Patents

Literature

30results about How to "Reuse of waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

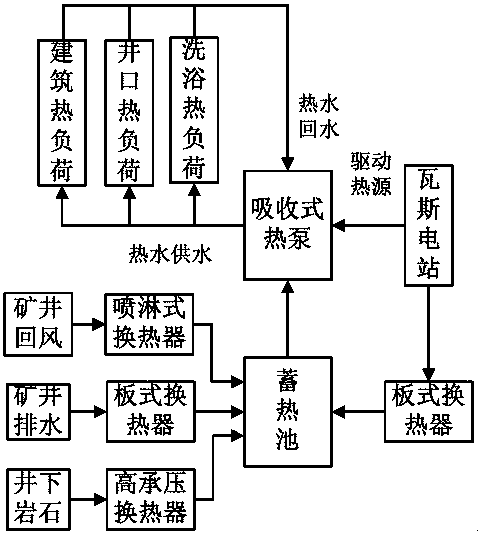

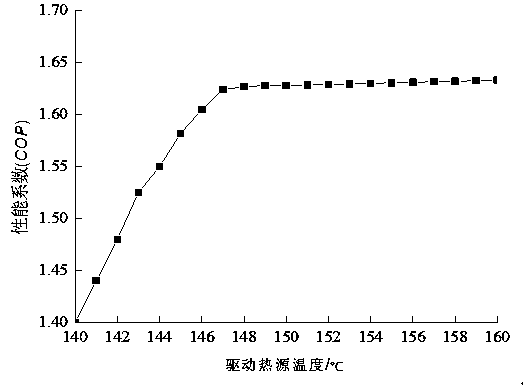

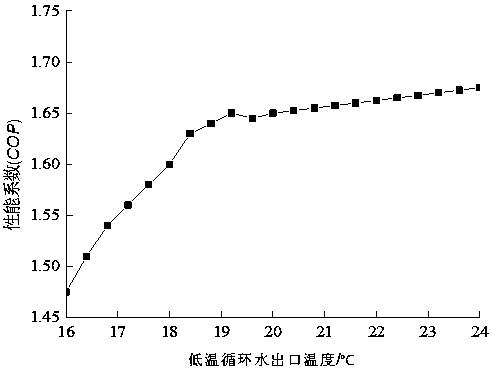

Multi-source coupling heat pump waste heat utilization system

InactiveCN108036547AReuse of waste heatImprove economyFluid heatersHeat pumpsCouplingAbsorption heat pump

The invention discloses a multi-source coupling heat pump wast heat utilization system. The system is characterized in that a large amount of waste heat can be generated in production of coal mine enterprises, and the system mainly comprises a waste heat resource in mine return air, a waste heat resource in mine drainage, a gas station generating set waste heat resource, underground coal mine rockheat storage and the like. System performance coefficient influence factors comprise driving heat source temperature, circulating water outlet temperature, hot water return temperature and hot watersupply temperature. Available waste heat sources of mining areas are obtained, the heat supply processes of different heat sources are achieved, the multi-source coupling heat pump waste heat utilization system is obtained, and the mining area waste heat reutilization is achieved. By means of various influence factors, optimal work parameters of the multi-source coupling heat pump waste heat utilization system are obtained, the driving heat source temperature is 148 DEG C, the circulating water outlet temperature is 19.5 DEG C, the heat water return temperature is 45.5 DEG C, and the hot watersupply temperature is 56 DEG C. By building the multi-source coupling heat pump waste heat utilization system, an effective way of improving the economical efficiency and saving fuel is provided, andtechnical reference is provided for building the multi-source coupling absorption type heat pump waste heat utilization system for the mining areas and other industry.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO ECONOMIC TECH RES INST +1

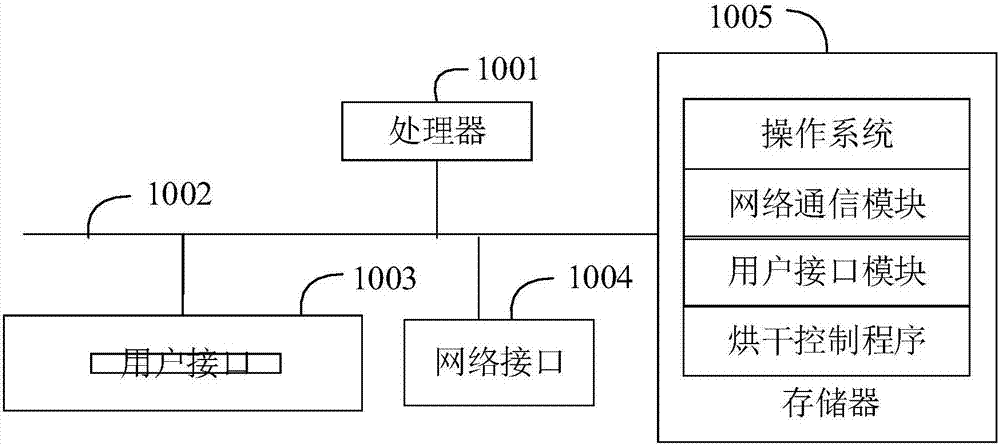

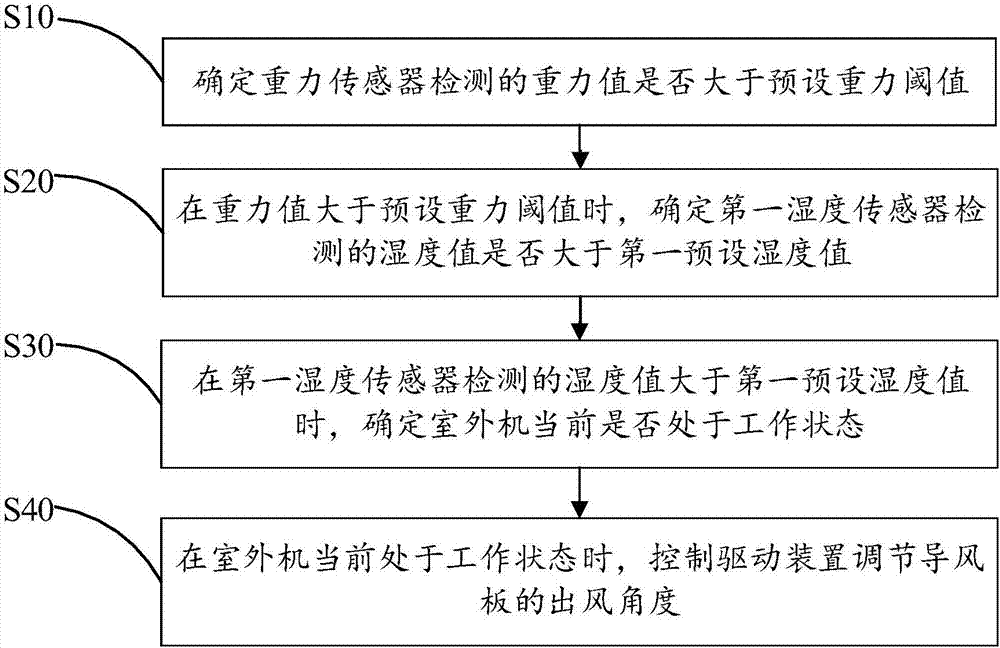

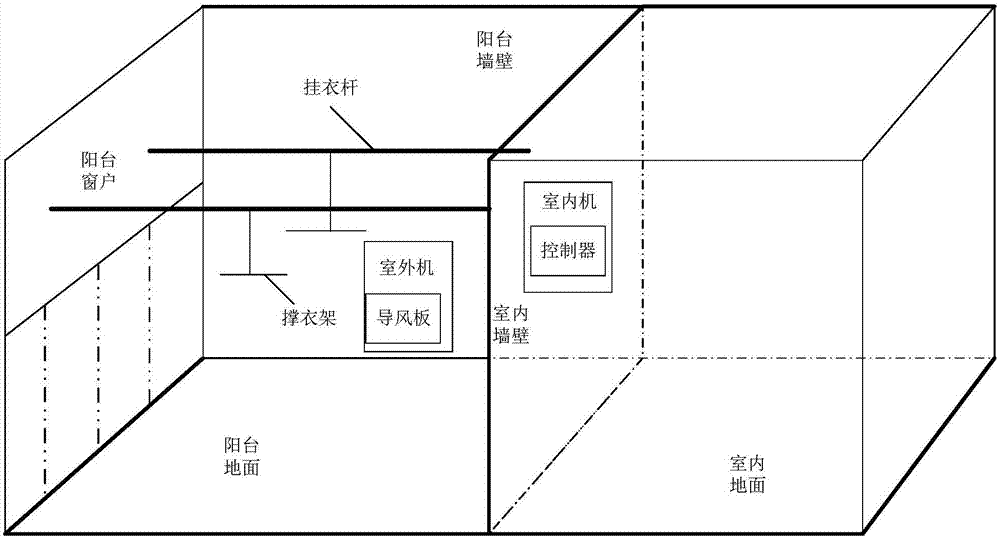

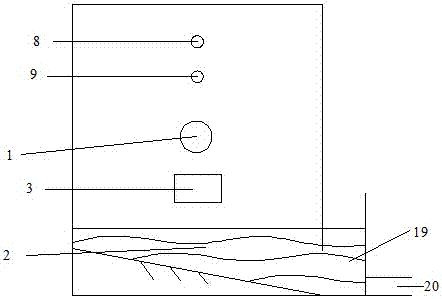

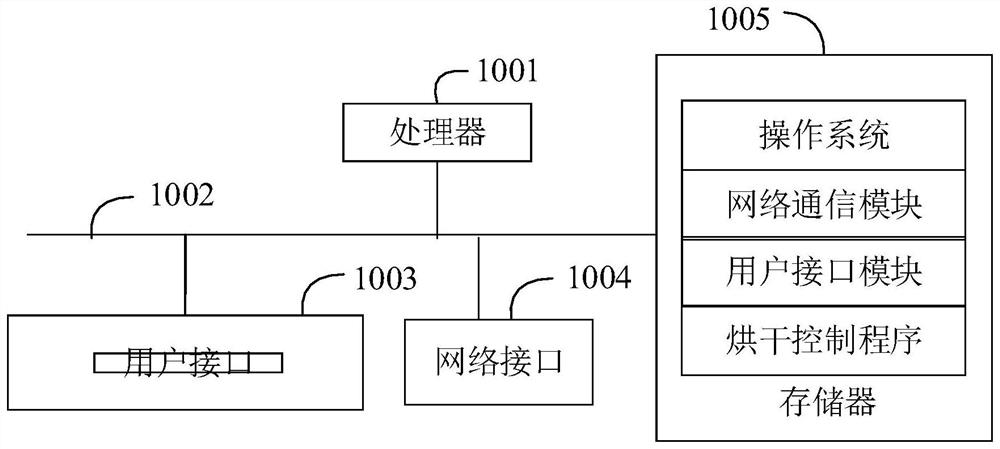

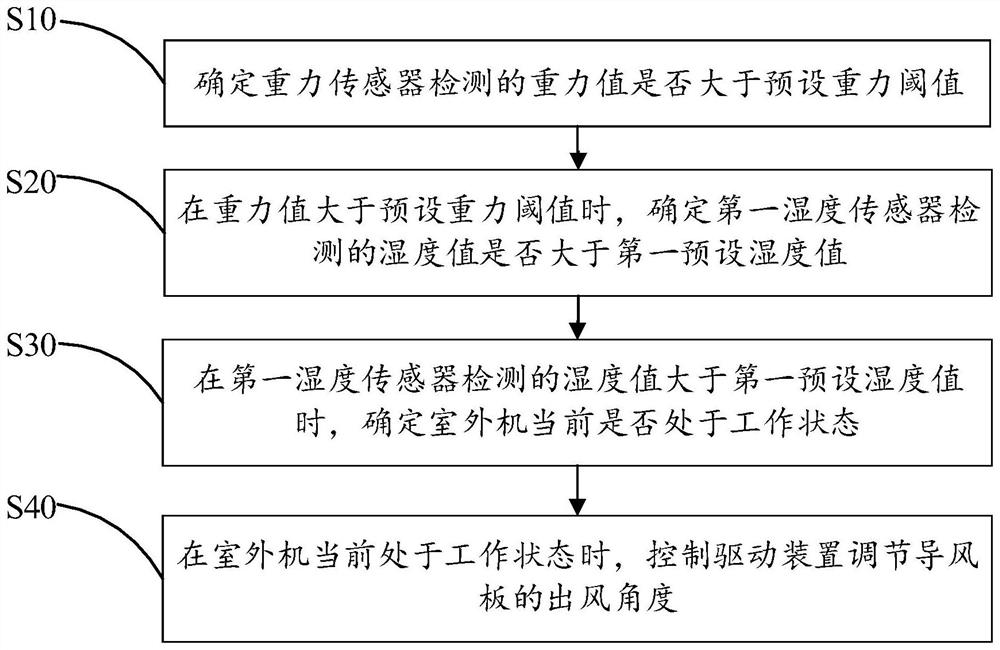

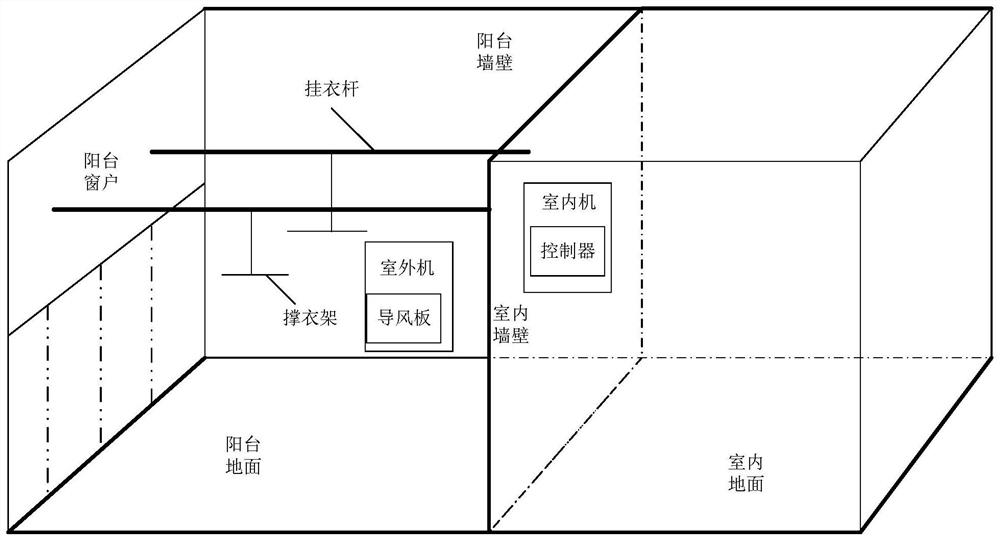

Drying control method and device and computer readable storage medium

ActiveCN107576013AEfficient drying operationSolve the problem of dripping water making the ground slipperyMechanical apparatusSpace heating and ventilation safety systemsEngineeringHumid climate

