Fabric texture and pattern correction method and weft straightener

A technology of fabric texture and flower shape, which is applied in the field of textile equipment and technology, can solve the problems of slow response, low correction precision, long adjustment stroke, etc., and achieve the effects of fast response speed, high correction precision and large speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

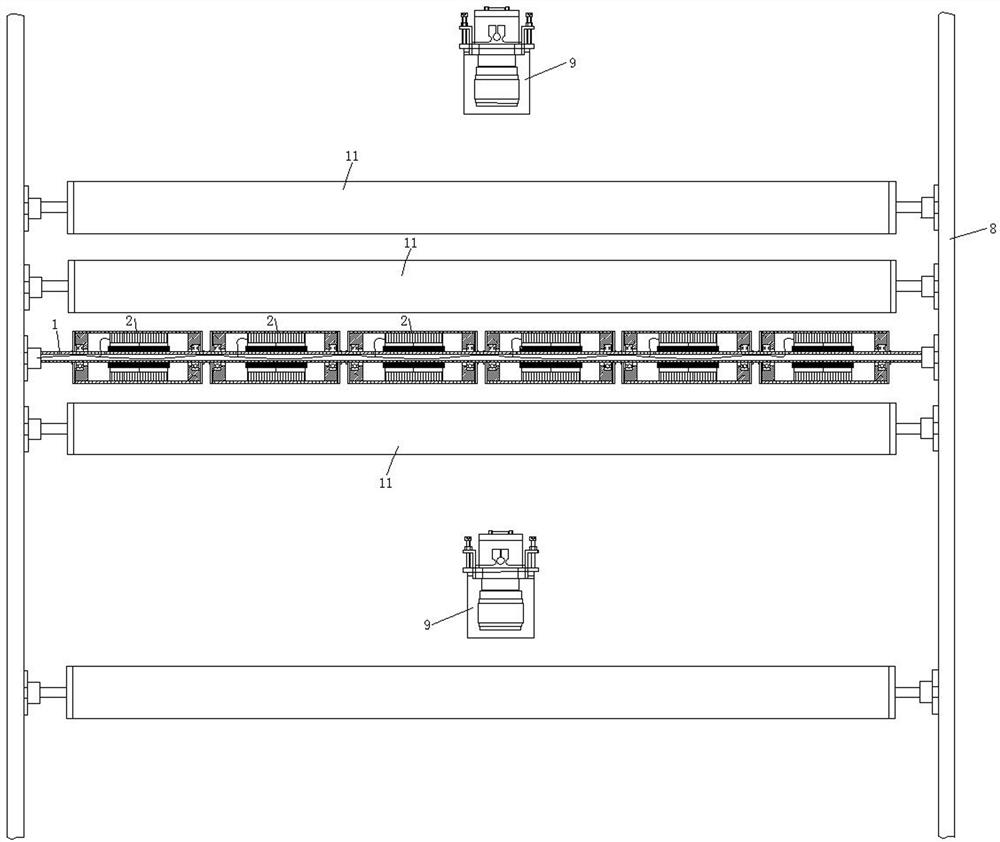

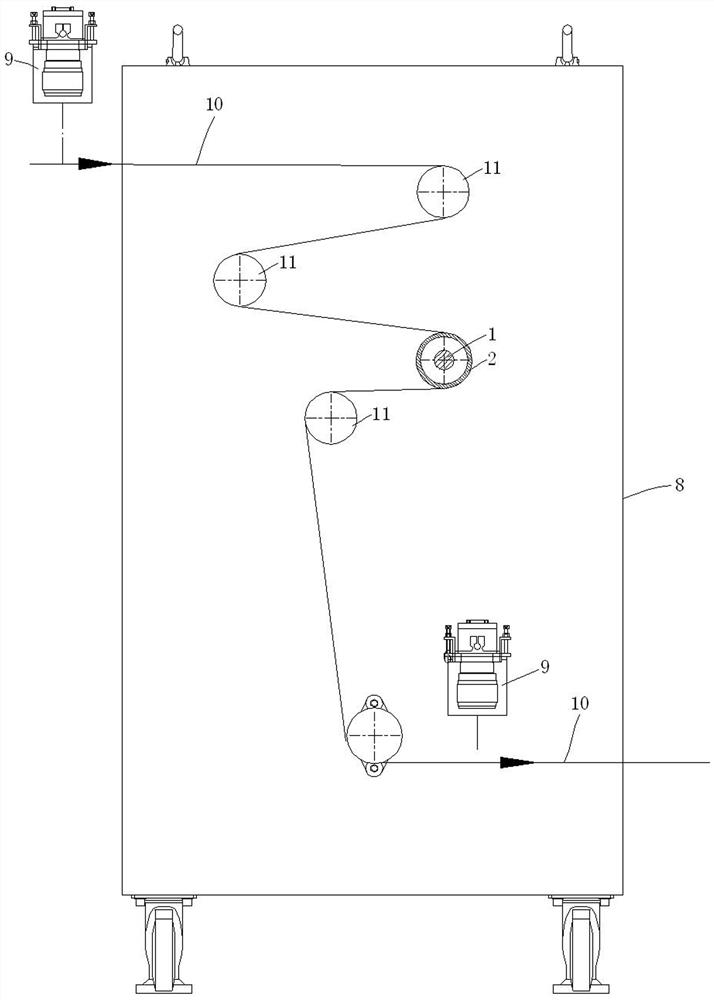

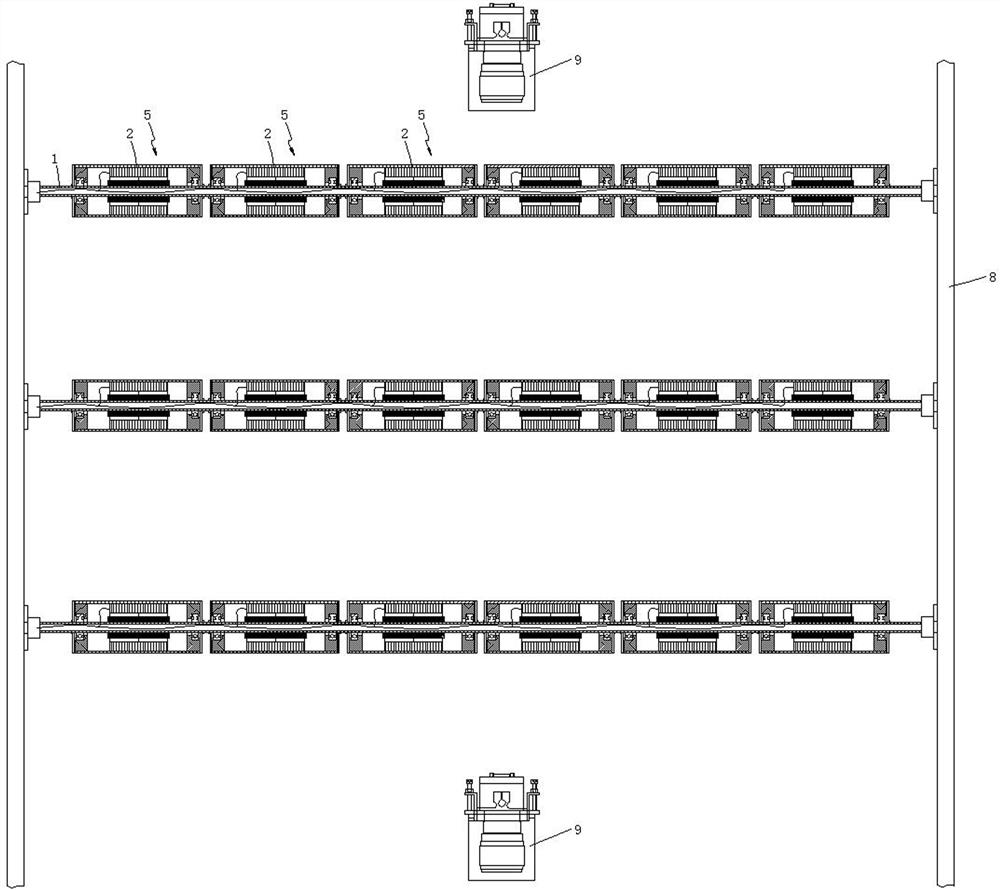

Image

Examples

Embodiment approach

[0042] As a preferred embodiment of the present invention, the method also includes that after step (1) and before step (2), the detection mechanism collects the weft yarn and pattern status data of the fabric 10 in operation, and transmits the collected data to Electric controller steps. In addition, in step (1), each sleeve is preferably controlled by an electric controller to actively rotate at the same rotational speed and pull the fabric, of course, it can also be driven to rotate passively by the fabric.

[0043] As a preferred embodiment of the present invention, step (2) specifically includes: performing the following control according to the direction of fabric weft skew / flower shape skew and weft bend / flower shape bending, the position of the variation area in the width direction, and the amount of variation,

[0044] (2-1) When the weft skew / flower shape skew or weft bend / flower shape bending direction of the fabric is consistent with the running direction of the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com