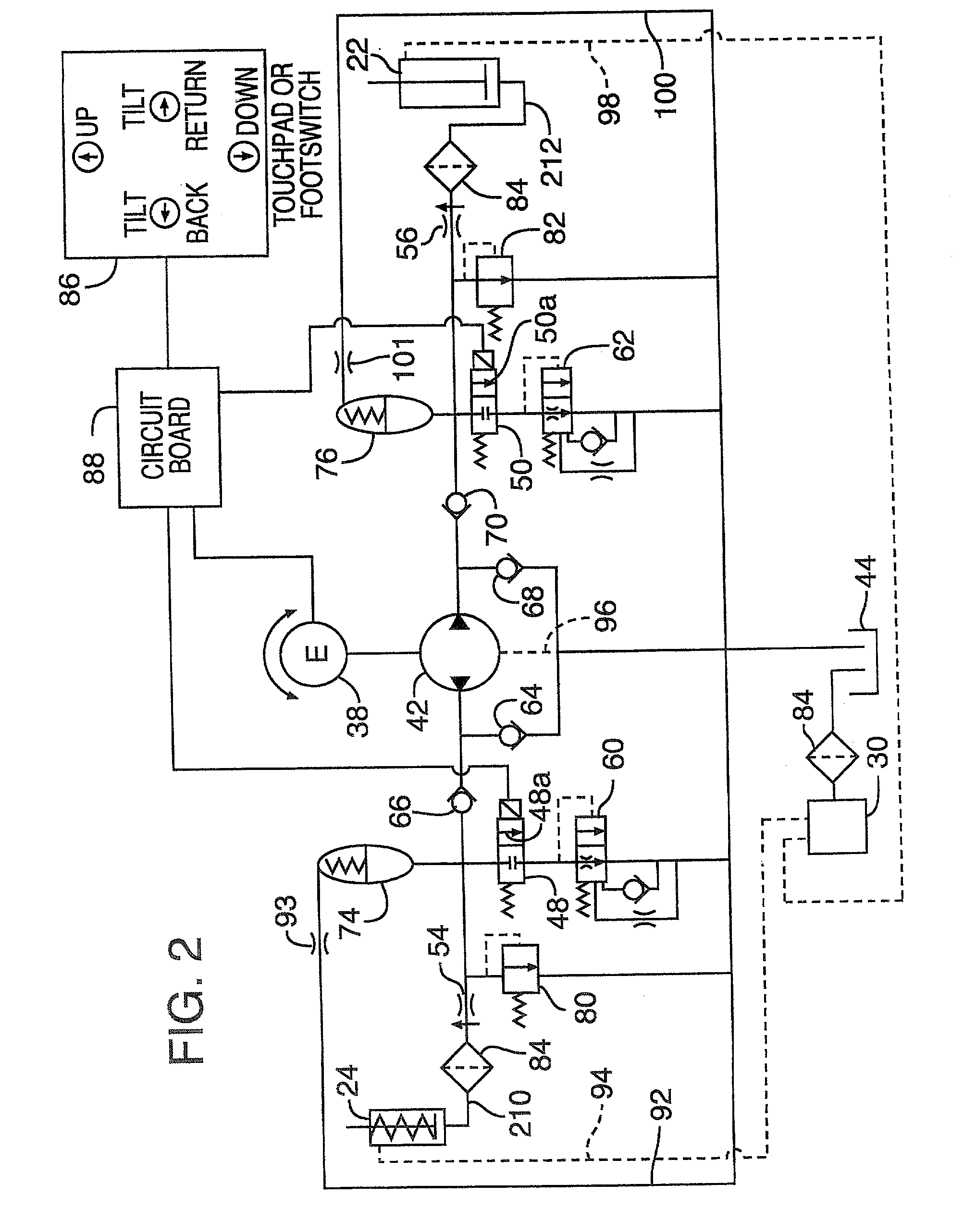

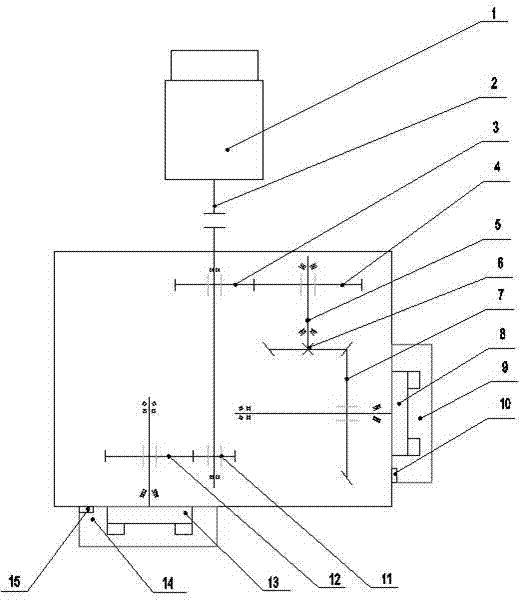

Hydraulic drive system

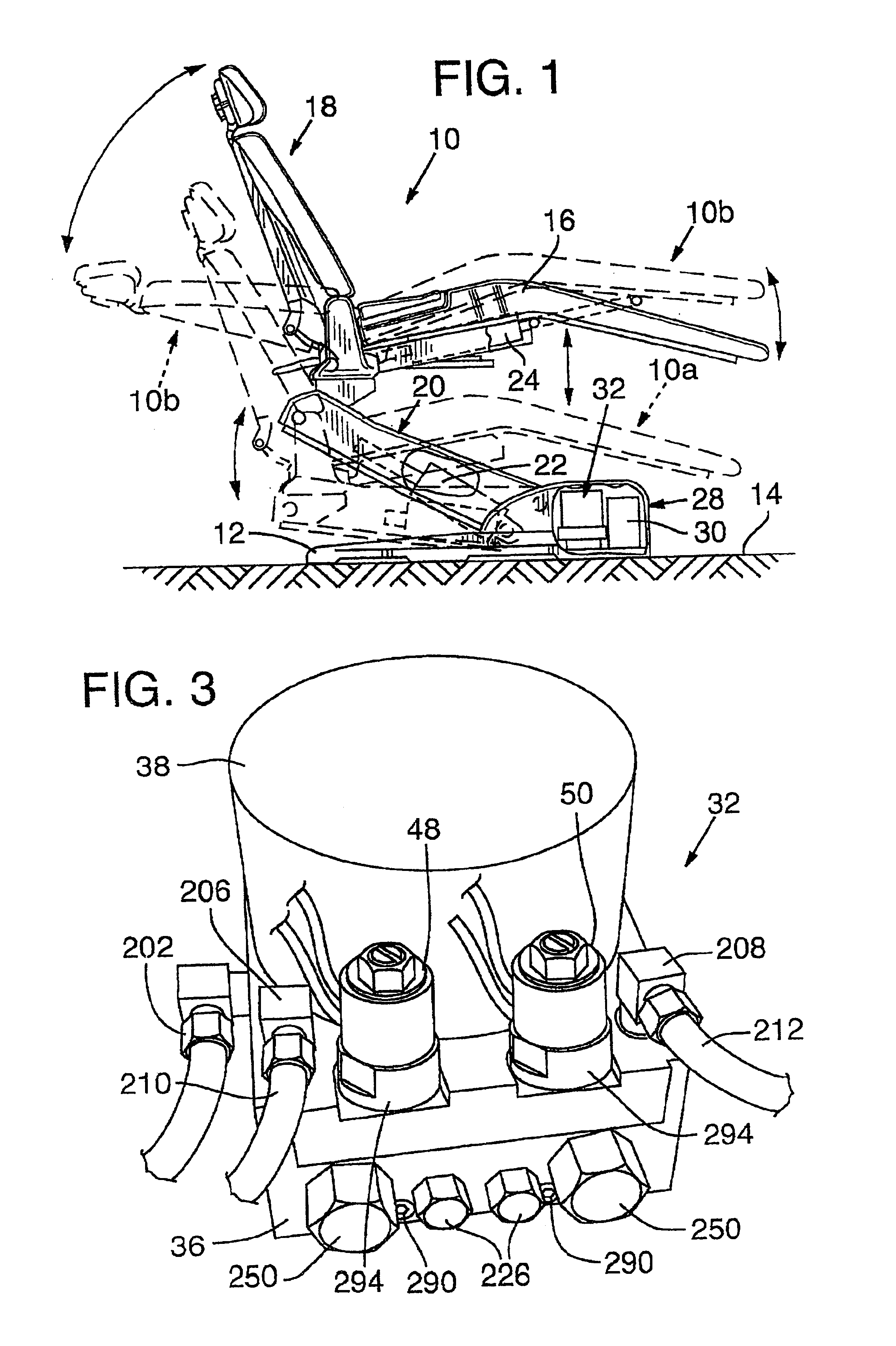

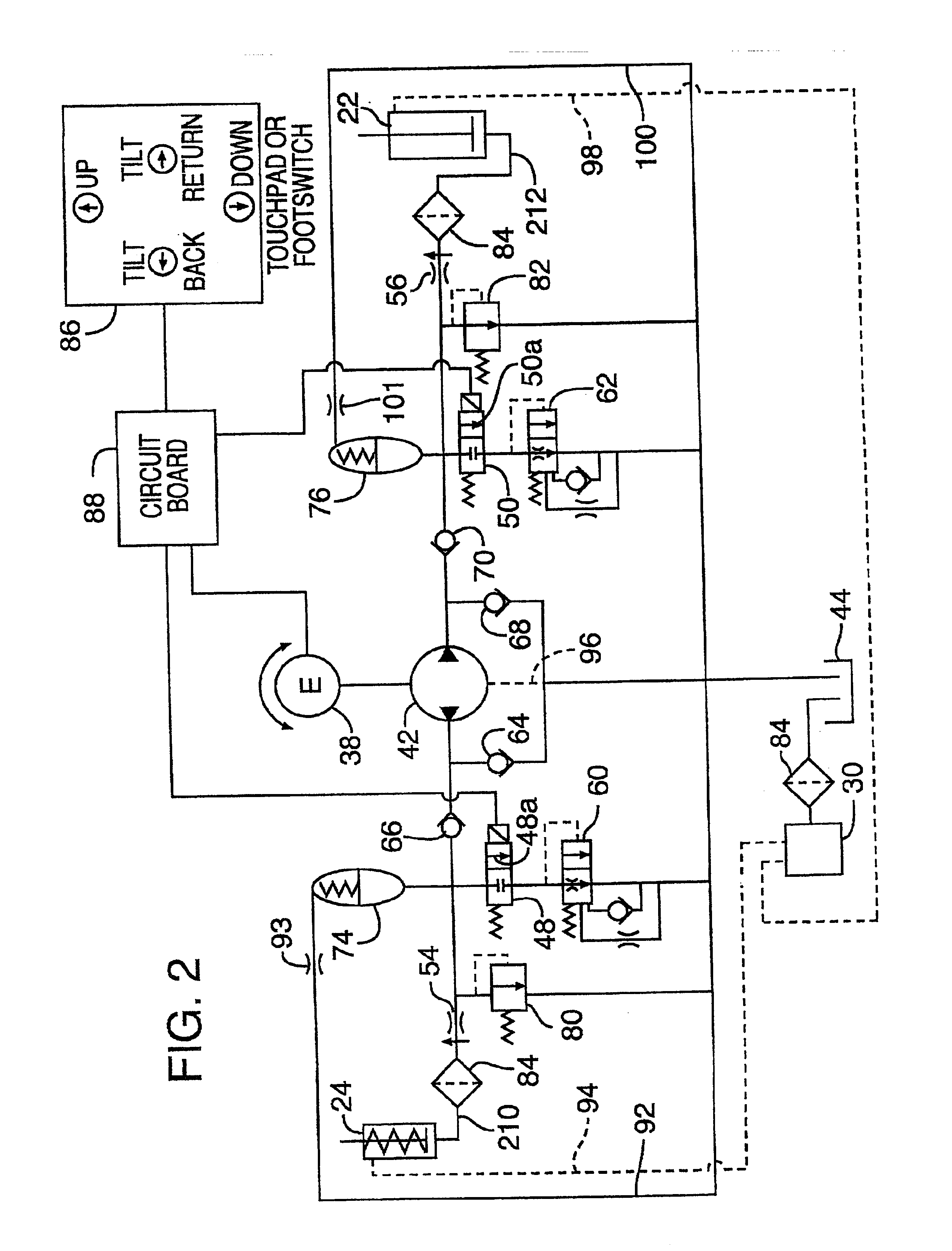

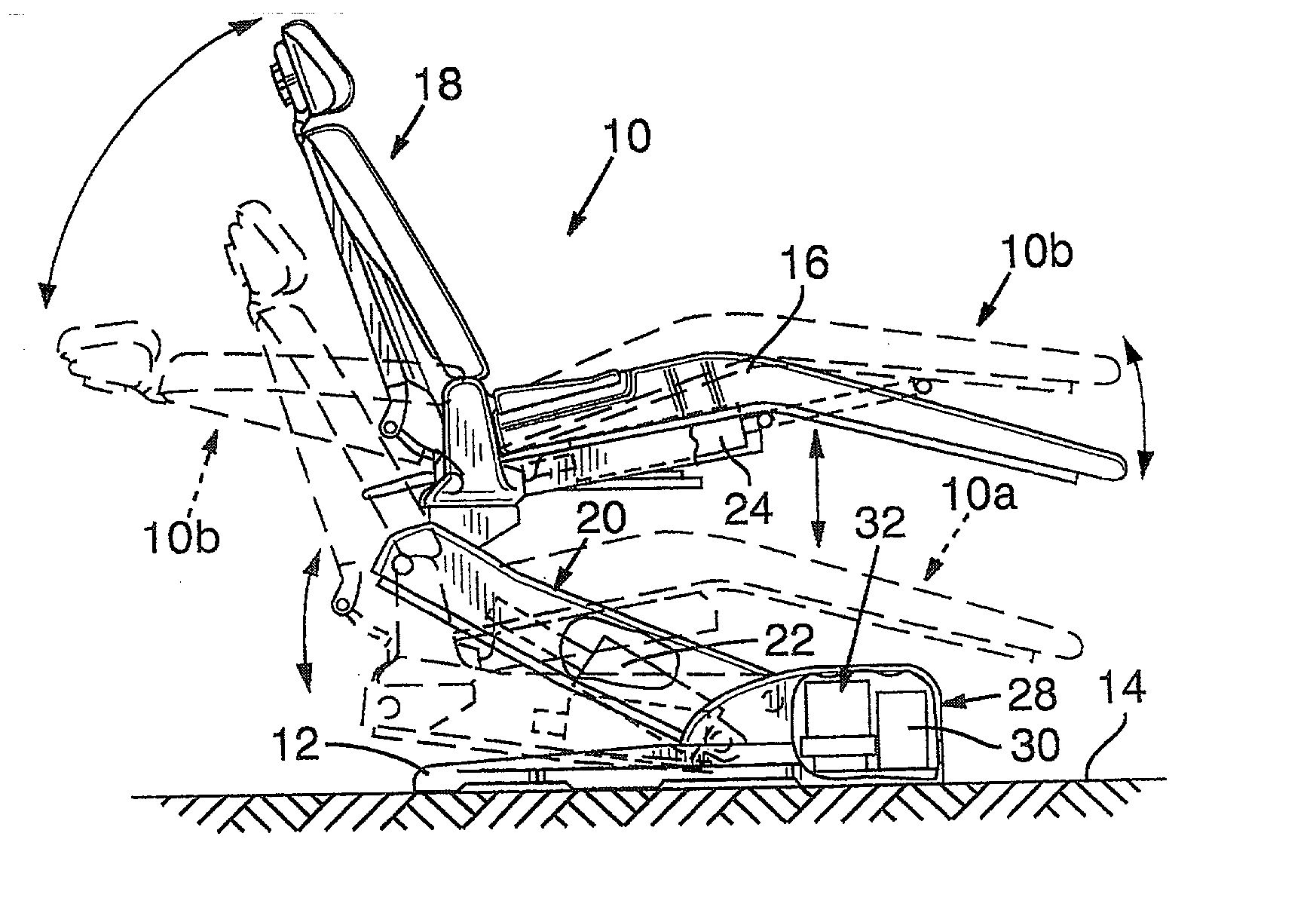

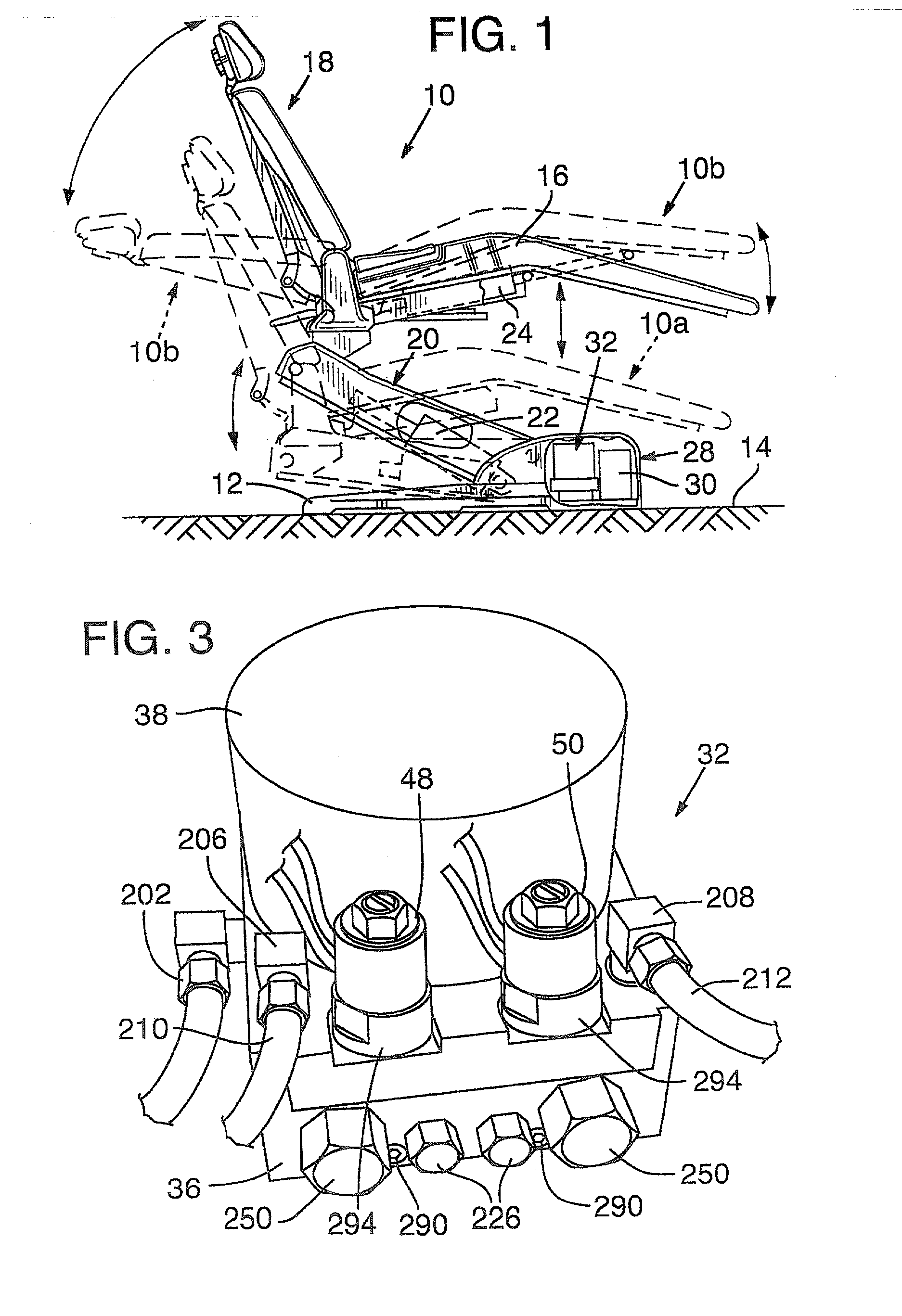

InactiveUS6814409B2Guaranteed uptimeStop operationFluid couplingsOperating chairsFluid controlGear pump

A hydraulic drive and fluid control system for a mechanism having at least two fluid actuated cylinder includes a bi-directional motor / gear pump. A monolithic block manifold has intersecting bores formed therein in which valving and control mechanism for the fluid circuit is mounted. The fluid control system includes a variety of elements for providing smooth action of the cylinders at start, stop, and intermediate operations. These include piston-style accumulators, self-actuating fluid flow rate control valves and cushion valves.

Owner:A DEC INC

Hydraulic drive system

InactiveUS20020149248A1Efficient productionGuaranteed uptimeFluid couplingsOperating chairsGear pumpFluid control

A hydraulic drive and fluid control system for a mechanism having at least two fluid actuated cylinder includes a bi-directional motor / gear pump. A monolithic block manifold has intersecting bores formed therein in which valving and control mechanism for the fluid circuit is mounted. The fluid control system includes a variety of elements for providing smooth action of the cylinders at start, stop, and intermediate operations. These include piston-style accumulators, self-actuating fluid flow rate control valves and cushion valves.

Owner:A-DEC

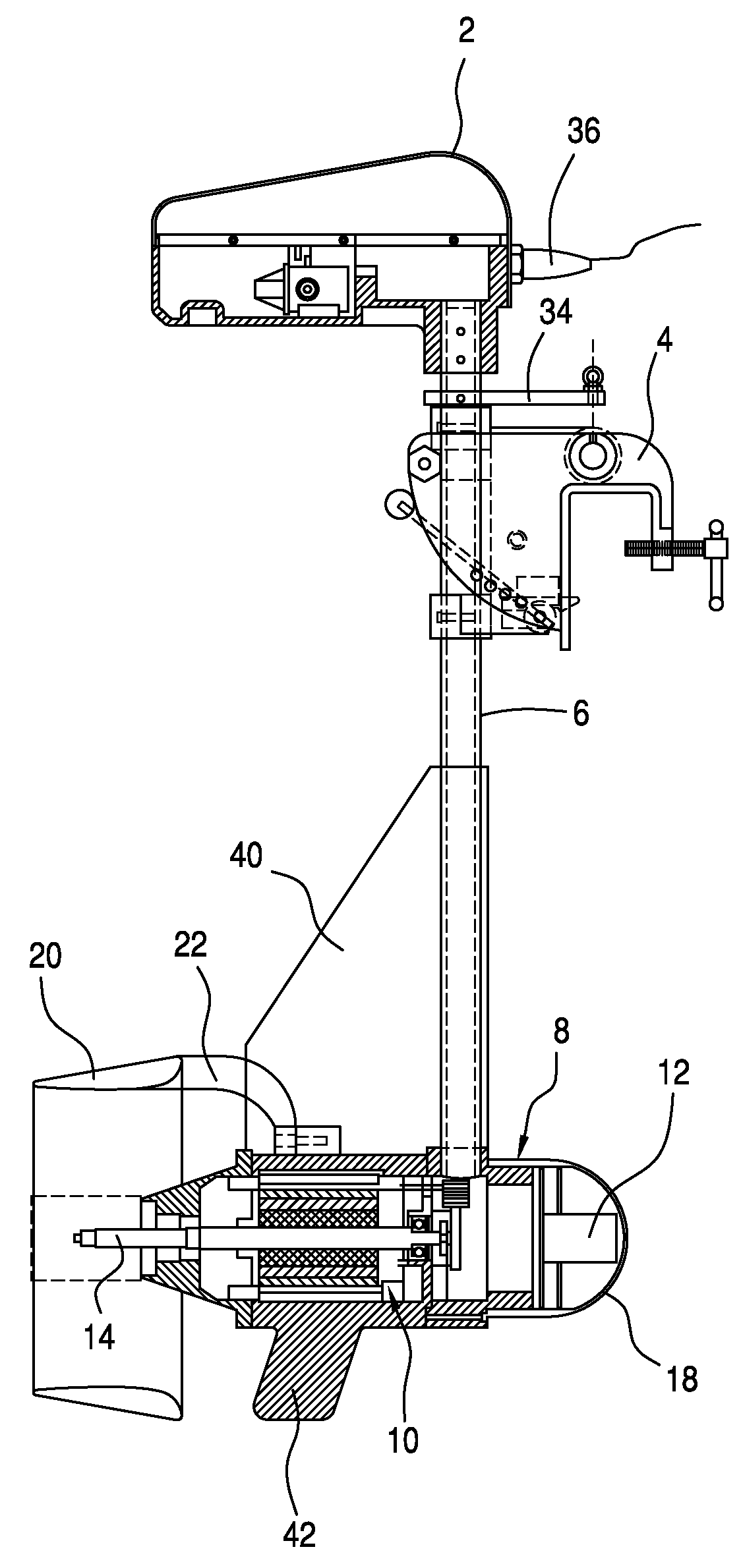

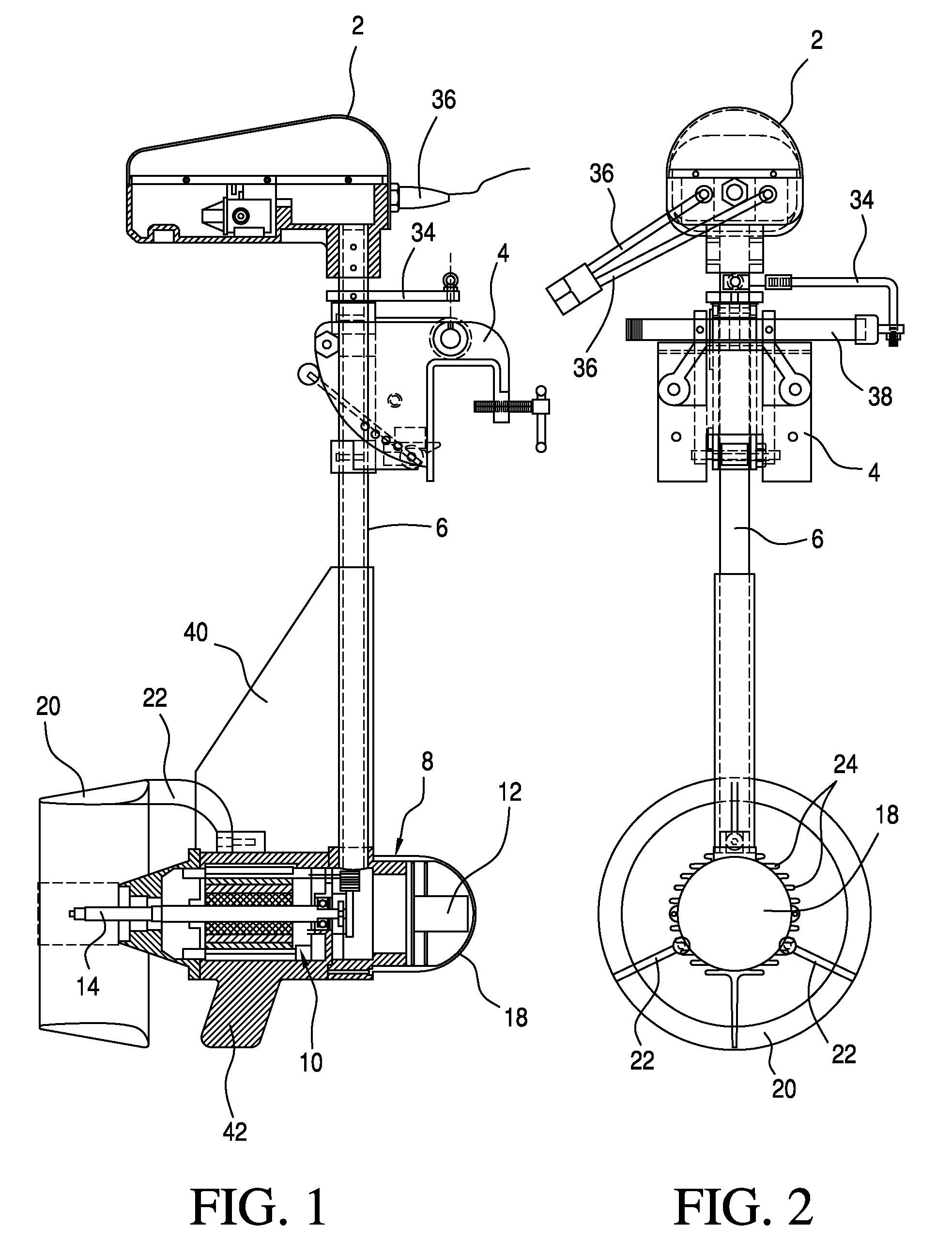

Marine propulsion device

InactiveUS20080293312A1High torque outputReduce energy consumptionPropulsion based emission reductionSteering ruddersHeat sinkMagnetic flux

A marine propulsion device such as an outboard motor includes a submersible electric motor having a propeller connected directly with the drive shaft of the motor. The motor is an efficient brushless motor having symmetrical elliptical coils connected with a stator which generate magnetic flux when current is passed through the coils to rotate a rotor for driving the drive shaft. The motor is arranged in a housing having a nozzle connected with a rear portion thereof which surrounds the propeller to reduce cavitation. Cooling fins are provided on the outer surface of the housing to assist with cooling the motor and a motor controller arranged in the housing.