The invention discloses a drying control method. The drying control method comprises the following steps that whether the gravity value measured by a gravity sensor is greater than the preset gravitythreshold or not is determined; when the gravity value is greater than the preset gravity threshold, whether the humidity value measured by a first humidity sensor is greater than the first preset humidity value or not is determined; when the humidity value measured by a first humidity sensor is greater than the first preset humidity value, whether an outdoor machine is currently in a working state or not is determined; and when the outdoor machine is currently in the working state, the driving device is controlled to adjust the wind angle of a wind guiding plate. The invention further discloses a drying control device and a computer readable storage medium. By means of the drying control method, automatic feedback adjusting can be achieved according to the operating condition of the air-conditioner, clothing hanging, clothing and humidity of the ground, the problem that the clothing is difficultly dried in the humid climate area is solved, the problem of waste heat reuse of the air conditioner is also solved, and the use efficiency of the drying function of the outer machine is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

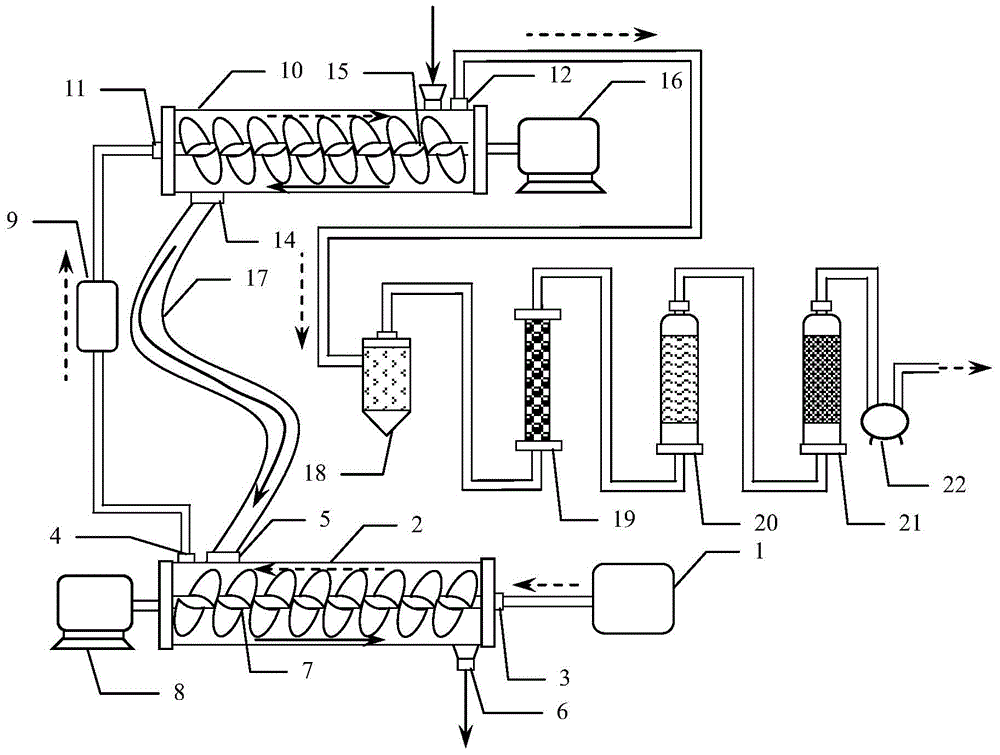

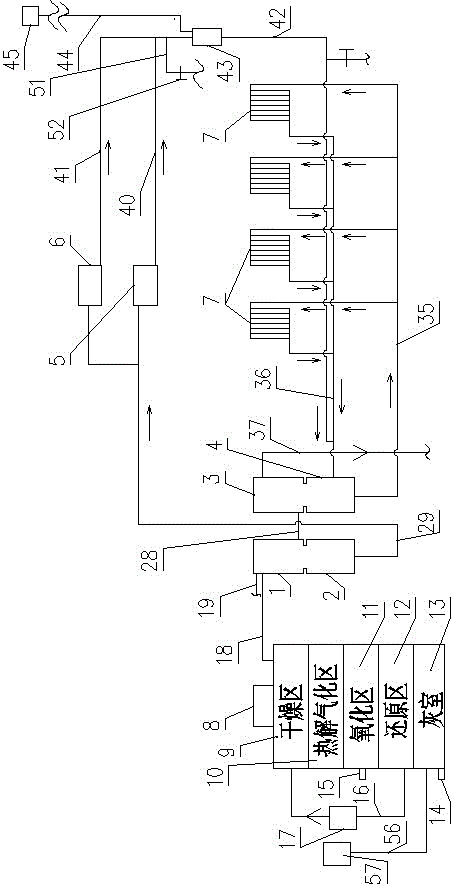

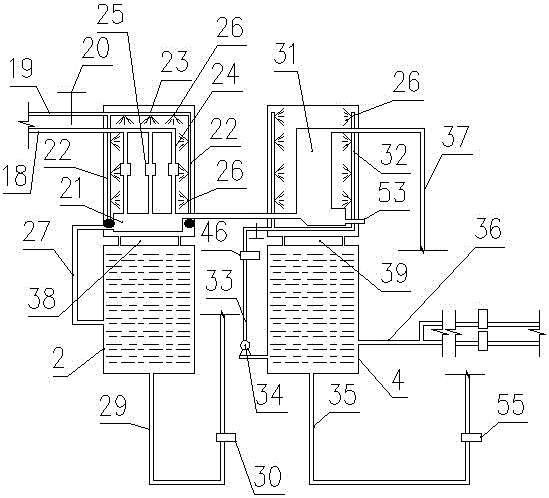

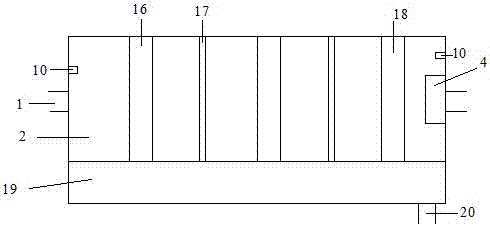

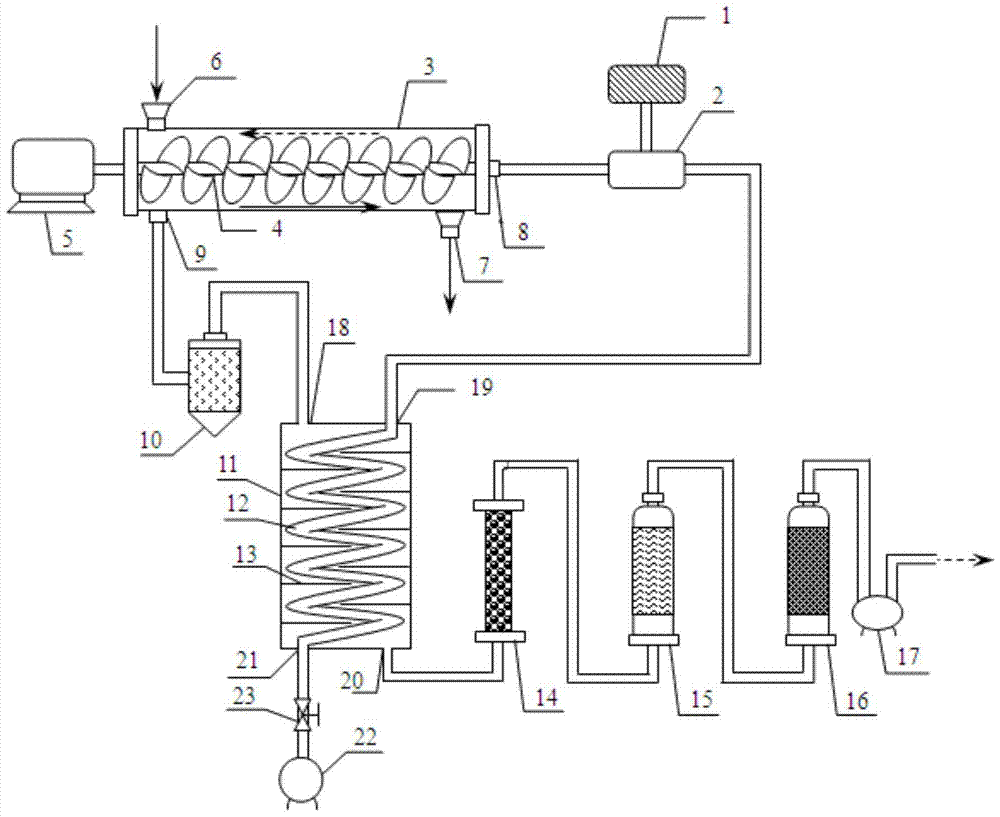

A multi-stage thermal desorption remediation system for organic polluted soil

ActiveCN104607455BImprove utilization efficiencyShorten repair timeContaminated soil reclamationCombustion chamberRetention time

The invention relates to a multi-stage thermal desorption remediation system for organic polluted soil, and belongs to the technical field of soil remediation. The system consists of a first-stage thermal desorption device, a second-stage thermal desorption device, a tail gas treatment device, a secondary combustion chamber and a falling type conveying belt. Soil is preheated and desorbed primarily by high-temperature tail gas generated by thermal desorption; a two-stage or multi-stage polluted soil treatment method is adopted, and the residual heat of the tail gas is utilized fully, so that the comprehensive utilization ratio of heat energy of the system is improved obviously; soil enters a thermal desorption cabin with relatively high temperature under the gravity effect by virtue of the S-shaped falling type conveying belt, so that the energy consumption of a conveying and transmitting device and the conveying process is prevented; meanwhile, the soil conveying path and the conveying time are prolonged, the retention time is prolonged, and thus soil pollutants are desorbed relatively fully. The thermal desorption soil remediation system is reasonable in structure, is simple to operate, is convenient to use, has no secondary pollution, recycles residual heat of tail gas, and has wide application prospect and high practical value.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

