Electric scissor motor

A technology for electric shears and motors, which is applied to electric components, electromechanical devices, electrical components, etc., can solve the problems of large occupation volume, high manufacturing cost, and difficult to dissipate heat, and achieve large torque output, low manufacturing cost, and good heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

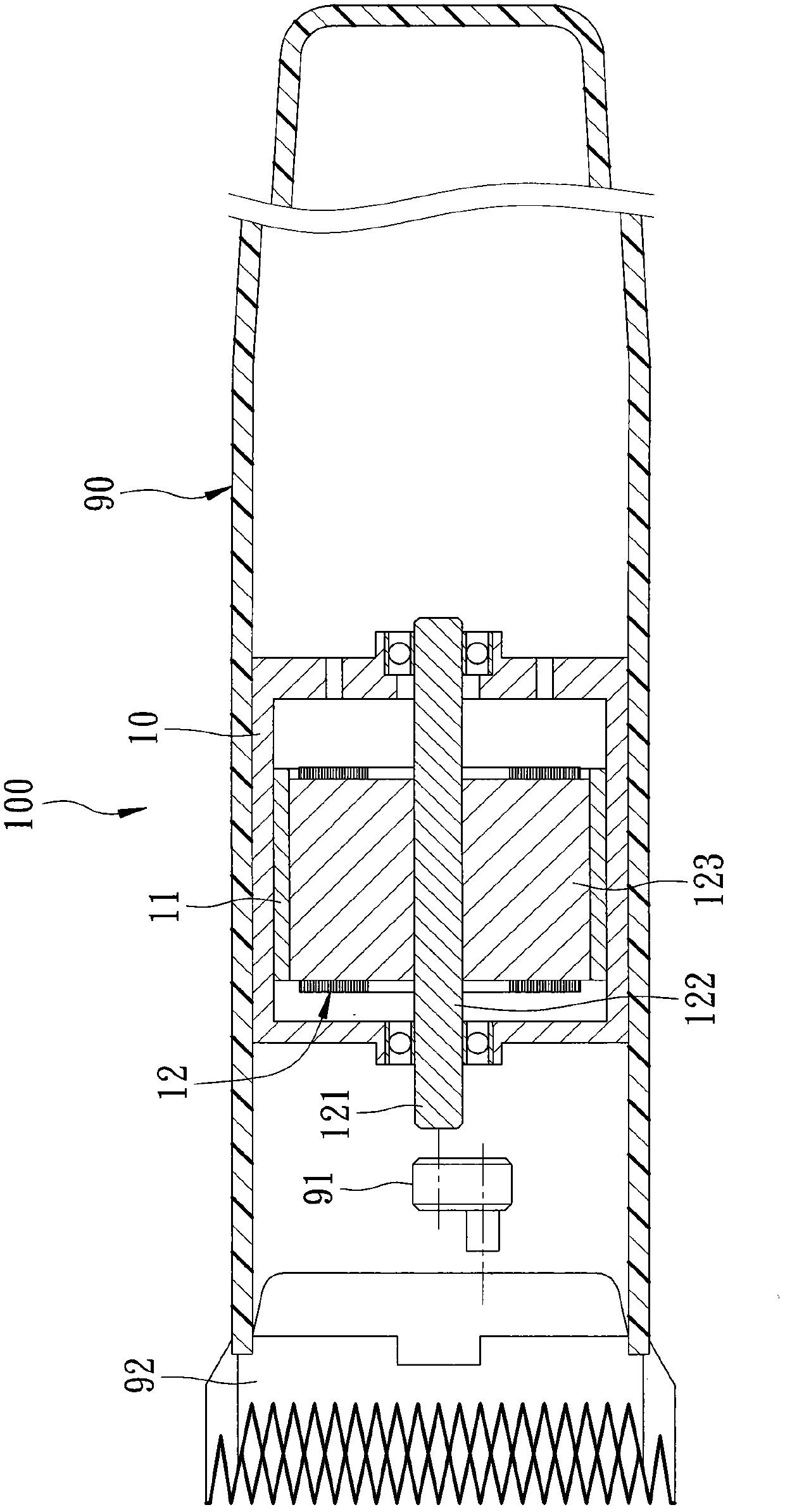

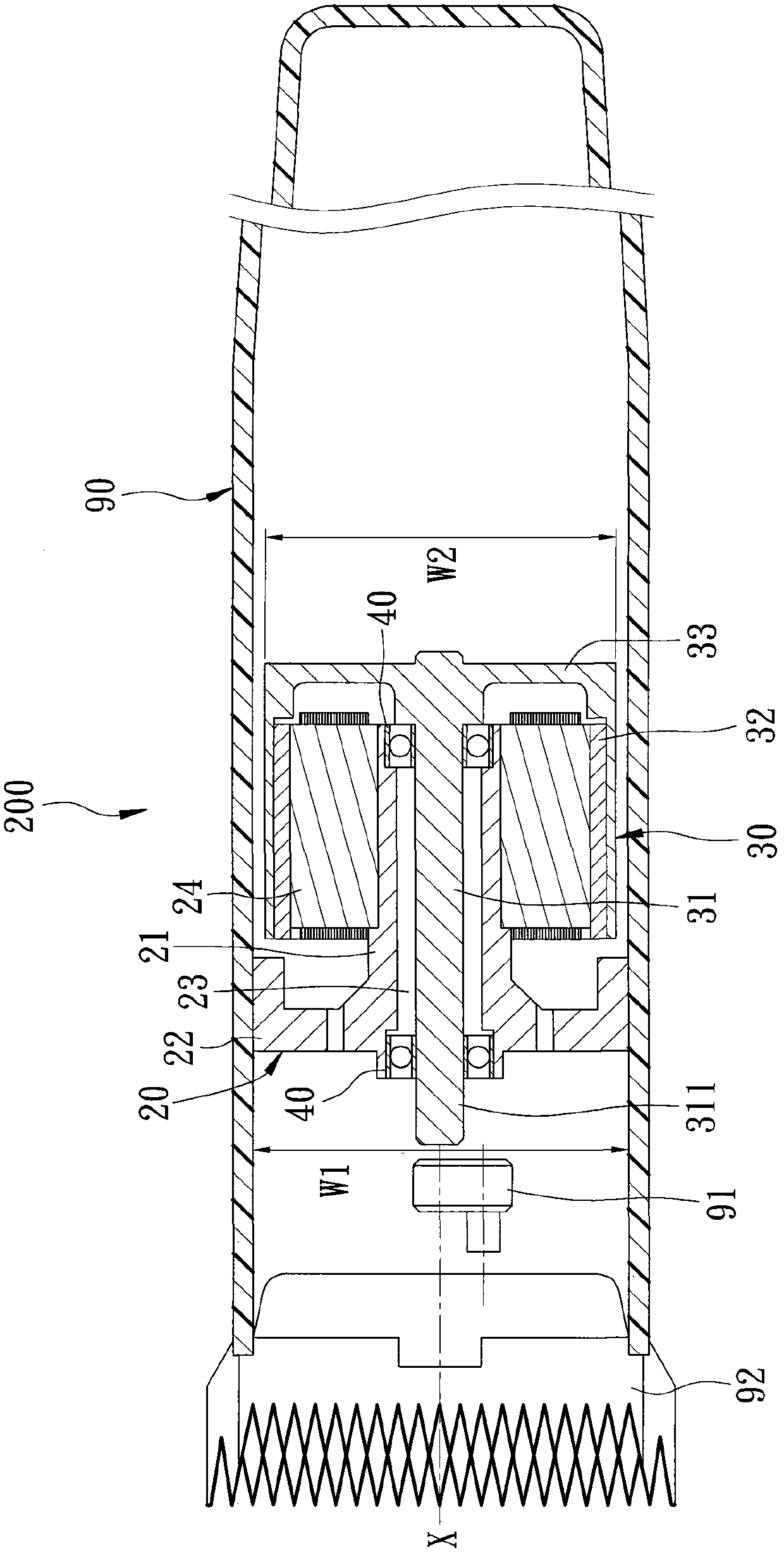