Owner:SCOTT SEAN

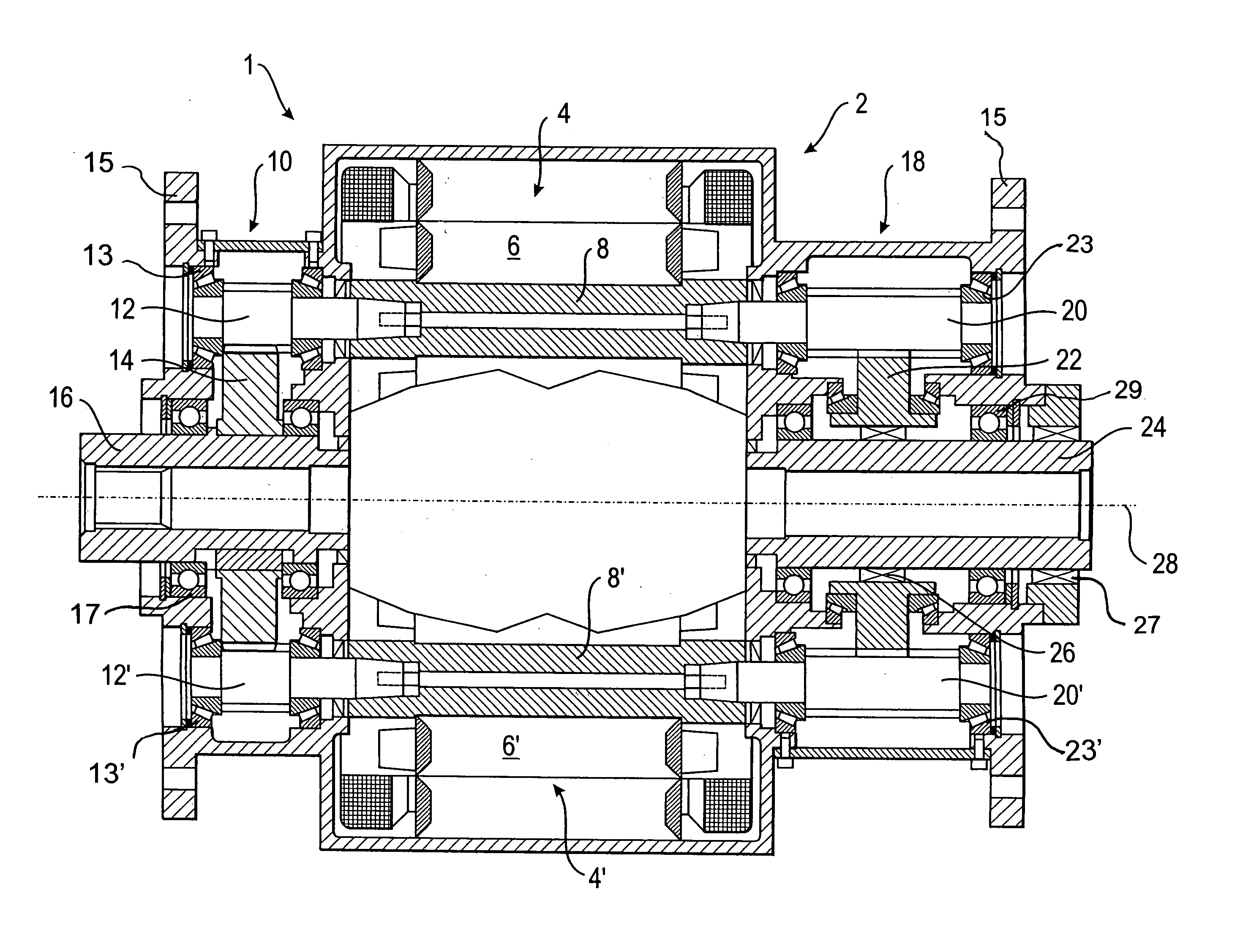

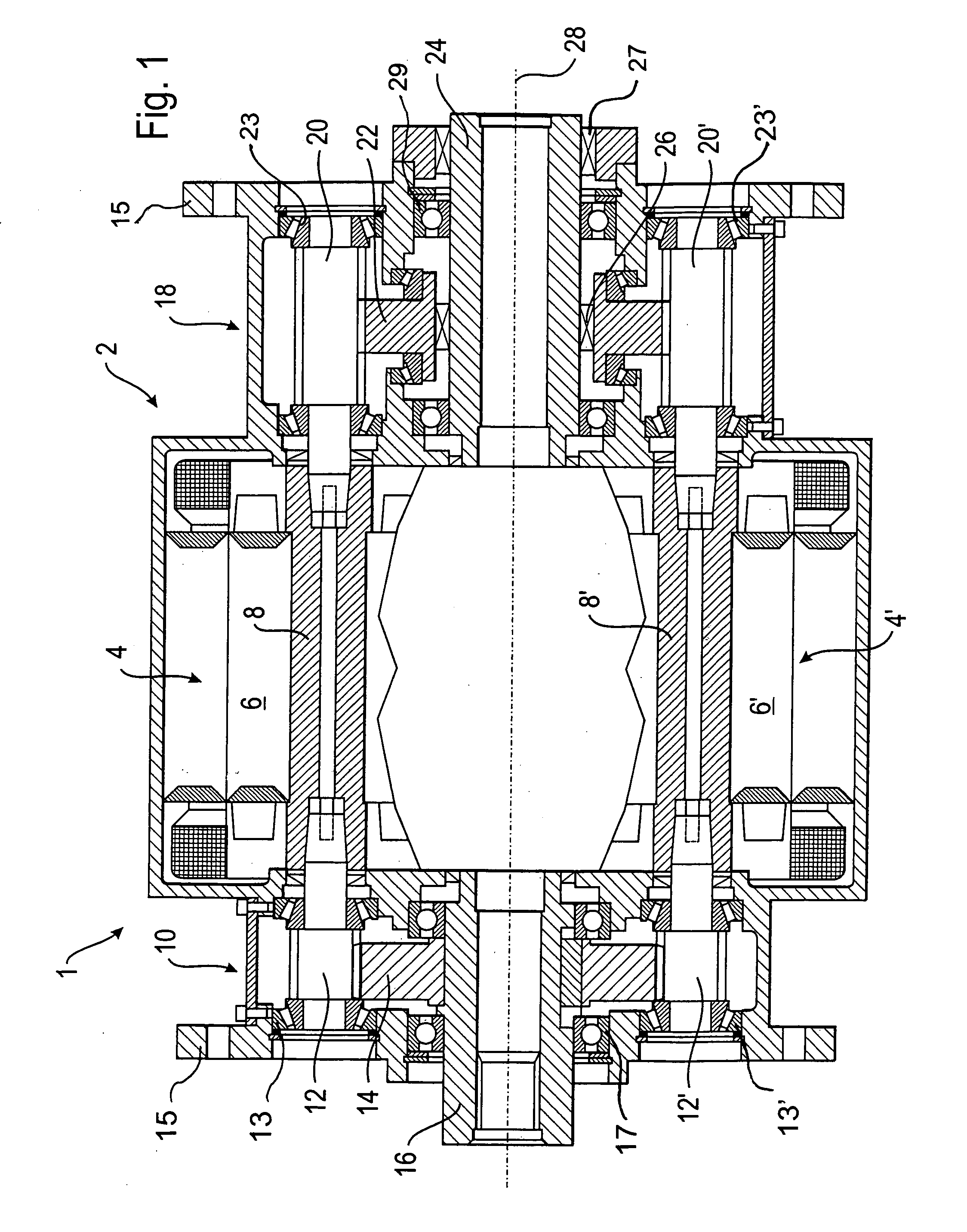

Engine arrangement

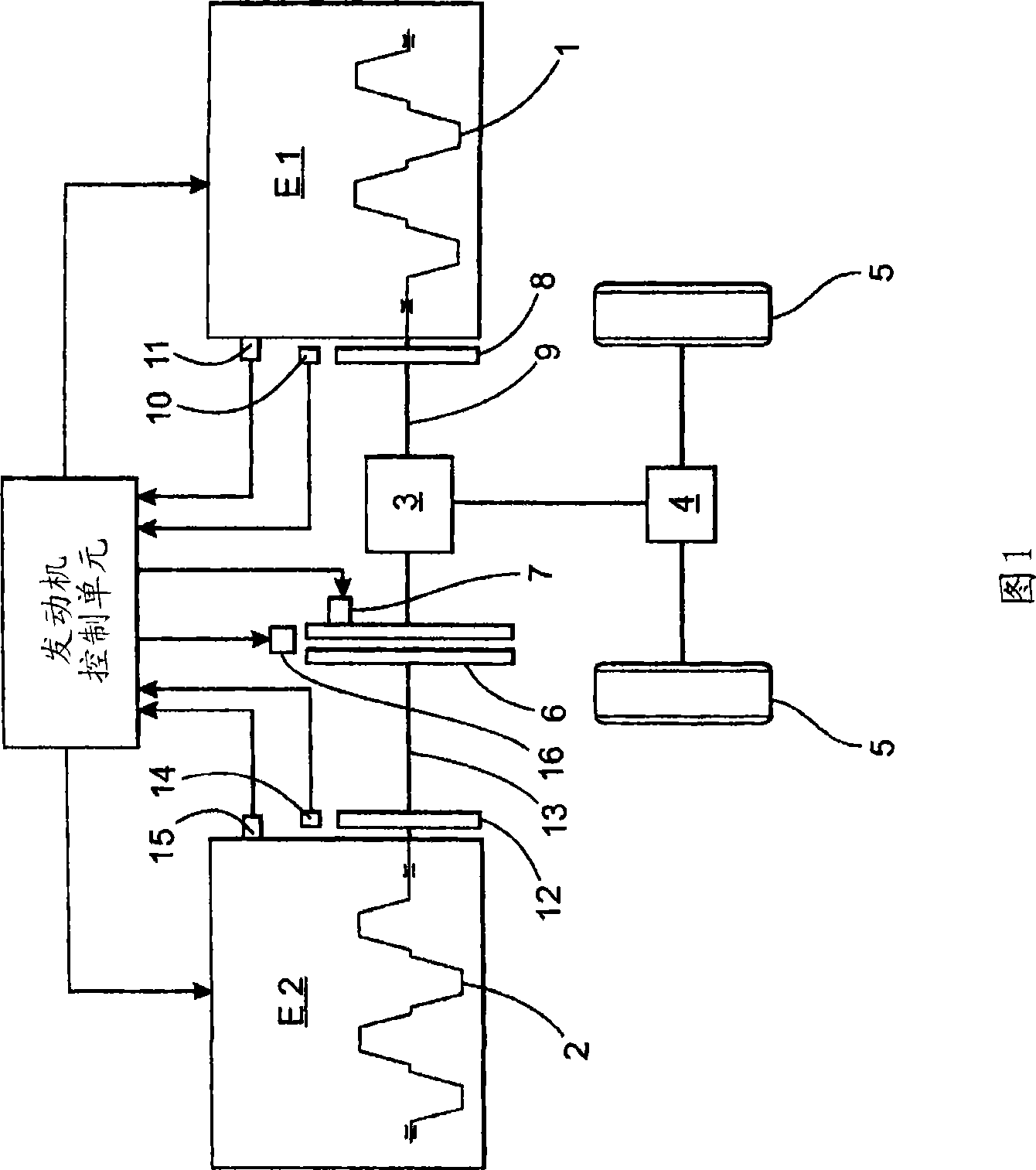

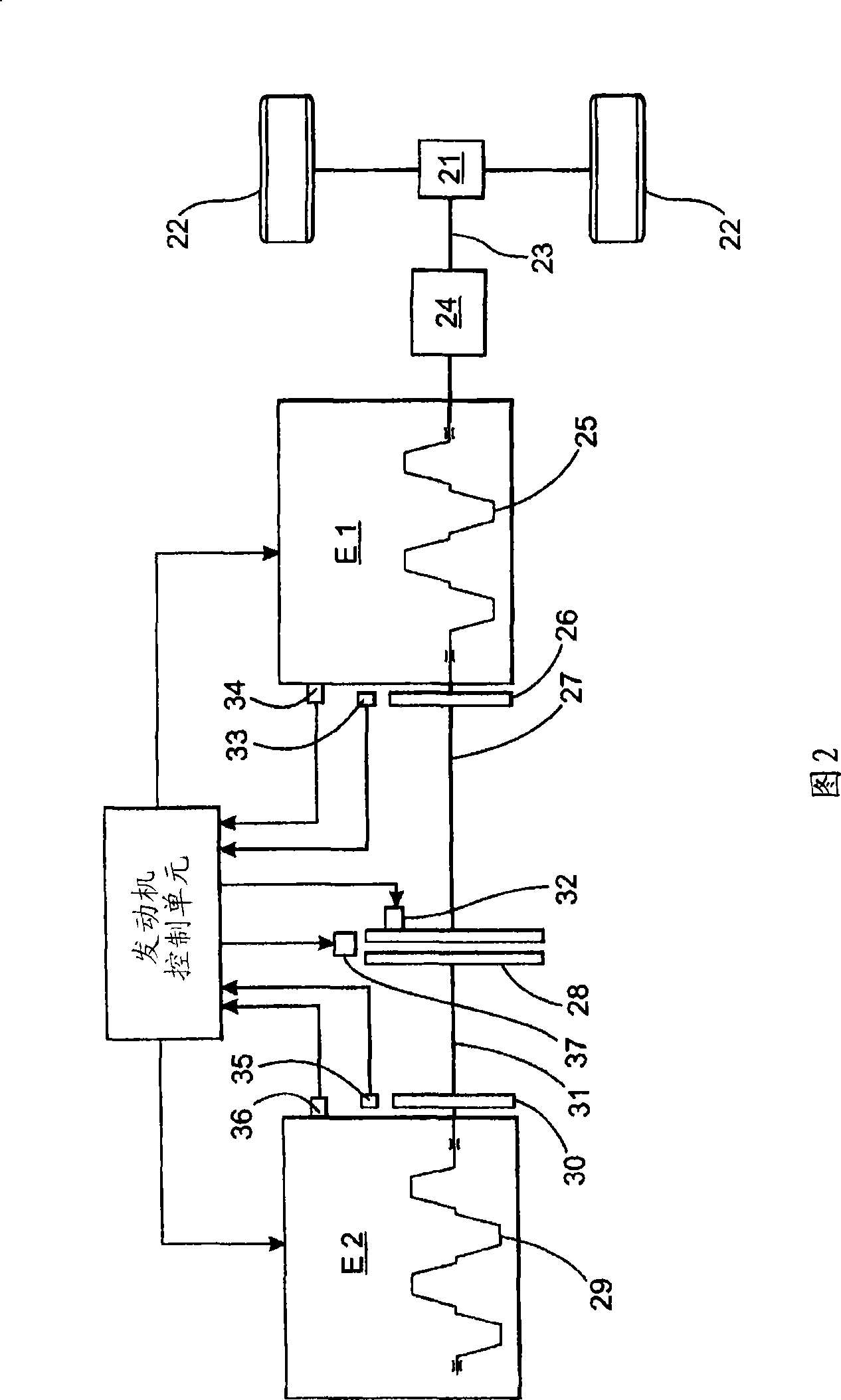

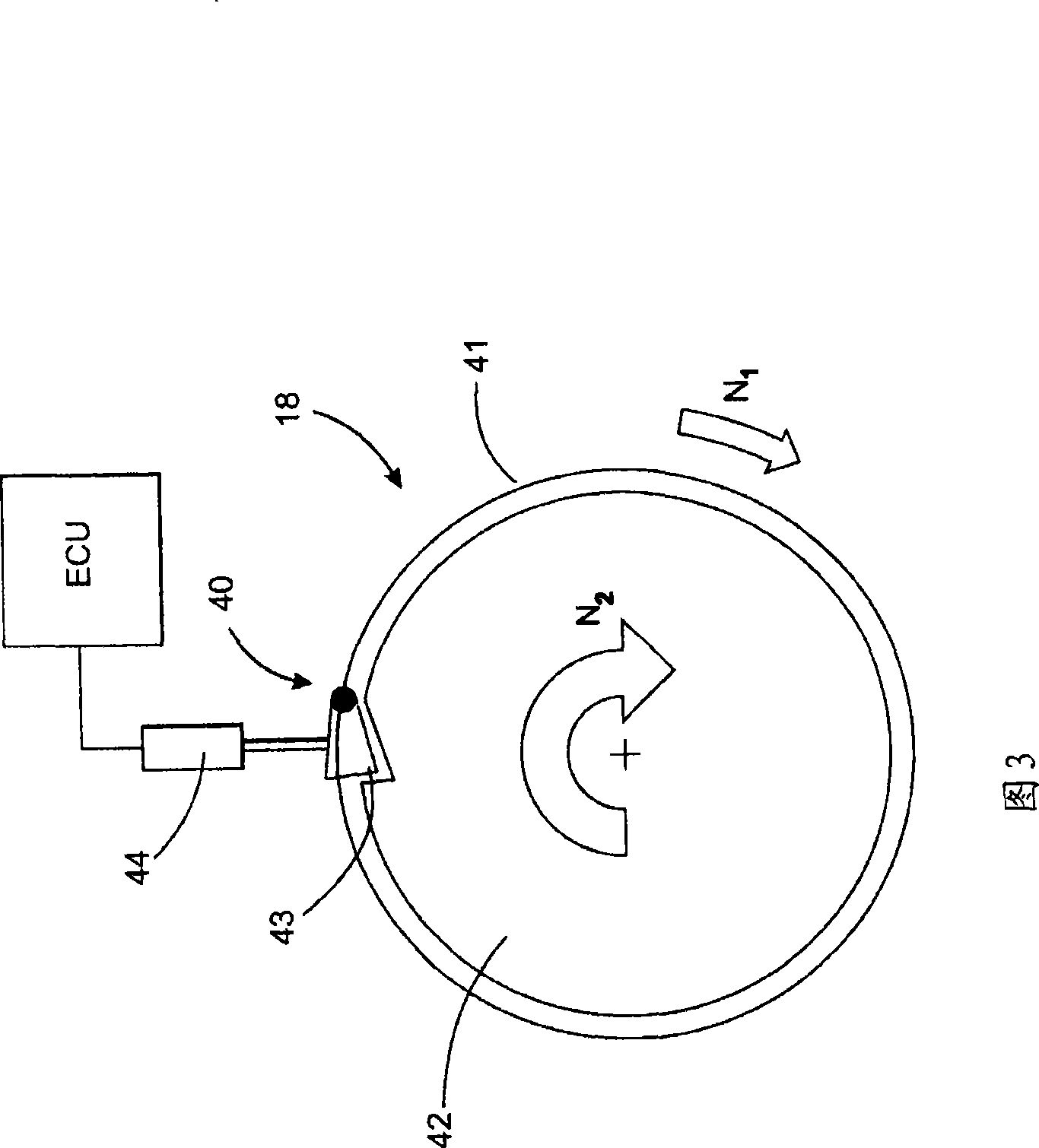

InactiveCN101450660AEliminate or at least reduce torque lossHigh torque outputElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

The invention relates to an engine arrangement and a method for controlling the same; the engine arrangement comprising a first and a second internal combustion engine, wherein each engine comprises a crankshaft and at least one cylinder with a piston connected to said crankshaft, a controllable clutch arranged between the crankshafts, an engine control unit for controlling the first and second engine and sensors for monitoring at least one operating parameter for the said engines connected to the engine control unit. According to the invention, the relative angular position of the crankshafts of the first and second engines are controlled using a sensed crankshaft position and the ignition timing sequence of the respective first and second engines. A controllable friction clutch is used to lock up the crankshafts of the first and second engines in said at least one predetermined relative angular position.

Owner:VOLVO CAR CORP

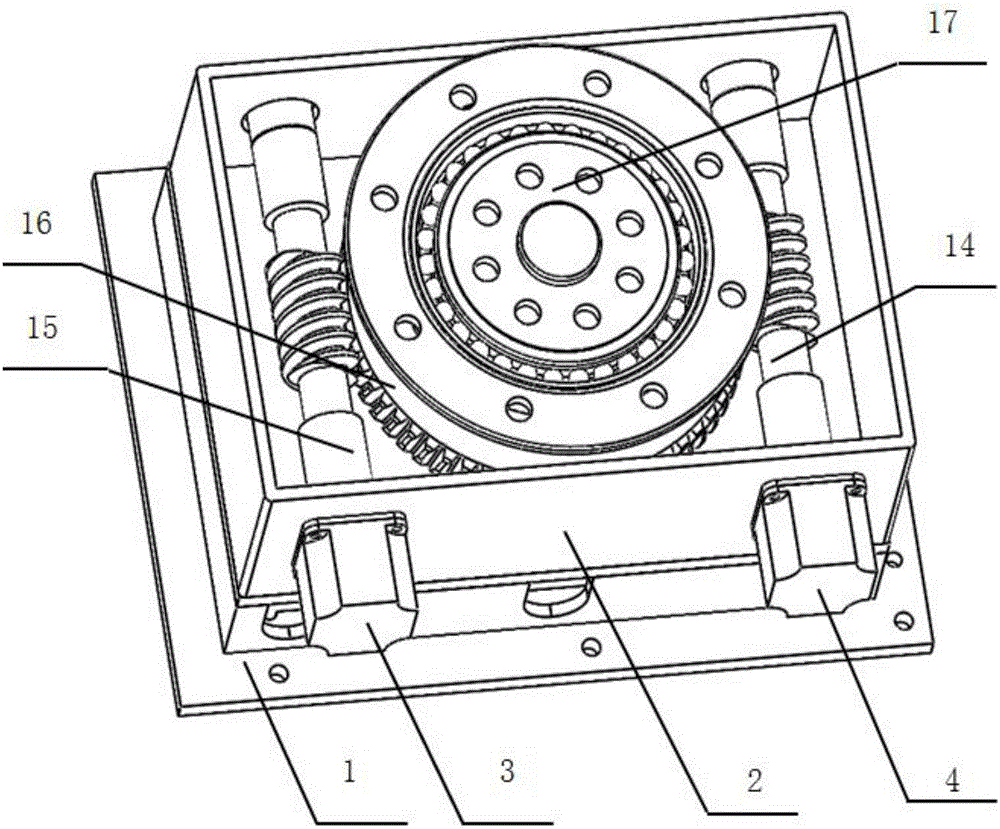

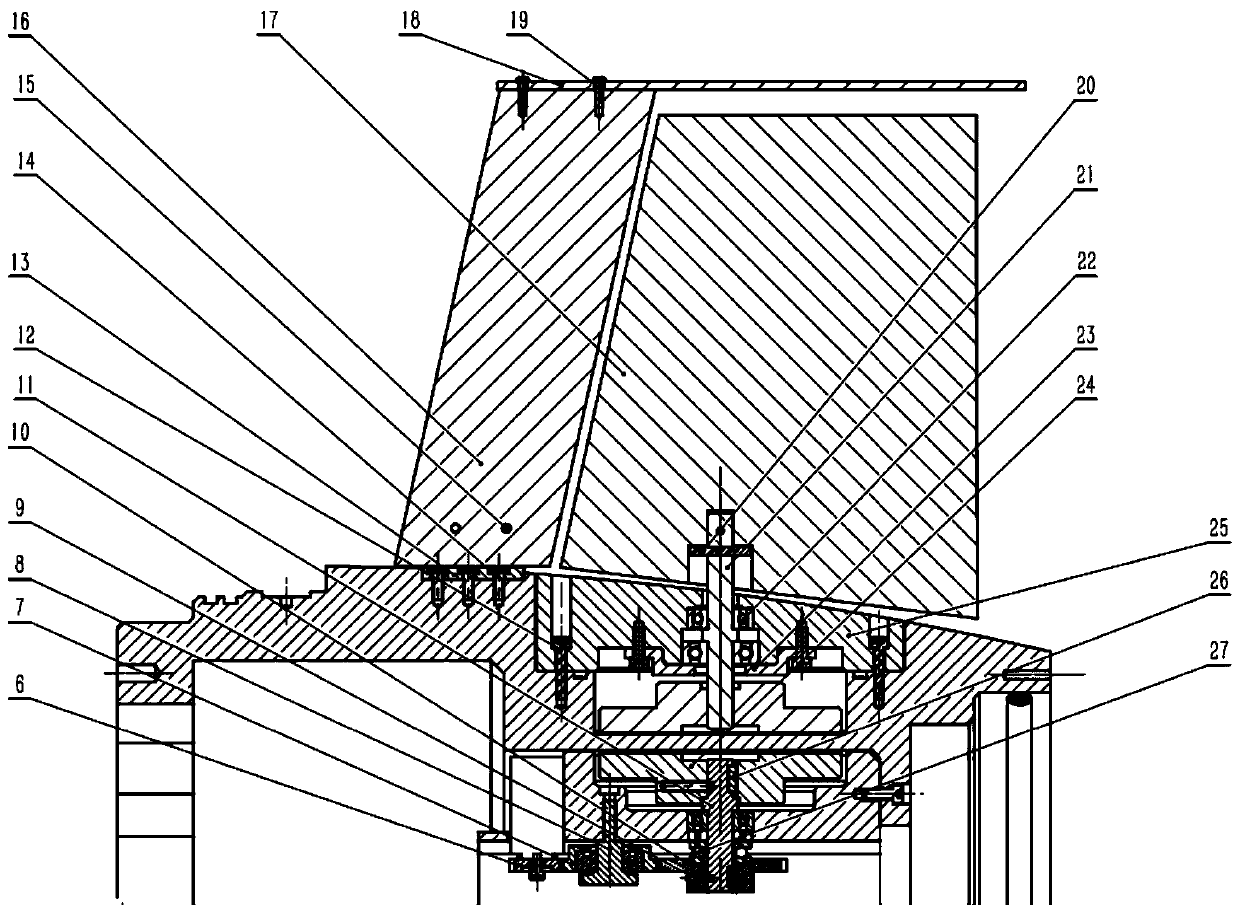

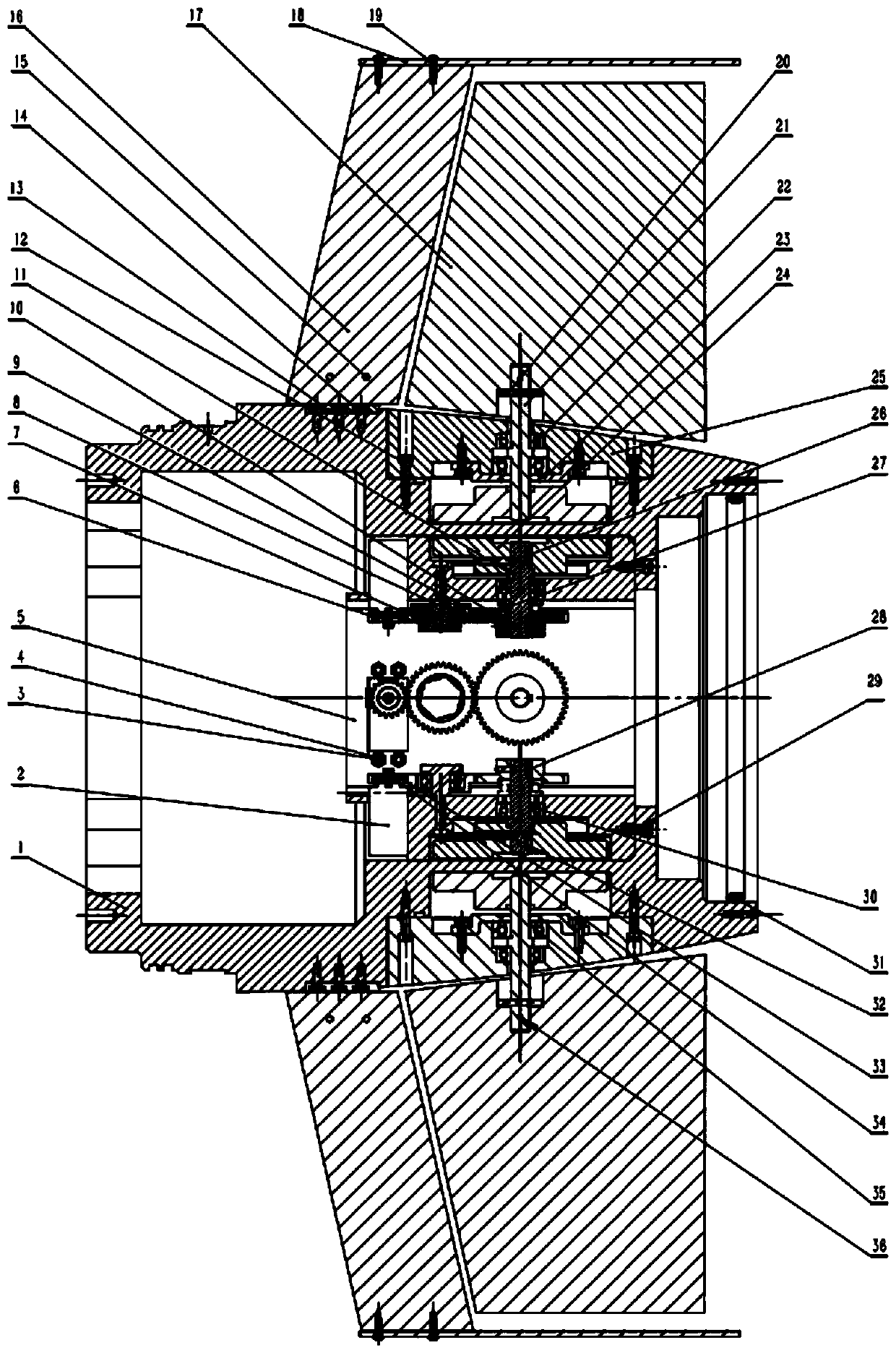

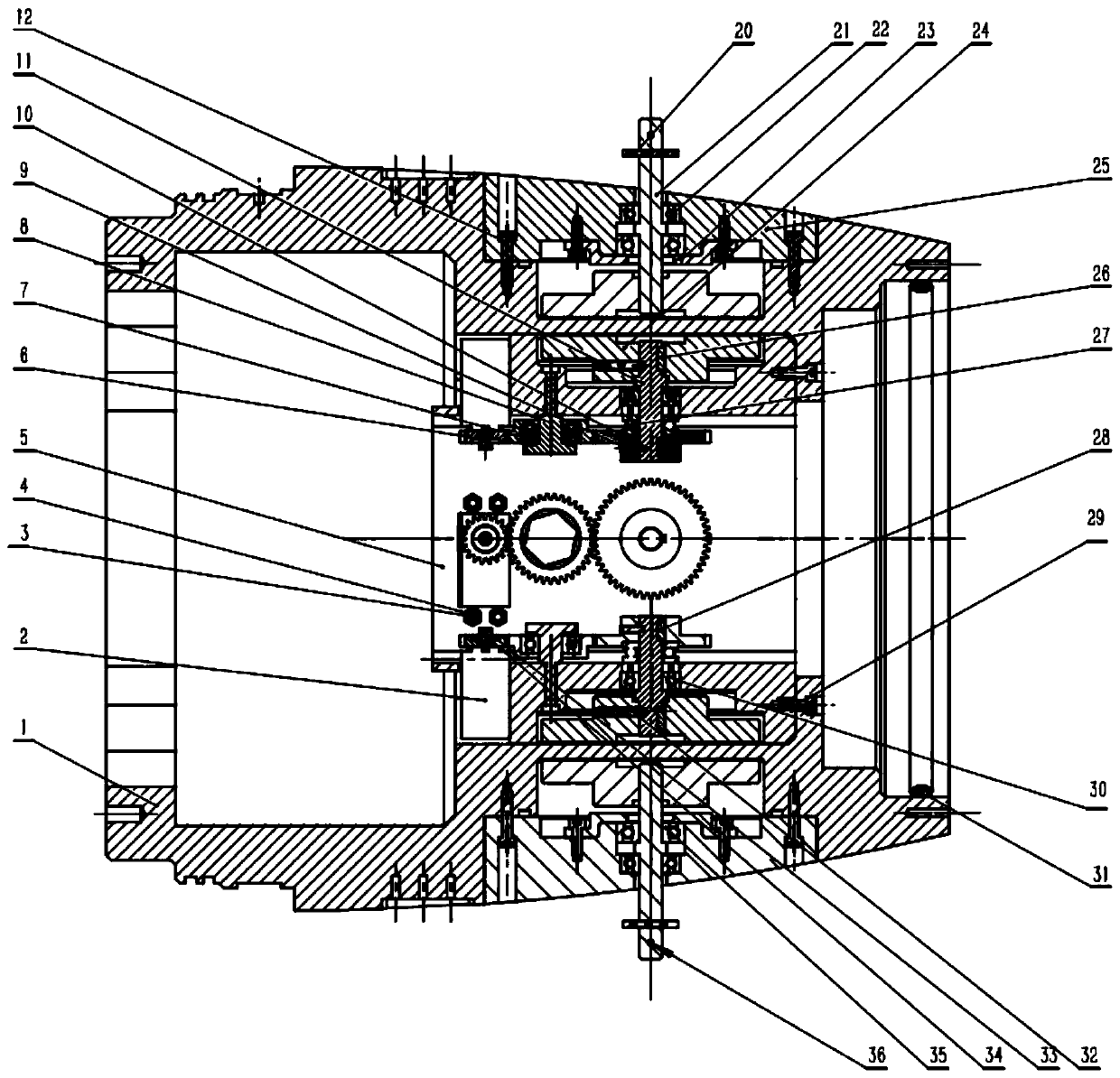

Six-freedom-degree manipulator driven by two motors

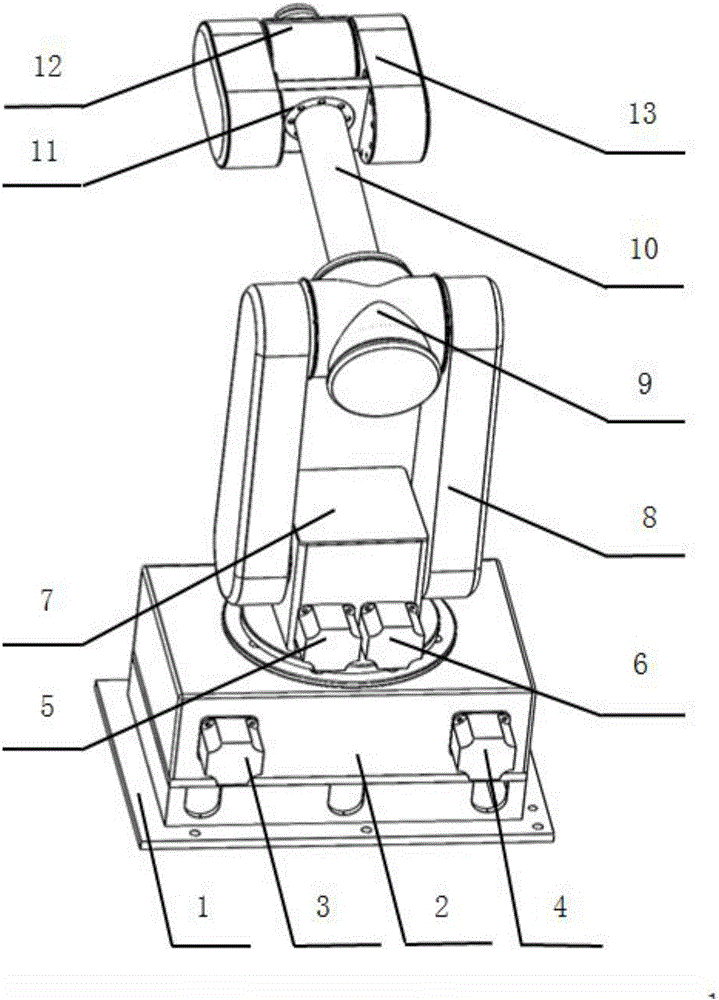

ActiveCN106181996AHigh torque outputEliminate transmission backlashProgramme-controlled manipulatorJointsMotor speedManipulator