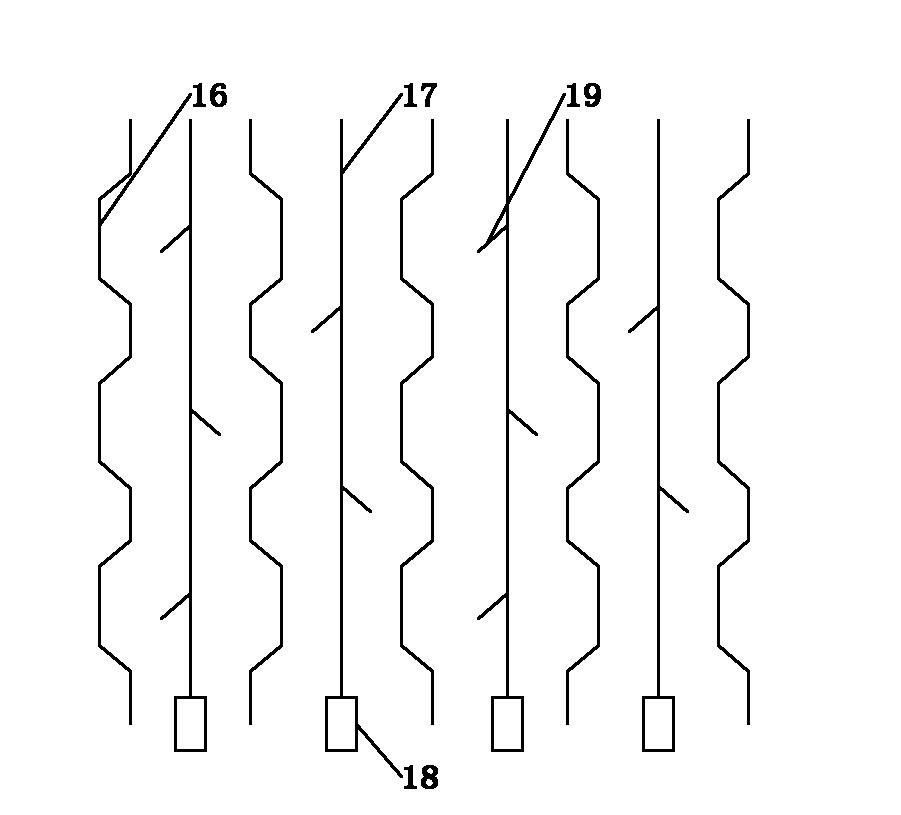

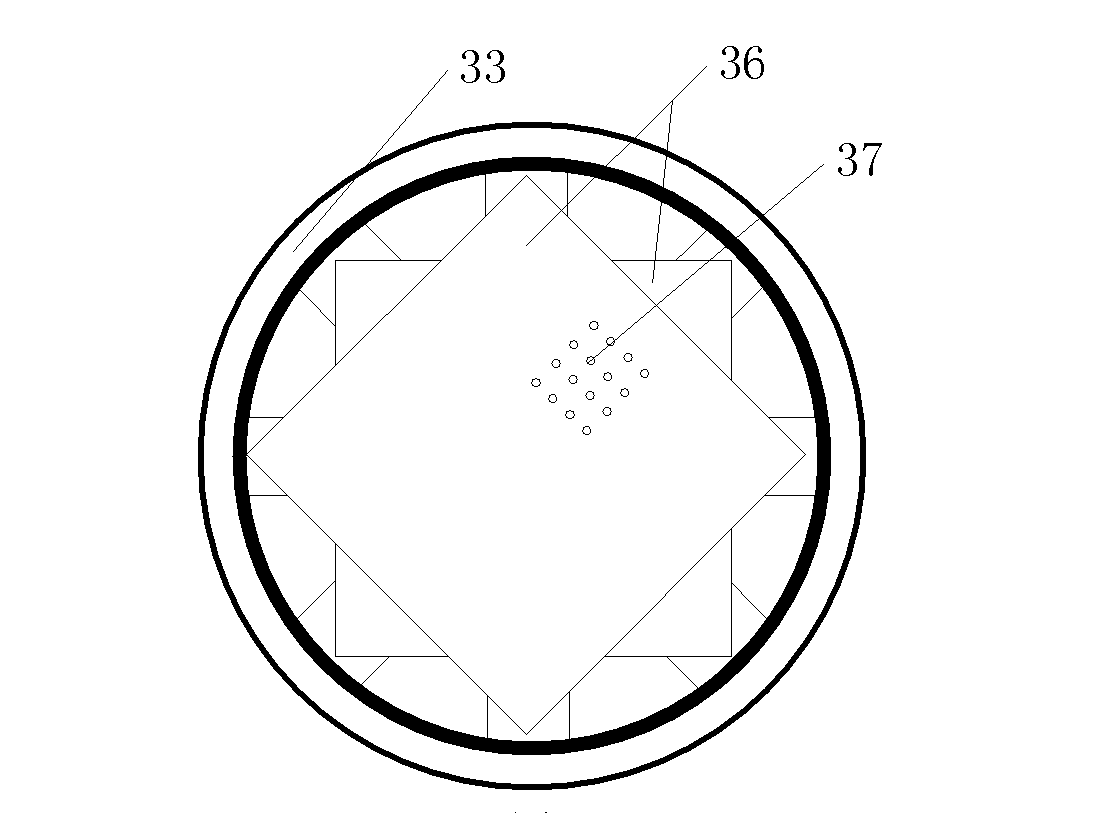

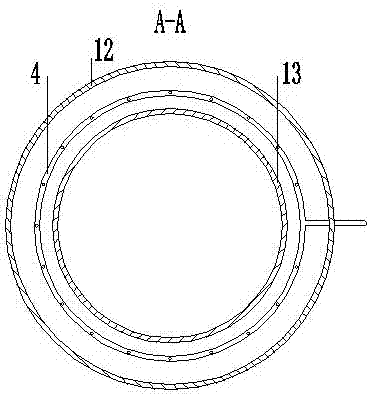

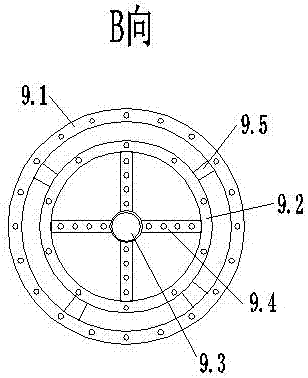

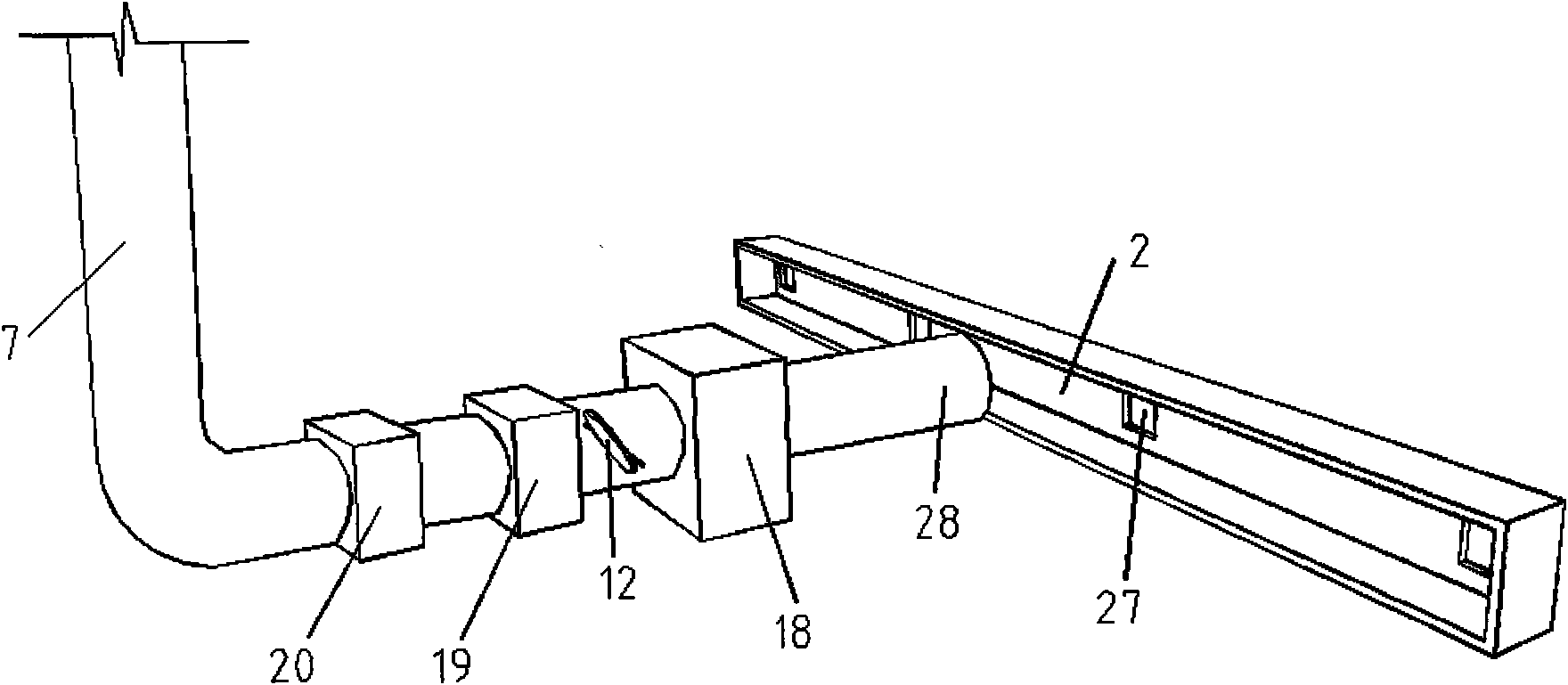

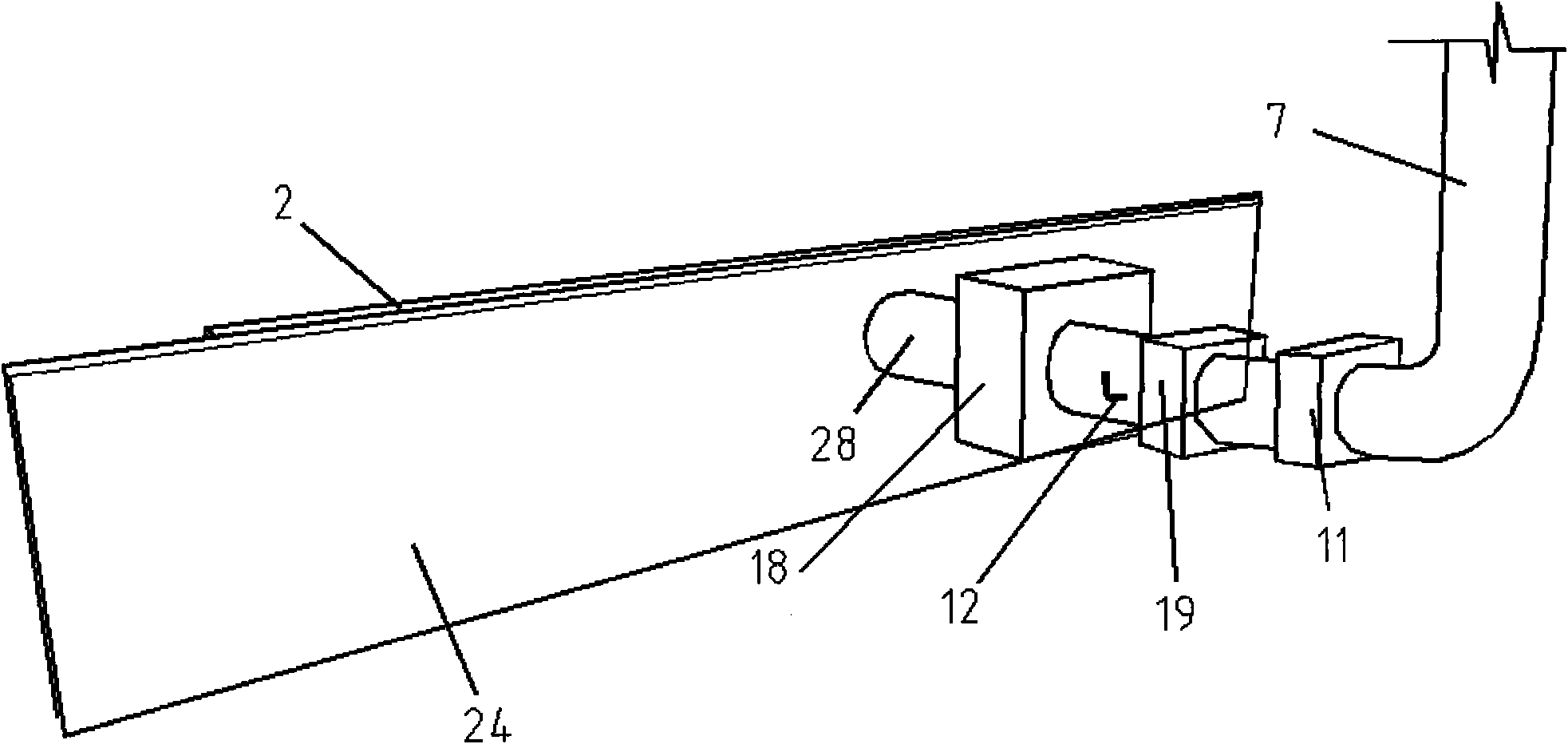

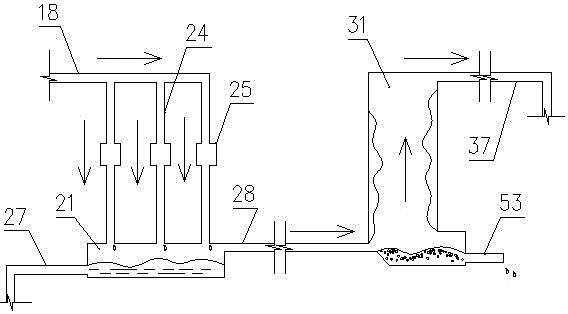

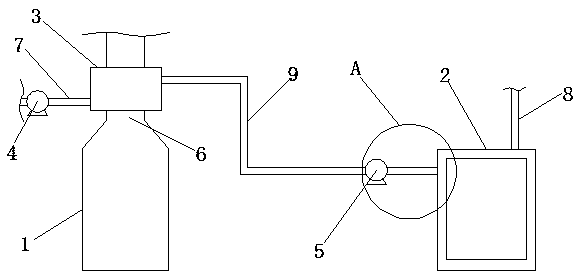

Technical device for recycling tail gas and residual heat during production of active carbon with phosphoric acid method

ActiveCN102527201AAchieve recyclingReuse of waste heatCarbon compoundsChemical industryElectricityPhosphoric acid

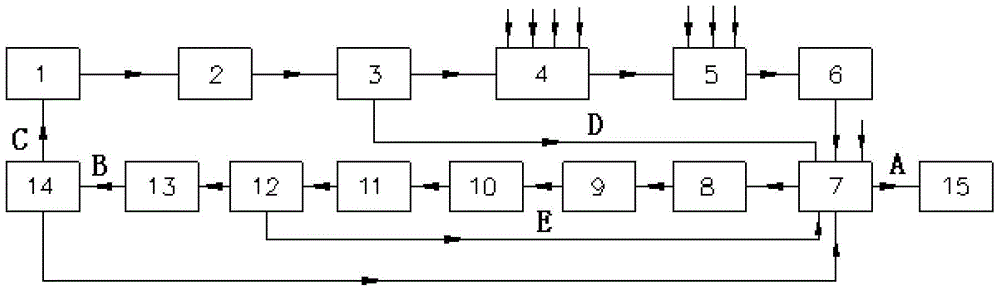

The invention provides a technical device for recycling tail gas and residual heat during production of active carbon with a phosphoric acid method. The technical device comprises a phosphoric acid tail gas collecting device, a phosphoric acid tail gas residual heat utilizing device and a concentrated residual phosphoric acid energy-saving device, wherein the phosphoric acid tail gas input end of the phosphoric acid tail gas collecting device is connected to a kiln phosphoric acid tail gas flue; the phosphoric acid tail gas output end of the phosphoric acid tail gas collecting device is connected to an emptying port; a diluted phosphoric acid collecting groove is connected to the diluted phosphoric acid input end of the phosphoric acid tail gas residual heat utilizing device; the output of the phosphoric acid tail gas residual heat utilizing device is connected to the input end of the concentrated residual phosphoric acid energy-saving device; and the output end of the concentrated residual phosphoric acid energy-saving device is connected to a concentrated phosphoric acid recovering pool. Phosphoric acid tail gas is treated through an electric demisting device with a honeycomb electrode structure, phosphoric acid tail gas residual heat is utilized by arranging more than two groups of heat exchange tubes in the flue, phosphoric acid is concentrated under a vacuum condition through a sieve through hole structure, and phosphoric acid recovery and residual heat reutilization of tail gas during production of active carbon with the phosphoric acid method are realized, so that energy consumption is lowered, and pollution is lowered.

Owner:福建省芝星炭业股份有限公司

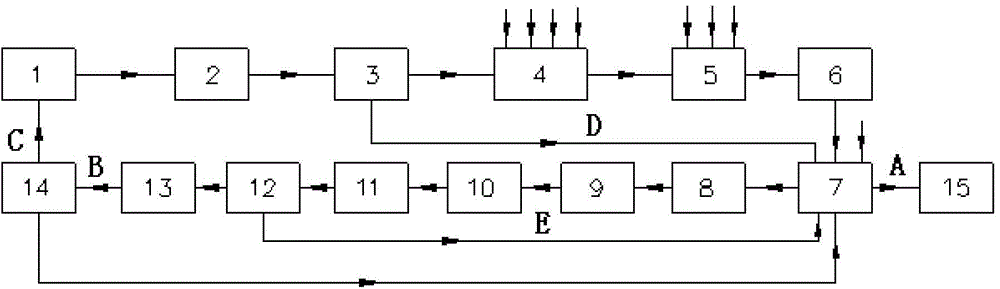

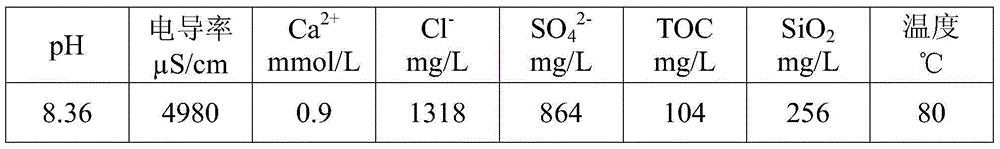

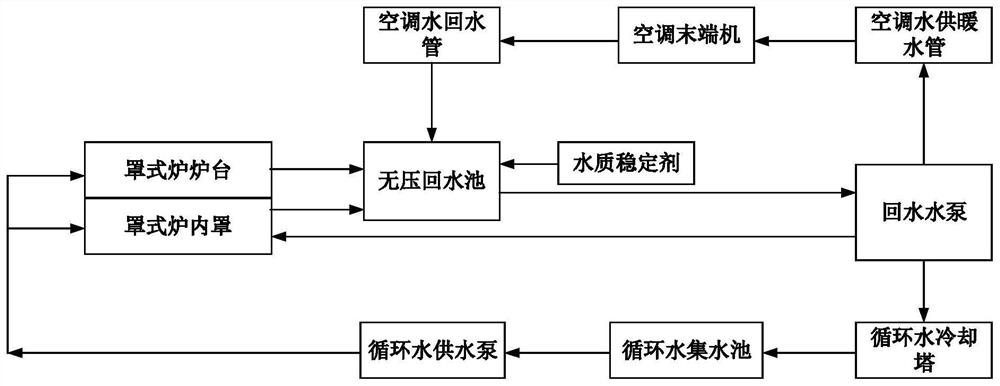

System and method of power station boiler for treating and recycling heavy oil wastewater

ActiveCN104671607AEfficient use ofReuse of waste heatTreatment using aerobic processesScale removal and water softeningEngineeringSuperheated steam

