Pneumatic motor

a pneumatic motor and rotor technology, applied in the direction of valve arrangement, sealing arrangement of engines, machines/engines, etc., can solve the problems of increased vibration of the motor, reduced stability, and conventional pneumatic motors that don't have sufficient power output stability, etc., to achieve stabler and larger torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

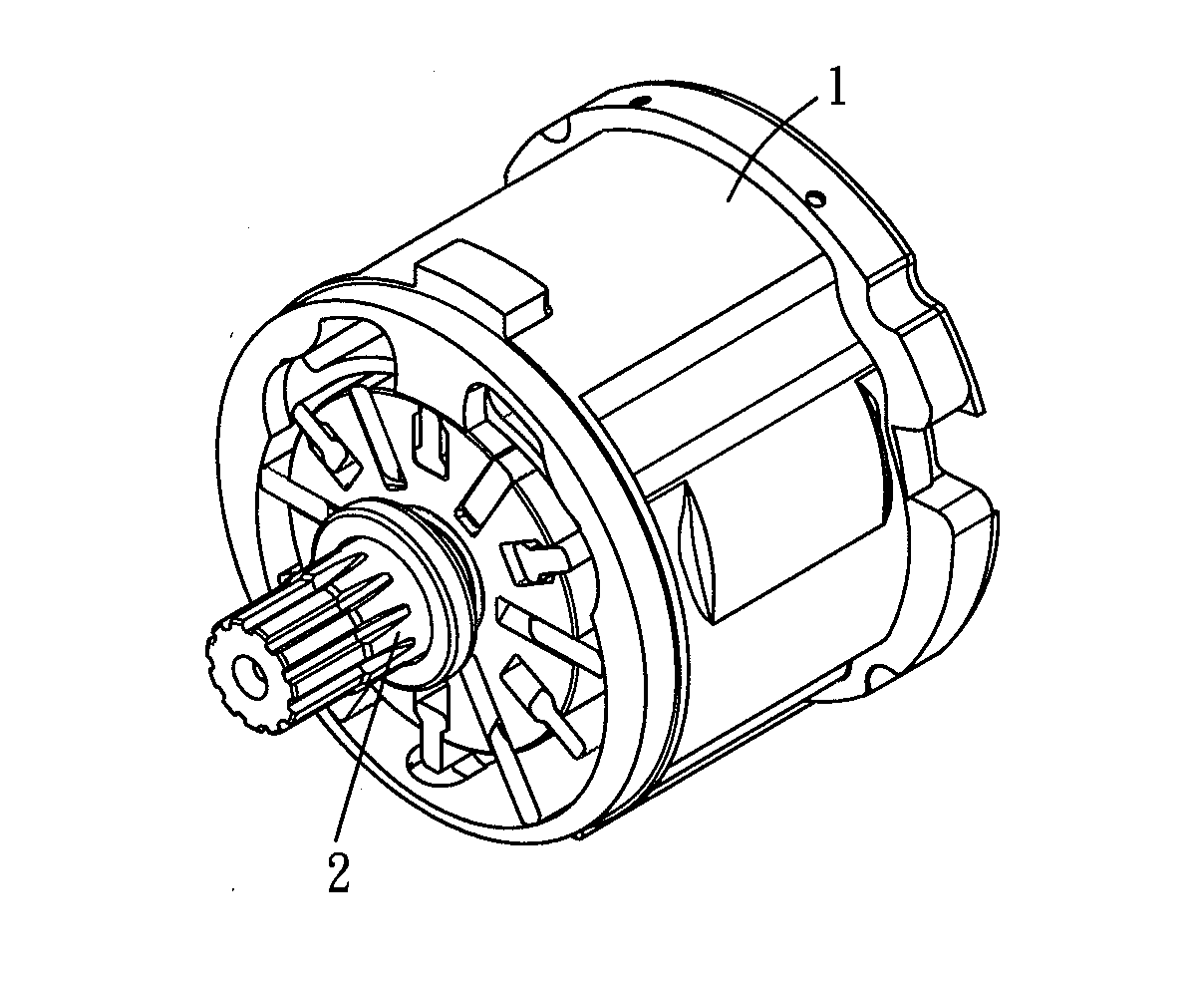

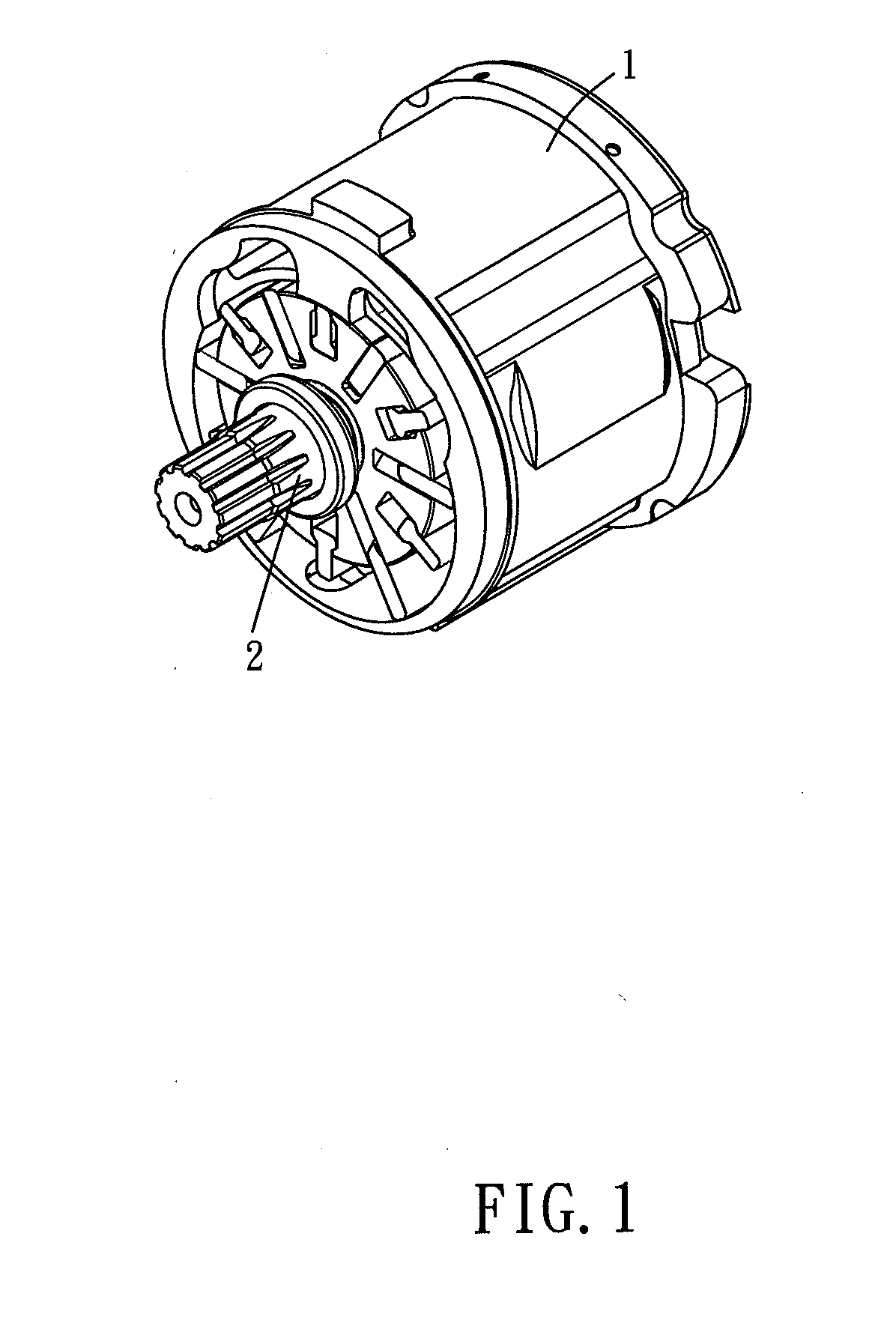

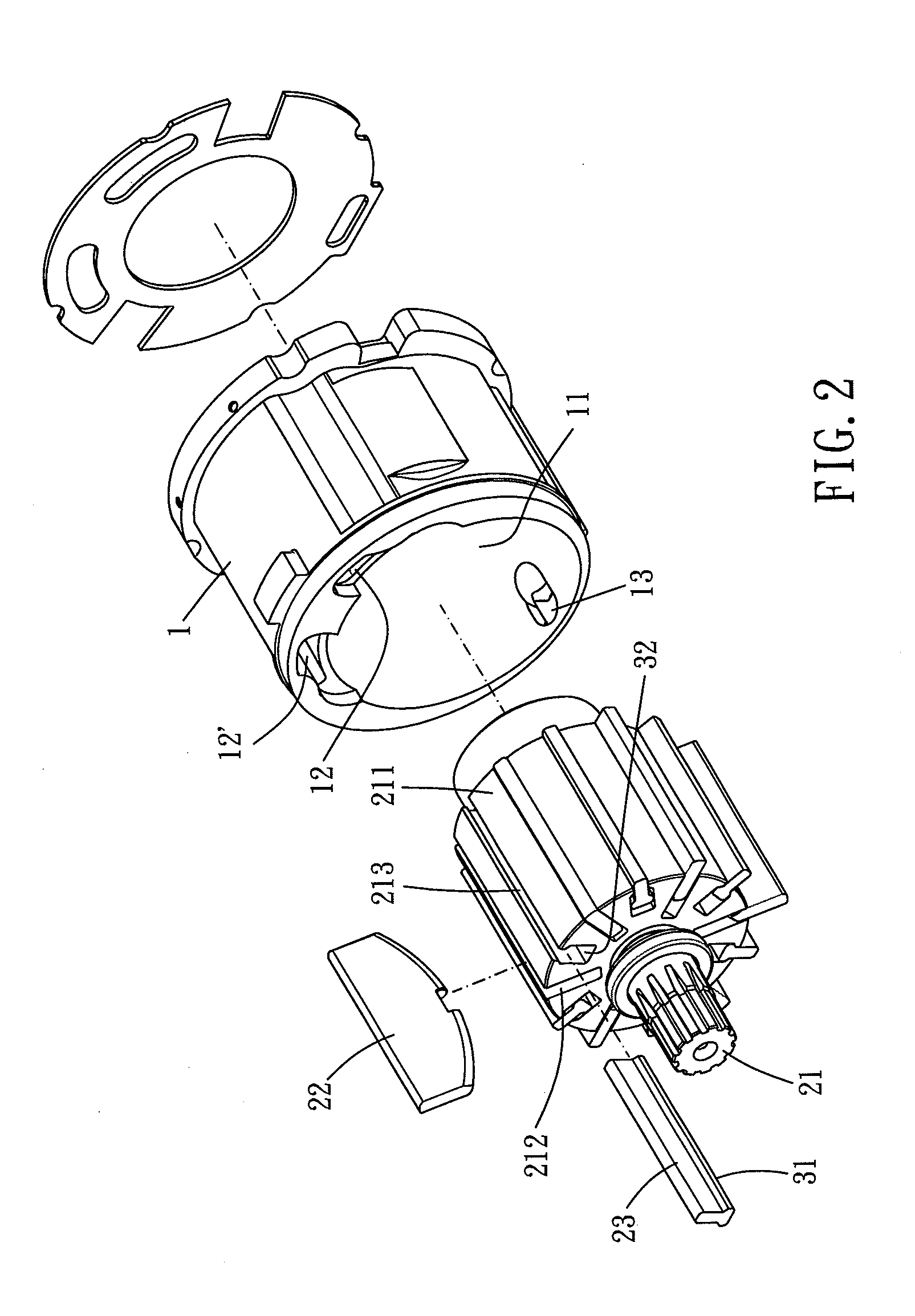

[0023]Please refer to FIG. 1 and FIG. 2 for a major embodiment of the present invention. The pneumatic motor of the present invention is adapted for being installed in pneumatic tools and for being driven by compressed air. The pneumatic motor of the present embodiment includes a cylinder 1, a rotor 2, and a limitation mechanism.

[0024]The cylinder 1 encloses a receiving room 11, an inlet 12, and an outlet 12, wherein the inlet 12 and the outlet 13 communicate with the receiving room 11. The cylinder 1 has an inner wall defined on a circumference of the receiving room 11. Compressed air is able to enter the receiving room 11 via the inlet 12 and then to be discharged via the outlet 13. In other possible embodiment, the cylinder 1 can form a plurality of inlets and outlets, and path of compressed air is able to be changed by a valve. Thus, operating direction of the motor can be changed.

[0025]The rotor 2 includes an axle 21 and a plurality of main blades 22. An axial direction and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com