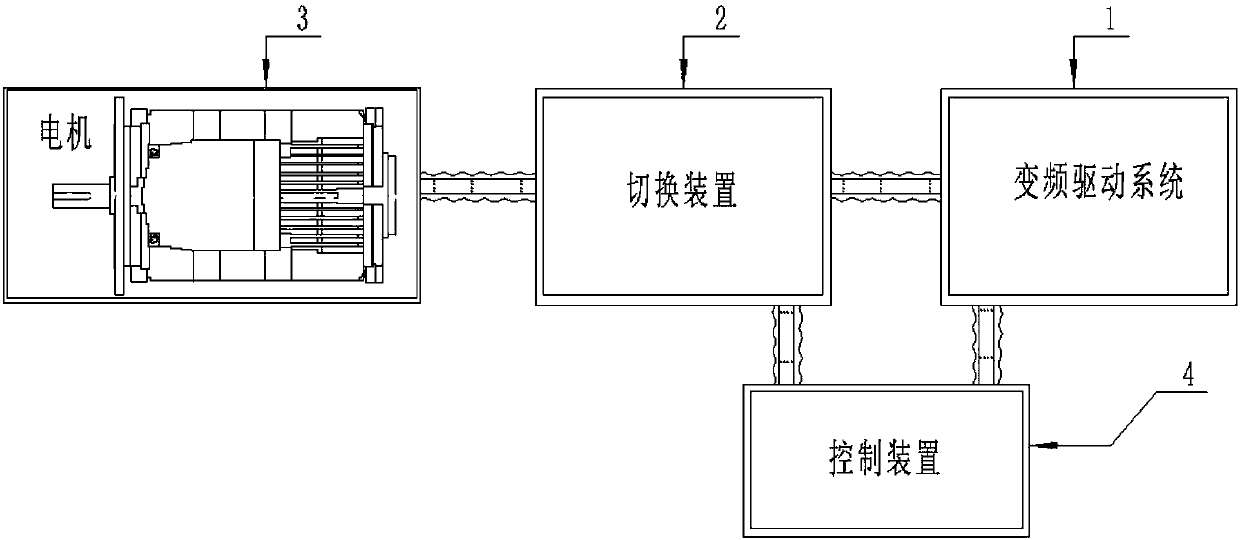

Multi-base-frequency and multi-power switching motor and driving system

A drive system, multi-power technology, applied in the control system, AC motor control, electrical components, etc., can solve the problem that the spindle motor of CNC machine tool or electric vehicle motor cannot meet the low speed and high torque at the same time, so as to increase the speed regulation range, The effect of increasing the FM range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