The invention discloses a system and method of a power station boiler for treating and recycling heavy oil wastewater. The system comprises a heavy oil thermal recovery well, a silicon removal reactor and a softening reactor which are connected with one another in sequence, wherein the softening reactor is connected with a liquid inlet of an evaporator, a condensed water outlet of the evaporator is sequentially connected with a biological aerated filter and a desalting device, and a water producing outlet of the desalting device is connected with a power station boiler and steam turbine system; a silicon removal medicament dosing opening is formed in the silicon removal reactor, a softening medicament dosing opening is formed in the softening reactor, and a steam exhaust outlet of a steam turbine in the power station boiler and steam turbine system is connected with a heat source inlet of the evaporator; and a superheated steam outlet of the power station boiler in the power station boiler and steam turbine system is connected to the heavy oil thermal recovery well. By adopting the system disclosed by the invention, co-production of water, heat and electricity can be achieved, the heat energy can be effectively used, and the cycle thermal efficiency can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

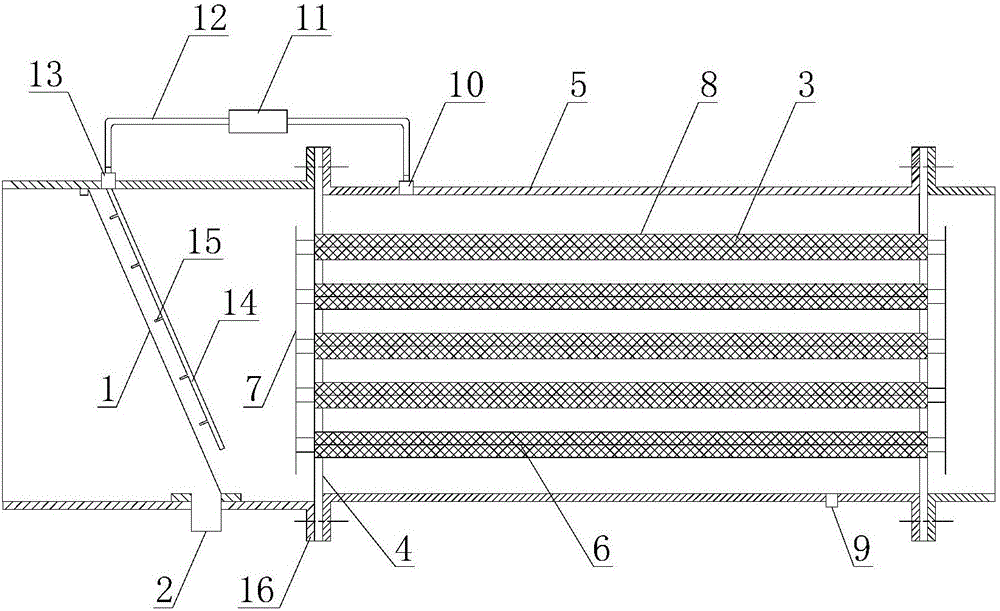

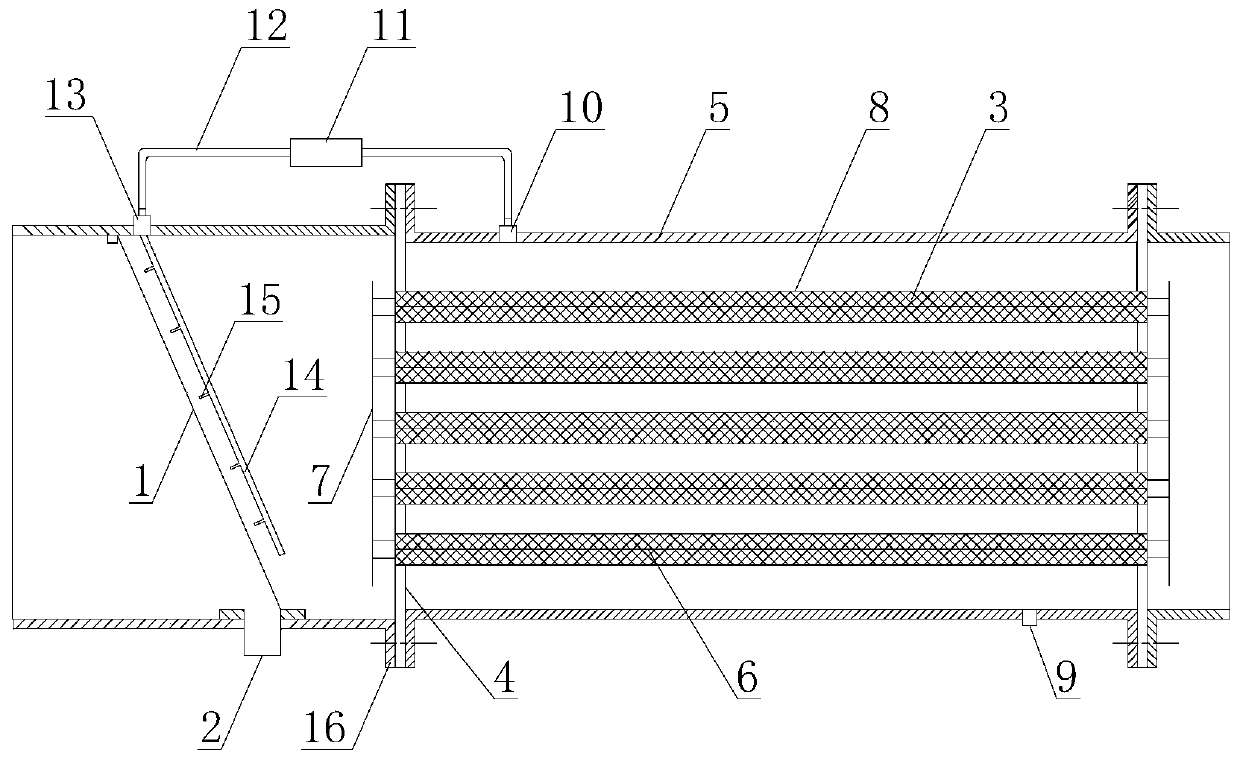

Low-temperature plasma technique-based kitchen fume purification device and system

InactiveCN106731545AIncrease in sizeSmall degradation efficiencyGas treatmentDispersed particle filtrationActivated carbonEngineering

The invention provides a low-temperature plasma technique-based kitchen fume purification device and system. The low-temperature plasma technique-based kitchen fume purification device comprises a fume pretreatment module, a low-temperature plasma catalytic module and a spray-washing module; the fume pretreatment module comprises a metal net slantly arranged on the front side of a reactor and an oil groove connected to the lower end of the metal net; the low-temperature plasma catalytic module comprises a plurality of discharge tubes connected in parallel, two ends of the discharge tubes are fixed on a shell of the reactor through perforated plates, a high-voltage electrode is arranged in the axis, two ends of the high-voltage electrode are connected with high-voltage electrode plates, the outer side of the discharge tubes is wrapped by grounding electrodes, a catalyst is arranged in the middle position in the discharge tubes, and activated carbon is arranged on the tail part; the spray-washing module heats a cooling medium by using heat generated in the low-temperature plasma reaction process, and further the cooling medium which meets a set temperature requirement is used for purging the metal net. The synergistic effect of the plasma and the catalyst and reuse of afterheat are realized, a relatively good treatment effect is achieved, and economic operation is ensured.

Owner:CHONGQING UNIV

Equipment for treating VOCs (volatile organic chemicals) exhaust gases and use method of equipment

ActiveCN107131508AThorough treatmentReduce energy consumptionGas treatmentDispersed particle separationHigh concentrationCombustion chamber

The invention relates to equipment for treating VOCs (volatile organic chemicals) exhaust gases. The equipment comprises an inner barrel and an outer barrel which are vertically and fixedly arranged, an interlining cavity between the inner barrel and the outer barrel is communicated with a low-concentration exhaust pipe, the inner cavity of the inner barrel is connected with a high-concentration exhaust pipe, a primary combustion chamber communicated with the high-concentration exhaust pipe and a secondary combustion chamber located above the primary combustion chamber and communicated with the primary combustion chamber are further fixed in the inner barrel, a primary combustor and a secondary combustor are arranged in each of the primary combustion chamber and the secondary combustion chamber, a preheating cavity is arranged on the outside of the primary combustion chamber in a surrounding manner, the preheating cavity is communicated with the interlining cavity through a pipe provided with a pressure pump, the water outlet of the pipe is connected with atomizers arranged downwards, and the atomizers are located at the position above the joint of the low-concentration exhaust pipe and the outer barrel. The multi-stage multi-point atomization technology is utilized, liquid absorbing the exhaust gases is fully atomized, contact area and contact time of the exhaust gases and the absorbing liquid are increased, and absorption efficiency is improved.

Owner:山东泽轩环保科技有限公司

Combustion pool smoke discharging heat recovery and purification system

InactiveCN102183036ASolve the problem of waste heat utilizationSolve the purificationWater heatersChimneysDesorptionEngineering

The invention relates to a combustion pool smoke discharging heat recovery and purification system, belonging to the technical field of recycle of resources and building energy conservation. The system is characterized by mainly consisting of a horizontal flue, flue ports, a vertical chimney, a smoke control valve, a smoke residual heat recovery device, a smoke dust collection device and a smoke purification device; the horizontal flue is provided with a plurality of the flue ports to collect smoke; and the smoke is sequentially subjected to smoke residual heat recycle, smoke particle desorption, and removal of harmful gases such as sulfur oxide, nitrogen oxide in the smoke through the smoke residual heat recovery device, the smoke dust collection device and the smoke purification device, and finally the smoke is discharged through the vertical chimney. The system provided by the invention has the beneficial effects of smoke purification, low carbon discharging, efficient heating, outdoor environmental improvement and the like, can be used in dwelling houses in villages and small towns and industrial factory buildings without central heating, and has very important promotional value and obvious environmental and economic benefits.