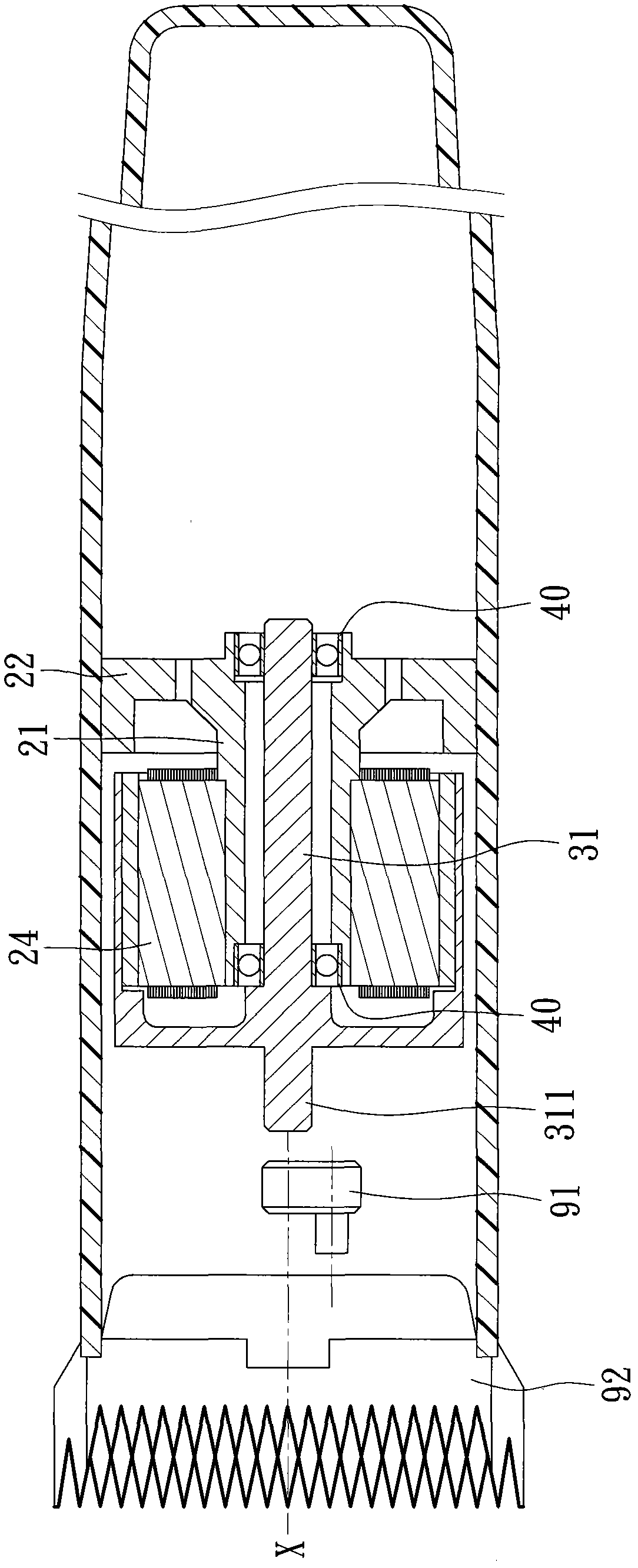

[0016] Such as figure 2 As shown, the first preferred embodiment of the electric shear motor 200 of the present invention includes a fixing base 20 , a rotor unit 30 , and two bearings 40 .

[0017] The fixing seat 20 is used to be fixed in an electric scissors housing 90, and includes a surrounding wall 21 extending along an axis X and surrounding it, a fixing wall 22 extending radially from the surrounding wall 21, and a fixed wall 22 formed on the surrounding wall 21. A mandrel hole 23 extending along the axis X in the surrounding wall 21 , and a winding 24 sleeved on the outer peripheral surface of the surrounding wall 21 along the axis X.

[0018] The fixed wall 22 is close to one end of the surrounding wall 21, and a fixed seat width W1 formed by the fixed wall 22 in the radial direction is greater than a rotor width W2 formed by the rotor uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com