The invention discloses a six-freedom-degree manipulator driven by two motors and belongs to the technical field of industrial robots. A manipulator base worm wheel can be driven through a base first servo motor speed reducer and a base second servo motor speed reducer simultaneously. A shoulder joint output shaft can be driven through a shoulder joint first servo motor speed reducer and a shoulder joint second servo motor speed reducer simultaneously. An elbow joint first output bevel gear can be driven through an elbow joint first servo motor speed reducer and an elbow joint second servo motor speed reducer or an elbow joint third servo motor speed reducer and an elbow joint fourth servo motor speed reducer simultaneously. A wrist joint first output bevel gear can be driven through a wrist joint first servo motor speed reducer and a wrist joint second servo motor speed reducer or a wrist joint third servo motor speed reducer and a wrist joint fourth servo motor speed reducer simultaneously. Therefore, the gear transmission clearance can be eliminated by loading moment on the servo motor speed reducers through a controller to form a moment difference, and the transmission accuracy of the manipulator is improved accordingly.

Owner:NORTHEASTERN UNIV LIAONING

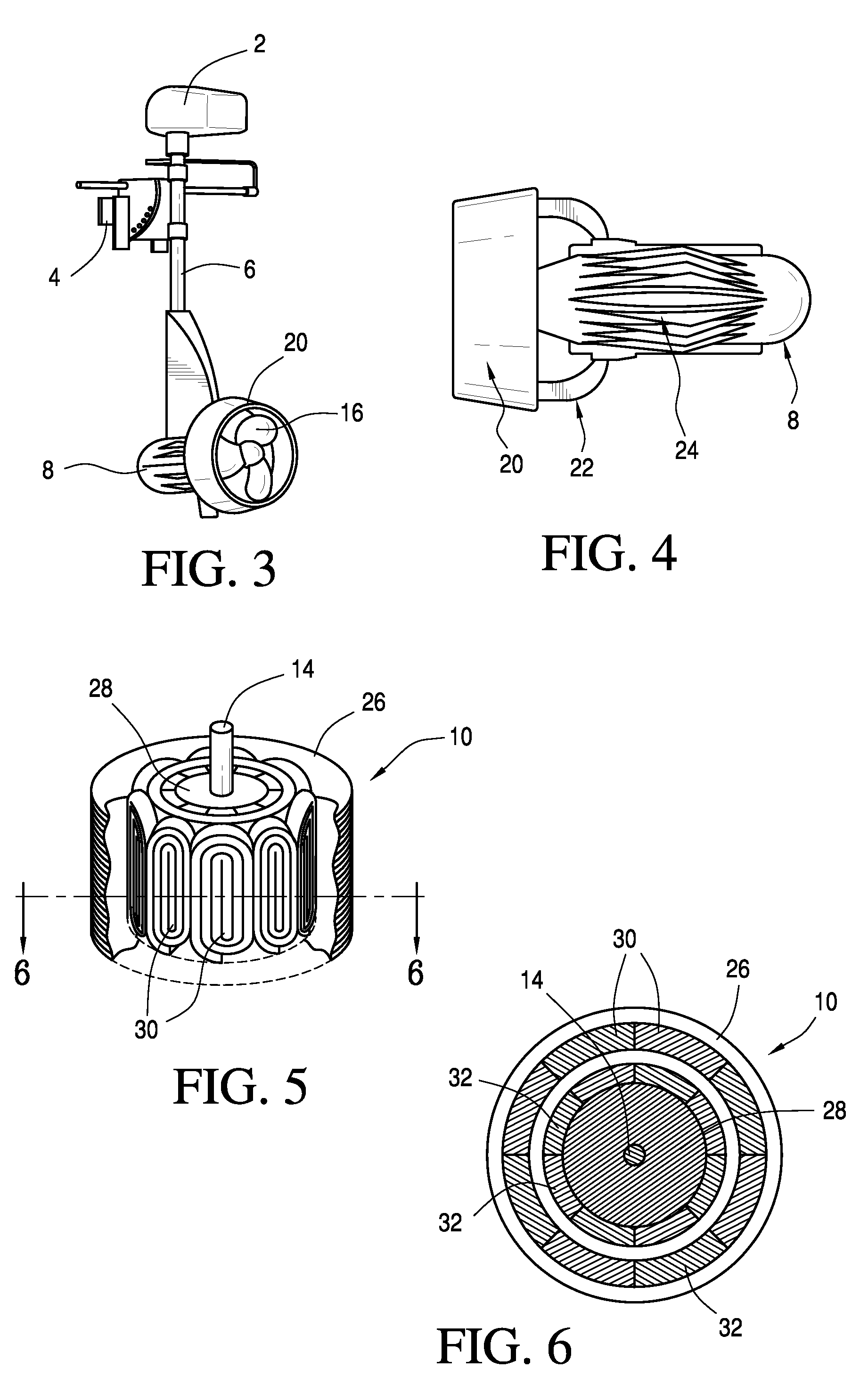

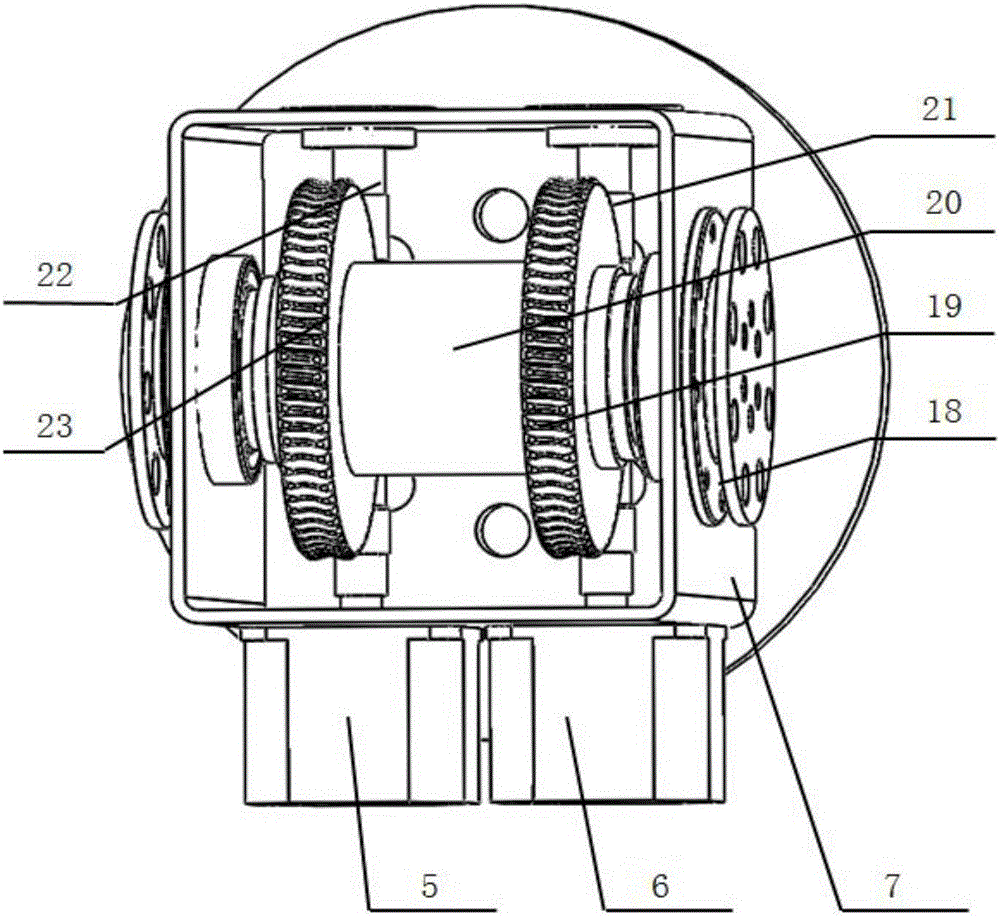

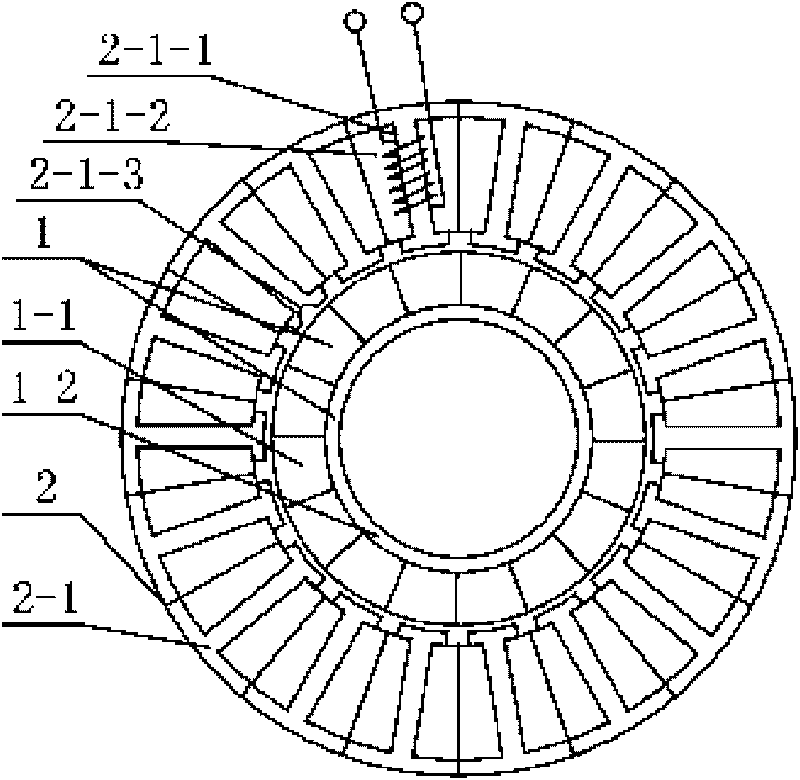

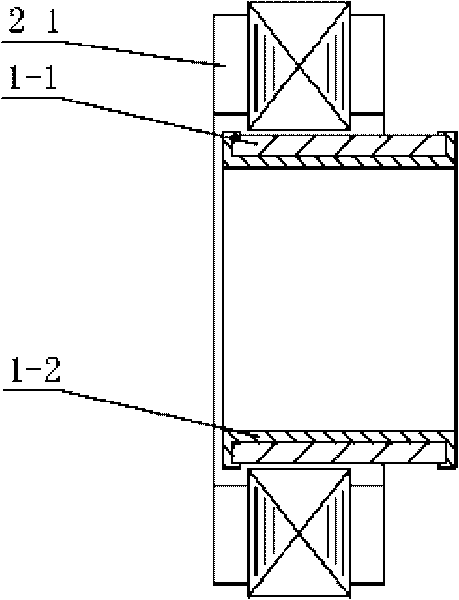

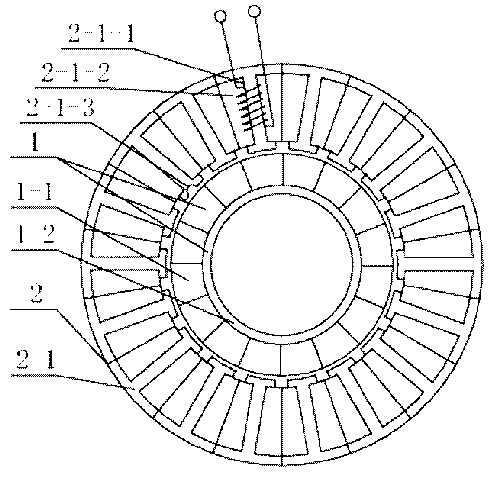

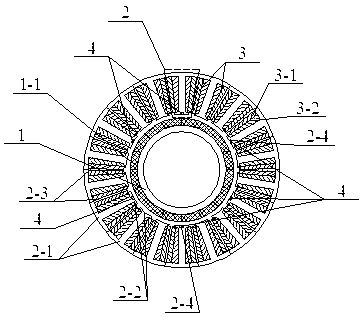

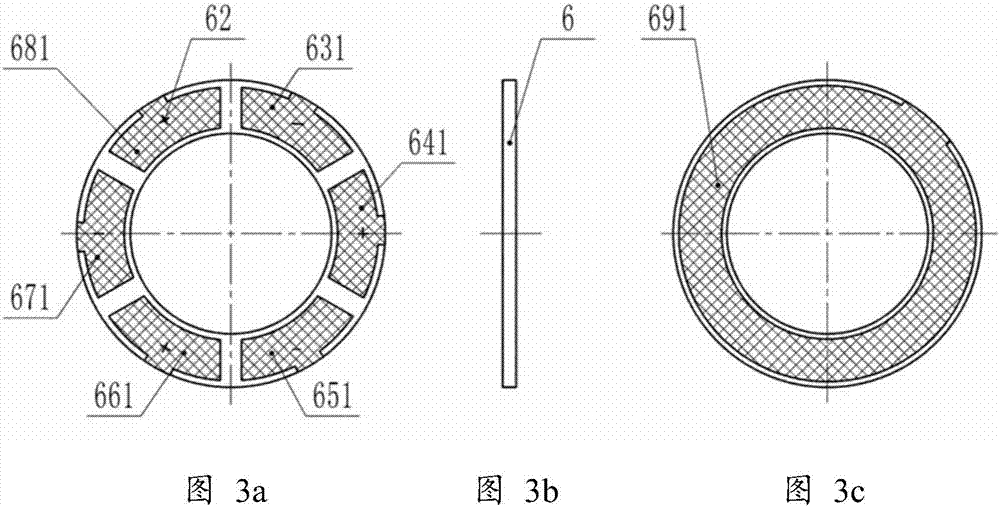

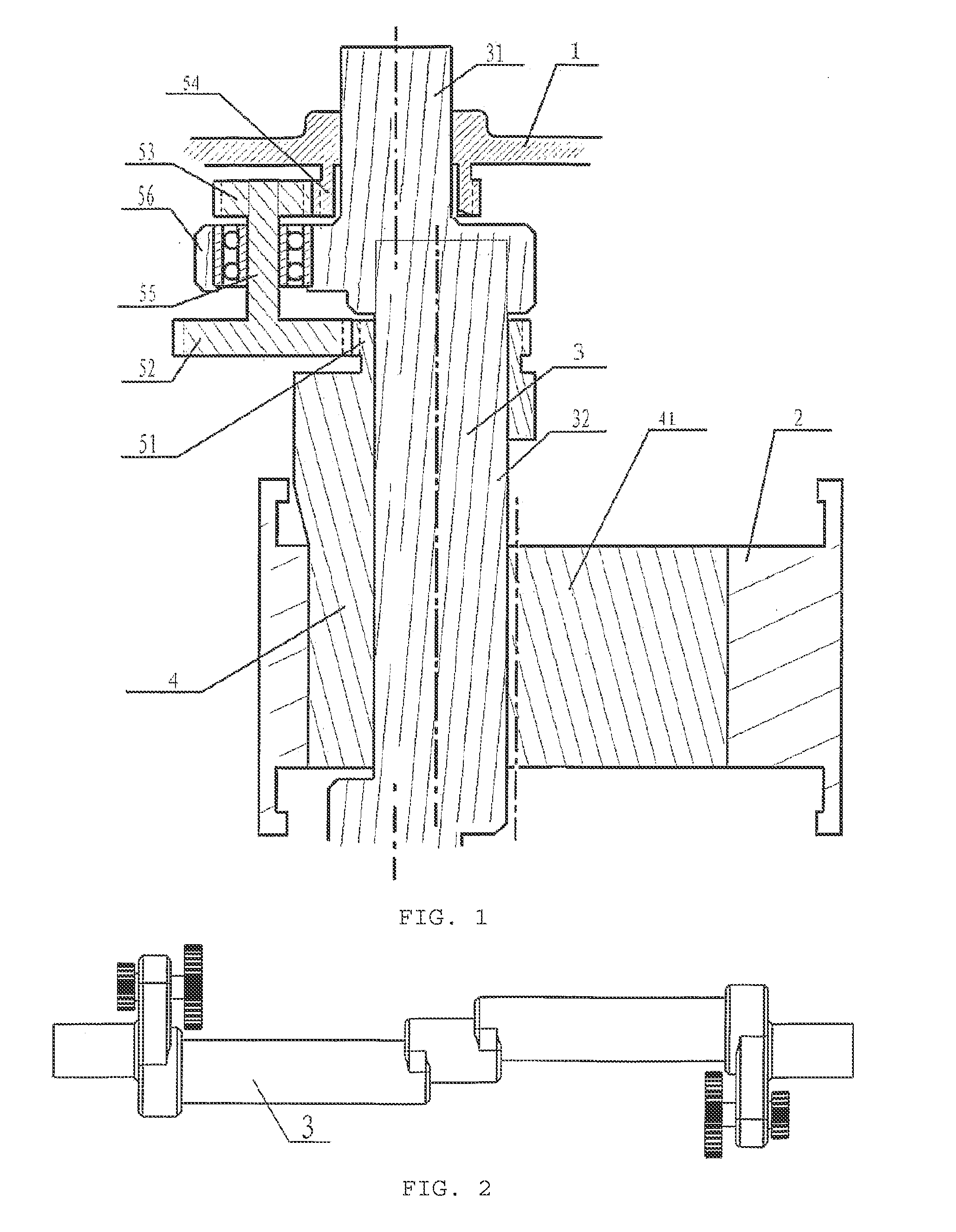

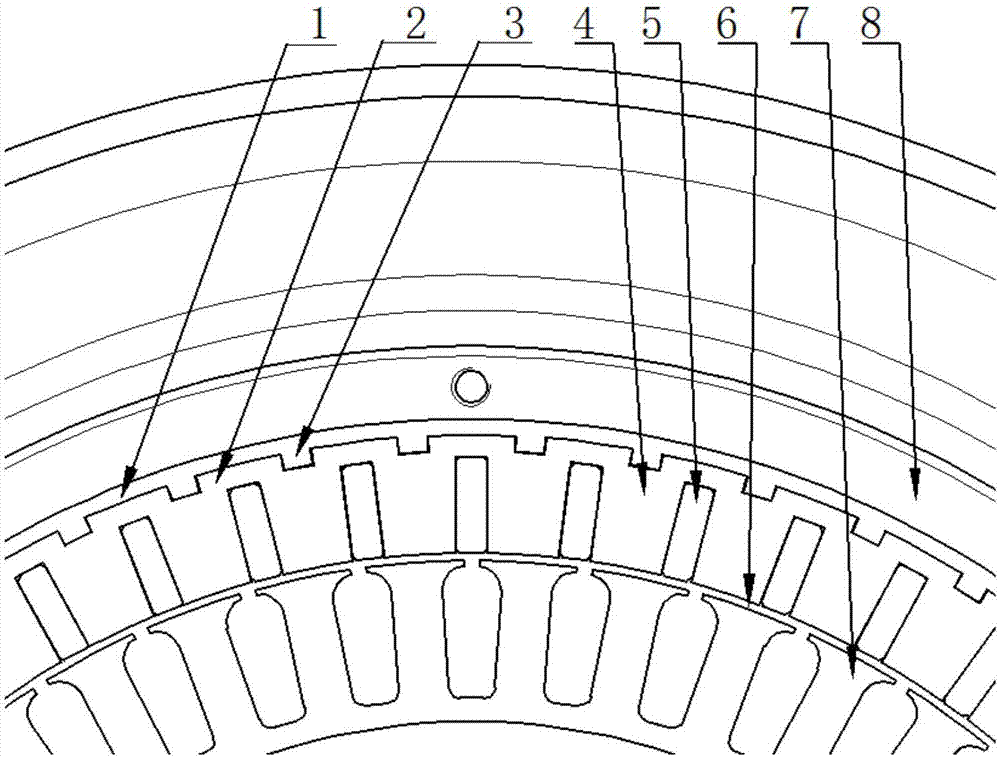

High-power density permanent magnetic brushless motor with moment holding function for mechanical arm

ActiveCN101702563AMeet the requirements of low speed operationReduce complex proceduresMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsElectric machine

The invention relates to a high-power density permanent magnetic brushless motor with moment holding function for a mechanical arm, belonging to the technical field of motors and solving the problem that a gear reducing device is required to be arranged in the traditional space mechanical arm driven by a high-speed motor to cause the motor system to have complex structure. A hollow disc type permanent magnetic rotor of the high-power density permanent magnetic brushless motor comprises a rotor magnetic pole and a clasp type rotor yoke, wherein the rotor magnetic pole and the clasp type rotor yoke are in clearance fit; each rotor iron core of a stator is provided with a stator tooth, a plurality of stator iron cores are connected in an end-to-end way to form the stator teeth and stator slots, which are arranged at intervals, three phases of symmetrical windings are arranged on the stator teeth in a fractional slot way, turn numbers of the each phase of windings are same, the same phase of windings wound on each stator tooth are mutually connected in series; air gaps are arranged between inner circle surfaces of the plurality of stator iron cores and outer circle surface of the rotor magnetic pole; and partial stator teeth in the stator teeth of the plurality of stator iron cores are provided with semicircular slots at the air gap sides to enable the motor body to have the moment holding function. The invention is used for the position control of the space mechanical arm.

Owner:HARBIN INST OF TECH

A magnetic coupling steering device for a deep sea autonomous underwater vehicle

InactiveCN109703728AAchieve torque outputHigh torque outputSteering ruddersUnderwater vehicleEnergy consumption

The invention relates to a magnetic coupling steering device for an autonomous underwater vehicle (AUV) in deep sea, belongs to the field of underwater robot, and specifically relates to a rudder rotating device of the autonomous underwater vehicle (AUV). Disc type magnetic couplers are arranged inside and outside an autonomous underwater vehicle (AUV) cabin. The external magnetic coupler and a bearing block are embedded into the cabin body, one end of an outer rudder shaft is connected with the external magnetic coupler, the other end of the outer rudder shaft is connected with a rudder through a cylindrical pin, the outer rudder shaft is installed on the bearing block through the bearing, one end of an inner rudder shaft is connected with the internal magnetic coupler, and the other endof the inner rudder shaft is connected with a gear; the inner rudder shaft is arranged on an inner support via a bearing. According to the embodiment, a driving mechanism uses a transmission mechanismto drive the inner rudder shaft to rotate, and uses the disc type magnetic couplers to drive the outer rudder shaft and the rudder to rotate synchronously, thus realizing rotation control over the rudder of the deep sea autonomous underwater vehicle (AUV). The magnetic coupling steering device has the advantages of being good in sealing performance, small in appearance resistance, low in energy consumption, high in reliability and the like.