Owner:DALIAN UNIV OF TECH

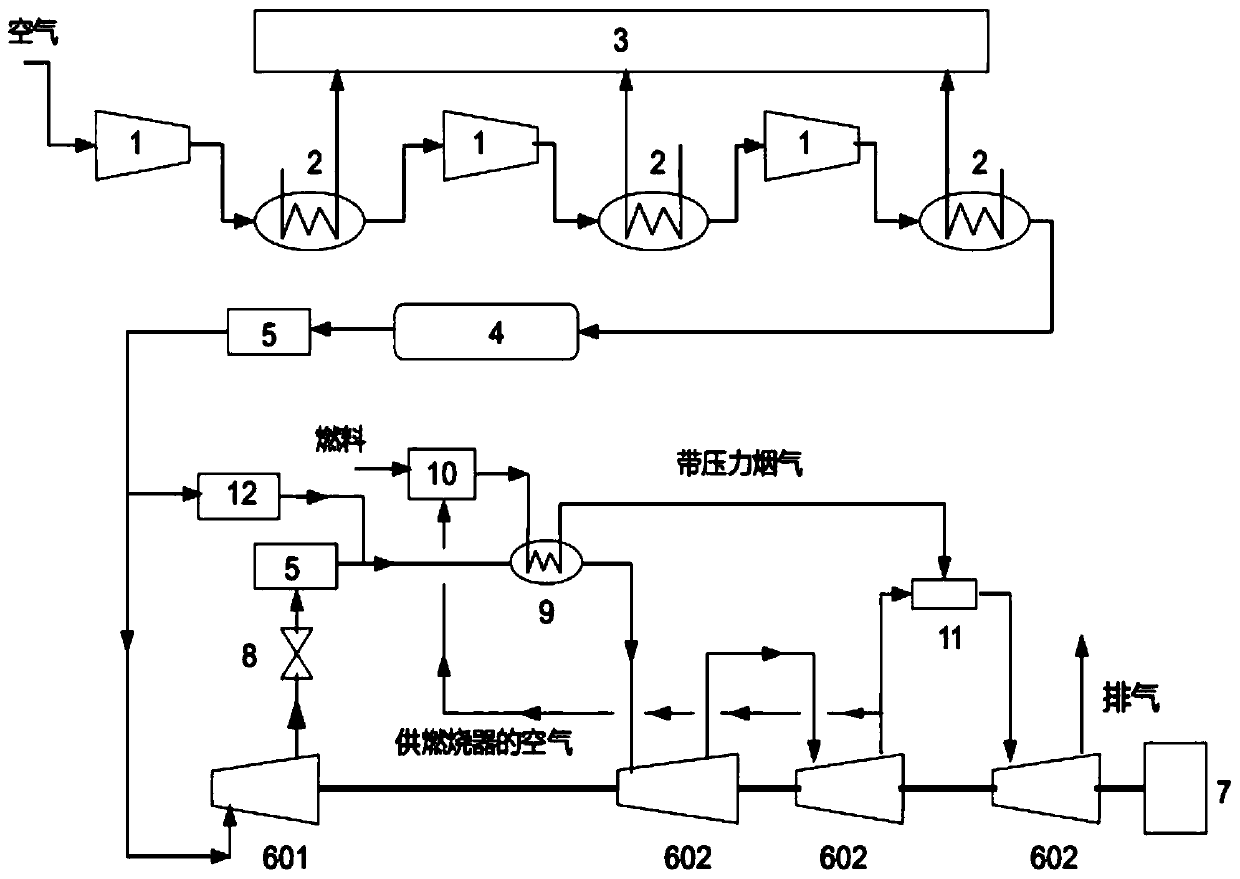

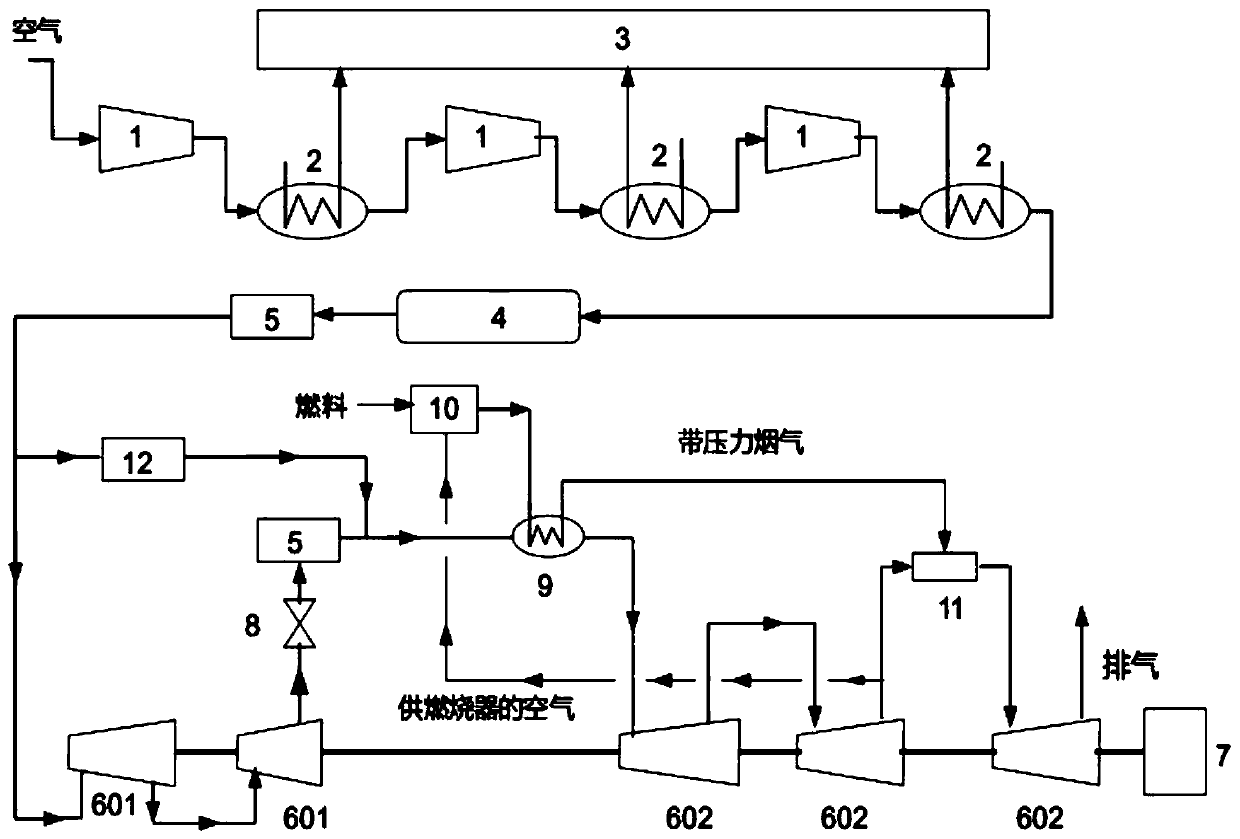

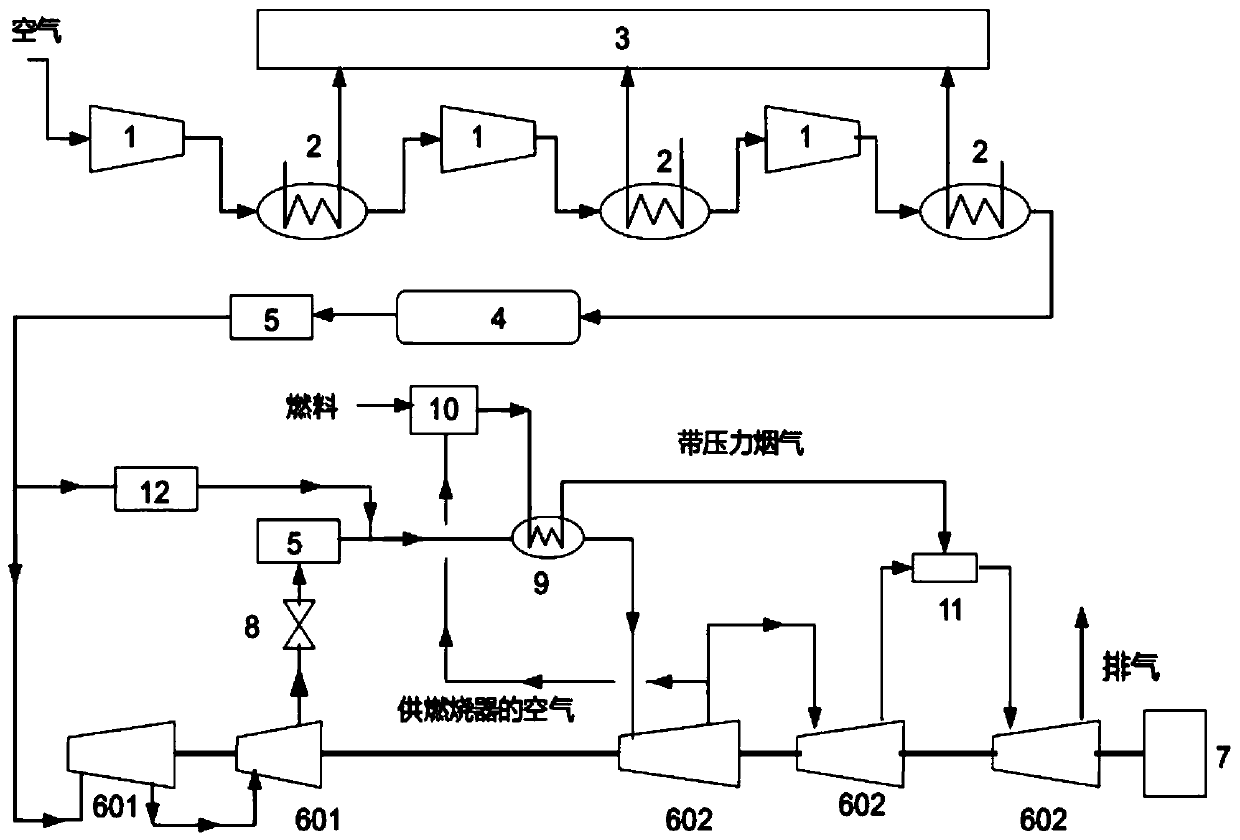

Novel compressed air energy storage system

InactiveCN109826778ASimple and scientific designCompact and reasonable structurePositive displacement pump componentsSteam engine plantsThermal energy storageUnit system

The invention discloses a novel compressed air energy storage system comprising an electric energy storage system and an electric energy release system. The electric energy storage system comprises aplurality of air compression units, a plurality of heat exchangers I, a heat storage tank and an air storage space, and the electric energy release system comprises a first expansion unit system, a second expansion unit system and a burner system; and the first expansion unit system comprises a plurality of first expansion units and a back pressure valve, and the second expansion unit system comprises a plurality of second expansion units, a plurality of heat exchangers II, an energy storage system waste heat recycling heat exchanger, a pressure reducing valve, a gas mixing device and a generator. According to the novel compressed air energy storage system, the first expansion unit system is provided with the back pressure valve so that the first expansion unit system has the ability of sliding pressure operation; an external burner is provided for proper afterburning through the second expansion units by using pressurized exhaust as supply air, and the performance ability of compressed air flow is improved; the gas mixing device is provided, so that reutilization of waste pressure and waste heat of burner flue gas is achieved; and the system efficiency is improved greatly.

Owner:郭祚刚 +1

Waste water collection and recycling device for industrial metallurgy

InactiveCN108911230AWell mixedImprove coagulation and sedimentation efficiencyUsing liquid separation agentTreatment involving filtrationWastewaterWater resources

The invention belongs to the technical field of industrial metallurgy, and in particular, relates to a waste water collection and recycling device for industrial metallurgy. In view of the problems ofsimple design structure, insufficient energy saving and environmental protection, and low coagulation and sedimentation efficiency, provided is the waste water collection and recycling device including a sedimentation tank; a waste water pipe is inserted at one end of the outer wall of the top of the sedimentation tank; a cooling water pipe sleeves one end, away from the sedimentation tank, of the circumferential outer wall of the waste water pipe; a clamping cavity is arranged between the circumferential inner wall and the circumferential outer wall of the cooling water pipe, and both ends of the circumferential outer wall of the clamping cavity are each connected with a water pipe in an inserted manner; the middle position of the outer wall of the top of the sedimentation tank is connected with a first connecting pipe in an inserted manner, and one end, away from the sedimentation tank, of the first connecting pipe is connected with a smoke exhaust pipe by a fastening bolt. Waste water and a coagulant in the sedimentation tank are fully mixed, the coagulation sedimentation efficiency is improved, the mixture is conveyed to a water outlet pipe and a main water pipe for recyclingutilization through a water pump and a circulating water pipe, water resources is are saved, waste heat of the waste water is reused, and energy saving and environmental protection are realized.