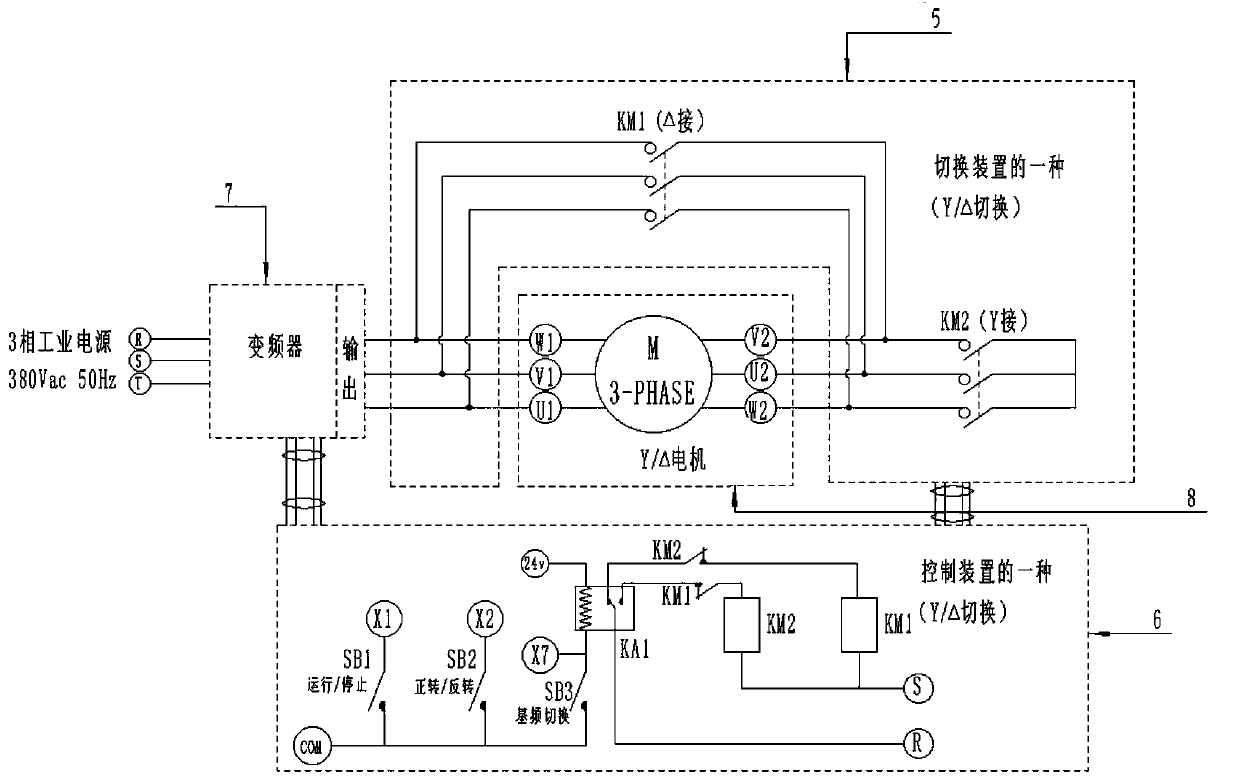

[0049] Such as figure 2 As shown, the star-angle switching device 5 is used to switch the star-angle of the stator winding of the Y / Δ motor 8, the star-angle control device 6 is respectively connected with the star-angle switching device 5 and the frequency converter 7, and the frequency converter 7 is Weihai Maike MV10 series inverter produced by Electric Technology Co., Ltd.

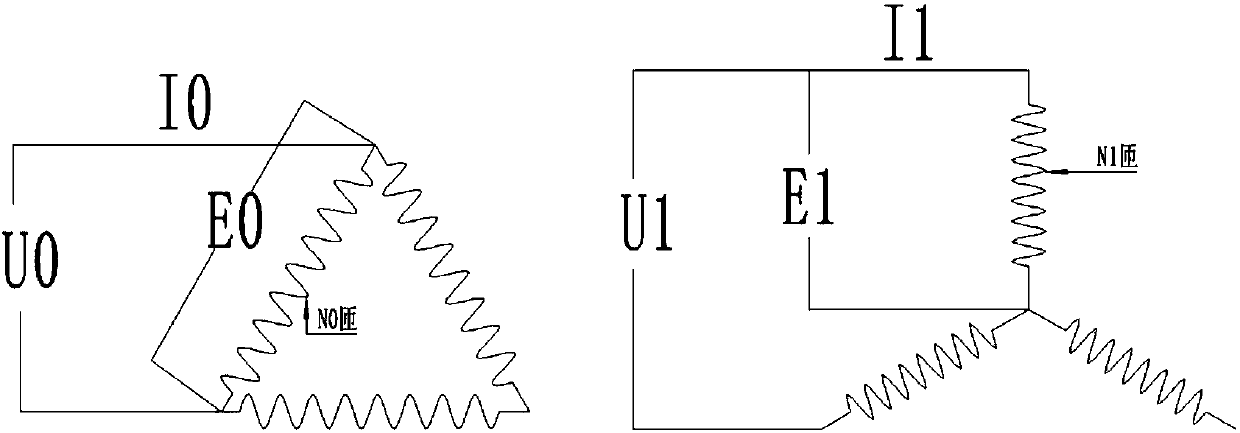

[0050] The star angle switching device 5 includes a delta switch KM1 and a star switch KM2, and the three head ends U1, V1, W1 and the three tail ends U2, V2, W2 of the stator winding on the Y / Δ motor 8 pass through the delta switch KM1 is connected, and the three tail ends U2, V2 and W2 of the stator winding on the Y / Δ motor 8 are connected to the star switch KM2. The voltage output terminal of the frequency converter 7 is connected to the three first terminals U1 , V1 , W1 of the stator winding of the Y / Δ motor 8 . When the angle switch KM1 is closed and the star connection switch KM2 is off, the ...

Embodiment 2

[0078] Such as Figure 5 As shown, the series-parallel switching device 9 is used for series-parallel switching of the stator winding of the motor 12, and the series-parallel control device 10 is used to control the action of the series-parallel switching device 9 and the frequency converter 11. The frequency converter 11 is selected from Weihai Maike Electric Technology Co., Ltd. MV10 series inverters produced by the company.

[0079] The AC380V power supply is connected to the input terminal of the frequency converter 7 .

[0080] The stator winding of the motor 12 is designed to have 9 taps to realize the winding in series and parallel, that is to say, the one-way connection method in the prior art is changed to two-way connection method to lead out the terminals respectively, and the three heads of the one-way winding are U1, V1 , W1, the three tails are U2, V2, W2; the three heads of the other winding are U3, V3, W3, and the three tails are U4, V4, W4.

[0081] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com