Owner:CHINA JILIANG UNIV

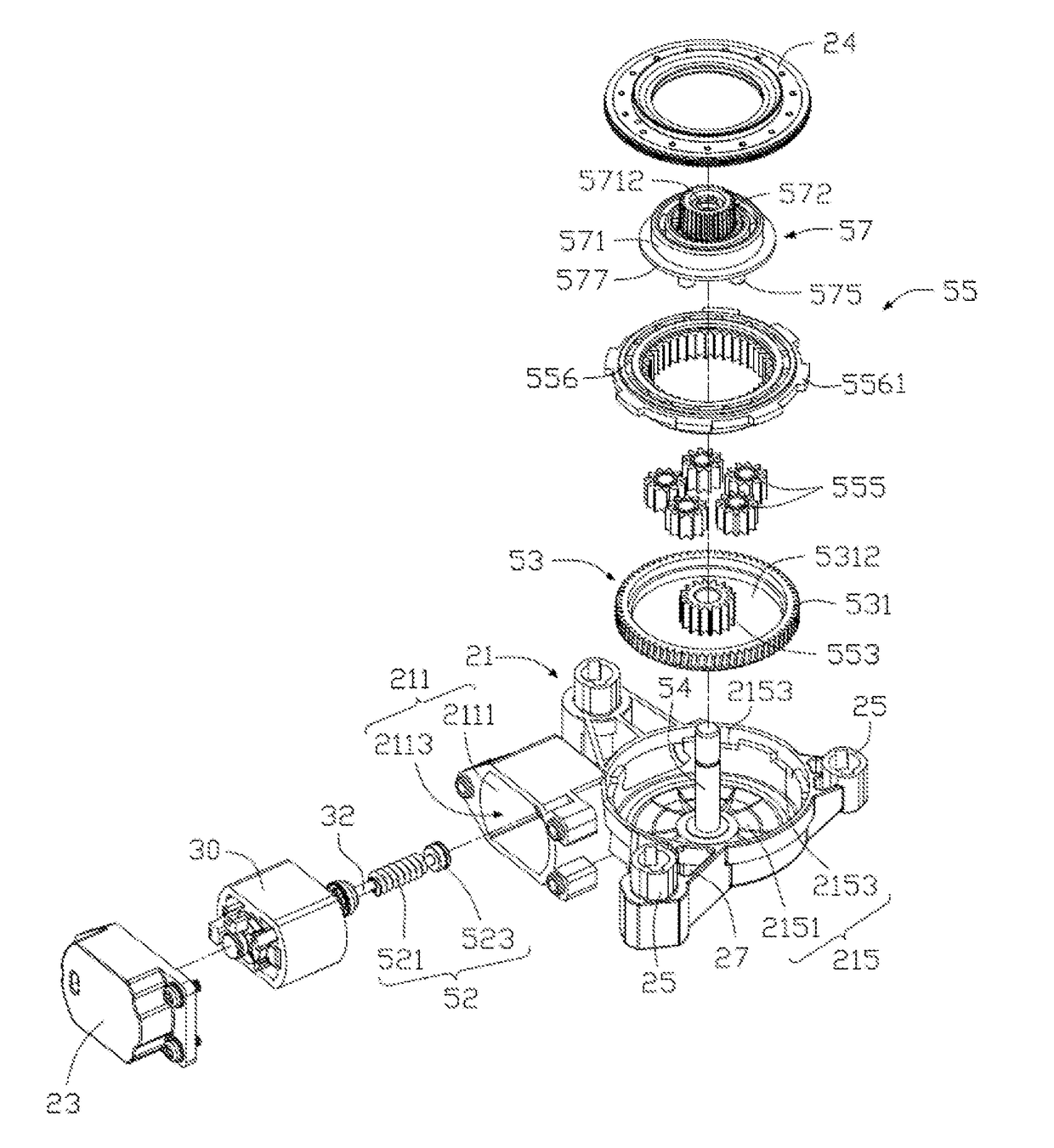

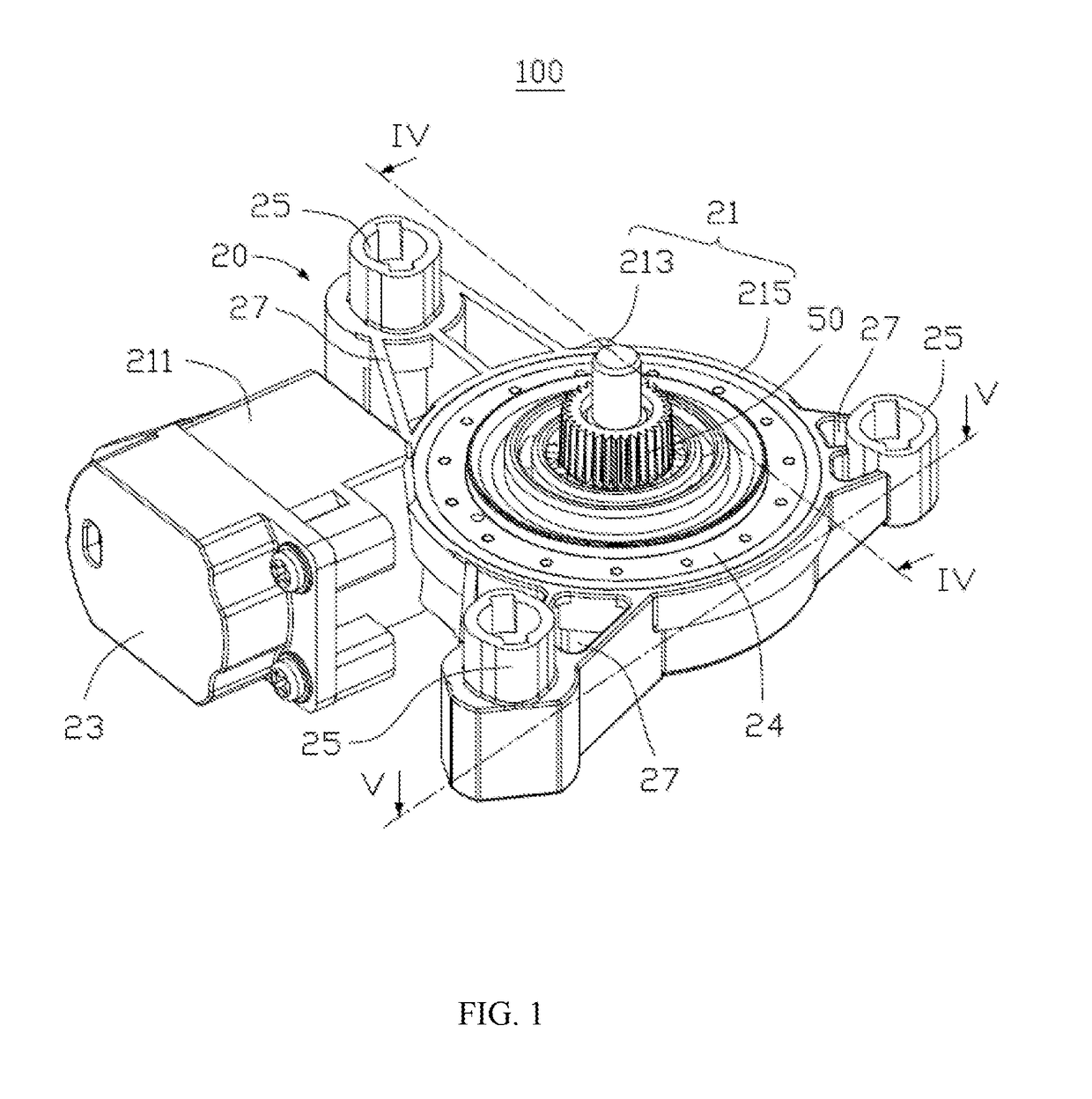

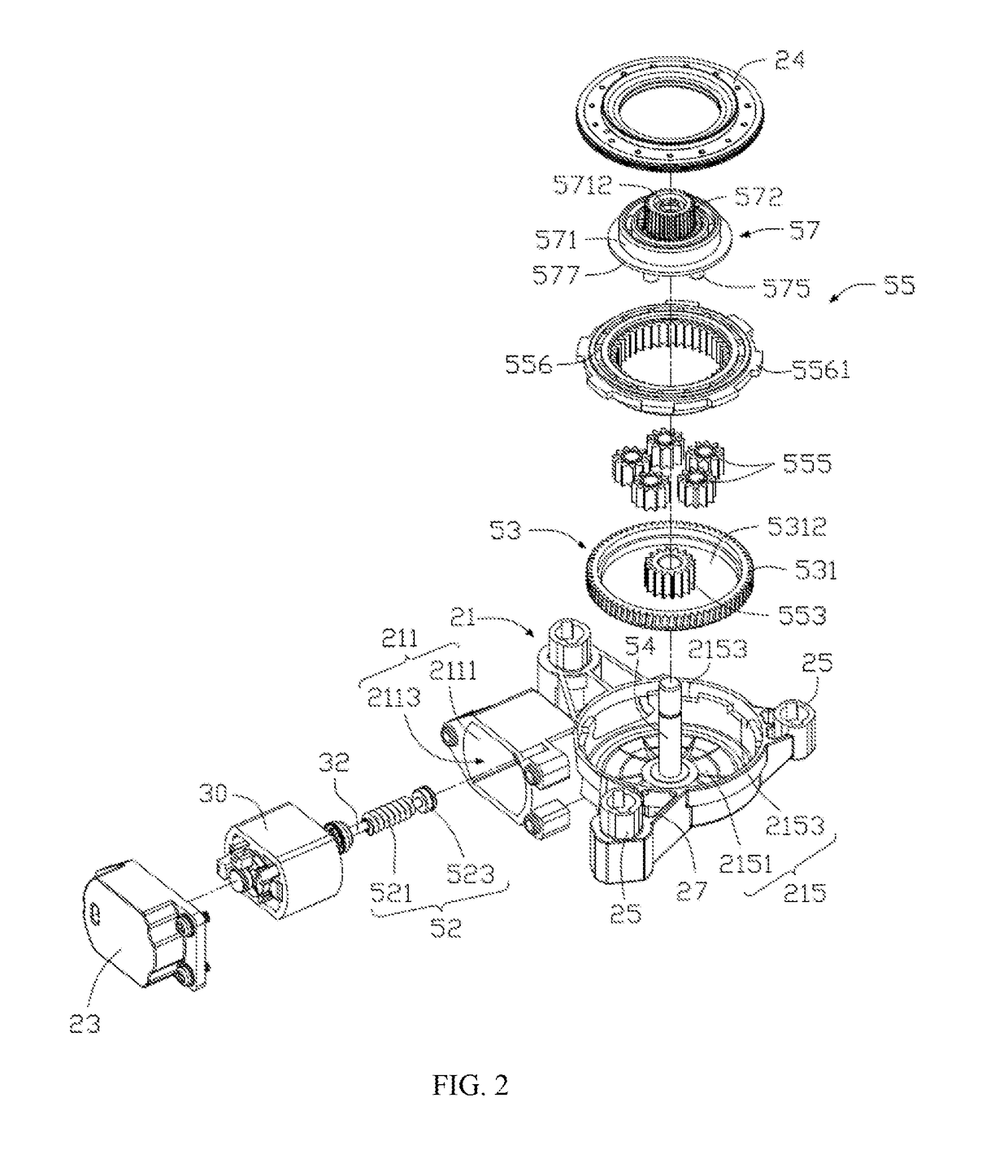

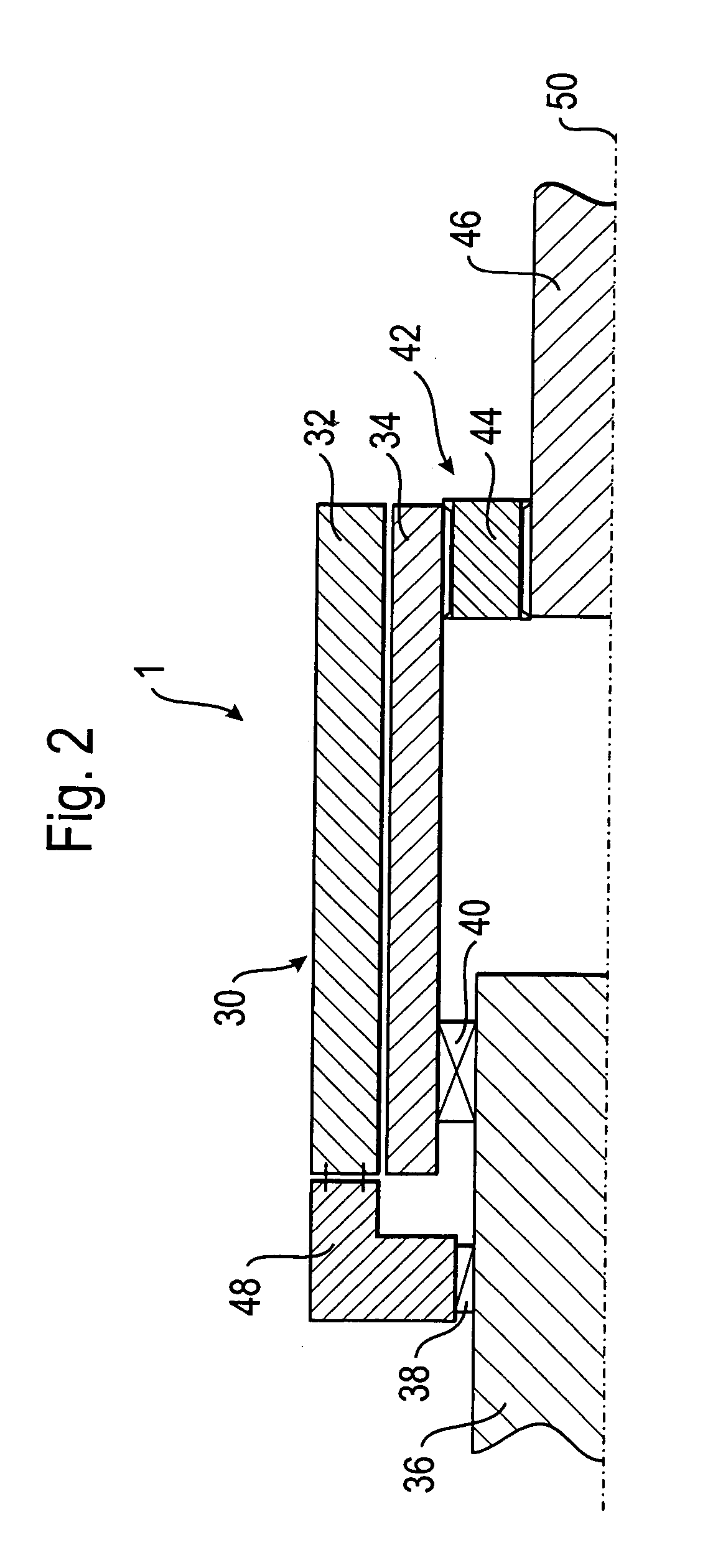

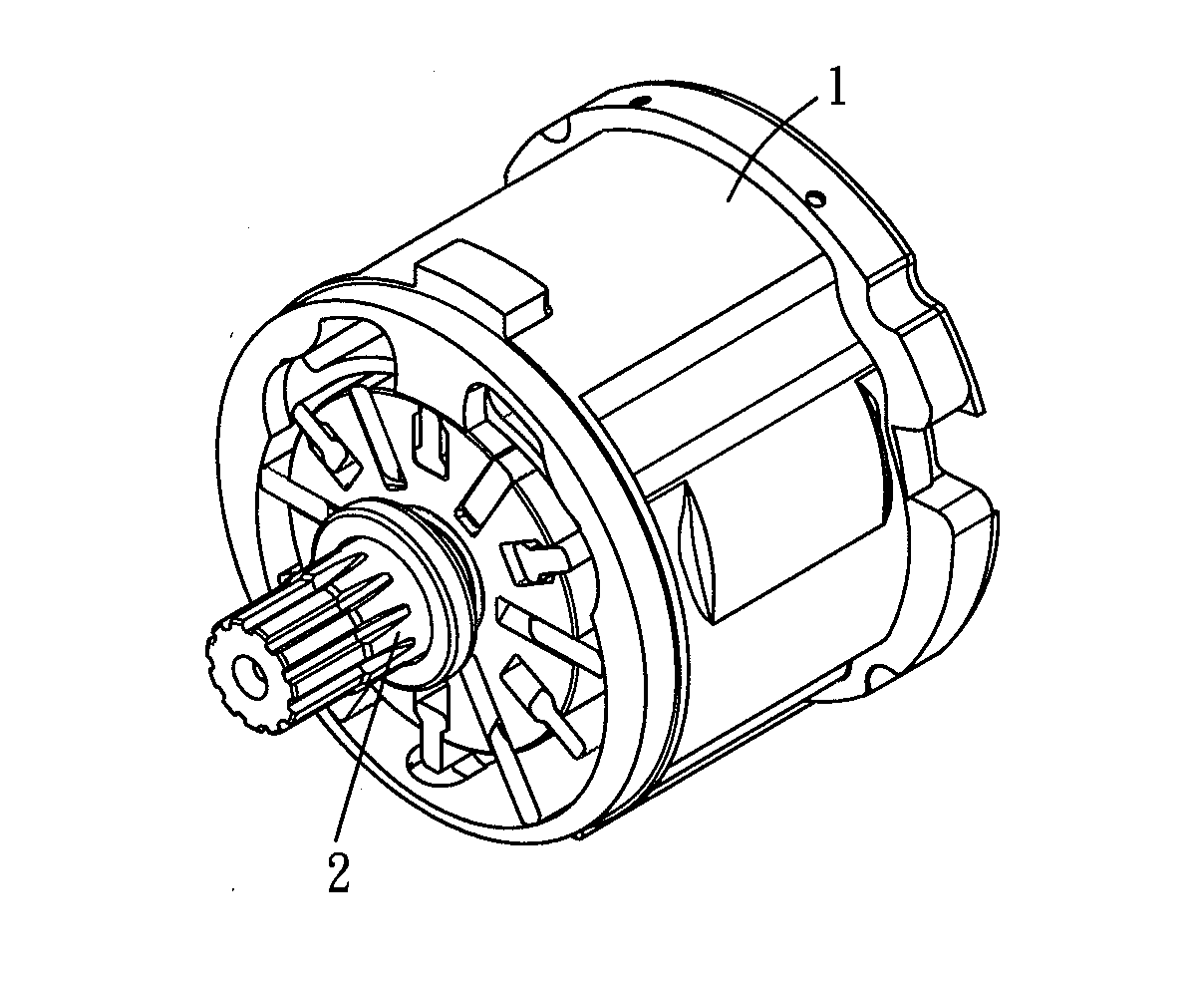

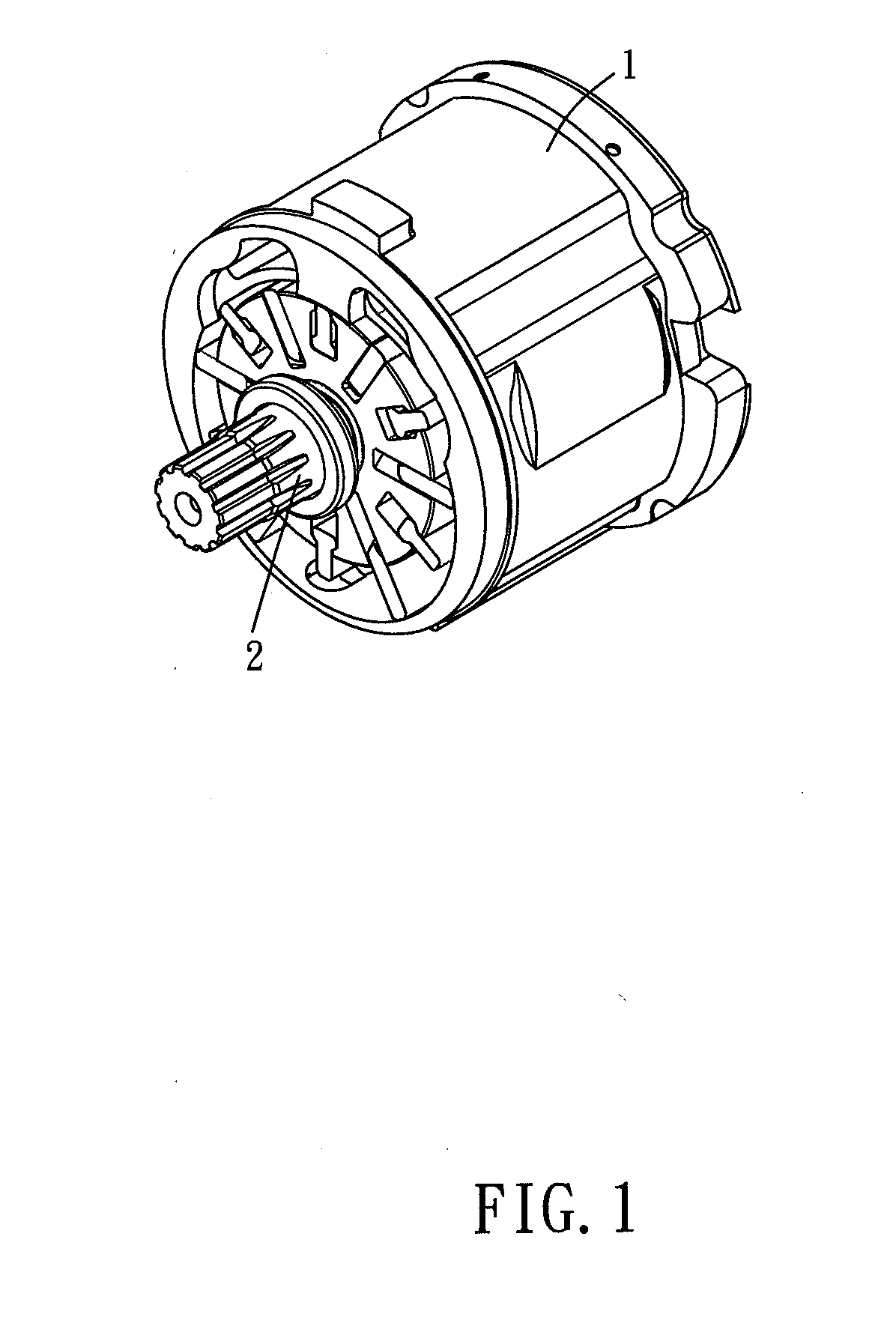

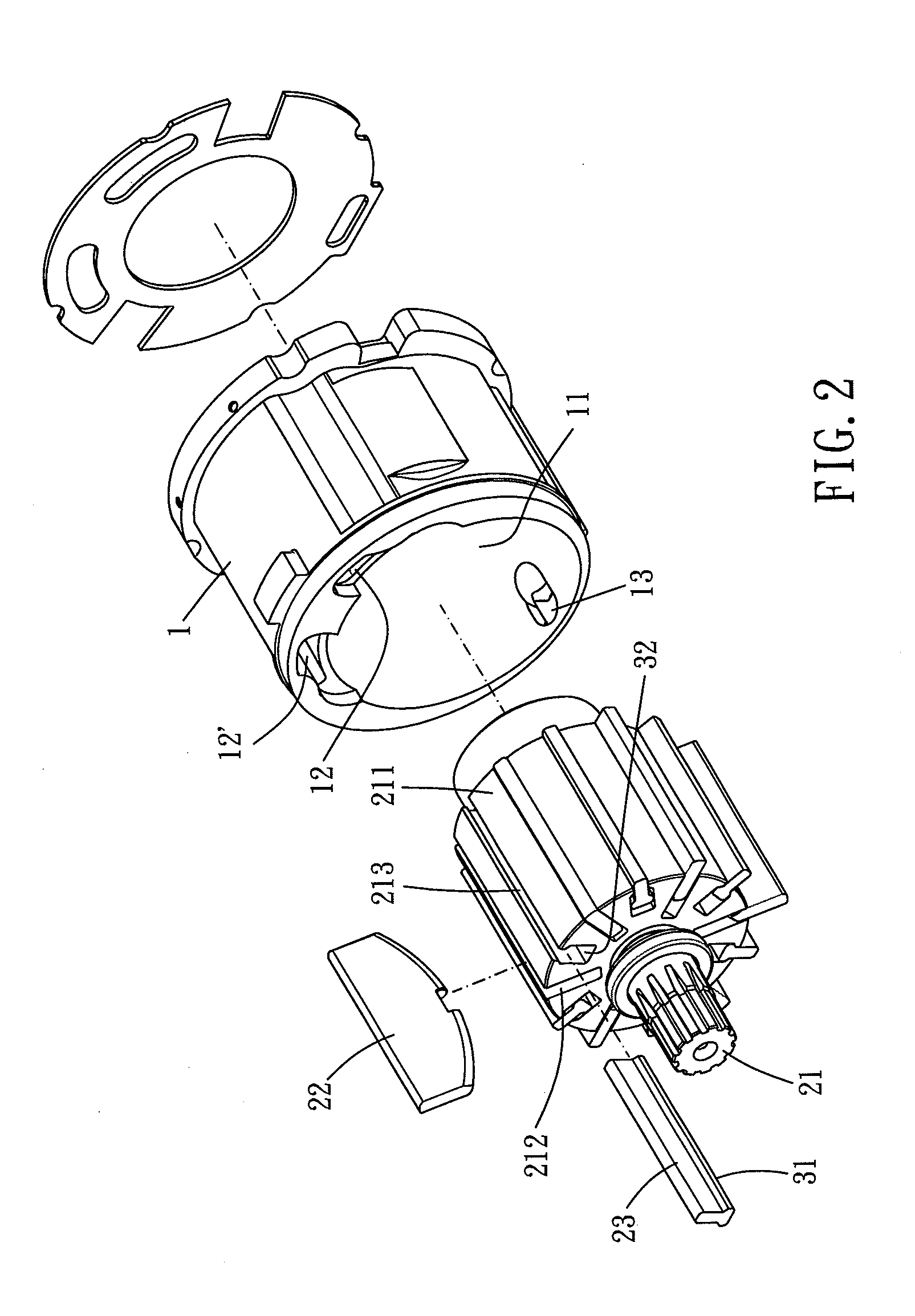

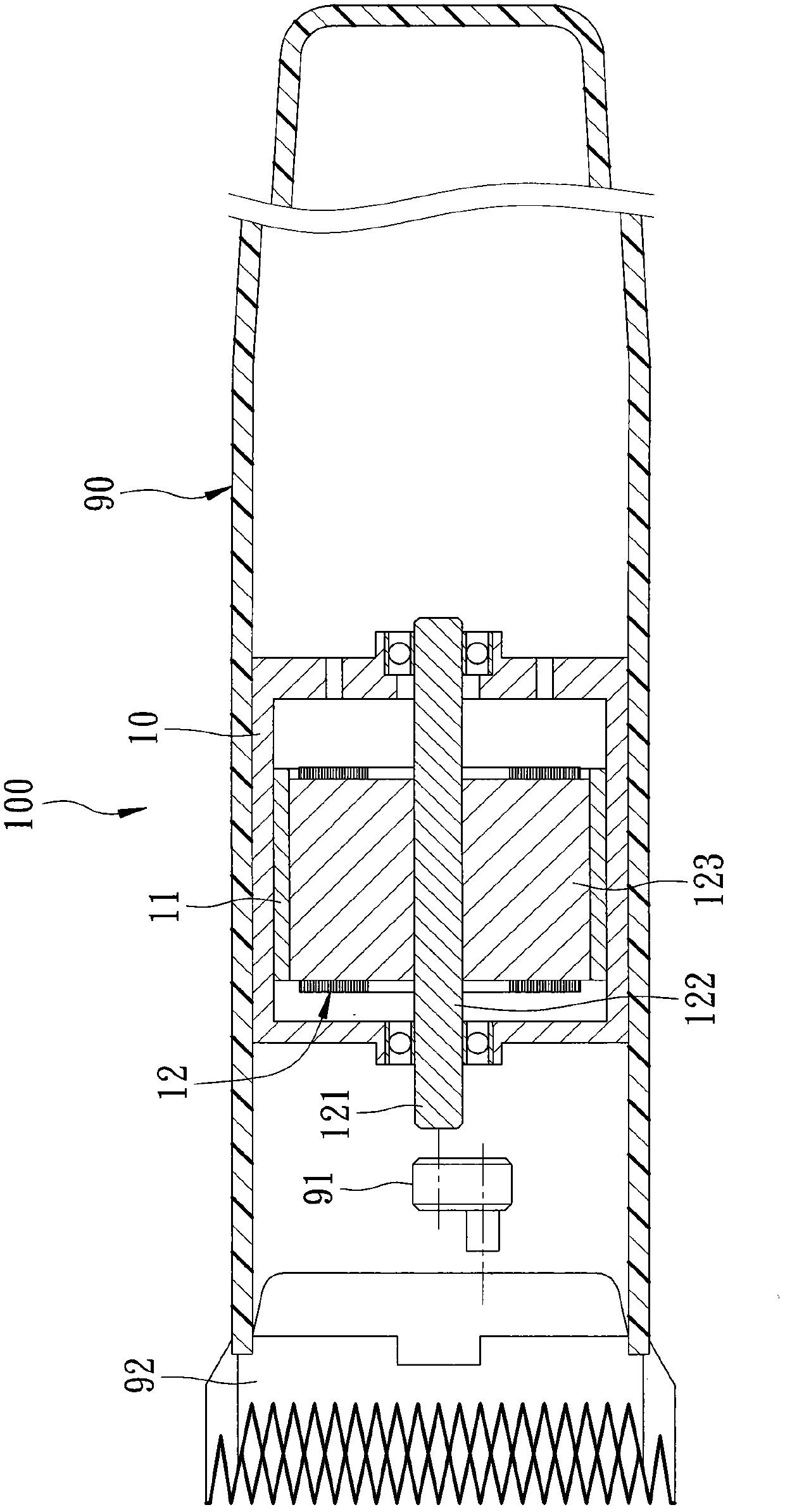

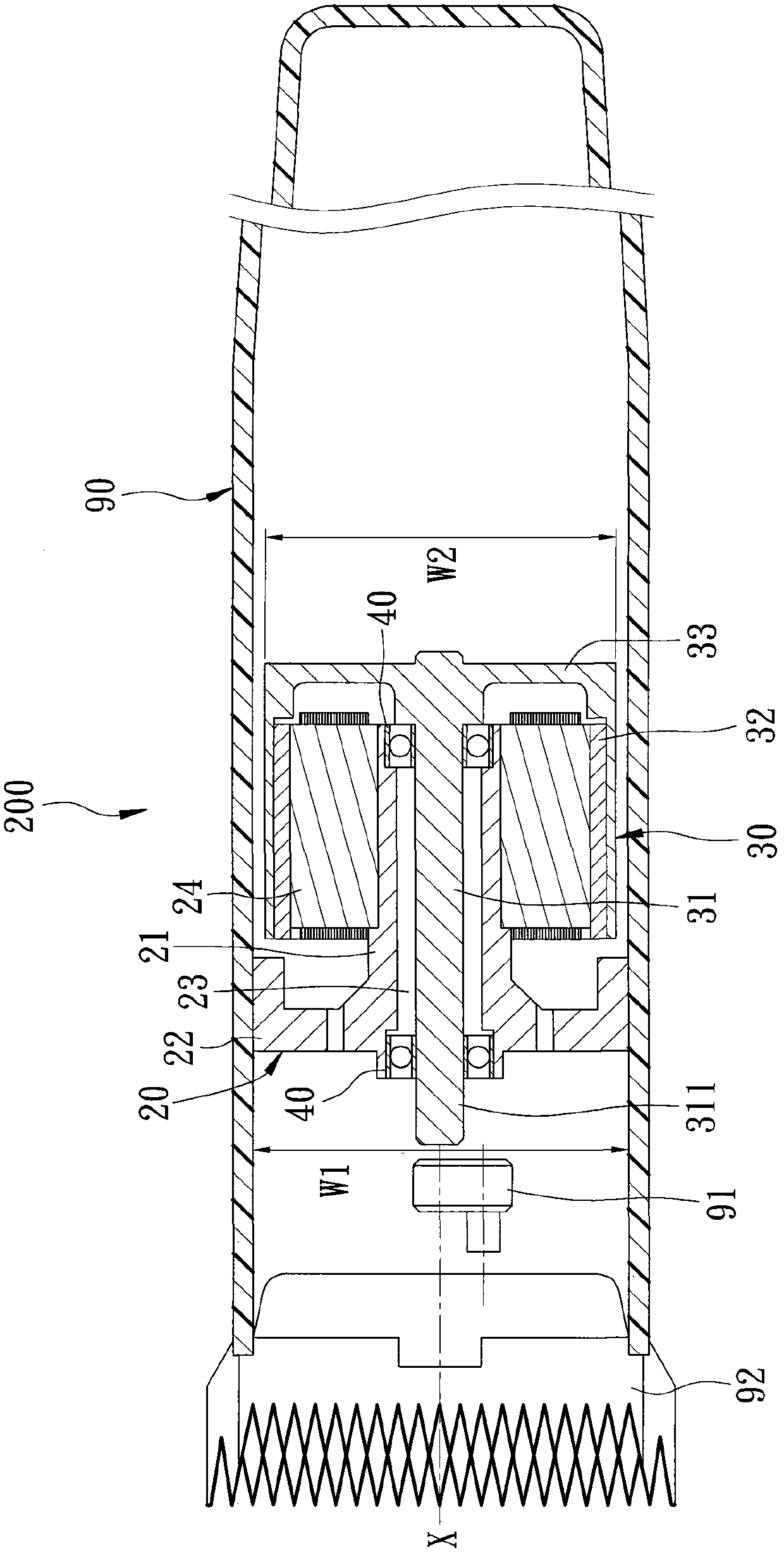

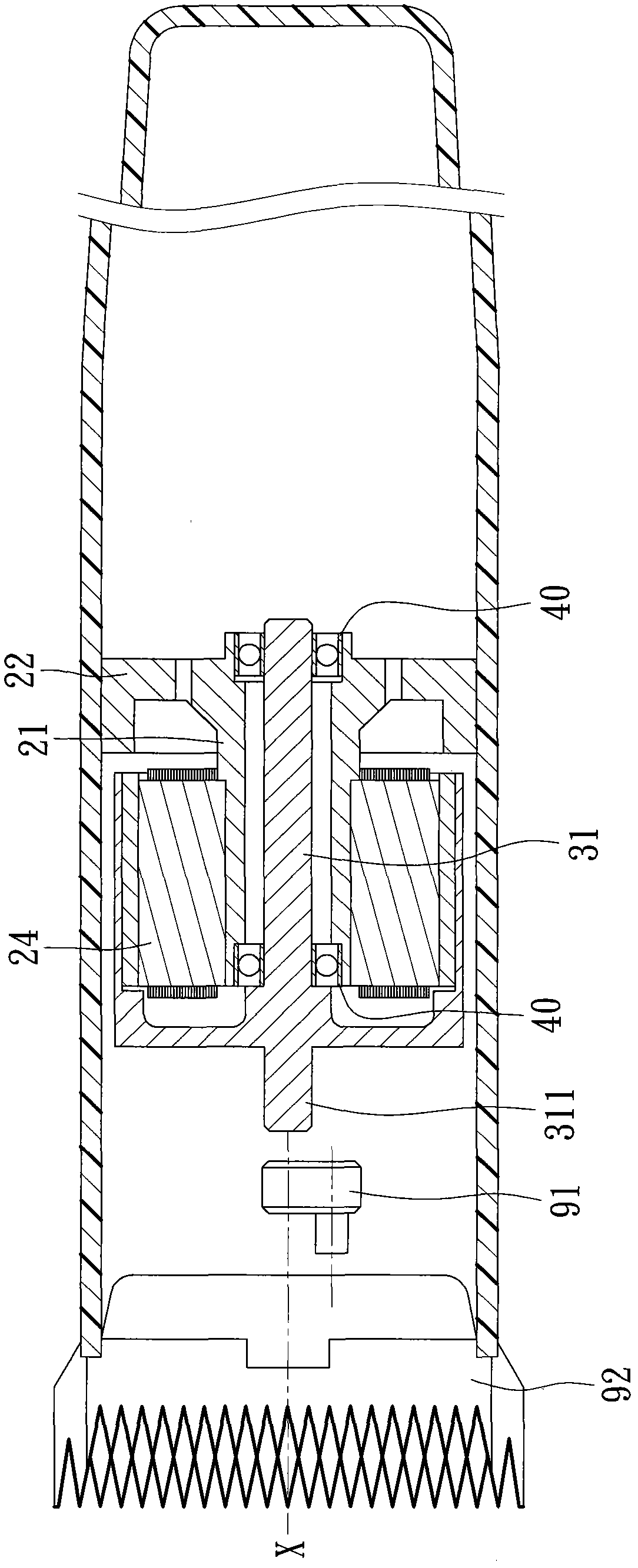

Driving mechanism

ActiveUS20170089118A1Increase gear ratioReduce resultWindowsMagnetic circuit rotating partsGear wheelElectrical and Electronics engineering

A driving mechanism drives a vehicle window to move up and down. The driving mechanism includes a housing, and a driving assembly and a transmission assembly. The driving assembly is engaged with the transmission assembly. The driving assembly is partially received in the housing. The transmission assembly includes a first transmission member connected to the driving assembly, a second transmission member engaging with the first transmission member, and a planetary gear set. The planetary gear set connects to an external device. The driving assembly drives the first transmission member which in turn drives the second transmission member to rotate. The second transmission member drives the planetary gear set which in turn drives the vehicle window to move.