Owner:王菲

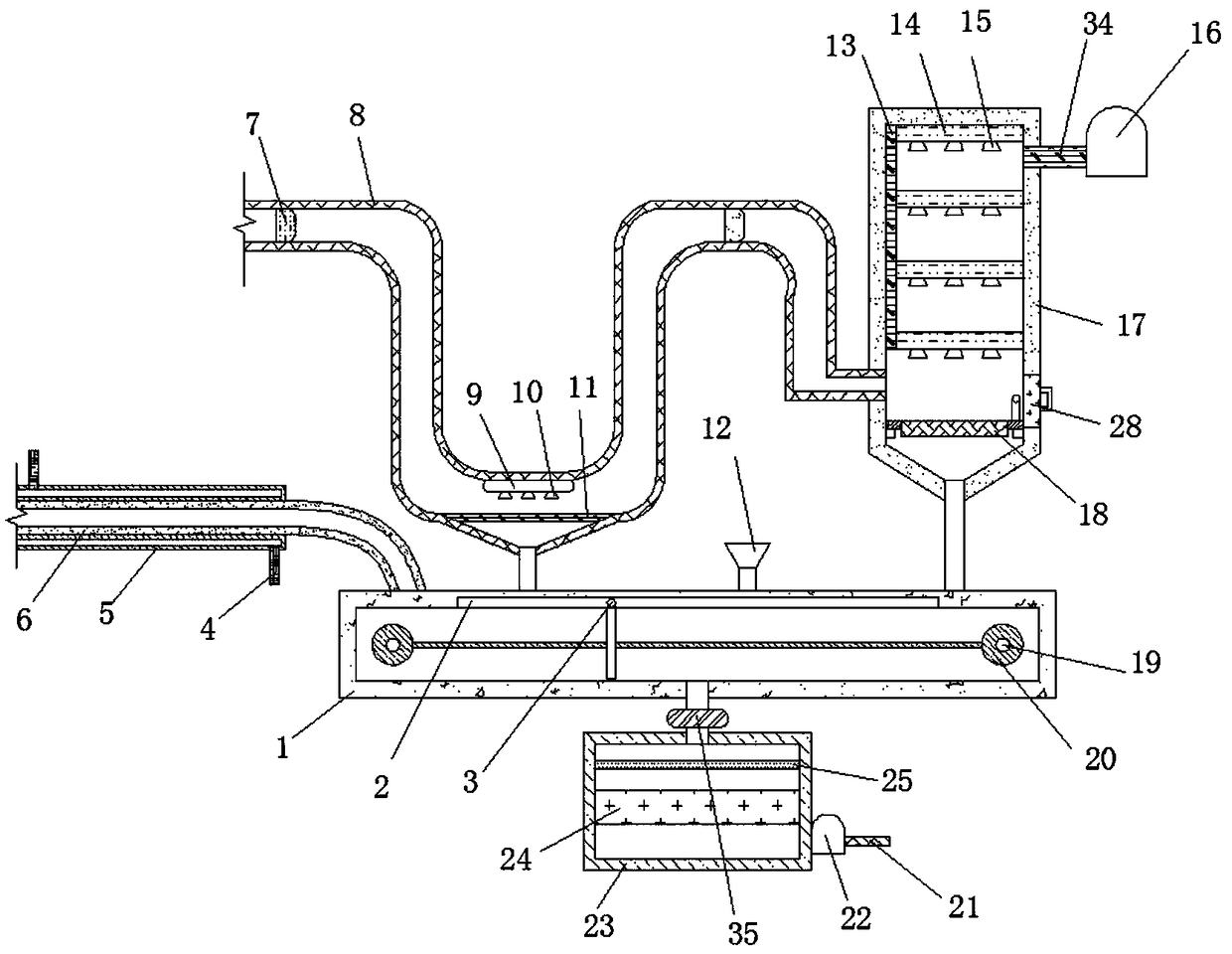

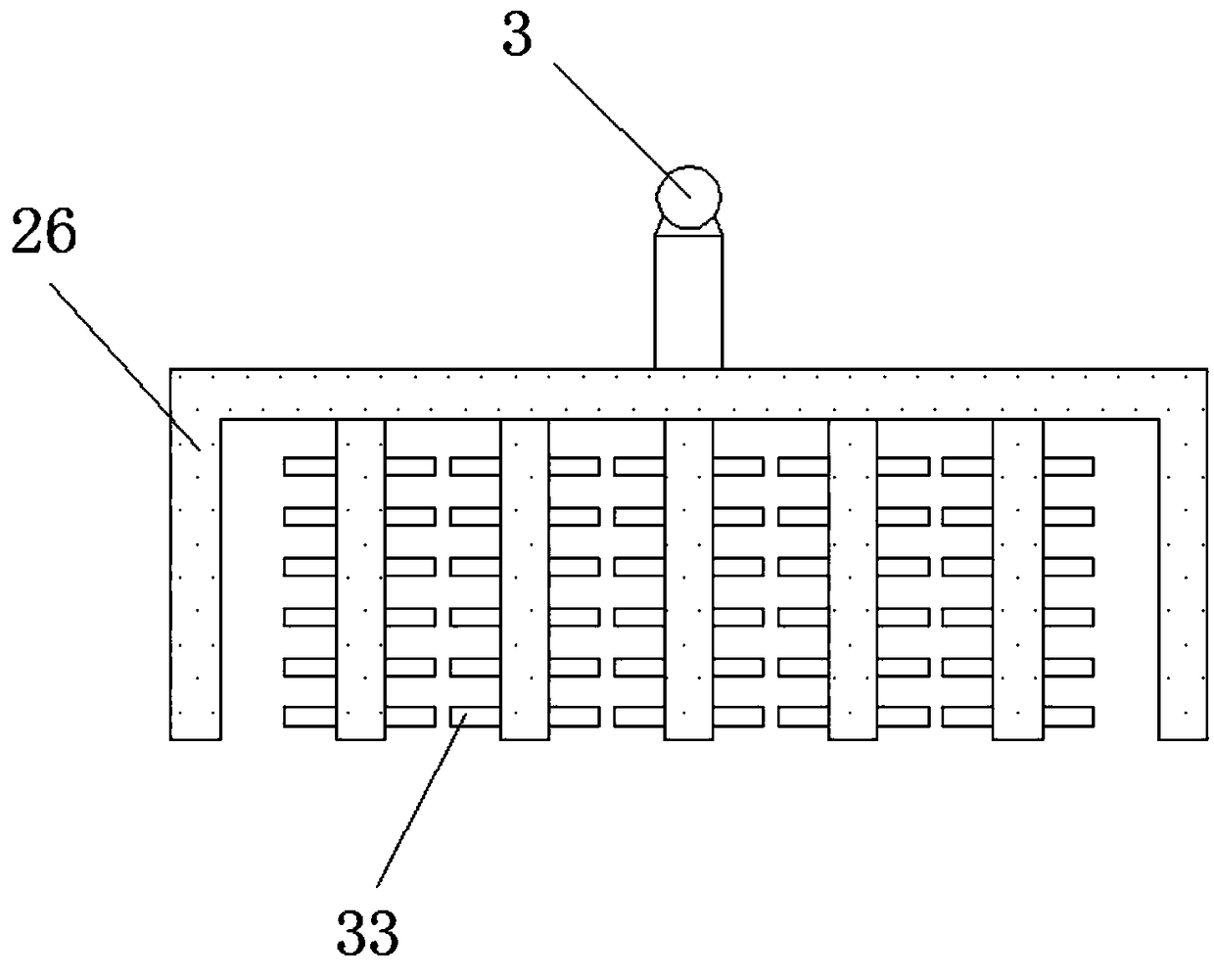

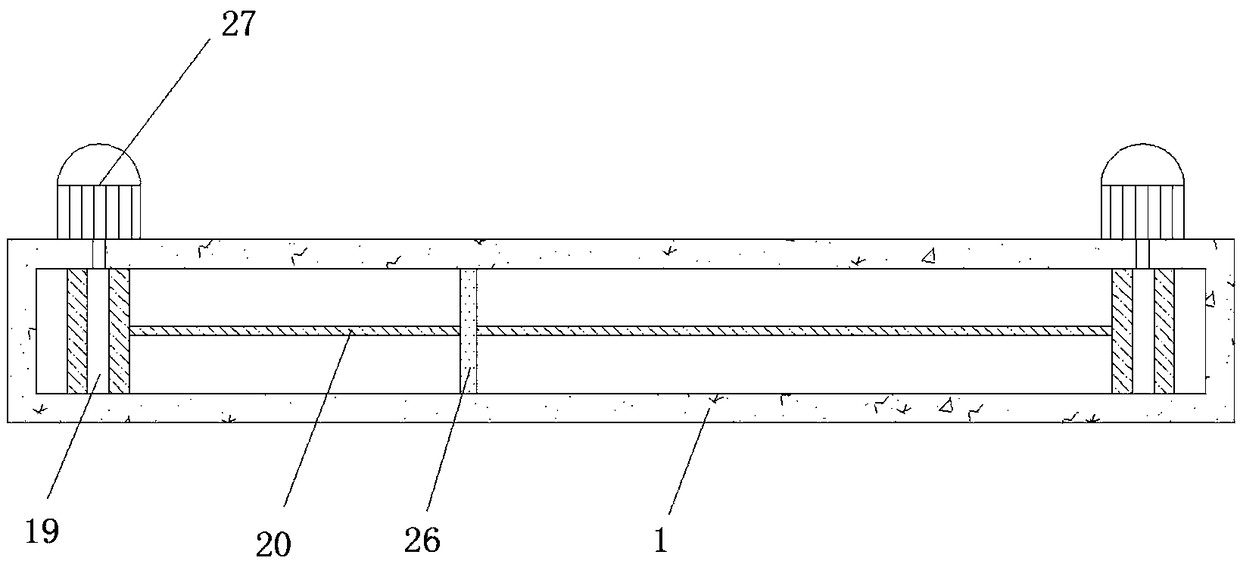

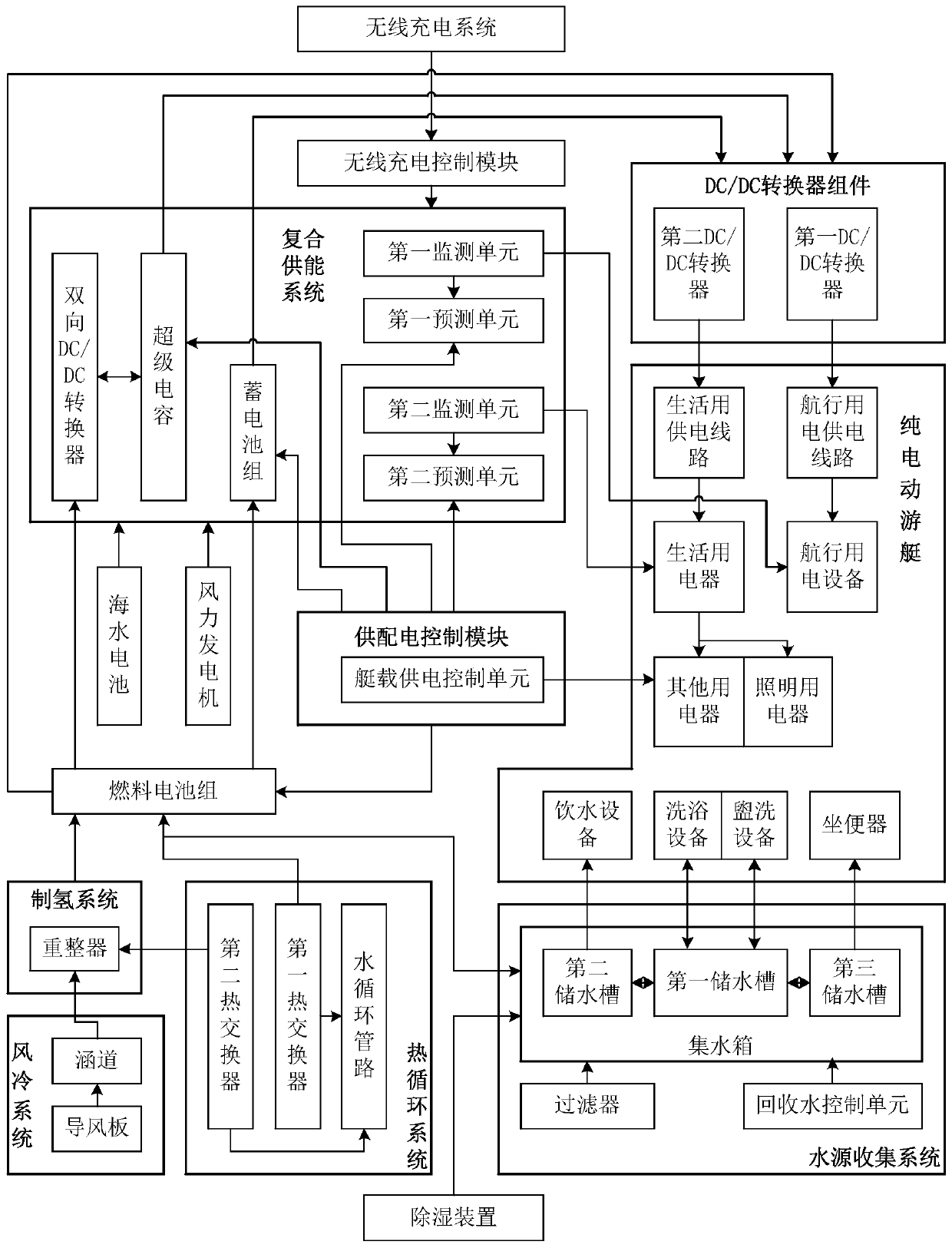

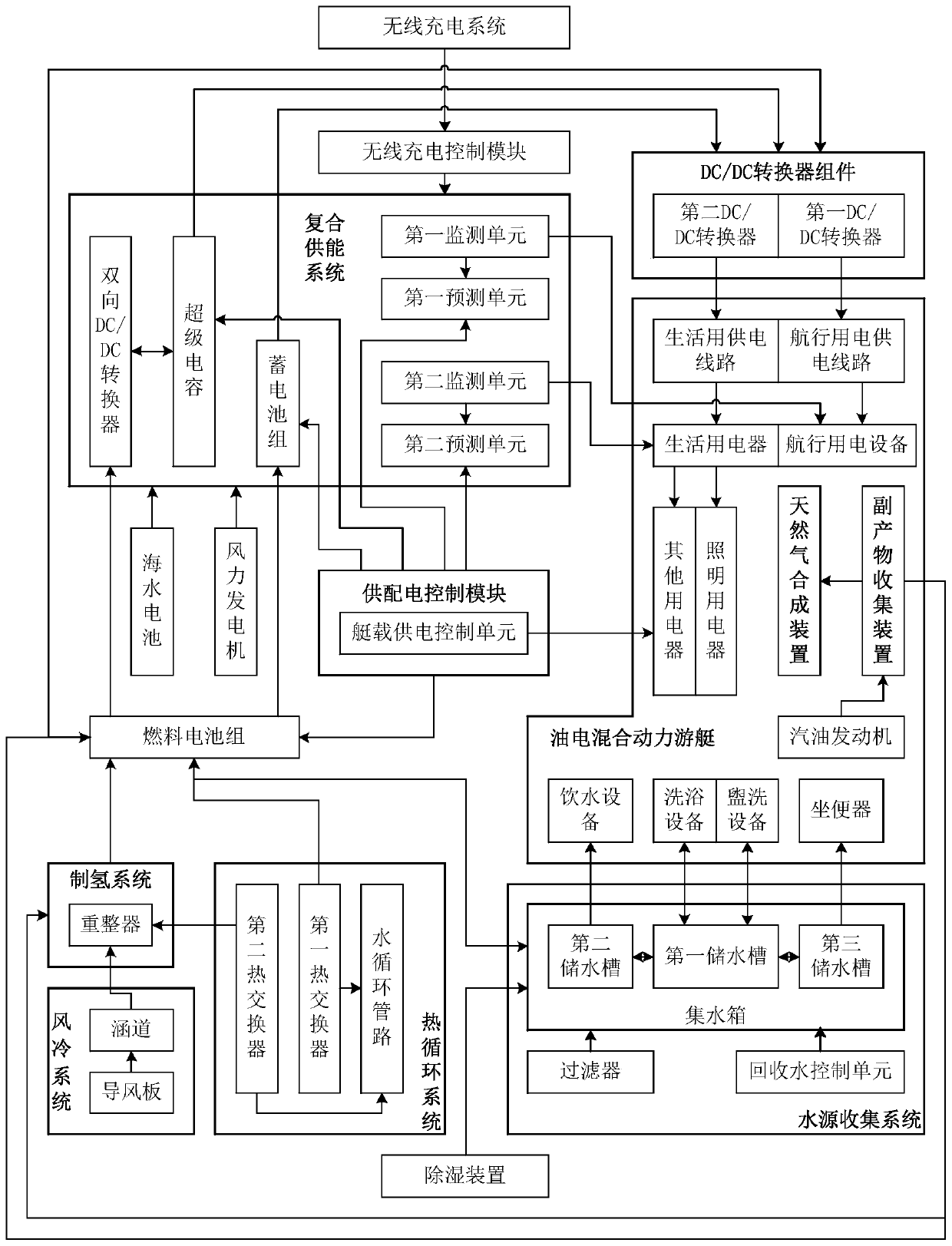

A yacht powered by water hydrogen power generation

ActiveCN109878674AImprove battery lifeImprove power generation efficiencyPropulsion based emission reductionAuxillariesCapacitanceSupply energy

The invention provides a yacht powered by water hydrogen power generation. The yacht includes a fuel cell stack, a composite energy supply system and a power supply and distribution control module; the fuel cell pack is used for generating electric energy by utilizing hydrogen and supplying power to a yacht load; the composite energy supply system comprises a storage battery pack and a super capacitor; the storage battery pack and the super capacitor are used for respectively providing a low-frequency component and a high-frequency component which are higher than the power supply capacity whenthe power supply capacity of the fuel cell pack cannot meet the yacht load, and are further used for storing extra electric energy in a controlled mode when the power supply capacity of the fuel cellpack meets the yacht load; the power supply and distribution control module is used for controlling the composite energy supply system to supply power to the yacht load and controlling the compositeenergy supply system to receive the extra electric energy. According to the yacht, the power is provided for the yacht through the water hydrogen power generation technology, more energy is saved, more environment protection effect is achieved, impact generated by load power fluctuation is buffered through the composite energy supply system, and the situation that the service life of the fuel cellpack is shortened due to load power fluctuation is avoided.

