Adjusting device and tuning equipment

A technology for adjusting devices and adjusting components, applied in electrical components, circuits, waveguide-type devices, etc., can solve the problems of heavy weight, large space occupation, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

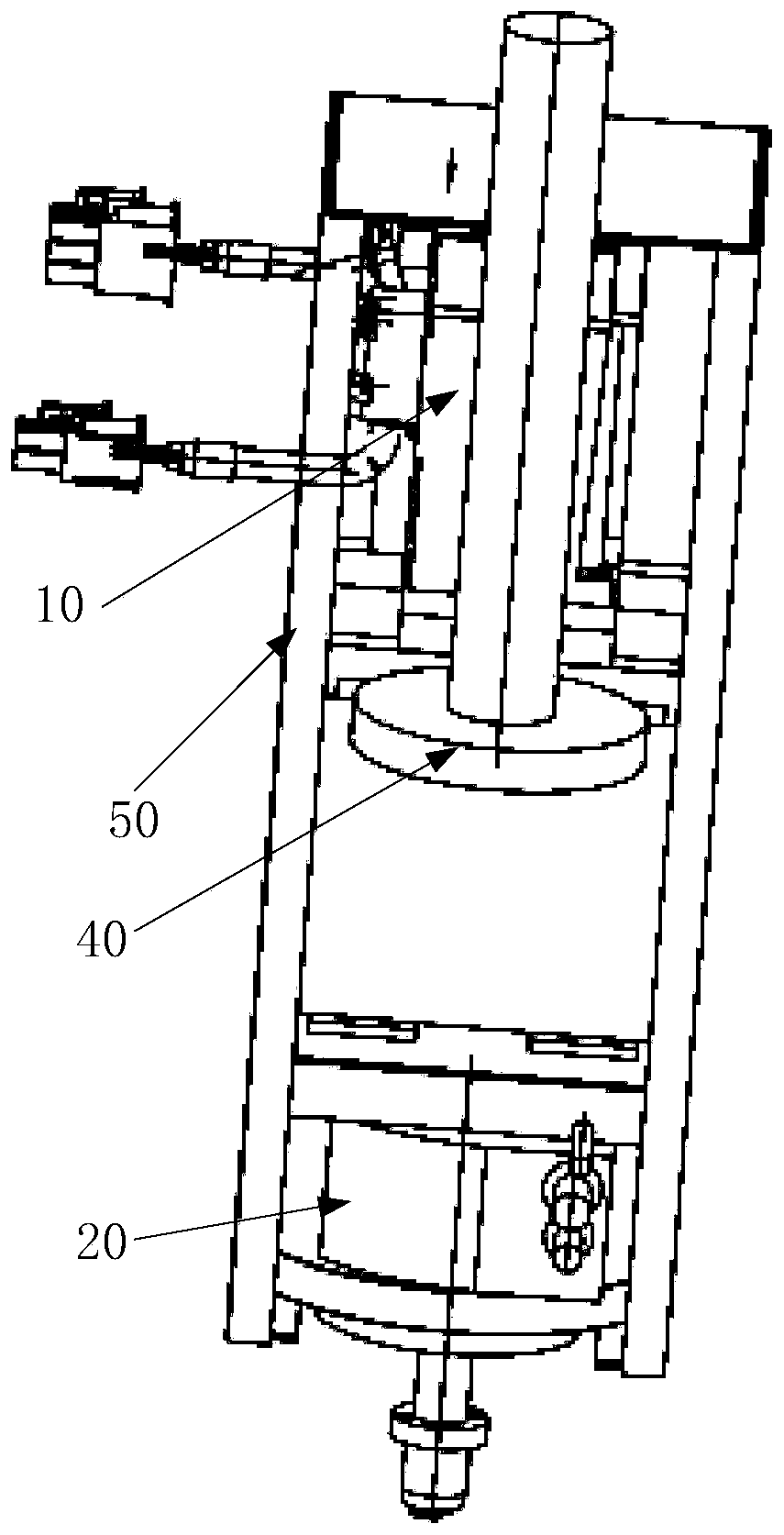

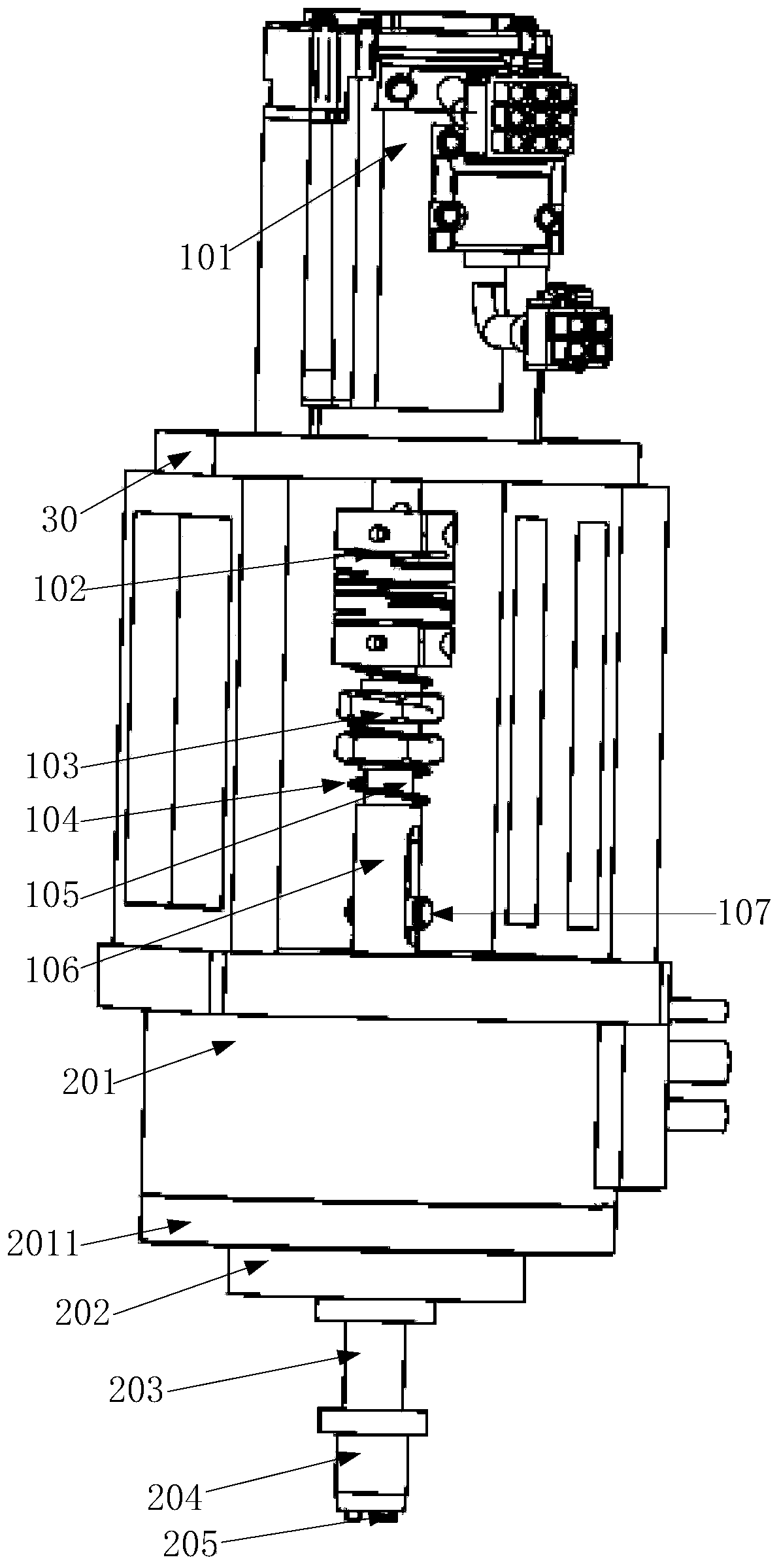

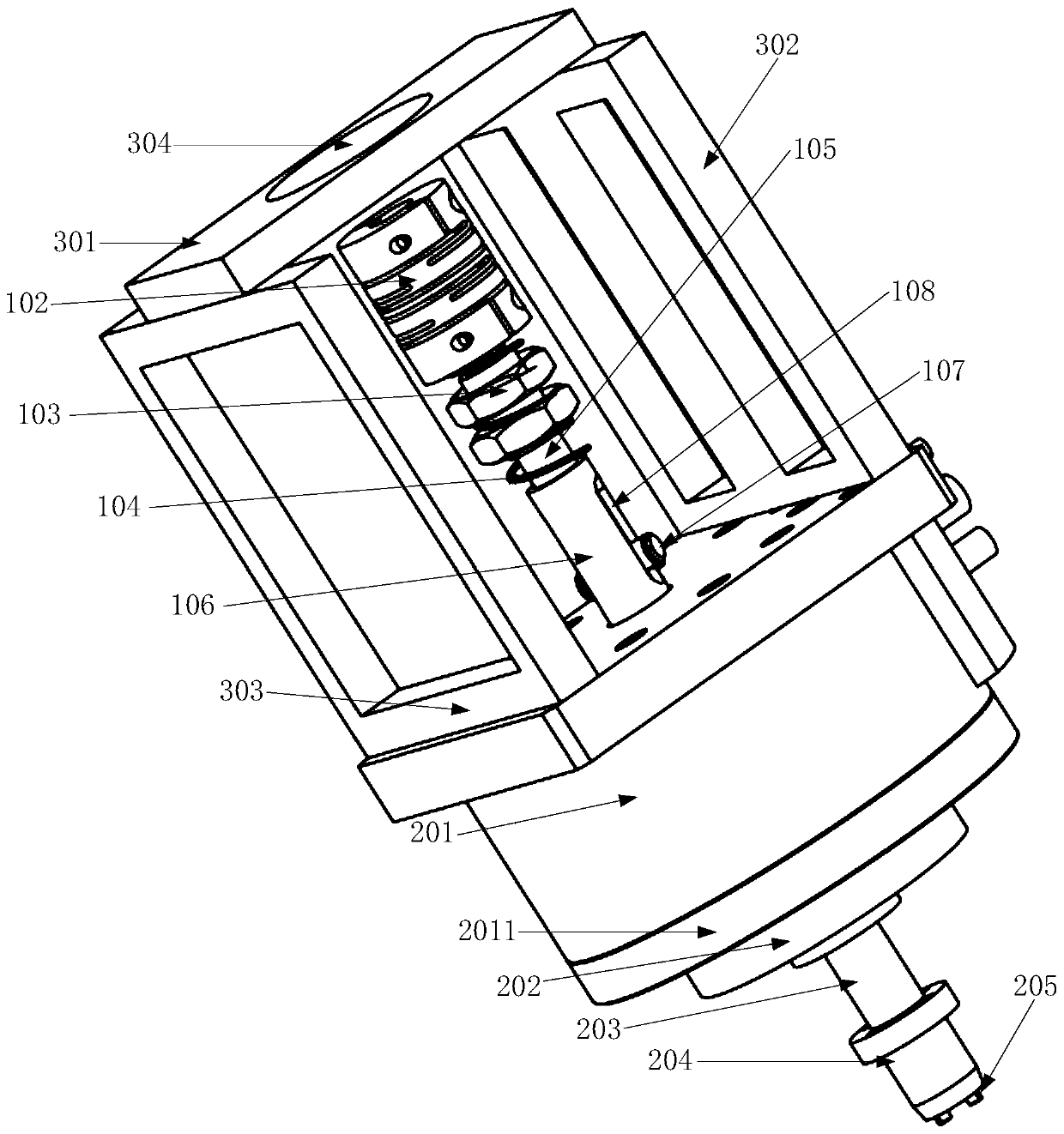

[0035] Such as figure 1 As shown, the adjustment device provided by the embodiment of the present application includes a screw adjustment assembly 10, a nut adjustment assembly 20 and a connecting bracket 30, and the connecting bracket 30 is installed on the top surface of the nut adjustment assembly 20 through a bolt structure. The screw adjustment assembly 10 is fixed on the top surface of the connecting bracket 30 by bolts, so that the front end of the screw adjustment assembly 10 penetrates into the hollow structure of the nut adjustment assembly 20, and the screw adjustment assembly 10 and the nut adjustment assembly 20 form a concentric structure. , the screw adjusting assembly 10 and the nut adjusting assembly 20 operate independently, forming a concentric rotating structure.

[0036] The adjustment device also includes a protective cover 50, the screw adjustment assembly 10, the connection assembly 30 and the nut adjustment assembly 20 are arranged in the protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com