Owner:JOHNSON ELECTRIC SA

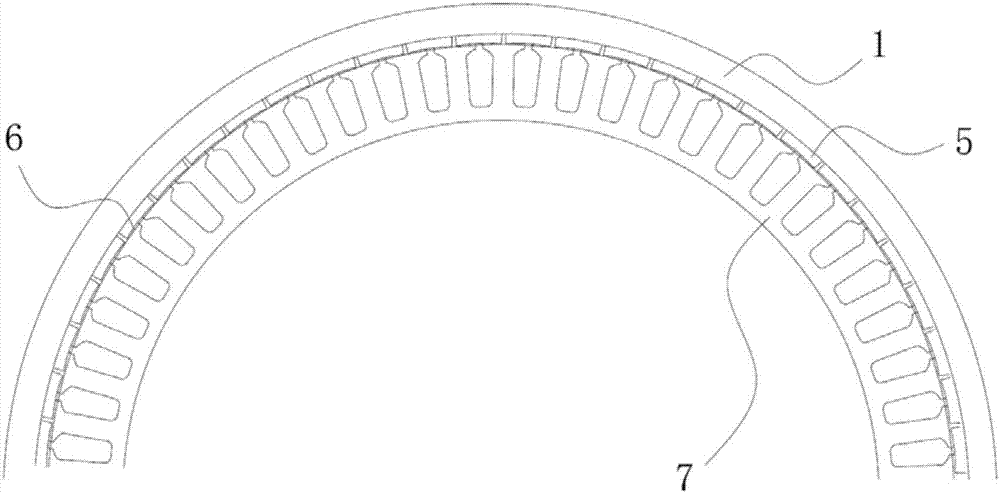

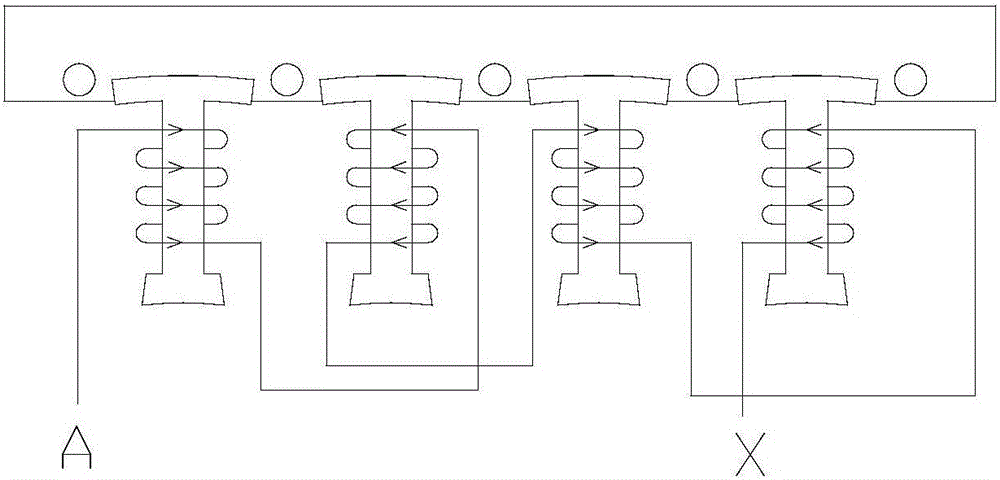

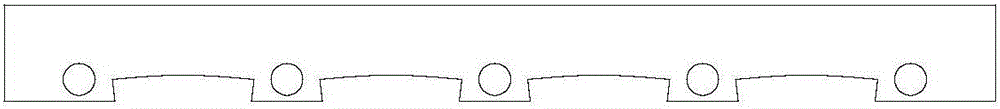

Compact type permanent magnet brushless motor with equal-resistance duplex winding and redundant hall structure

InactiveCN103236772AMeet the requirements of low speed operationReduce complex proceduresMagnetic circuit stationary partsWindings conductor shape/form/constructionBrushless motorsPermanent magnet rotor

The invention provides a compact type permanent magnet brushless motor with an equal-resistance duplex winding and a redundant hall structure, and relates to the technical field of a brushless motor with a redundant structure and high power density. The problem of system fault of the existing space manipulator motor system caused by the control failure of a circuit and the like can be solved. A plurality of stator cores are connected with one another end to end to form stator teeth and stator slots, which are separated from one another, a three-phase symmetry double-layer winding which is wound in a fractional-slot way is arranged on all the stator teeth, and air gaps are available between the surface of an inner circle formed by a plurality of the stator cores and the surface of an outer circle formed by hollow plate type permanent magnet rotors; and the pole faces of the stator teeth on six stator cores are respectively provided with a groove, the six stator cores are dispersed and evenly distributed, the center of each slot is arranged on the axial lead of the duplex winding, and each slot is internally embedded with a hall element respectively. The compact type permanent magnet brushless motor provided by the invention is a low-speed small-power brushless torque motor which has the redundant structure of the double-layer winding and a plurality of hall components.

Owner:HARBIN INST OF TECH

Oil-saving decarbonization additive of fuel vehicle

The invention discloses an oil-saving decarbonization additive for a fuel vehicle. The oil-saving decarbonization additive is prepared from 50 to 75 percent of methanol, 2 to 8 percent of n-butyl alcohol, 1 to 2 percent of isobutyl alcohol, 1 to 3 percent of tert-butyl alcohol, 1 to 2 percent of polysorbate, 1 to 2 percent of sodium dodecyl benzene sulfonate, 2 to 3 percent of oleic acid, 5 to 10percent of petroleum ether, 1 to 2 percent of triethanolamine, 2 to 6 percent of ethanediol, 2 to 5 percent of octanol, 1 to 4 percent of ethane, 1 to 3 percent of ethanol, 1 to 2 percent of compositemetal corrosion inhibitor and 0.5 to 2 percent of rubber and plastic anti-swelling protective agent. The oil-saving decarbonization additive disclosed by the invention does not require a complicatedtechnology, can be prepared into fuel which can be directly used by vehicles by being simply adding in an alcohol ether stock solution, and can be immediately prepared during use; the oil-saving decarbonization additive is stable in characters and can be stored for standby use for a long term under a sealing condition, and compared with gasoline and diesel oil, requirements on conditions for transportation and storage of the oil-saving decarbonization additive are lower; the oil-saving decarbonization additive can also be used as a burning promoter of finished gasoline and diesel oil, the concentration of carbon monooxide, hydrocarbon and oxynitride in tail gas can be reduced, the burning rate and the burn-off rate of the gasoline and the diesel oil can be increased, and emission of the tail gas can be reduced.

Owner:江门市汇德新能源科技有限公司

Electric drive apparatus

InactiveUS20070037650A1Small spacingMisalignment between interacting shafts can also be effectively avoidedToothed gearingsMechanical energy handlingElectricityGear wheel

An electric drive apparatus includes at least one electric motor having a rotor and at least two driven shafts which are disposed in coaxial relationship and driven at different rotation speed during operation of the electric motor. The driven shafts are constructed for separate connection to the rotor. Interposed between the rotor and at least one of the driven shafts is a gear mechanism in the absence of any direct interaction of the gear mechanism with the other one of the driven shafts.

Owner:SUMITOMO SHI DEMAG PLASTICS MACHINERY

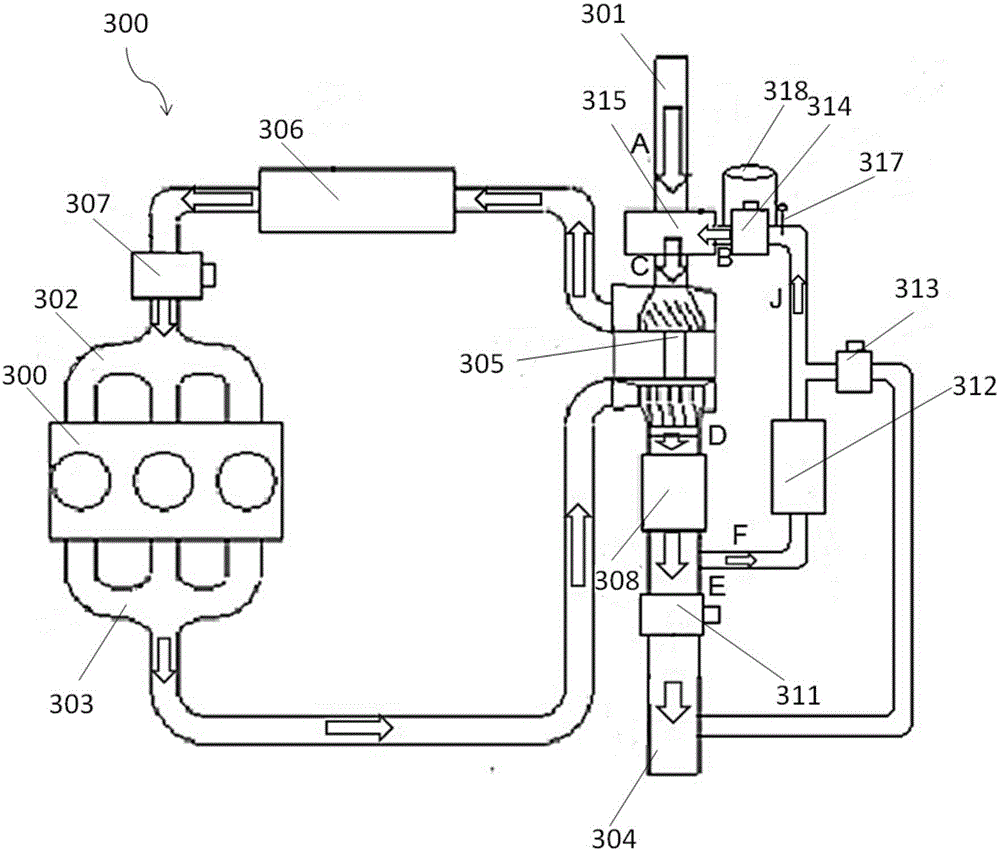

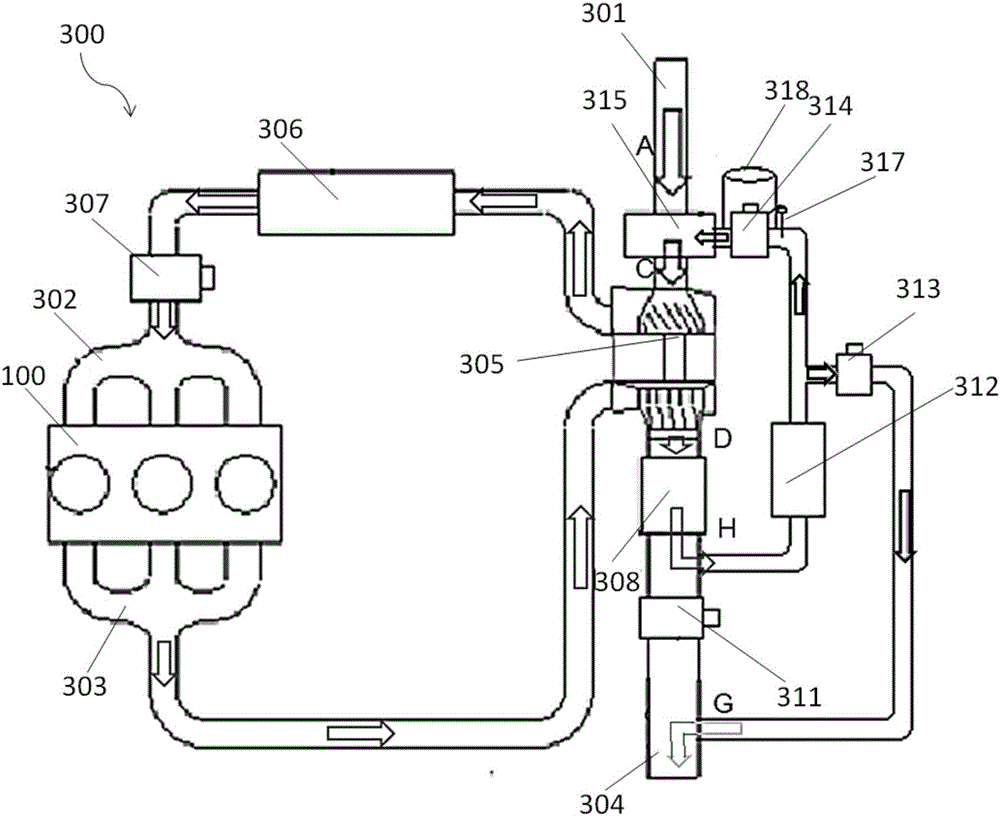

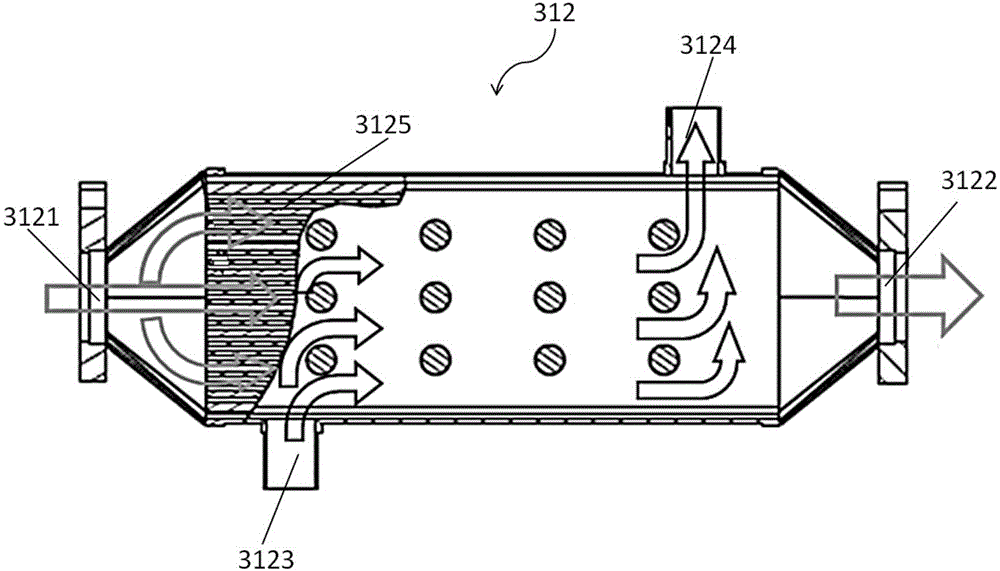

Waste gas and waste heat reusing system, engine and vehicle

InactiveCN106762240ACompact structureShorten warm-up timeElectrical controlInternal combustion piston enginesRecuperatorWaste heat

The invention discloses a waste gas and waste heat reusing system, an engine and a vehicle and relates to the vehicles. The waste gas and waste heat reusing system is applied to the vehicle. The vehicle comprises the engine, an engine water path and an engine gas path. The waste gas and waste heat reusing system comprises an EGR system and a waste heat recovery system. The EGR system is arranged at the engine gas path and used for recycling and refluxing waste gas exhausted by the engine into the engine for reusing after the waste gas is cooled and enabling the waste gas to be used for warming up the engine at the same time. The waste heat recovery system is arranged at the engine water path and is used for absorbing waste heat by the EGR system to warm up the engine after low-temperature cold start of the engine. According to the waste gas and waste heat reusing system, the engine and the vehicle, with arrangement of the waste gas and waste heat reusing system on the vehicle engine, the waste heat recovery system is integrated into the EGR system, so that the structure arrangement of the exhaust side of the engine is compacter, and the risks of uneven heating and local boiling of a heat exchanger in the application process of the traditional waste heat recovery technology are prevented.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS

Pneumatic motor

InactiveUS20140000447A1Stabler and large torque outputHigh strengthValve arrangementsEngine of arcuate-engagement typePneumatic motorEngineering

A pneumatic motor includes a cylinder and a rotor disposed in the cylinder. The rotor includes an axle, and main and secondary blades are slidably received in a plurality of main and secondary sliding slots formed on the axle. The secondary blades touch an inner wall of the cylinder to promote torque output when located at angles equal to or smaller than a specific angle from an inlet of the cylinder. On the contrary, the secondary blades are away from the inner wall of the cylinder to reduce friction between the rotor and the cylinder when located at angles larger than the specific angle from the inlet. Thus, revolution speed of the rotor is retained in a tolerant range, and torque output is promoted significantly.

Owner:HYPHONE MASCH IND CO LTD

Electric scissor motor

InactiveCN102638122BReduce volumeImprove cooling effectMagnetic circuit rotating partsMechanical energy handlingEngineeringConductor Coil

The invention relates to an electric scissor motor which comprises a fixing seat, a rotor unit and two bearings. The fixing seat comprises a surrounding wall, a fixing wall, a mandrel hole and a winding, wherein the surrounding wall extends along and surrounds an axis, the fixing wall extends from the surrounding wall along the radial direction, the mandrel hole is formed in the surrounding wall and extends along the axis, and the winding is sleeved on the outer peripheral face of the surrounding wall along the axis; and the winding and the fixing wall are arranged at an interval along the axis. The rotor unit comprises a mandrel, a magnetic ring and a force arm, wherein the mandrel penetrates through the mandrel hole along the axis, the magnetic ring surrounds the winding, and the force arm extends from the mandrel along the radial direction and is connected with the magnetic ring. The bearings are respectively arranged at the two ends of the surrounding wall and are connected between the surrounding wall and the mandrel.

Owner:王火标

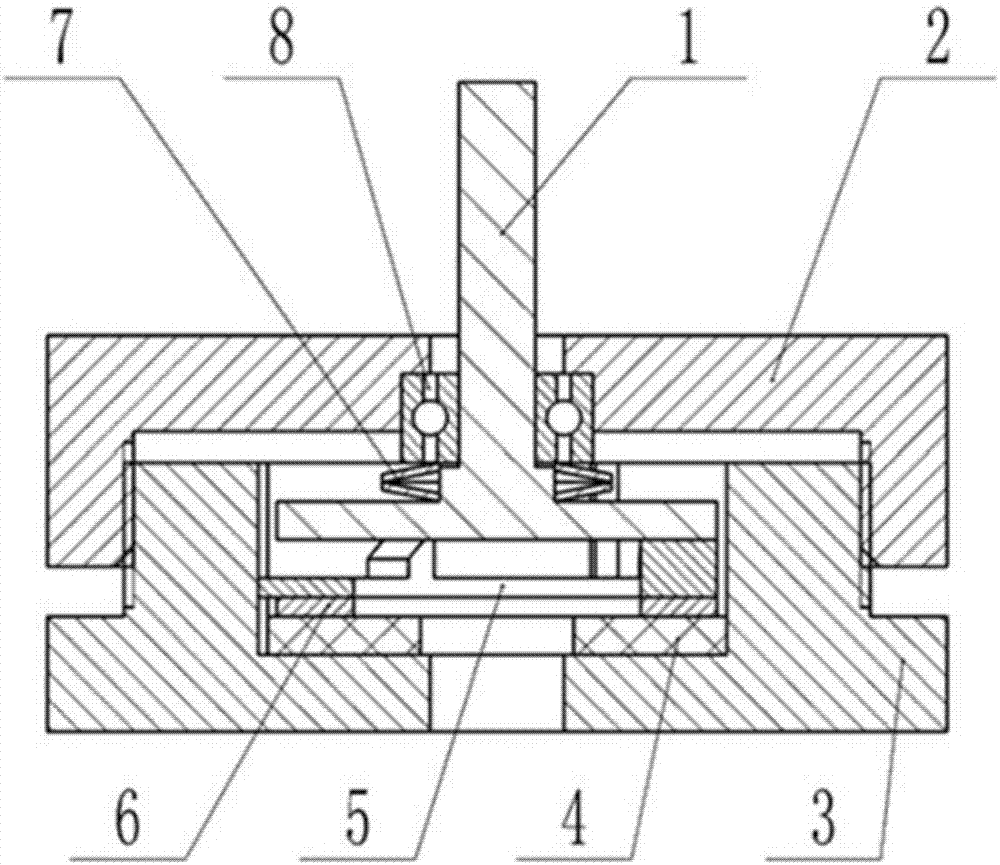

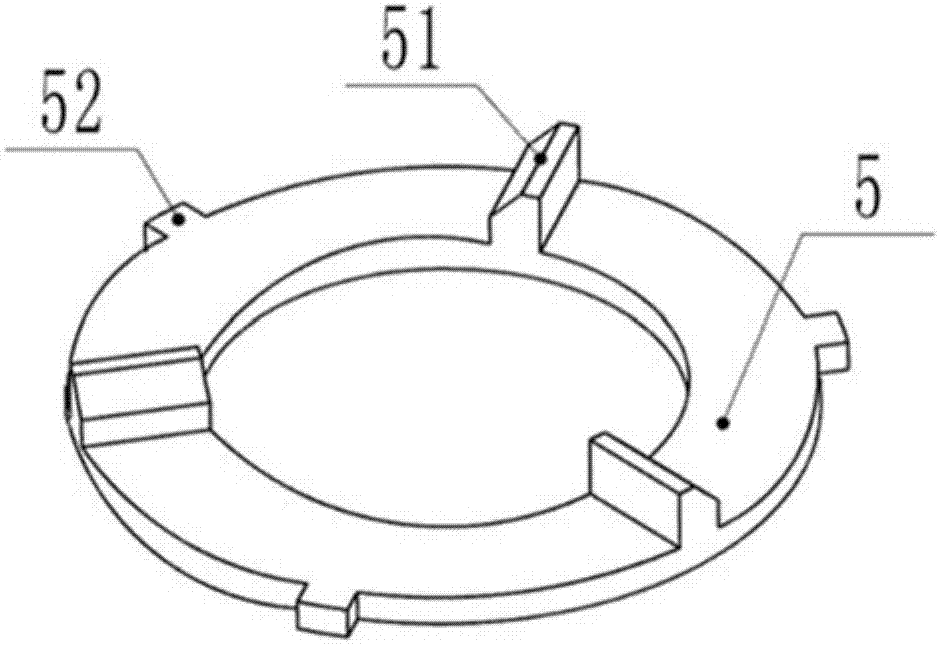

Micromotor employing multilayer annular piezoelectric ceramic

ActiveCN107306097AReduce the driving voltageAvoid destabilizationPiezoelectric/electrostriction/magnetostriction machinesLow voltageMicromotor

The invention discloses a micromotor employing multilayer annular piezoelectric ceramic, and belongs to the field of a piezoelectric driver, a small and special electrical machine and a miniature driver. The micromotor comprises a shell, wherein a stator and a rotor are arranged in the shell, the stator comprises a stator round ring, contacts are arranged at one side of the stator round ring, the multilayer annular piezoelectric ceramic is arranged at the other side of the stator round ring, the multilayer annular piezoelectric ceramic is uniformly divided into an even number of partition regions, the polarization directions of two adjacent partition regions are opposite, the energization directions of two adjacent layers of annular piezoelectric ceramic are opposite, a positive electrode and a negative electrode are arranged on an upper surface and a lower surface of the multilayer annular piezoelectric ceramic, the positive electrode is also divided into an even number of partition regions which are in one-to-one correspondence to the partition regions of the multilayer annular piezoelectric ceramic, the number of the partition regions of the multilayer annular piezoelectric ceramic are two times of the number of the contacts, and the positions of the contacts are corresponding to empty regions between the partition regions of two adjacent electrodes. Compared with the prior art, the micromotor has the characteristics of low-voltage driving performance, high stability and large torque output.

Owner:北京派和智能装备技术有限公司

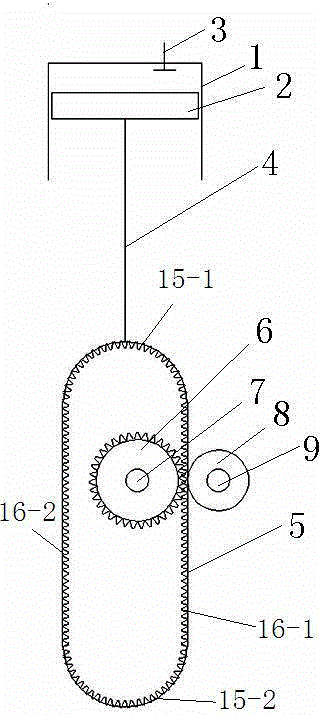

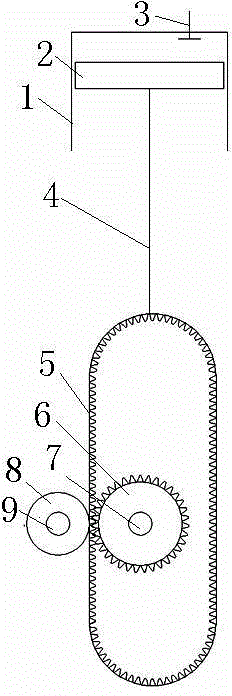

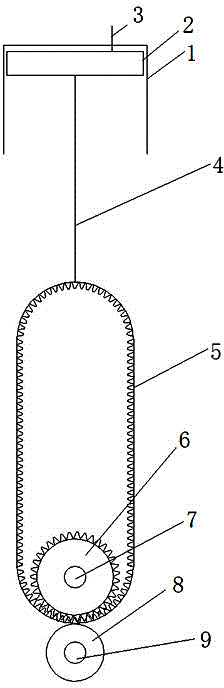

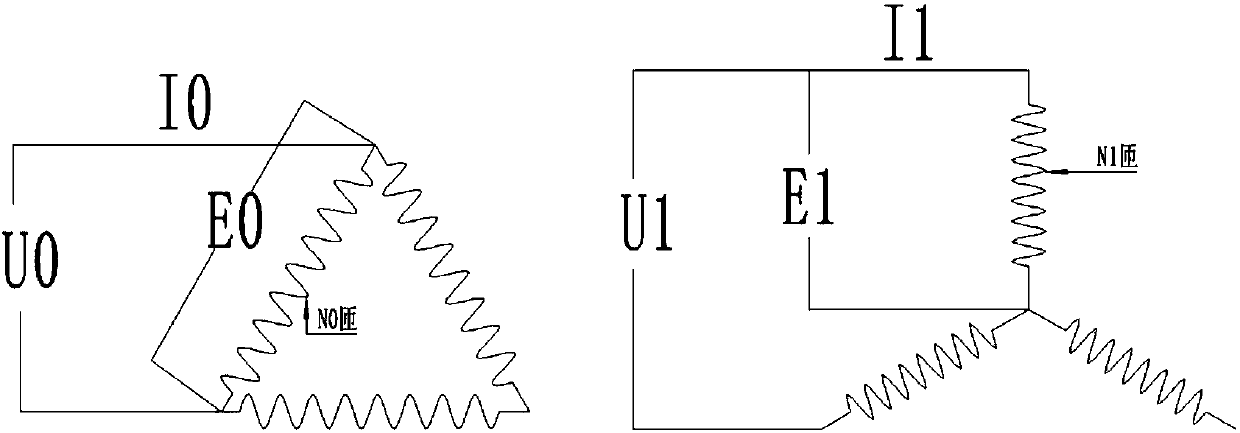

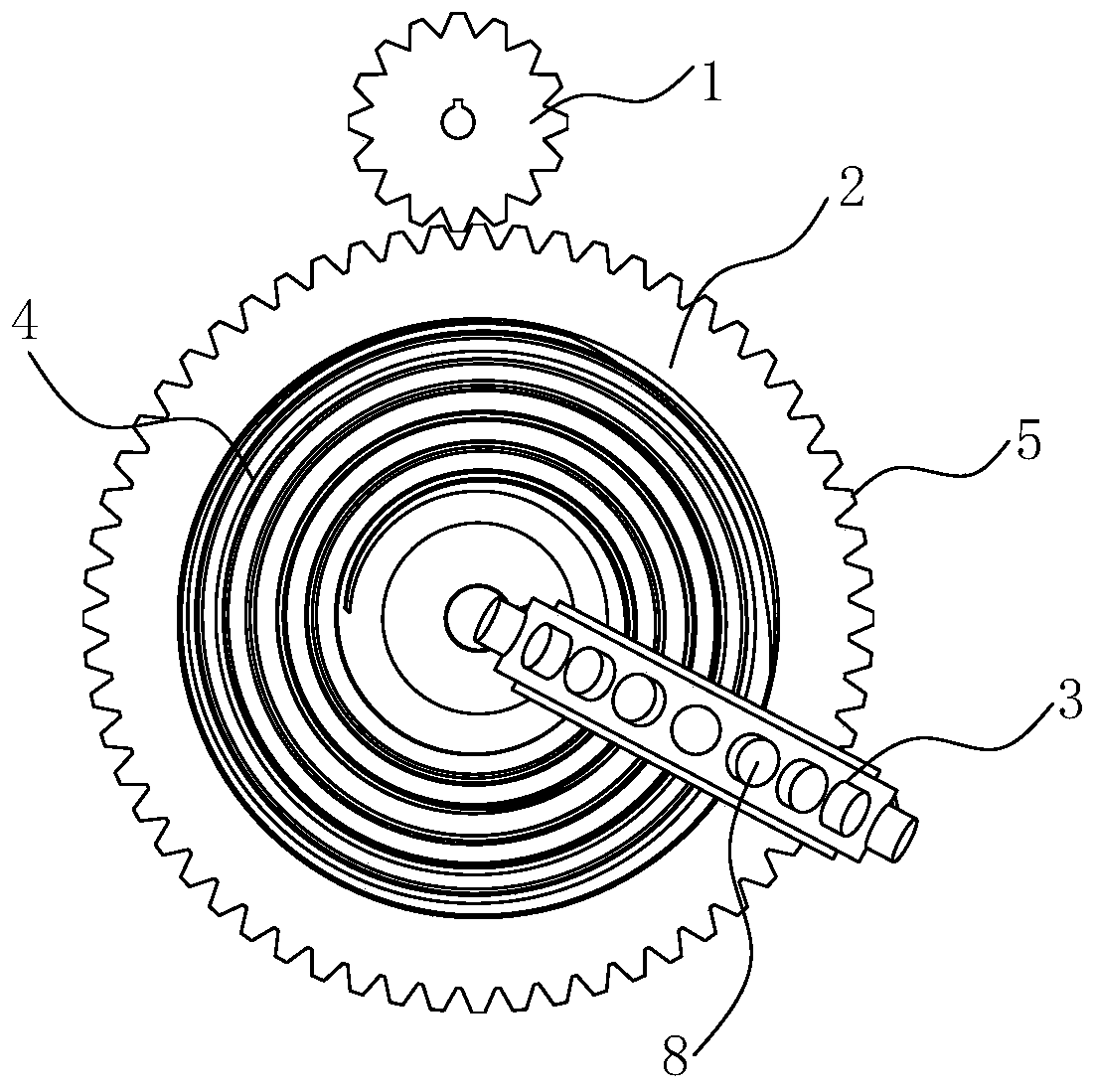

Cycle internal combustion engine capable of implementing constant-volume combustion

PendingCN104832285AImprove cycle thermal efficiencyHigh torque outputMachines/enginesCombustionEngineering

The present invention discloses an internal combustion engine capable of implementing constant-volume combustion and belongs to the technical field of mechanical engines. The internal combustion engine comprises a cylinder, wherein a piston of the cylinder is connected with a connection rod; the output end of the connection rod is connected with a noncircular gear; a main planetary gear engaged with the noncircular gear is arranged at the output end of the connection rod; a main shaft is fixedly arranged at the center of the main planetary gear and is rotationally connected to a planetary gear disc; the main shaft deviates from the center of the planetary gear disc; a guide shaft parallel to the main shaft is arranged on the planetary gear disc; a guide wheel is arranged on the guide shaft and is in contact with the inner surface or the outer surface of the noncircular gear; the output end of the main shaft is connected with a secondary planetary gear; an inner planetary gear engaged with the secondary planetary gear is arranged at the output end of the main shaft; a power output shaft is connected to the inner planetary gear. The internal combustion engine is capable of implementing constant-volume combustion, improving cycle heat efficiency and implementing large torque output.