Owner:德州新动能铁塔发电有限公司

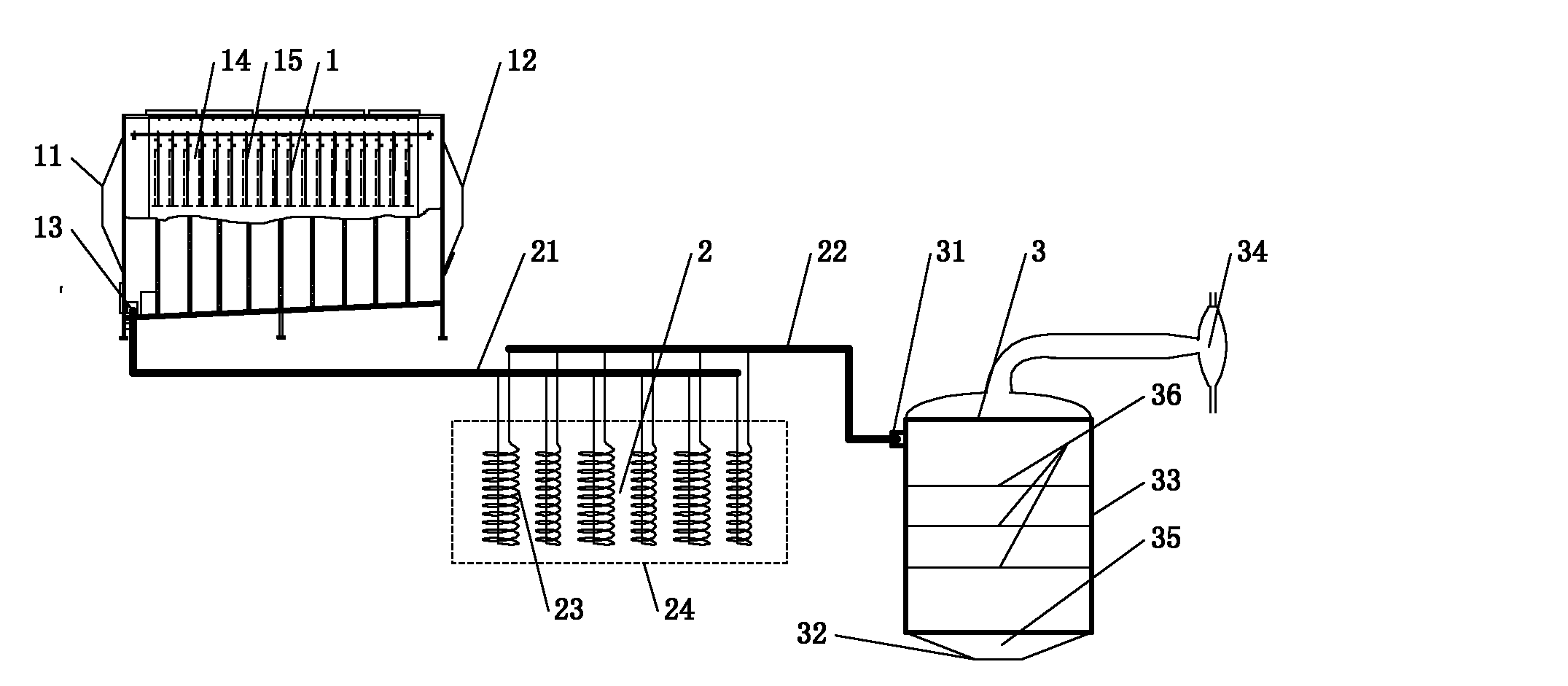

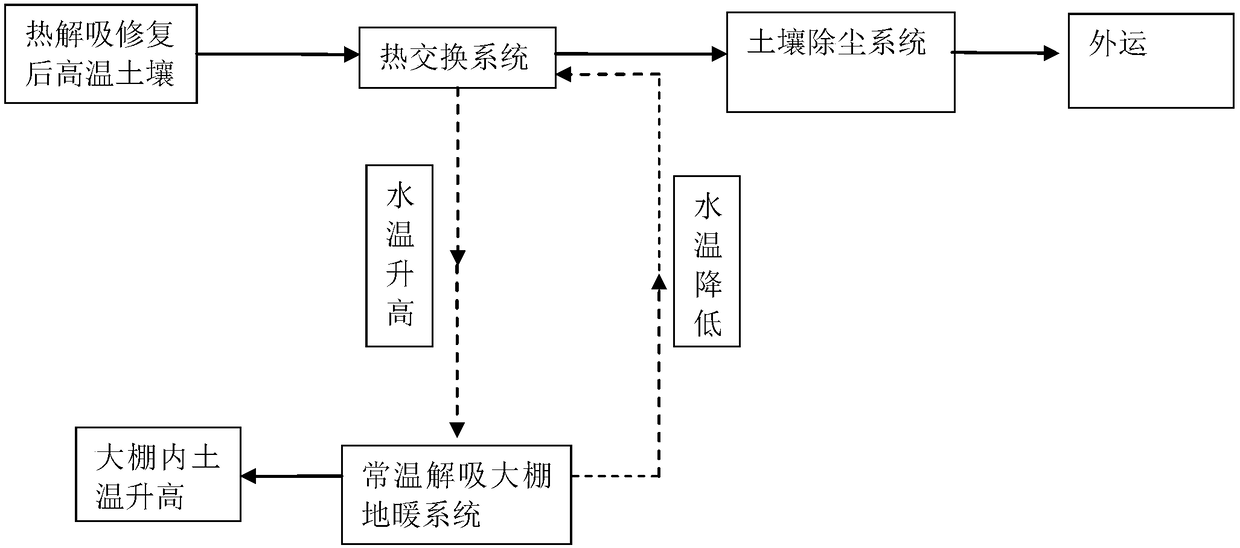

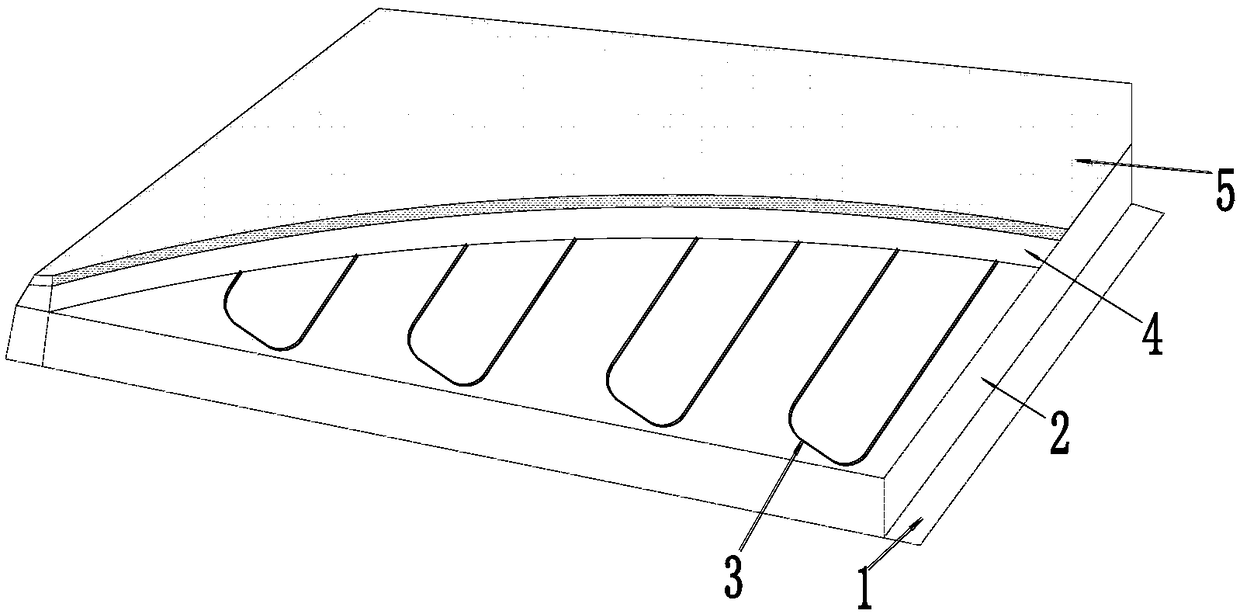

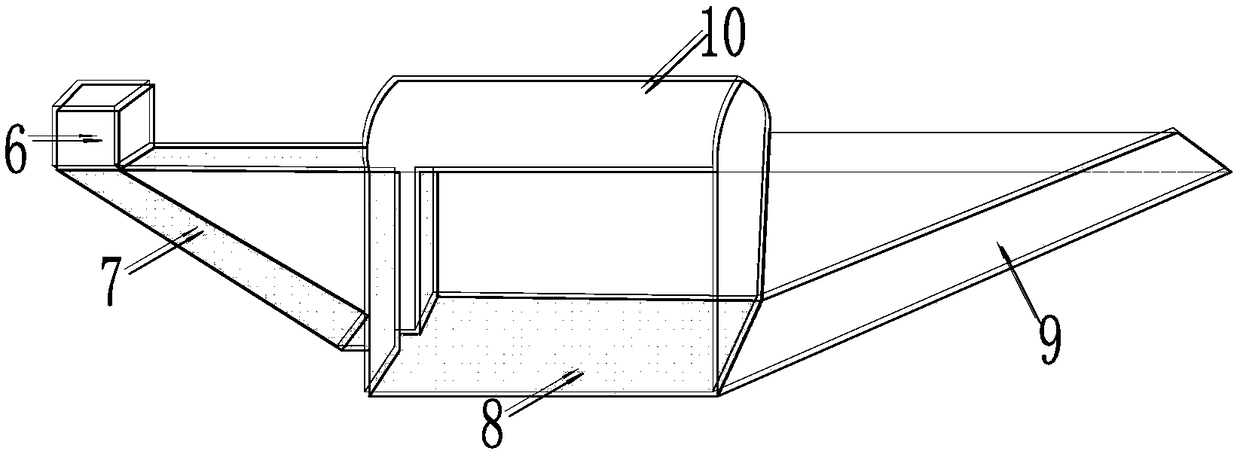

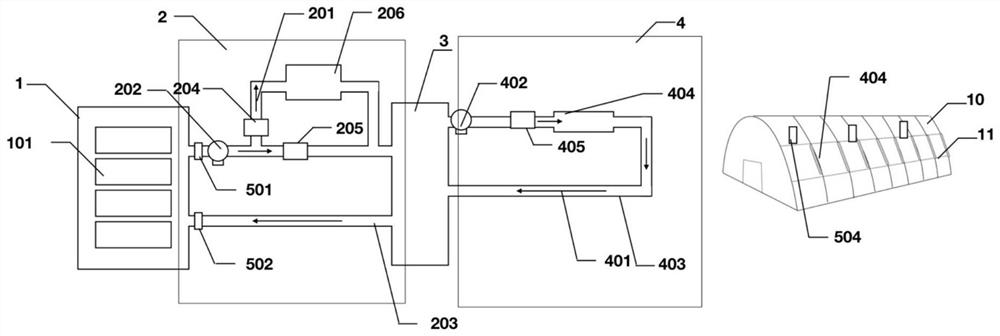

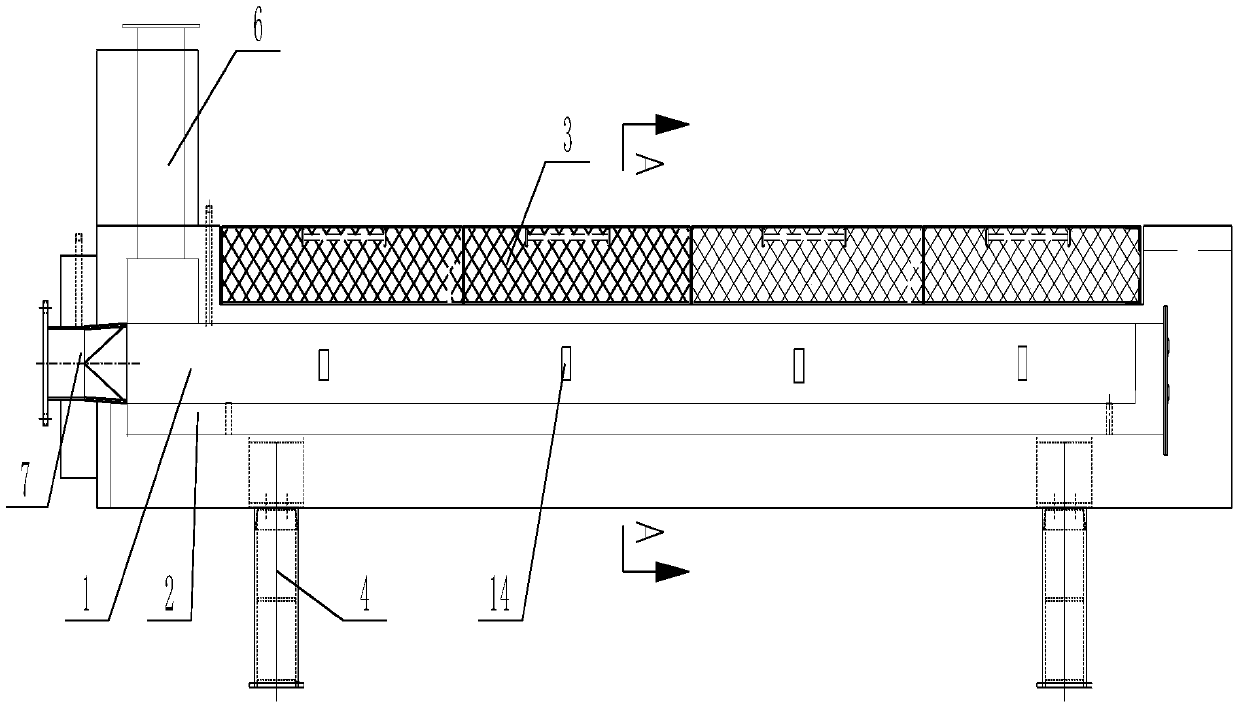

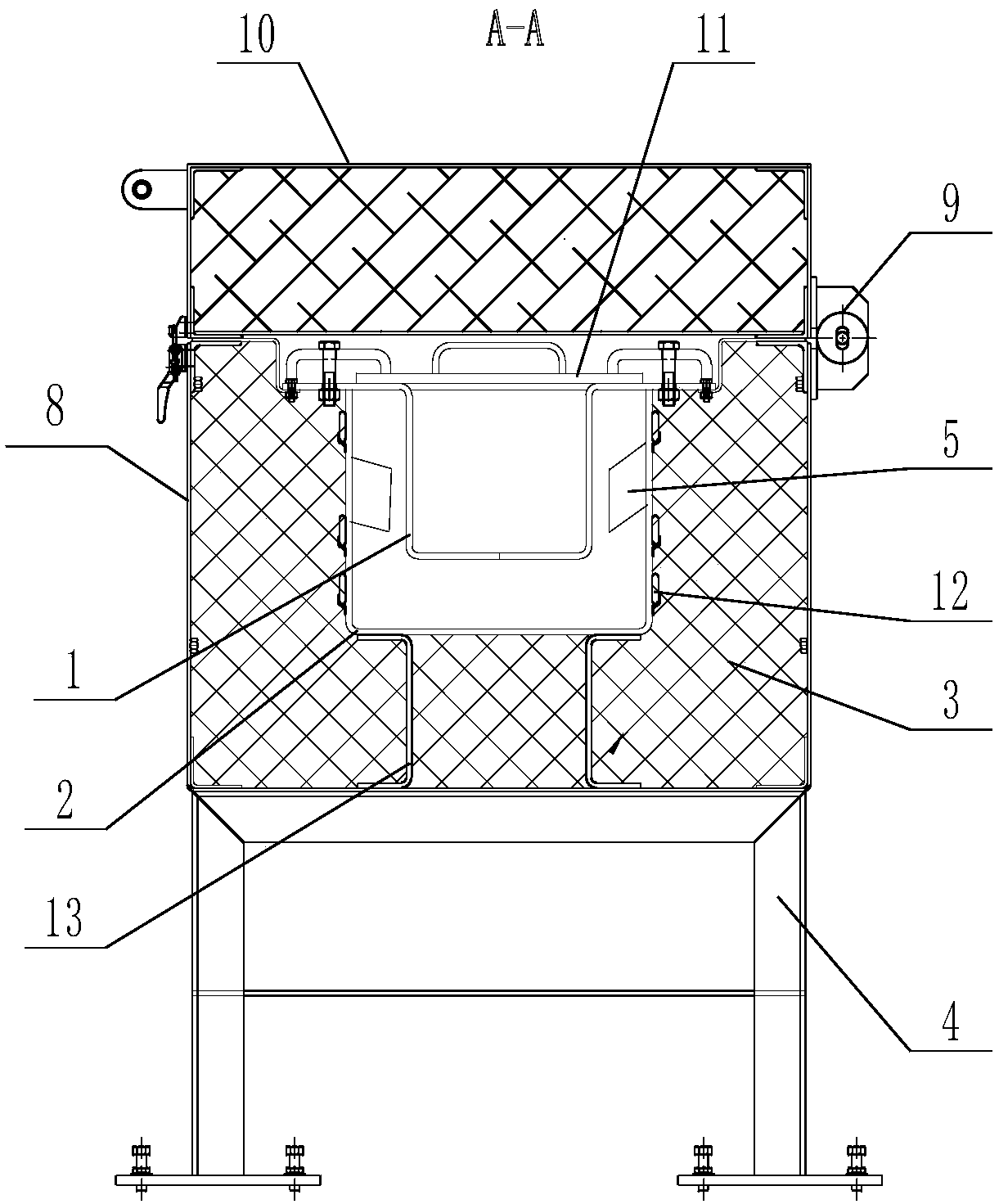

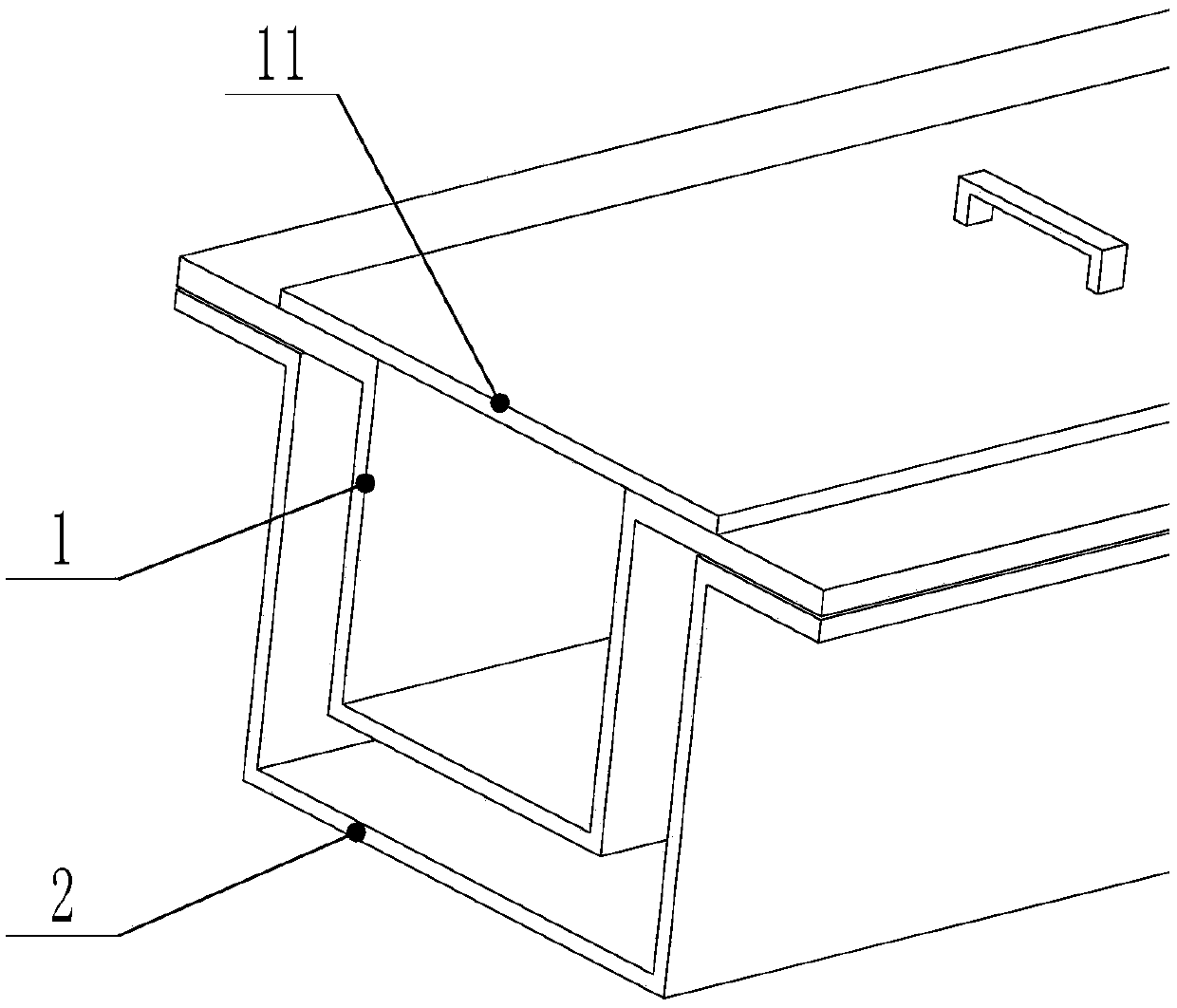

System and method for improving normal-temperature desorption greenhouse treatment efficiency by utilizing high-temperature soil waste heat

PendingCN108405591AImprove processing efficiencyEasy to transportContaminated soil reclamationHeating systemEngineering

The invention discloses a system and method for improving normal-temperature desorption greenhouse treatment efficiency by utilizing high-temperature soil waste heat. The system comprises a heat exchange system, a normal-temperature desorption greenhouse floor heating system and a soil dust removal system, wherein the normal-temperature desorption greenhouse floor heating system comprises a heating coiled tube; the heat exchange system comprises a heat exchange flow slot which is connected with the heating coiled tube; the soil dust removal system comprises a dust removal room, a sealed dustproof greenhouse and a transportation riding track; one end of the dust removal room is connected with the heat exchange flow slot; the other end of the dust removal room is connected with the transportation riding track; the sealed dustproof greenhouse is arranged on the upper part of the dust removal room; and the sealed dustproof greenhouse is provided with spraying equipment. The system utilizeswaste heat of high-temperature soil restored by a high-temperature thermal desorption technology as a heat source for heating normal-temperature desorption greenhouse floor heating circulating water,realizes cooling restored soil while improving restore efficiency through the normal-temperature desorption technology, improves normal-temperature desorption treatment efficiency, and reduces investment and operation cost at the same time.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Boiler flue gas cleaning waste heat recycling device

ActiveCN105709532AAchieve dust removalReuse of waste heatBatteries circuit arrangementsUsing liquid separation agentInsulation layerThermodynamics

A boiler flue gas cleaning waste heat recycling device comprises a boiler air outlet.The boiler flue gas cleaning waste heat recycling device is characterized in that a water tank with the sealed upper portion is connected with the boiler air outlet, a programmable logic controller (PLC) is positioned below the boiler air outlet and installed on the outer wall of the water tank, and the top of the water tank is provided with a storage battery.The top of the water tank is provided with a heat insulation layer, and the lower portion of the heat insulation layer is connected with a heat conduction plate.The heat conduction plate and the heat insulation layer form a first sealed space.A water inlet and a water outlet are positioned outside the left side of the first sealed space, a sensor is positioned in the left side of the first sealed space, and a heat insulation plate is installed beside the heat conduction plate.A spraying nozzle is installed below the heat insulation plate.The heat insulation plate and the heat insulation layer form a second sealed space, and a water inlet and a water outlet are positioned outside the right side of the second sealed space.The boiler flue gas cleaning waste heat recycling device has the advantage that flue gas dedusting and waste heat reuse are achieved.

