Integrated three-stage speed reduction electric drive axle

A three-stage deceleration and electric drive technology, which is applied to axles, wheels, control devices, etc., can solve the problems of large vehicle matching space requirements, large drive axle volume, and low integration, and achieve good vehicle adaptability, The effect of light weight of the motor and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

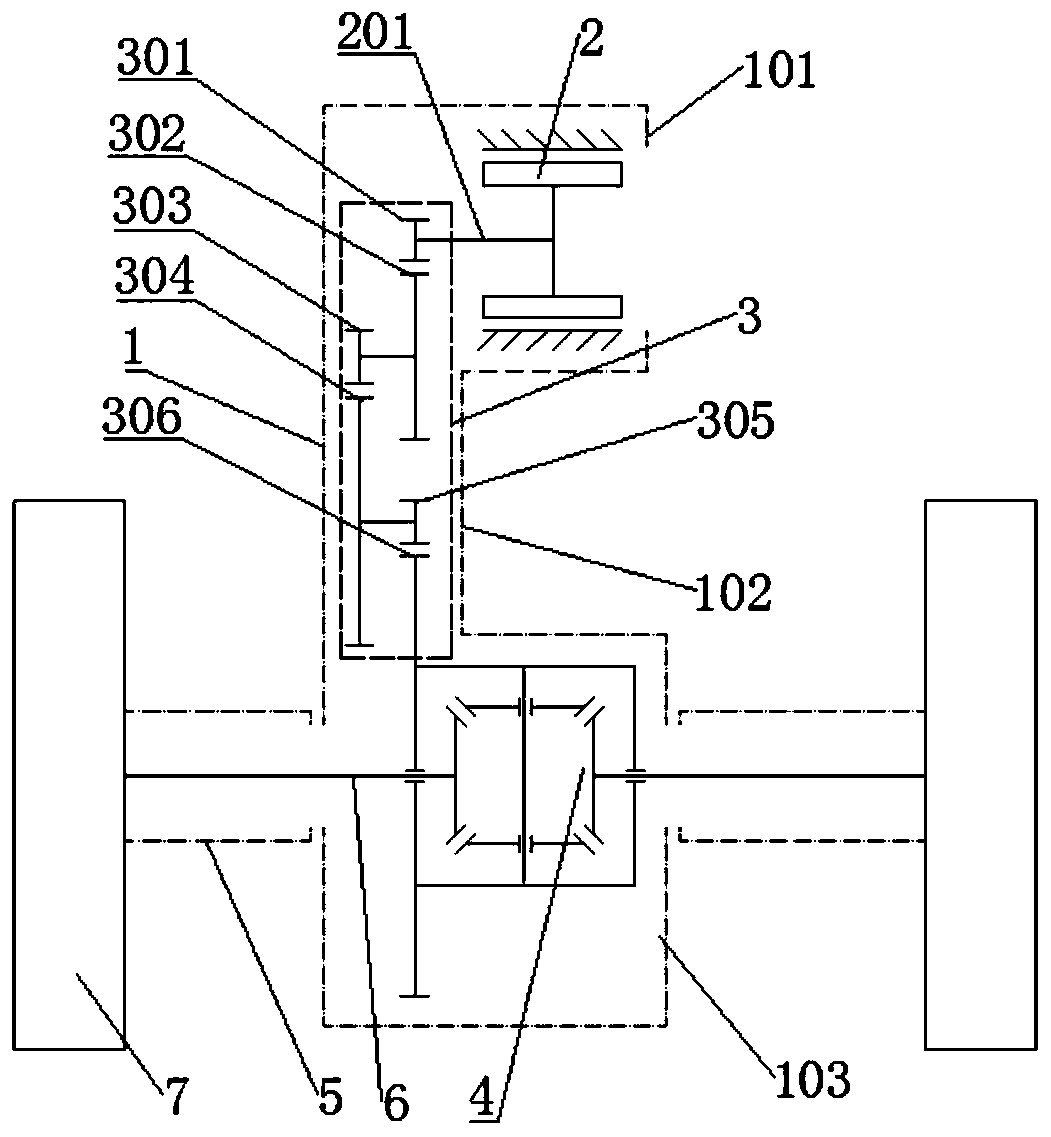

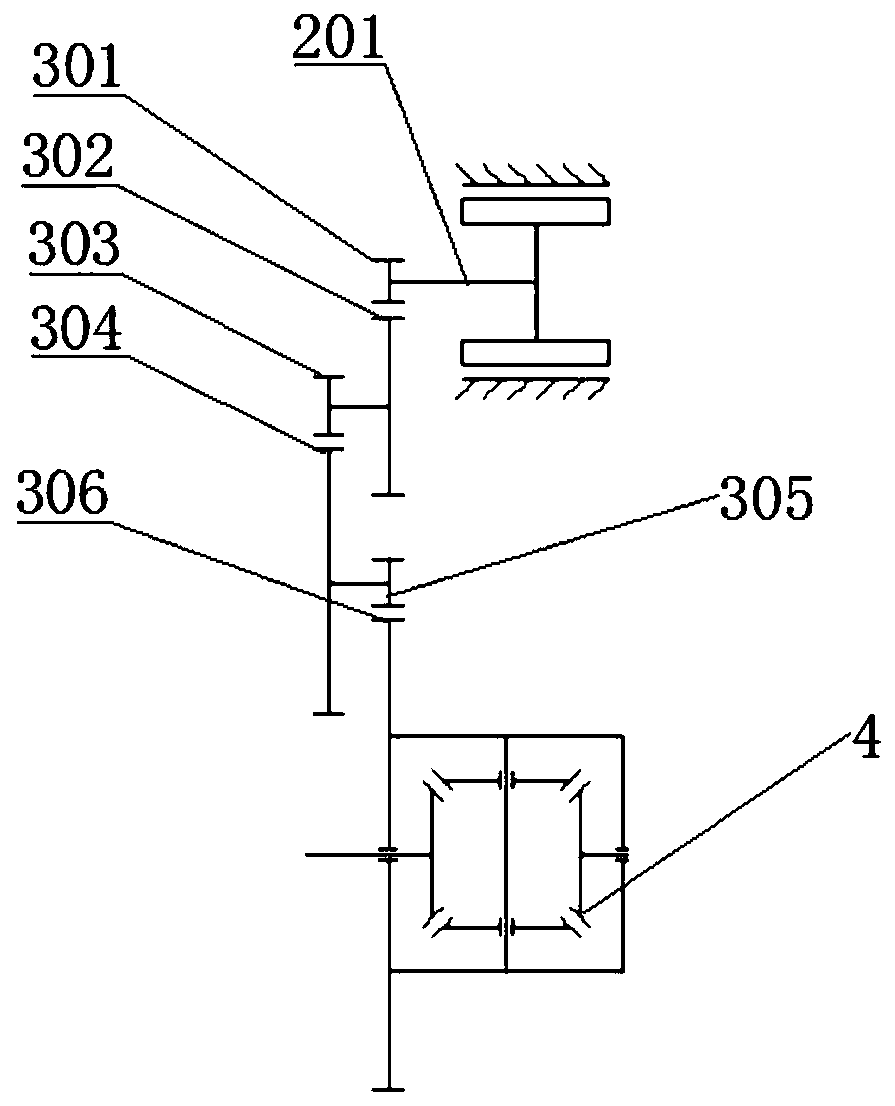

[0021] Such as figure 1 As shown, an integrated three-stage deceleration electric drive axle includes an integrated housing 1, and the integrated housing 1 is provided with a motor 2, a three-stage parallel reduction gear set 3 and a differential 4 that are sequentially connected in transmission. The integrated housing 1 is integrally formed; it also includes an axle housing 5, an axle shaft 6 and a wheel 7. The axle housing 5 is connected to the vehicle frame and is located on both sides of the integrated housing 1. The axle shaft 6 is set Inside the axle housing 5 , one end of the axle shaft 6 is connected to the output end of the differential 4 and the other end is connected to the wheel 7 .

[0022] The working principle of this embodiment is as follows:

[0023] Power transmission path: the power is output by the motor 2, after the deceleration and torque increase of the three-stage parallel reduction gear set 3, the power is transmitted to the half shafts 6 on the left ...

Embodiment 2

[0025] Such as figure 1 As shown, an integrated three-stage deceleration electric drive axle includes an integrated housing 1, and the integrated housing 1 is provided with a motor 2, a three-stage parallel reduction gear set 3 and a differential 4 that are sequentially connected in transmission. The integrated housing 1 is an integral casting structure, that is, the integrated housing 1 integrates the motor housing 101, the reducer housing 102 and the differential housing 103; it also includes the axle housing 5, the axle shaft 6 and the wheels 7, and the axle housing 5. The axle shafts 6 and the wheels 7 are arranged in pairs on both sides of the differential 4. The integrated housing 1 is used as the middle part of the axle, and is respectively connected with the axle housing 5 on the left and the axle housing 5 on the right. The housing 5 is connected to the vehicle frame and located on both sides of the integrated housing 1, the axle shaft 6 is arranged inside the axle ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com