Owner:李培石

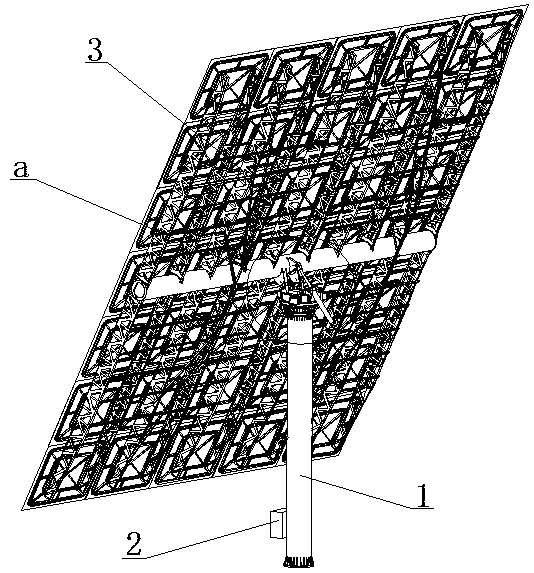

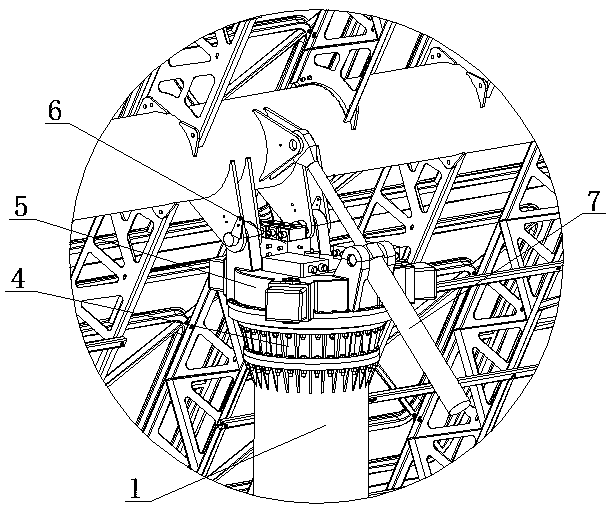

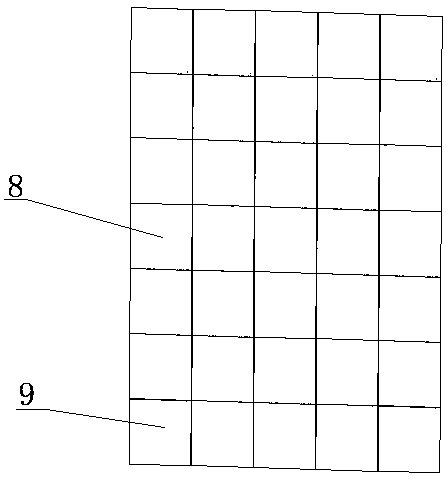

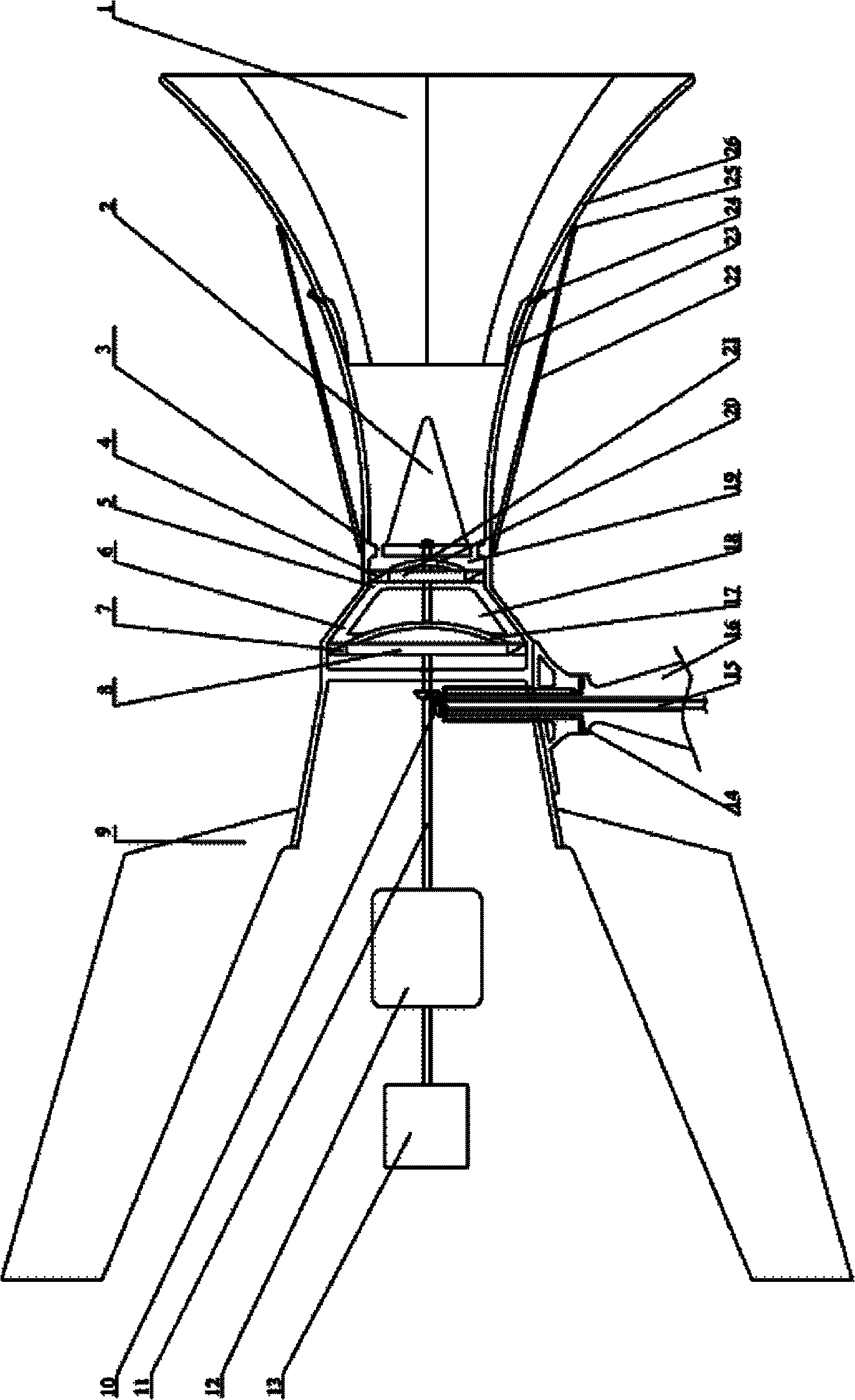

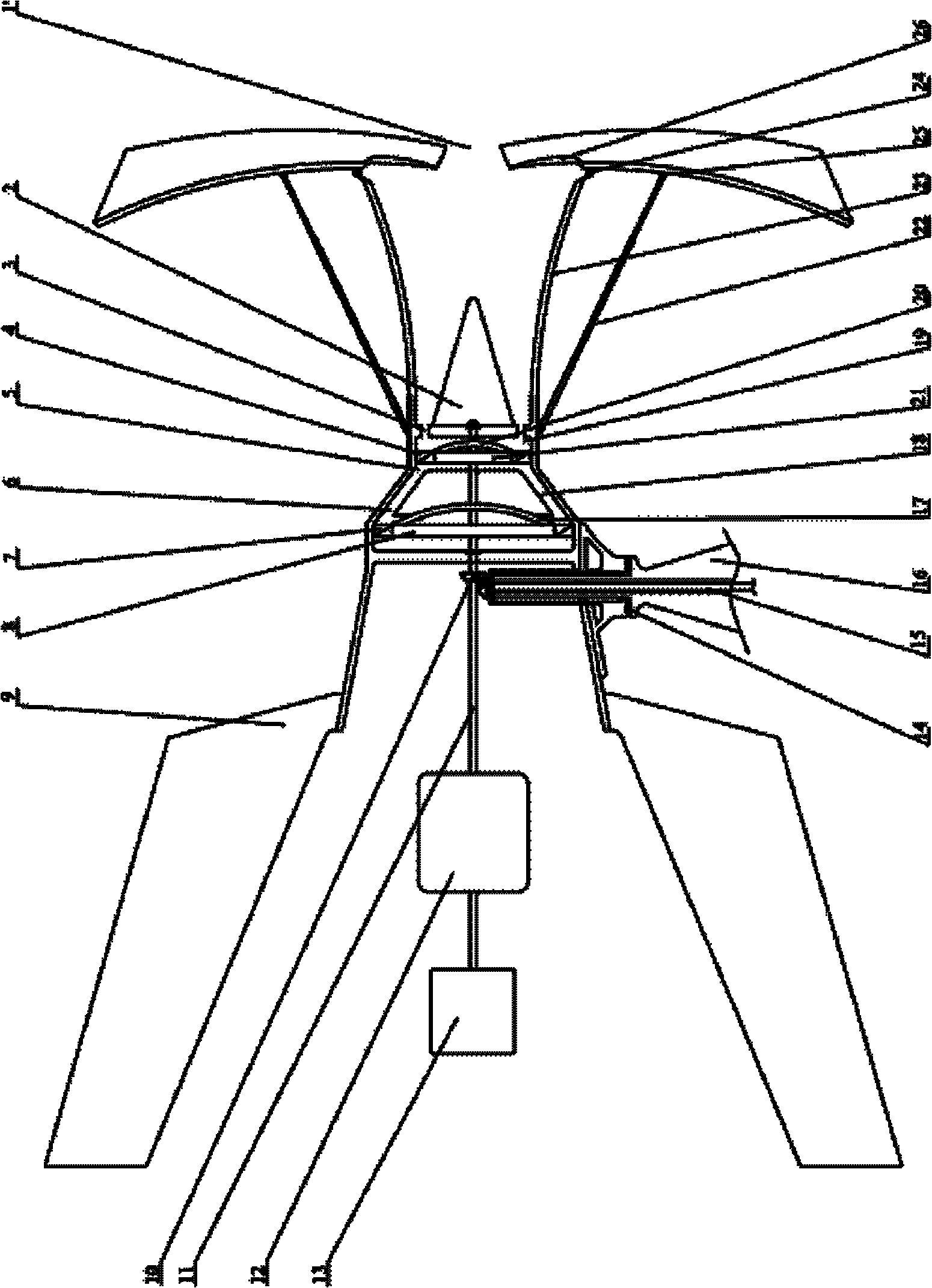

Large-size heliostat device

PendingCN110165986ALow costEven by forcePhotovoltaic supportsSolar heating energyHydraulic cylinderHeliostat

The invention discloses a large-size heliostat device, and the device comprises a vertical column, a horizontal rotation driving device and a reflection plate, wherein the horizontal rotation drivingdevice comprises a base fixedly connected to the vertical column and an upper base rotationally connected to the base. An eccentric shaft is arranged on the base, and the eccentric shaft deviates fromthe rotation axis of the upper base; at least three hydraulic cylinders are arranged in the circumferential direction of the upper base, and the hydraulic cylinders are rotationally connected with the upper base; the front ends of piston rods of the hydraulic cylinders are rotationally connected with the eccentric shaft; and the reflection plate is rotationally connected to the upper base. The hydraulic cylinders are used as power elements, so the device, compared with a motor, can output a larger torque, and can drive the large reflecting plate to rotate. The main driving device is the hydraulic cylinders, so the hydraulic cylinders, compared with a motor and a speed reducer, are low in cost and simple in structure, and the overall manufacturing cost of a heliostat is effectively reduced.

Owner:HANGZHOU SINO DEUT POWER TRANSMISSION EQUIP

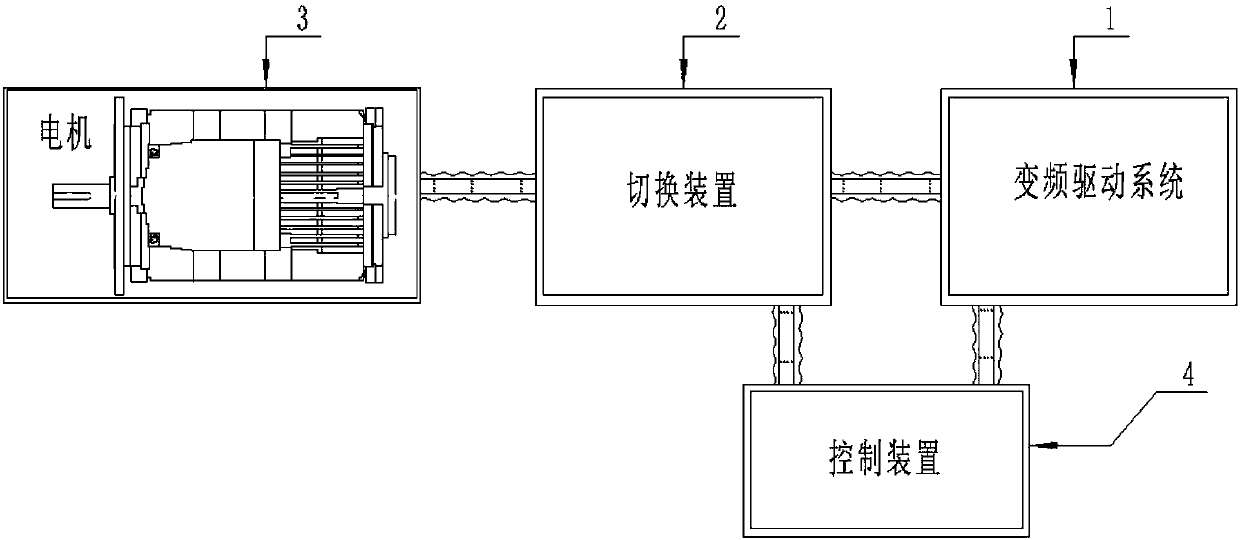

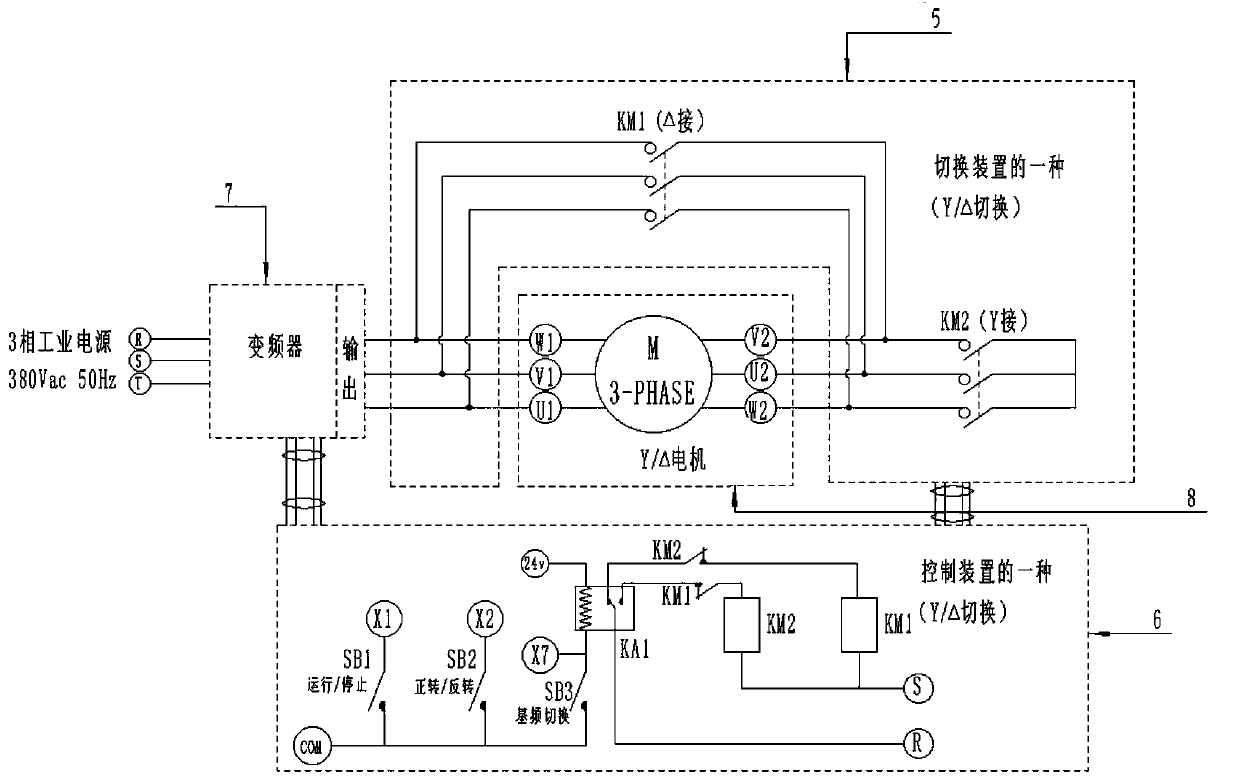

Multi-base-frequency and multi-power switching motor and driving system

InactiveCN107749729AIncrease FM rangeLarge speed rangeAC motor controlBase frequencyFrequency conversion

The invention relates to a multi-base-frequency and multi-power switching motor and a driving system. An existing numerical control machine tool main shaft motor or an electric car motor can not simultaneously satisfy requirements of a low speed and a large torque, and a high speed and large power. By using the motor and the system, the above technical problem is solved. A frequency conversion driving system, a switching device, the motor and a control device are included. The frequency conversion driving system is used for driving the motor to work and carrying out frequency conversion speedregulation. The switching device is used for switching working modes of the motor. The control device is used for controlling motion of the switching device and the frequency conversion driving system. The motor and the system are widely used in technical fields of a numerical control machine tool, an electric car and the like.

Owner:WEIHAI POLY LIWEI MOTORS CO LTD

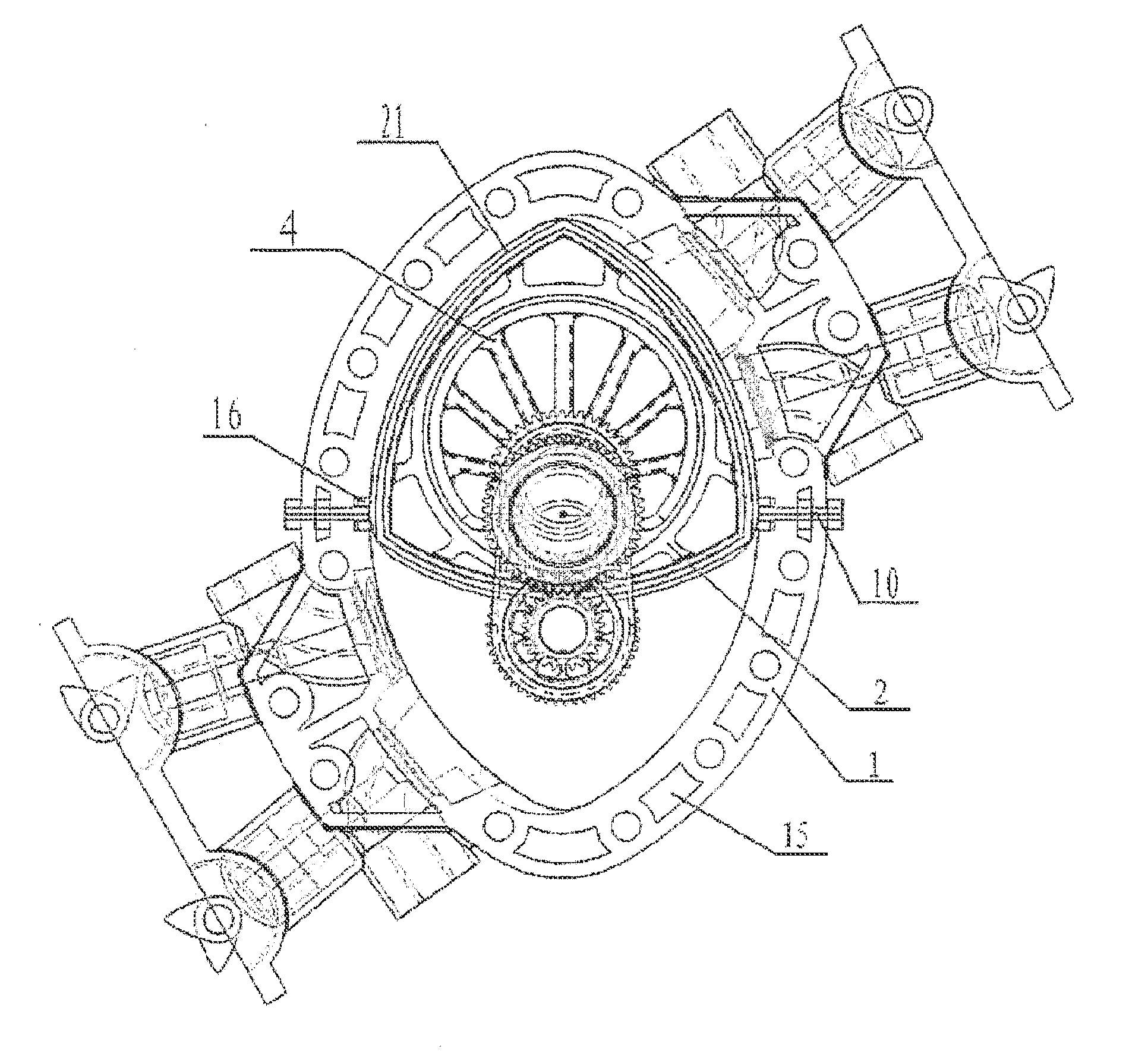

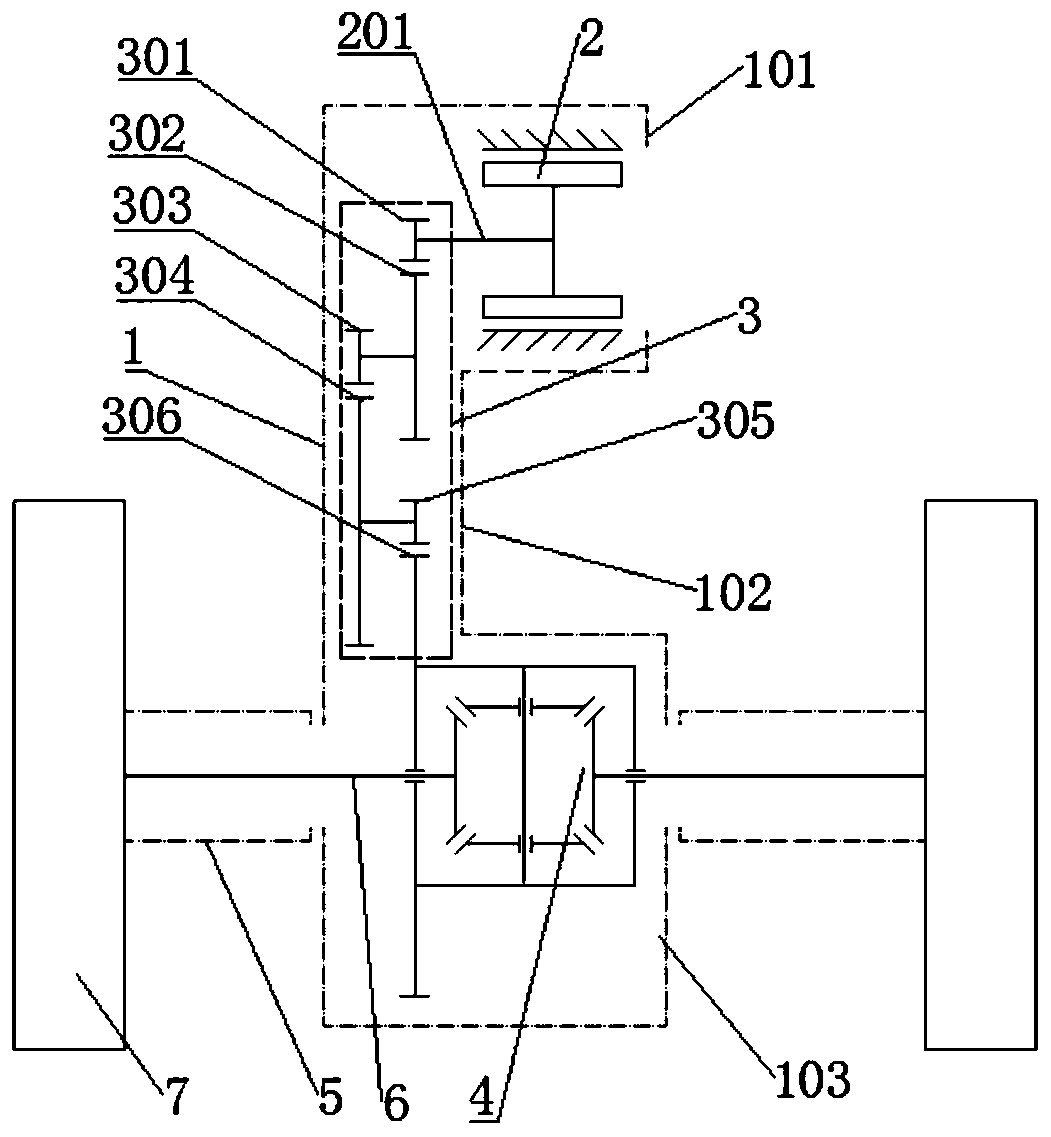

Olive-shaped rotary engine

InactiveUS20110126795A1High output torqueImprove good performanceInternal combustion piston enginesPump componentsGear wheelRotary engine

This invention involves internal combustion engine, especially the olive-shaped rotary engine. The olive-shaped rotary engine not only overcomes the defects of large reciprocating inertia the existing piston reciprocating engine has, complex structure and large volume but also overcomes the defects of small output torque the existing rotary internal combustion engine has, the fuel not being able to fully combust and high manufacturing process requirements. If the fuel can't be fully combusted, it will lead to a higher amount of fuels. This invention consists of crankshaft, shell and triangle rotor. Within centre hole of the triangle rotor is equipped with connecting handle, which is connected with crankshaft through gear set. The shuttle-like moving path when the rotor of the connecting handle is connected with the centre of the crankshaft results from the driving of the gear set, realizing the basic working process of the internal combustion engine. The internal combustion engine is of simple structure, small volume and light weight. In addition, it operates stably, produces small vibration, improves output torque and makes fuel fully combust. It's of wide range of available fuels and minor mechanical wear.

