Waste gas and waste heat reusing system, engine and vehicle

An engine and exhaust gas technology, applied in the field of vehicles, can solve the problems of partial boiling, prolong the warm-up time, increase the loss of cooling liquid heat dissipation, etc., achieve high power and torque output, avoid uneven heating, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

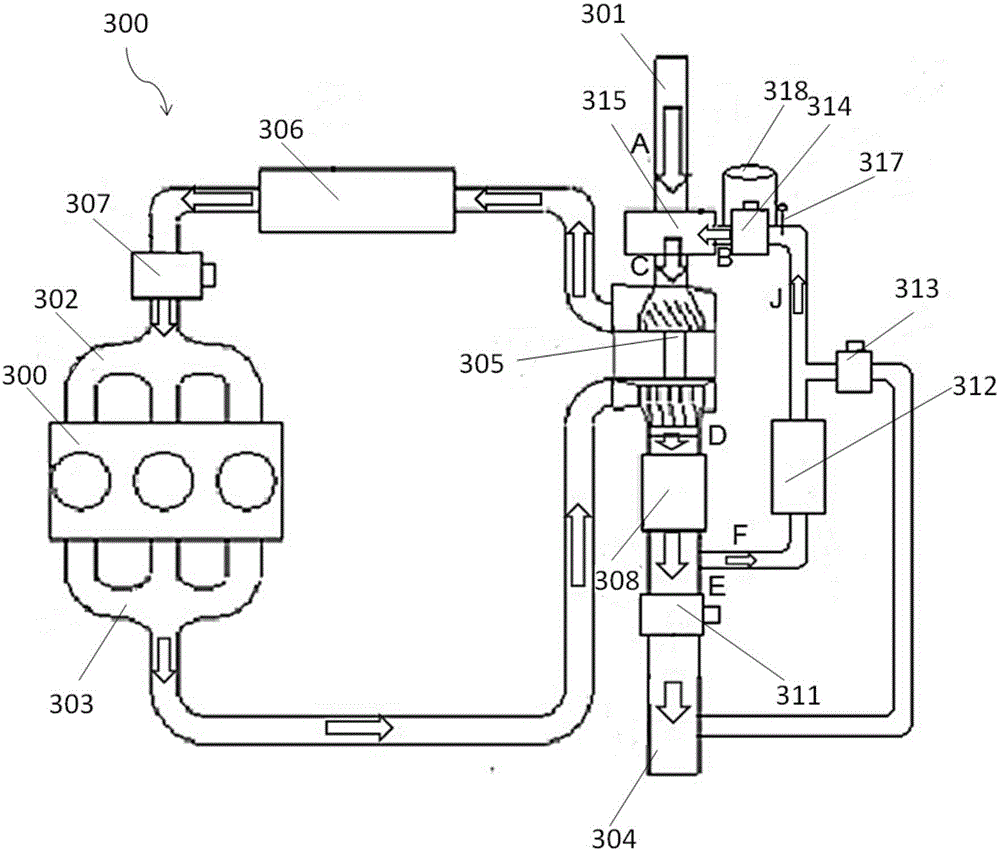

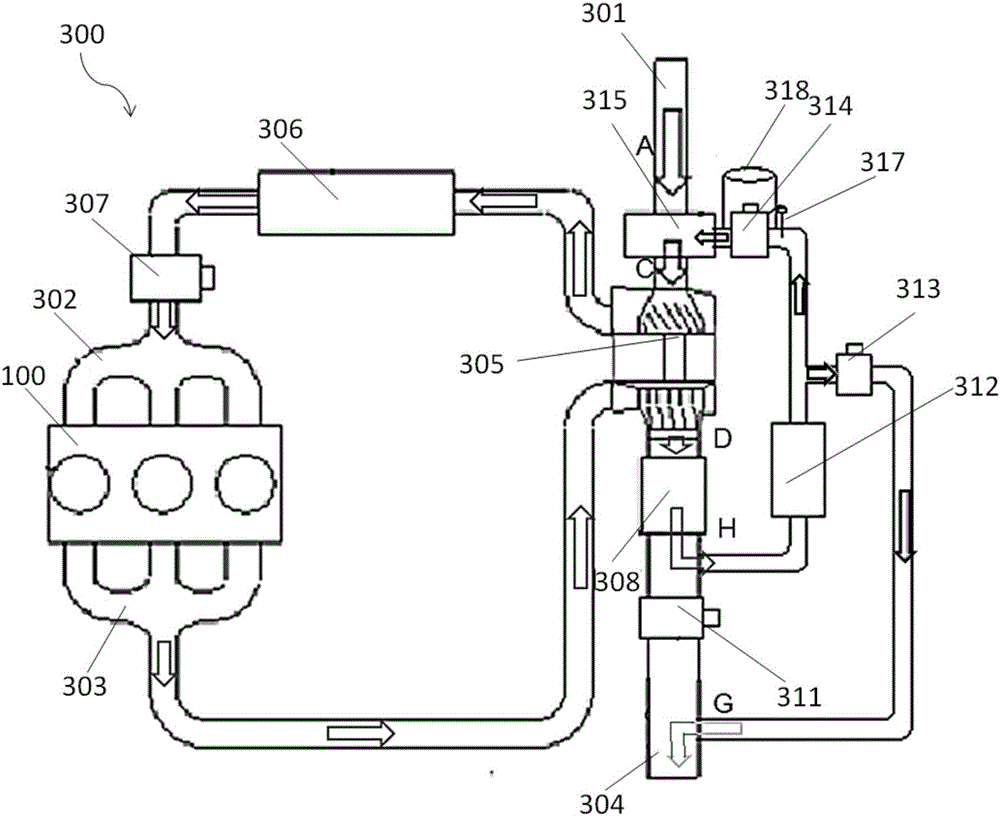

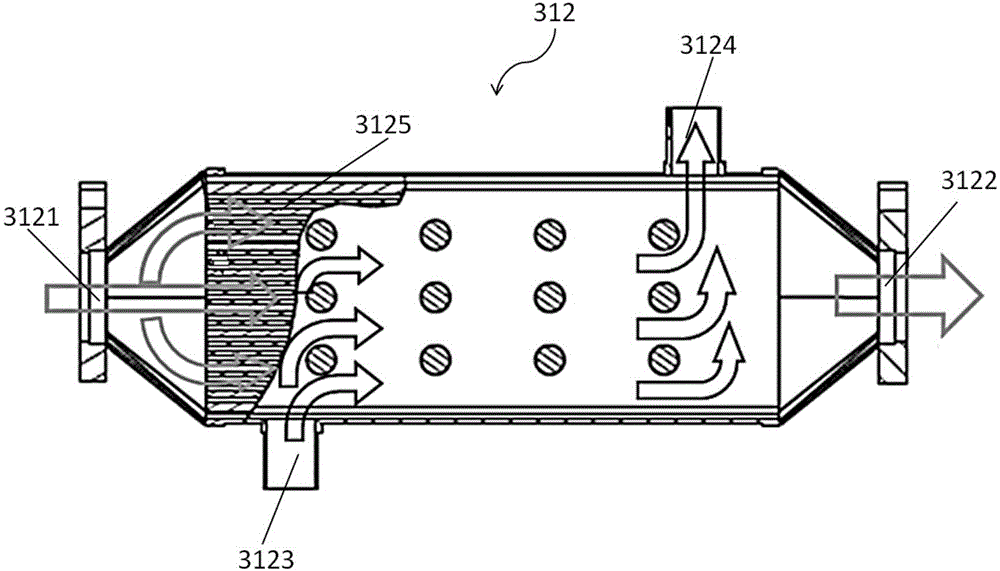

[0042] figure 1and figure 2 It is a structural schematic diagram of an exhaust gas and waste heat recycling system according to an embodiment of the present invention.

[0043] figure 1 or figure 2 The exhaust gas and waste heat recycling system is shown in . The exhaust gas and waste heat recycling system is applied to the vehicle 400 (such as Figure 5 As shown), the vehicle 400 includes an engine 100, an engine water circuit 200 and an engine gas circuit 300, and the exhaust gas and waste heat recycling system includes an EGR system 310 and a waste heat recovery system. The EGR system 310 is arranged at the engine air passage 300 , and is used for cooling the exhaust gas discharged from the engine 100 and then recirculating it back to the engine 100 for reuse, and at the same time using the exhaust gas for warming up the engine 100 . The waste heat recovery system is arranged at the engine waterway 200 , and is used to absorb waste heat through the EGR system 310 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com