Cycle internal combustion engine capable of implementing constant-volume combustion

A constant-volume combustion and internal combustion engine technology, applied to mechanical equipment, machines/engines, etc., can solve the problems of lower heat utilization efficiency, small torque arm of the crankshaft structure, and inability to output maximum torque, etc., to achieve improved cycle thermal efficiency and high torque output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

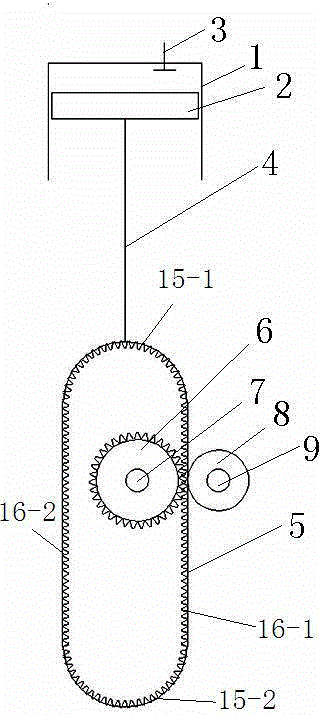

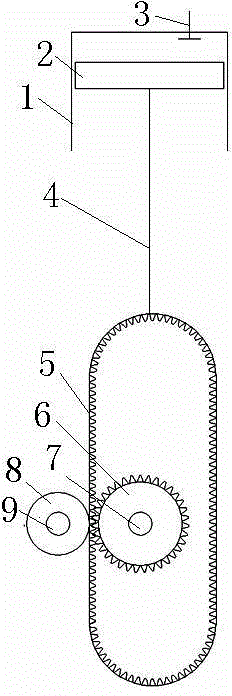

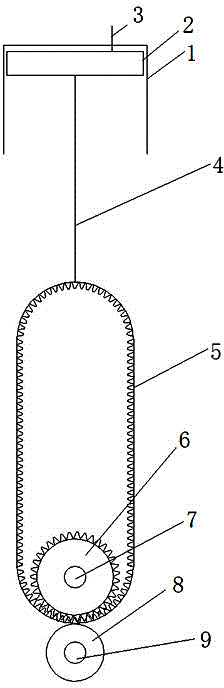

[0015] The constant volume combustion cycle internal combustion engine includes a cylinder, the piston of the cylinder is connected with a connecting rod, and the output end of the connecting rod is connected with a non-circular gear. The two arc-shaped tooth segments are provided with a planetary main gear that meshes with a non-circular gear. The center of the planetary main gear is fixed with a main shaft, and the main shaft is rotationally connected to the planetary wheel. The disc is provided with a guide shaft parallel to the main shaft. The centers of the main shaft, guide shaft and planetary wheel are on the same straight line. The guide shaft is provided with a guide wheel. The guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com