Owner:SHANGDONG ICD HIGH PERFORMANCE FIBERS

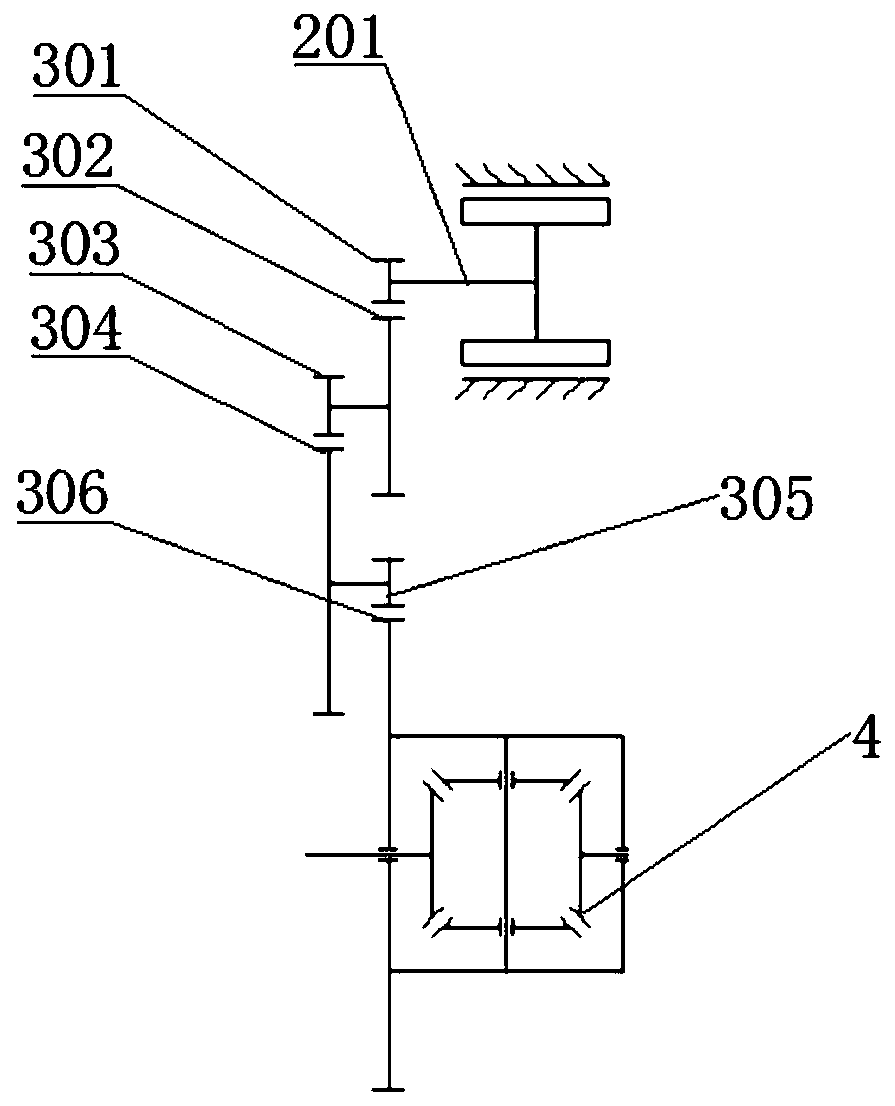

Integrated three-stage speed reduction electric drive axle

The invention relates to the technical field of electric vehicles, and particularly relates to an integrated three-stage speed reduction electric drive axle. The integrated three-stage speed reductionelectric drive axle comprises an integrated shell, wherein the integrated shell is internally provided with a motor, a three-stage parallel speed reduction gear set and a differential mechanism whichare in transmission connection in sequence, and the integrated shell is of an integrally-formed structure. The integrated three-stage speed reduction electric drive axle further comprises an axle housing, a half shaft and wheels, wherein the two sides of the integrated shell are connected with the axle housing, the half shaft is arranged in the axle housing, one end of the half shaft is connectedwith the output end of the differential mechanism, and the other end of the half shaft is connected with the wheels. The system is high in integration degree, compact in structure and small in occupied space, a transmission shaft is not needed, a battery pack can be arranged in the middle of a vehicle girder, the adaptability to the complete vehicle is good, and the assembling process is simple.

Owner:GUANGXI YUCHAI MASCH CO LTD

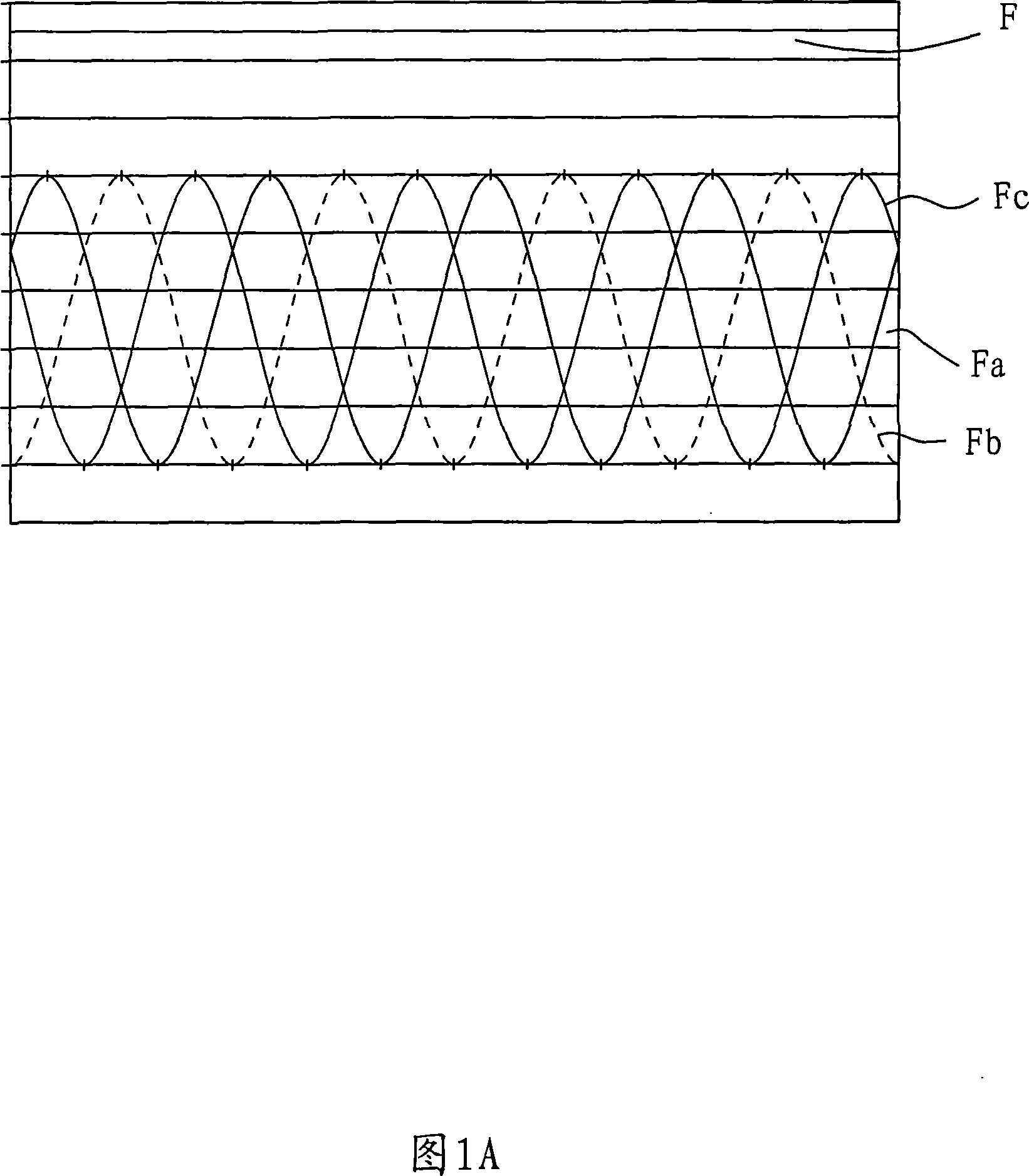

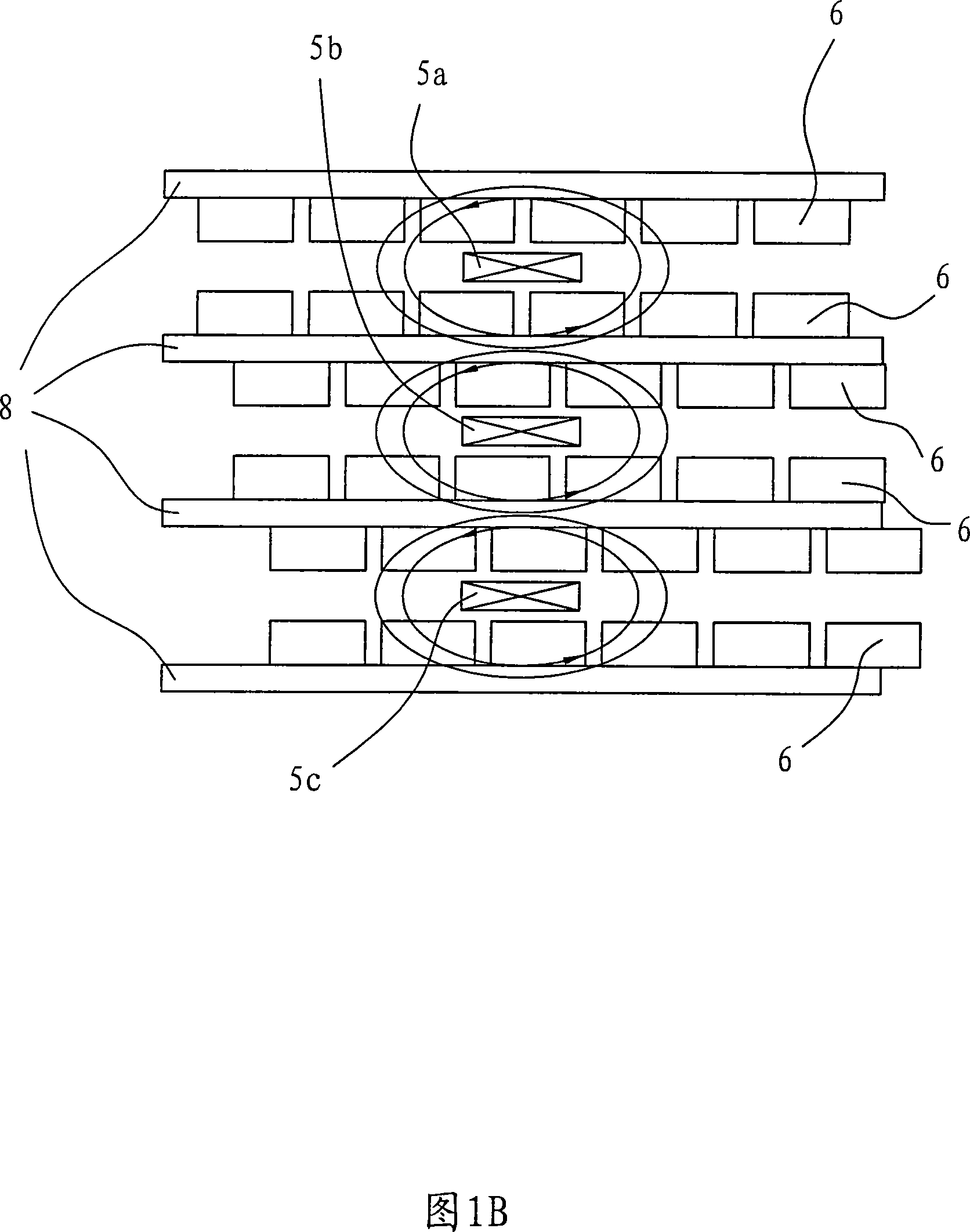

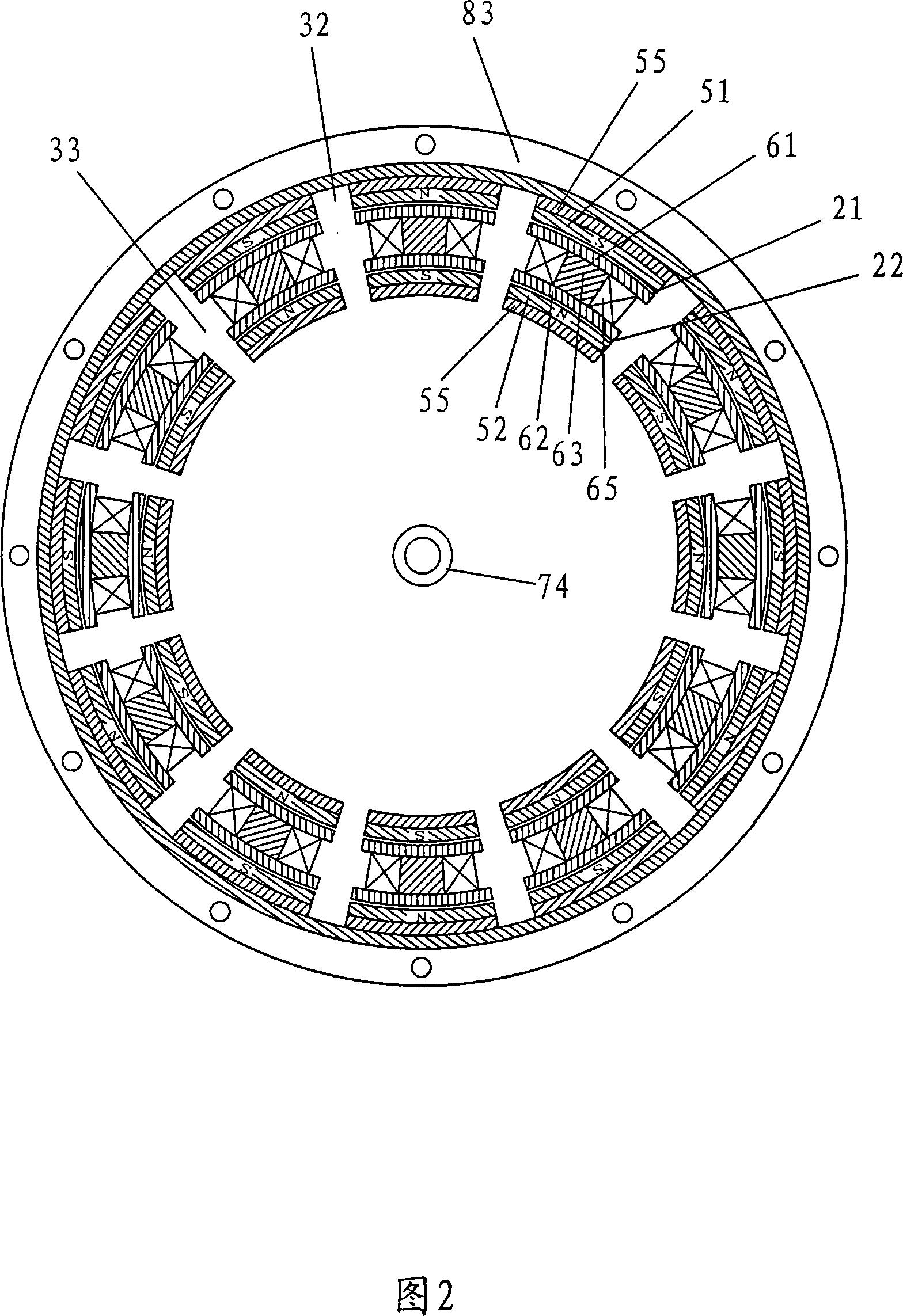

Polyphase brushless electric motor

InactiveCN101110546AGuaranteed flux concentrationIncrease parallel air gapMagnetic circuitPropulsion systemsBrushless motorsThree-dimensional space

A multiphase brushless motor utilizes a multiphase arrangement of armature members in a brushless motor to correlate magnet polar fronts of magnet members with corresponding magnet polar fronts of armature members to achieve mutual deflection and reduce adverse impact of a breakdown torque on an output torque. In addition, with the help of one or more brushless motors, more parallel air gaps are increased in a multiphase brushless motor in a three-dimensional space, thus providing a higher torque output through a multiphase cluster under a condition of limited moving direction. Or more individuals connected in series and moving independently are arranged.

Owner:UNION PLASTIC HANGZHOU MACHINERY +1

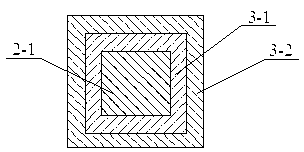

Permanent magnetic synchronous wheel hub motor and electric vehicle

PendingCN107171525AStable working conditionExtended service lifeMagnetic circuit rotating partsElectric machinesElectric machineSurface mounting

The invention discloses a permanent magnetic synchronous wheel hub motor and an electric vehicle, and belongs to the field of electric vehicles and parts thereof, aiming at addressing the problem of unstable installation of permanent magnets in current structure. According to the invention, the permanent magnetic synchronous wheel hub motor includes a stator core, a magnetic conductive material which sleeves the outside of the stator core, a rotor outer ring which sleeves the outside of the magnetic conductive material and a wheel hub which sleeves the outside of the rotor outer ring. The magnetic conductive material is provided with a plurality of embedded grooves thereon, each embedded groove is embedded with one permanent body, and the adjacent permanent magnetic bodies have opposite magnetic poles. According to the invention, the electric vehicle includes the permanent synchronous wheel hub motor. According to the invention, the permanent magnetic synchronous wheel hub motor and the electric vehicle herein are more secure and reliable compared with current surface-mounted structures, and does not cause the permanent magnet to have displacement even the torque output is increased. Further, the wheel hub motor has the characteristics of stable working status in terms of the entire motor, long service life, higher cost performance and lower manufacturing cost.

Owner:NINGBO BRANCH OF JIANGSU YADEA TECHNICAL DEV CO LTD

Block type iron core winding method of compact permanent magnet brushless motor

ActiveCN105720761AGuaranteed winding accuracyReduce process complexityManufacturing dynamo-electric machinesLower toothThree-phase

The invention discloses a block type iron core winding method of a compact permanent magnet brushless motor, and belongs to the field of the motor. According to the method provided by the invention, the low weight, small size and reliability of the motor are all taken into consideration, and the problem of winding difficulty resulting from too low tooth strength when the size of the motor is very small is solved. The compact permanent magnet brushless motor provided by the invention comprises a hollow multi-pole permanent magnet rotor and a stator in which Hall elements are embedded; the iron core of the stator is of segmented iron core structure; multiple stator teeth are arranged on the stator iron core; a stator slot is formed between every two stator teeth; three Hall elements are embedded in the stator slots in a three-phase symmetrical mode; three-phase symmetrical windings are winded on the stator teeth; the method for winding the three-phase symmetrical windings comprises following steps of fixing the stator iron core of the segmented structure on a winding die; fixing with pressure plates; reserving gaps among the stator teeth for manual winding, wherein the sizes of the gaps are the sizes of winding heads; after finishing winding one stator tooth; continuing to wind a next stator tooth, wherein all stator teeth under one phase are winded once.

Owner:HARBIN INST OF TECH

Dual-purpose gear case for milling machine

InactiveCN103785863AHigh torque outputFunction increaseLarge fixed membersMilling equipment detailsEngineeringMachine tool

A dual-purpose gear case for a milling machine comprises a motor and a gear case body. The motor is installed outside the gear case body, the motor is connected with the gear case body through an input shaft, a shaft, a horizontal type drive gear, a horizontal type driven gear, a drive circular arc bevel gear, a driven circular arc bevel gear, a vertical type drive gear and a vertical type driven gear are installed in the gear case body, the driven circular arc bevel gear is installed on a horizontal type main shaft, and the vertical type driven gear is installed on a vertical type main shaft. The dual-purpose gear case has the advantages that the functions of the milling machine can be increased, the switchover between vertical milling and horizontal milling can be fast achieved, operation labor intensity is low, the precision of the main shafts cannot be reduced during the process of the switchover of milling main shaft states, machining auxiliary time is shortened, and machining efficiency is improved.

Owner:滕州博信机床有限公司

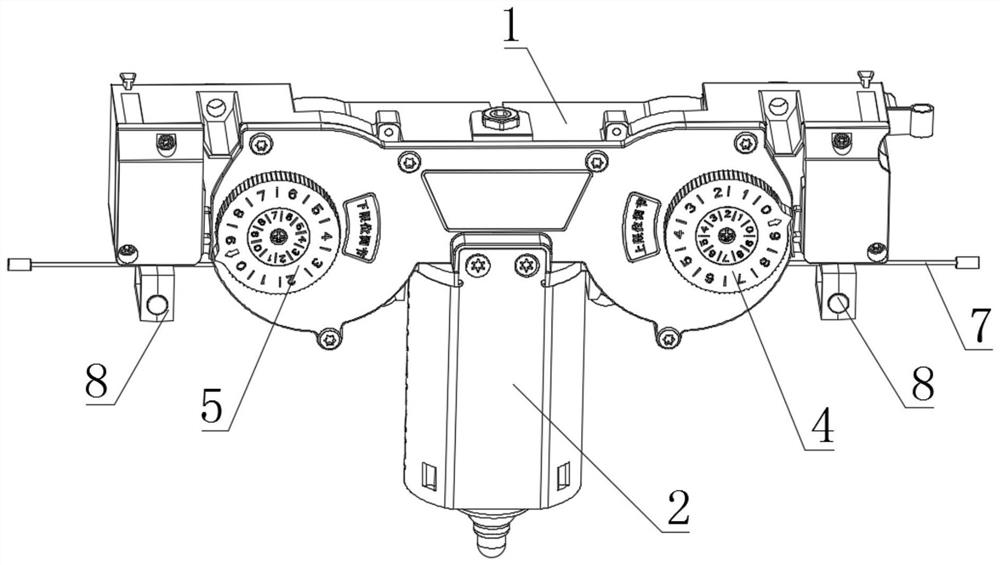

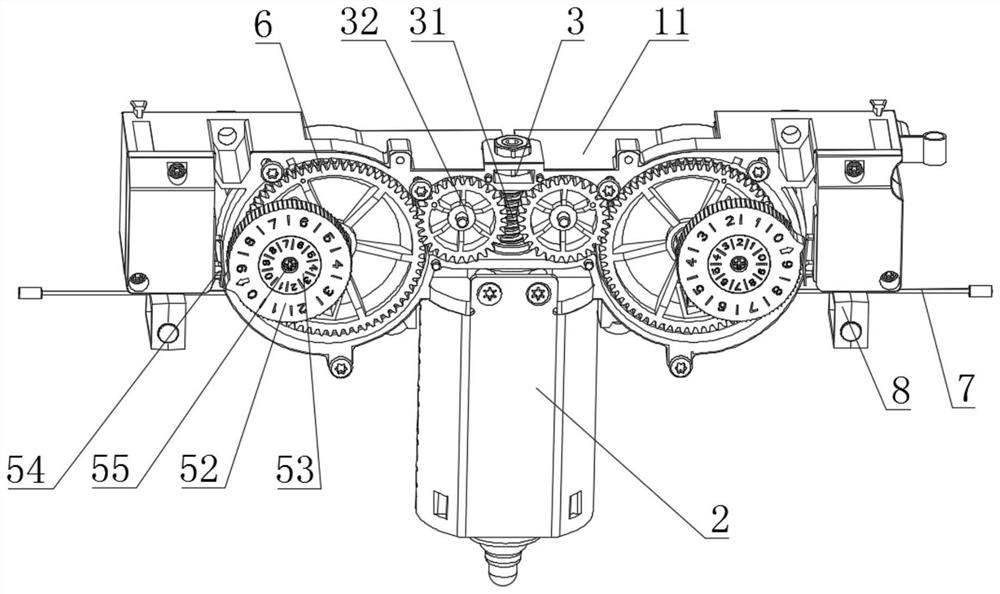

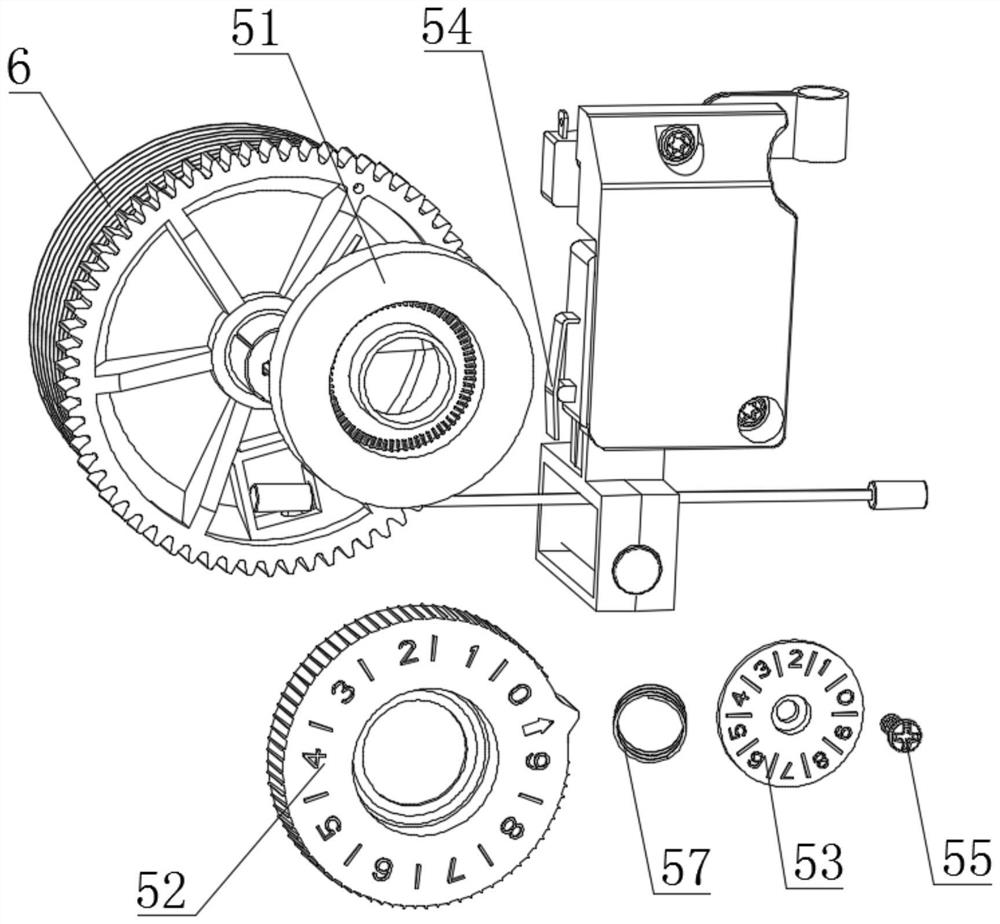

Adjusting device and tuning equipment

ActiveCN111193092ACompact structureReduce commutation transmission and deceleration modulesWaveguide type devicesRotational axisClassical mechanics

The invention is suitable for the technical field of concentric double-shaft tool clamps, and provides an adjusting device. The adjusting device comprises a screw adjusting assembly, a nut locking assembly and a connecting support. The nut locking assembly and the screw adjusting assembly are connected together through the connecting support. The nut locking assembly is arranged on the screw rod adjusting assembly in a sleeving manner; the nut locking assembly and the screw adjusting assembly form two rotating structures which operate independently and are concentric, the screw and the nut areadjusted and locked through the independent concentric rotating shafts, the two rotating shafts which operate independently and coaxially in the same direction are achieved, and the position, the rotating speed and the torsion of each shaft can be controlled independently.

Owner:CHENGDU INNOREV IND

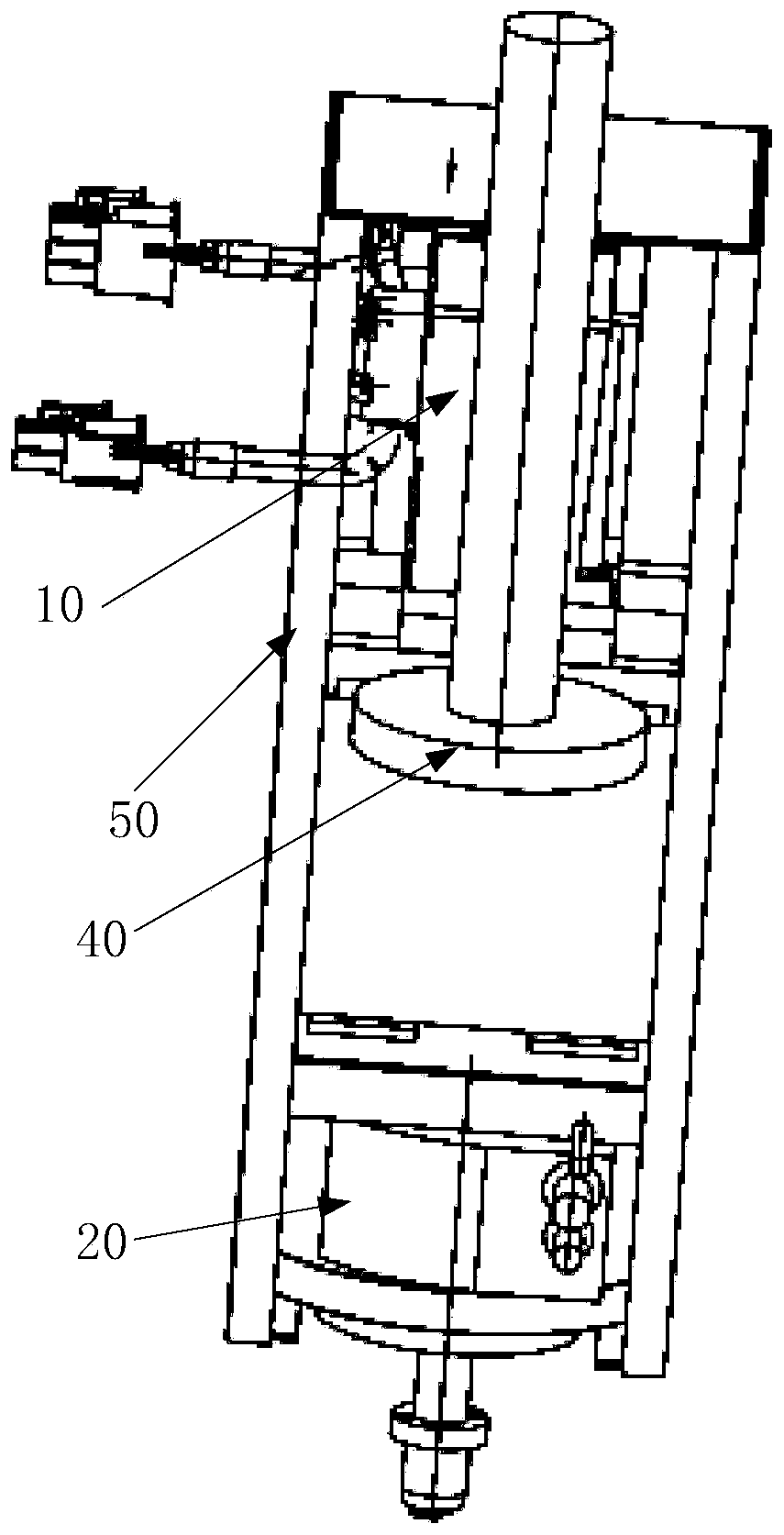

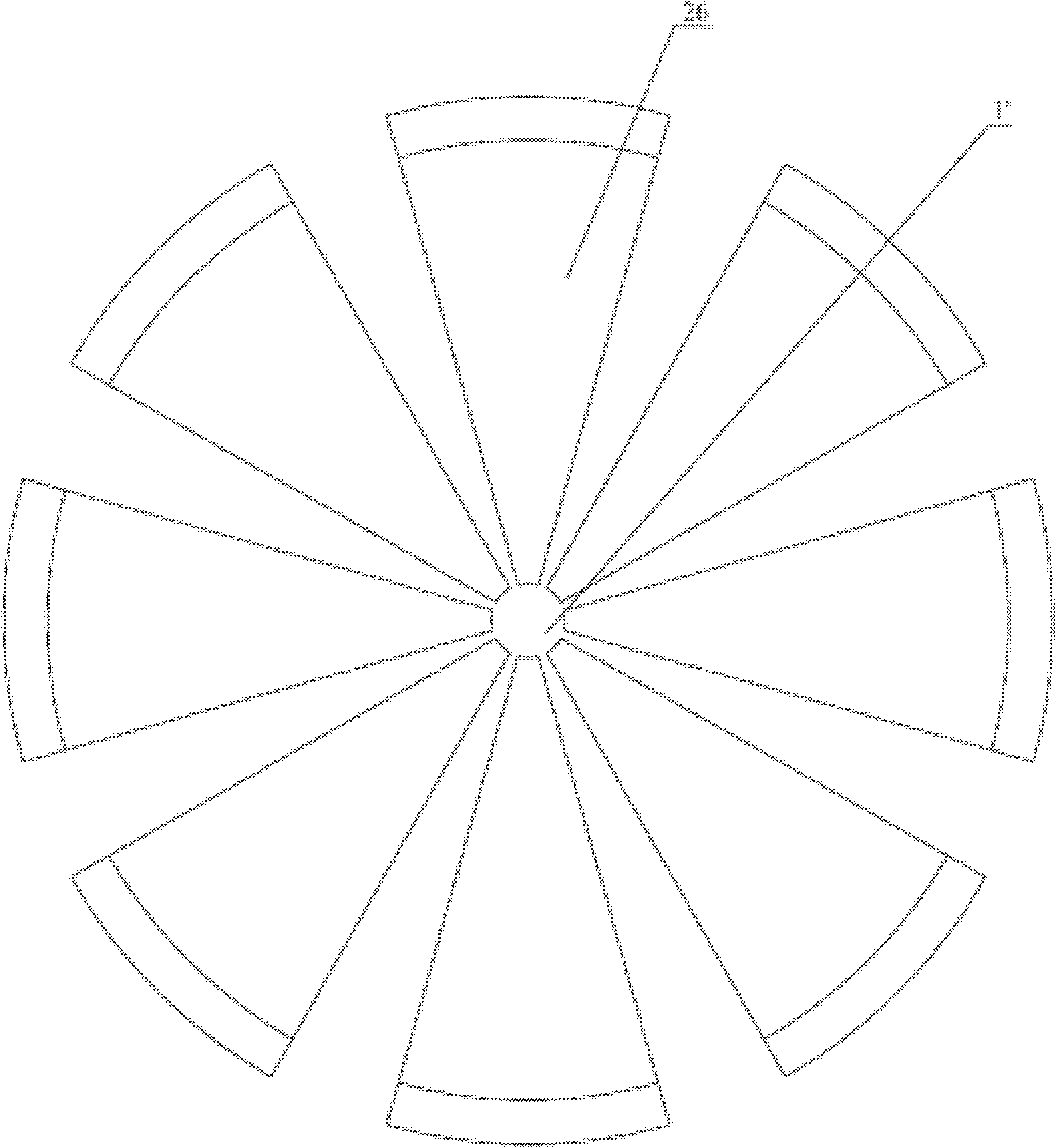

Air stream collecting device, wind motor and wind energy collecting device

InactiveCN102312769AOvercoming secondary energy conversion lossesTimely releaseWind motor controlMachines/enginesEngineeringWind force

The invention provides an air stream collecting device, which comprises an air stream collecting channel with a large outer orifice and a small inner orifice, wherein the channel wall of the air stream collecting channel at least comprises a movable part; and when the wind power exceeds a preset value, the movable part is compressed to release a part of air stream surpassing the preset value. The invention further discloses a wind motor and a wind energy collecting device using the air stream collecting device. Due to the adoption of the invention, the potential safety hazard on equipment caused by blast air such as typhoon or strong wind and the like can be eliminated effectively.

Owner:丛洋

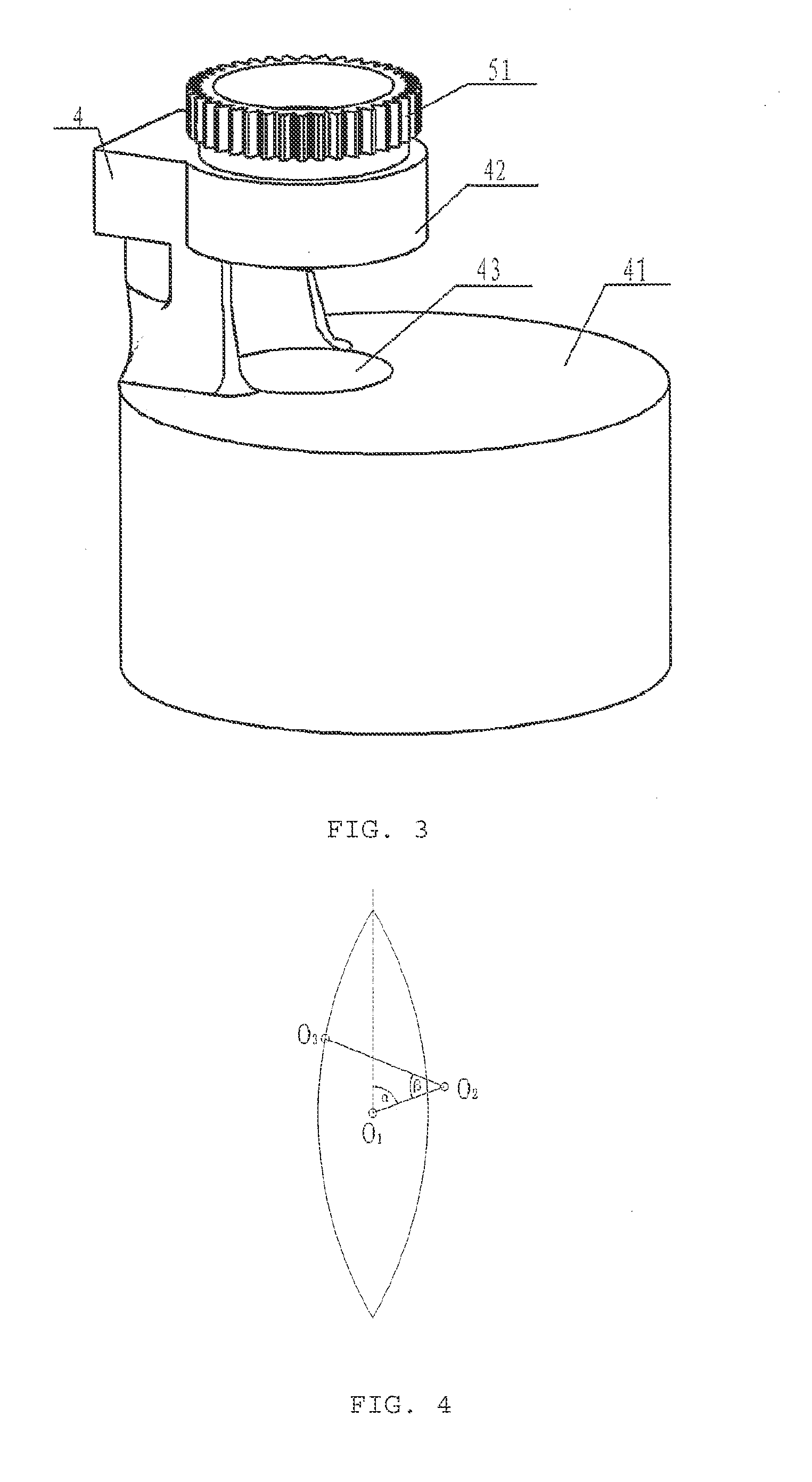

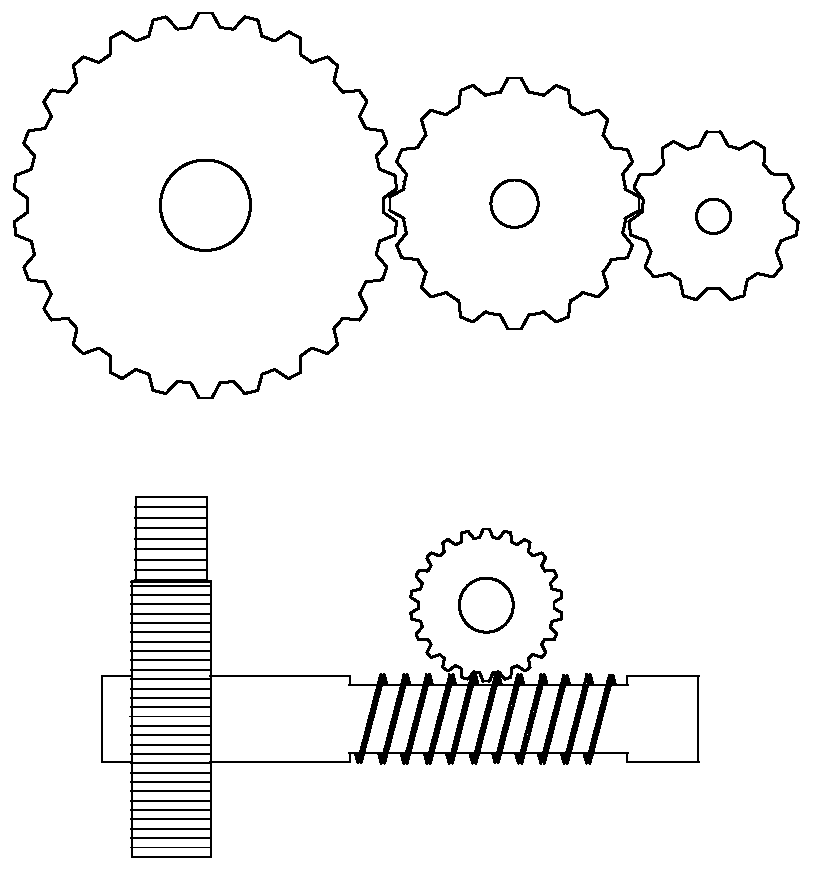

Worm wheel

InactiveCN110056610AReduce volumeReduce weightToothed gearingsPortable liftingRolling resistanceGear drive

The invention relates to the field of driving devices, and particularly provides a worm wheel. The worm wheel comprises a wheel body and second gear teeth, wherein the second wheel teeth are arrangedon the circumferential face of the wheel body, the second wheel teeth are cylinders extending along the radial directions of the worm wheel, and sliding friction or rolling friction is formed betweenthe second wheel teeth and spiral teeth; the wheel body comprises an outer wheel ring and an inner wheel ring, and the inner wheel ring and the outer wheel ring are connected through a plurality of spokes uniformly distributed around the center of the wheel body; a shaft hole is formed in the center of the inner wheel ring, and the second wheel teeth are arranged on the surface of the outer wheelring. The worm wheel is small in size, compact in structure, and can realize large-driving-ratio drive and large-torque output; and the worm wheel has the both advantages of gear drive and worm drive,and is simple in structure, low in manufacturing cost and convenient to popularize and popularize.

Owner:赵若君

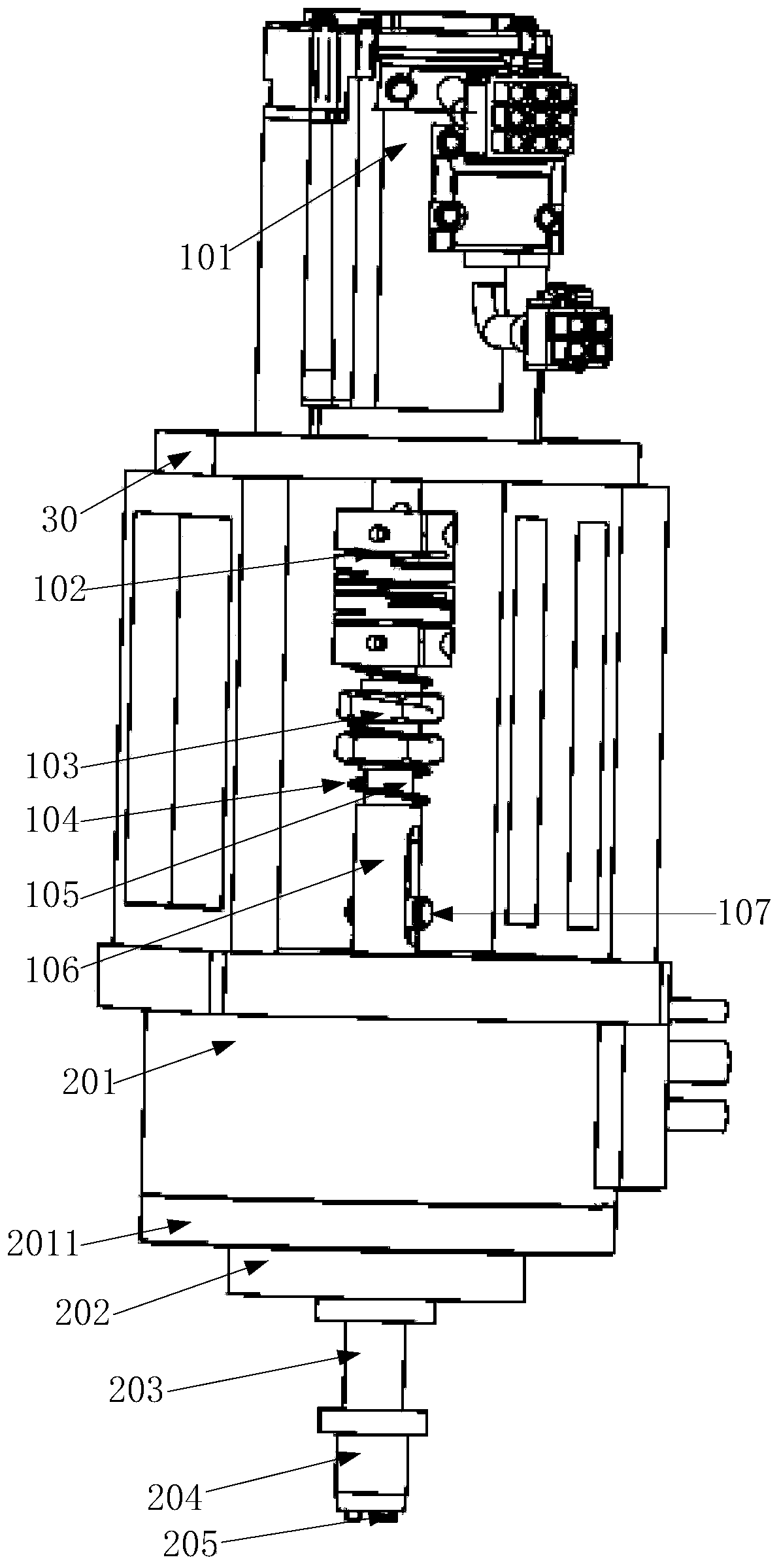

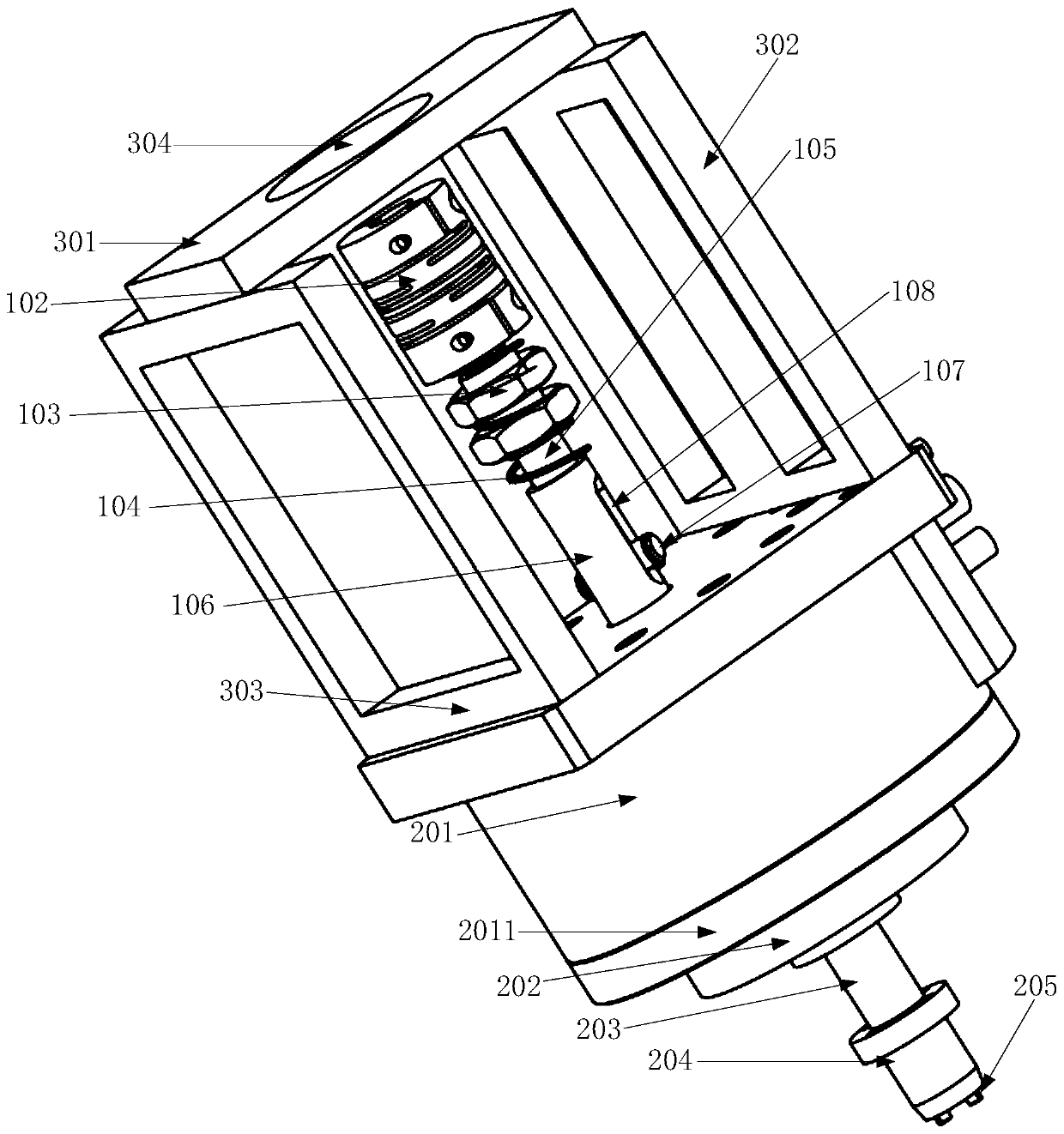

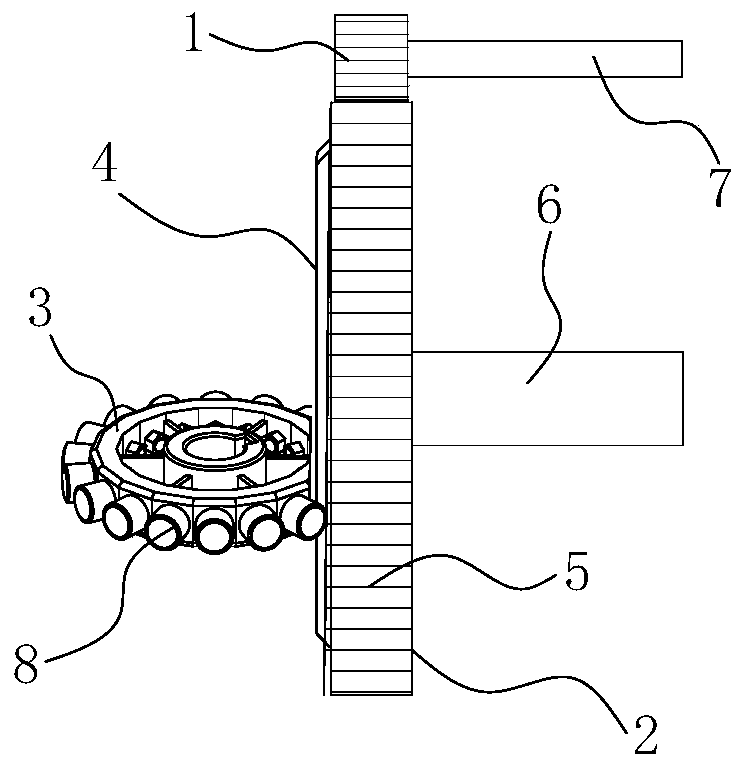

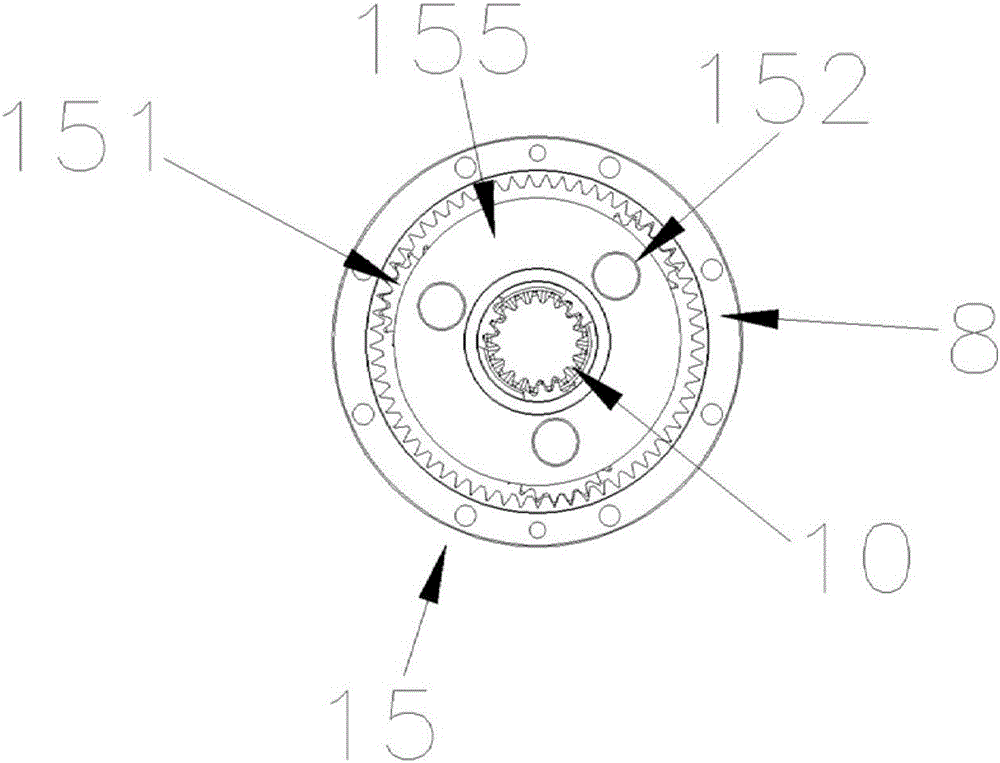

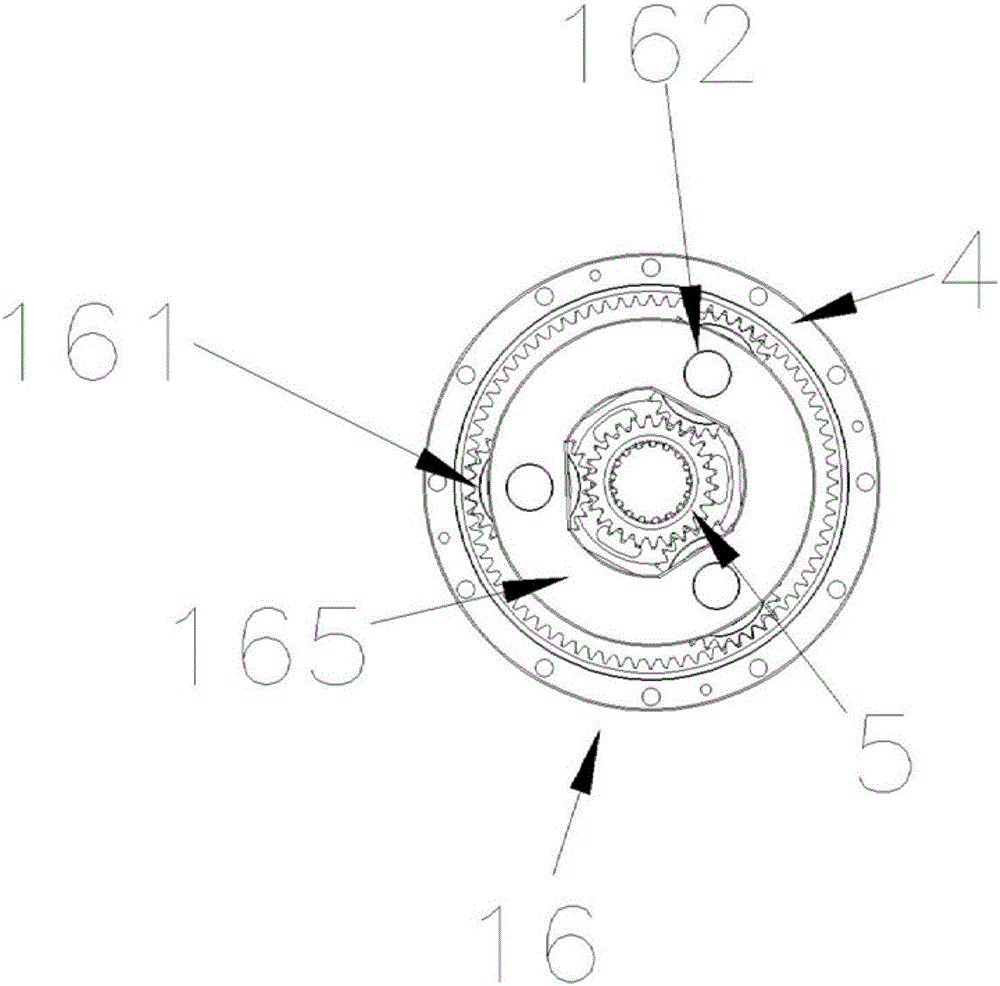

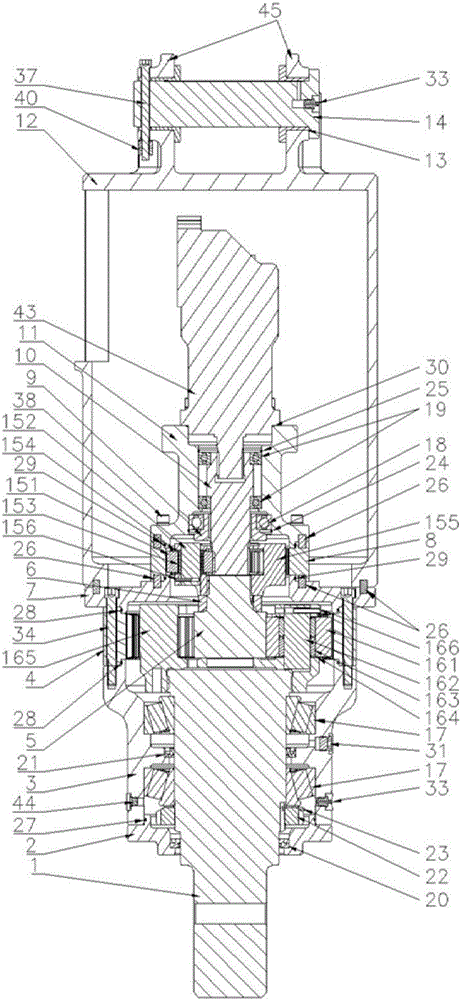

Spiral drilling machine

ActiveCN106122385AHigh torque outputStable structureConstructionsToothed gearingsHydraulic motorEngineering

The invention discloses a spiral drilling machine which comprises an oil seal cover. A bearing seat, a secondary rotation assembly, a flange and a motor outer shell are sequentially connected above the oil seal cover. An output shaft is connected to the inner sides of the oil seal cover and the bearing seat. One end of the output shaft penetrates through the bearing seat and the oil seal cover and is used for being externally connected with a load. The other end of the output shaft is engaged with the secondary rotation assembly. A secondary sun lgear in the secondary rotation assembly penetrates through the flange and is connected with a primary rotation assembly in an engaged mode. A primary sun gear shaft in the primary rotation assembly is connected with a hydraulic motor installed on a motor base in an engaged mode. The primary rotation assembly, the motor base and the hydraulic motor are all connected inside the motor outer shell. The spiral drilling machine has the beneficial effects that the spiral drilling machine can be used for mounting various drill bits, and through the primary rotation assembly and the secondary rotation assembly, large torque output can be achieved when a small-displacement hydraulic motor is adopted; and in addition, the primary rotation assembly and the secondary rotation assembly are connected in an engaged mode, a split structure is adopted, the structure is reliable, and maintenance is convenient.

Owner:张家港保税区永大机械有限公司

Lifting control device of electric drive airer

ActiveCN111824994ARealize thinner and lighterReduce thicknessOther drying apparatusWinding mechanismsElectric driveWheel drive

A lifting control device of an electric drive airer comprises a motor, a transmission mechanism, a rope winding wheel, an upper limit control mechanism and a lower limit control mechanism. The transmission mechanism comprises a worm and a first transmission gear. The diameter of the first transmission gear is smaller than that of the rope winding wheel. The upper limit control mechanism and the lower limit control mechanism each comprise a first contact switch, a pinion, a driving wheel, a regulating wheel, a fixed disc and a spring. The rope winding wheel drives the driving wheels to rotate through the pinions. The driving wheels drive the regulating wheels to rotate through meshing of first meshing threads and second meshing threads. A convex part of each regulating wheel controls a motor to stop. A clamping structure with a through hole and a slot is disposed on a rope winding part. The through hole is formed in the radial direction, and the slot extends circumferentially to be connected with a rope winding groove. Large torque can be output by the small-size motor, and the rope winding wheel can have a smaller diameter and a smaller thickness, so that the whole lifting controldevice is light, thin and small; the limit control mechanisms are simple and compact in structure, convenient to install and easy to adjust; and a clothes airing rope is easy and convenient to installand replace.

Owner:GUANGZHOU NOVO SUN SHADING TECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com