Owner:桃源县泰香粮油科技开发有限公司

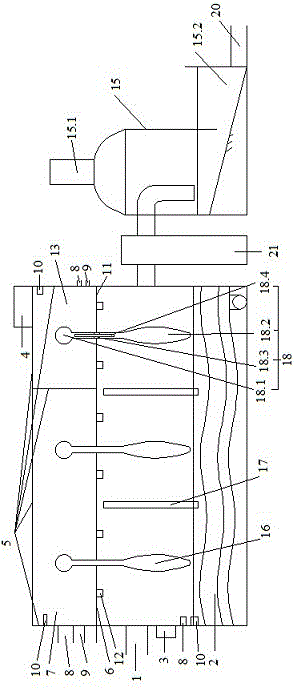

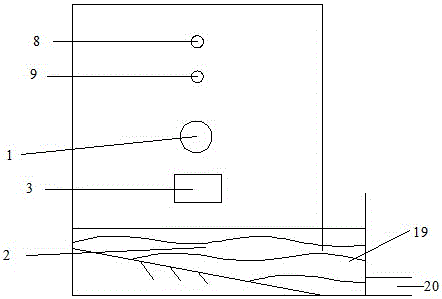

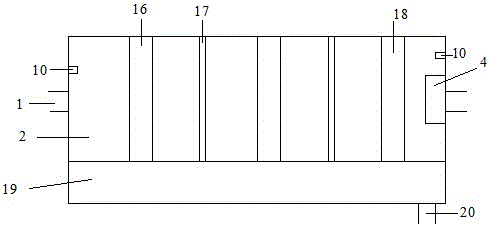

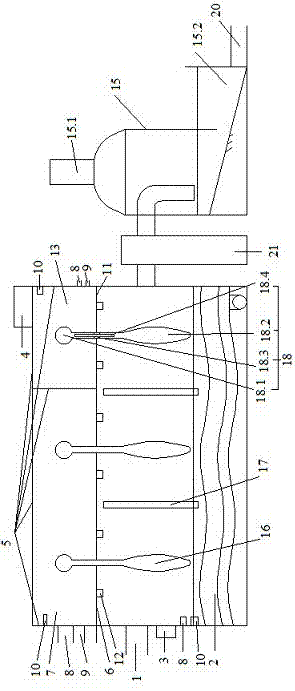

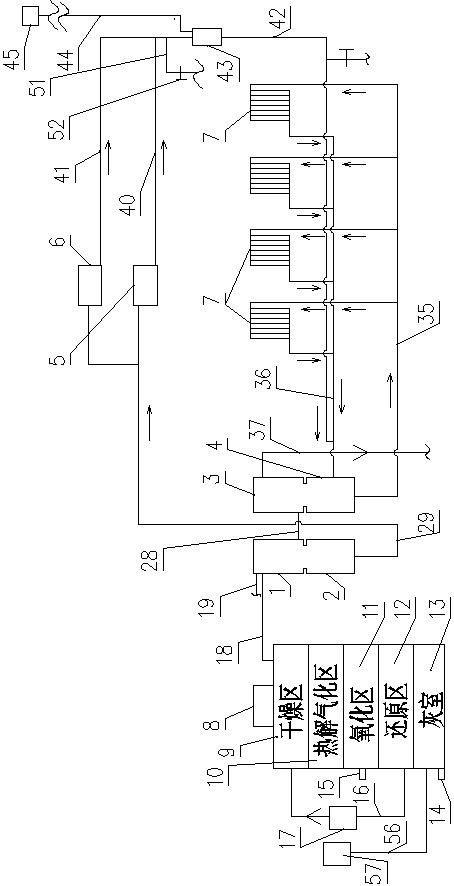

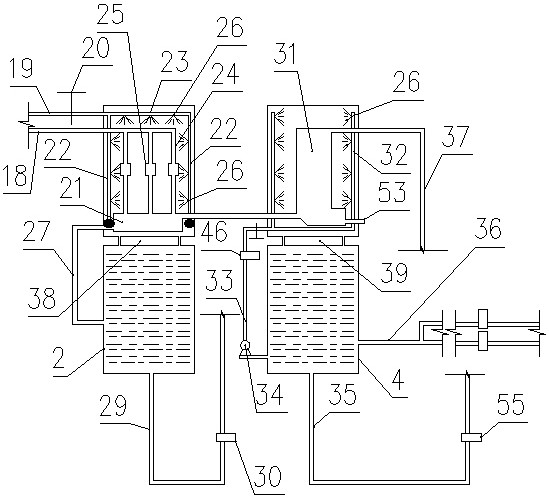

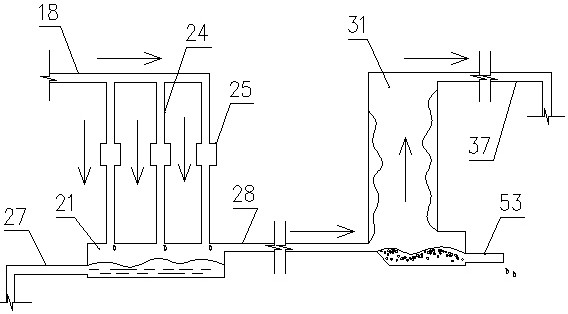

Rural small multifunctional biomass-energy heat-gas coproduction heating device

ActiveCN106403000AMeet heating needsSolve needsSpecific water treatment objectivesTreatment involving filtrationEngineeringWater collection

The invention discloses a rural small multifunctional biomass-energy heat-gas coproduction heating device. The rural small multifunctional biomass-energy heat-gas coproduction heating device comprises a gasification furnace, a fuel gas dewatering device, a first hot water collection tank, a fuel gas decoking device, a second hot water collection tank, a kitchen hot water device, a bath hot water device, and a plurality of water heating devices. The fuel gas dewatering device is of a hollow box structure, and the bottom of the fuel gas dewatering device communicates with the top of the first hot water collection tank. The bottom of the first hot water collection tank is connected with a kitchen-bath hot water outlet pipe, the kitchen hot water device and the bath hot water device are connected with the kitchen-bath hot water outlet pipe after being connected in parallel, and a filter filtering device is arranged on the kitchen-bath hot water outlet pipe. The fuel gas decoking device is of a hollow box structure. The rural small multifunctional biomass-energy heat-gas coproduction heating device is simple in structure, a deep pit does not need to be excavated below a house foundation when the heating device is mounted, and construction is convenient. According to the rural small multifunctional biomass-energy heat-gas coproduction heating device, low-cost biomass fuel which extensively exists in rural areas can be used, clean fuel gas and hot water are produced at the same time, and thus heat-gas coproduction is achieved.

Owner:ZHENGZHOU UNIV

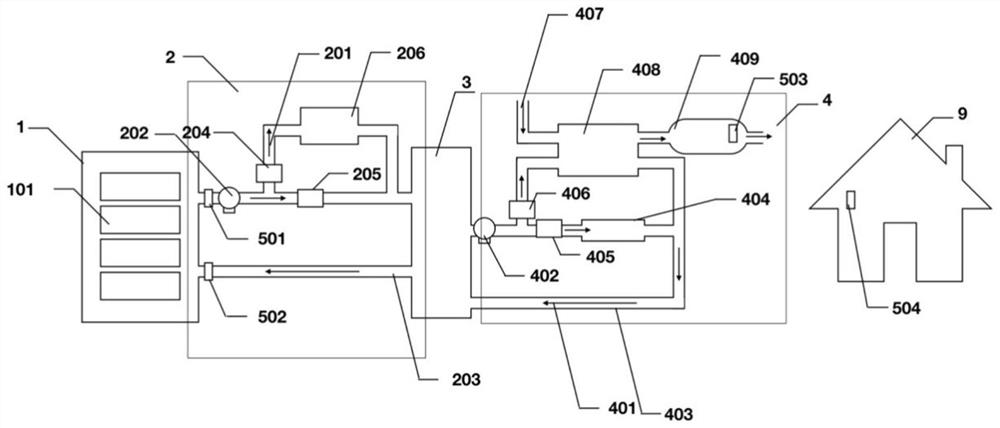

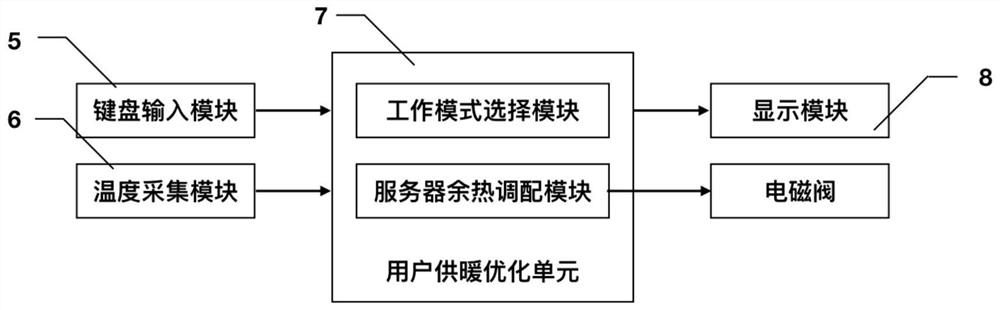

Automatic temperature regulation and control system based on server waste heat

PendingCN113905584AReuse of waste heatRealize regulationClimate change adaptationSaving energy measuresTemperature controlControl system

The invention relates to an automatic temperature regulation control system based on server waste heat. The system comprises a server waste heat collection unit used for collecting waste heat generated by a server during data processing, a cold liquid circulating unit used for conveying the obtained server waste heat energy to a first heat exchanger through electric energy, the first heat exchanger used for further converting the server waste heat extracted by the cold liquid circulating unit and conveying the server waste heat to a water circulating unit, the water circulating unit used for providing domestic water and indoor heating or refrigeration for a user side, and a temperature control unit which realizes automatic adjustment and control of the temperature through a temperature acquisition module, a keyboard input module, a user heating optimization unit and a display module; and therefore, the experience comfort of the user is improved. According to the system, server waste heat recycling is achieved, the heat generated by the server is converted in time, and the heat is used for home heating, greenhouse heating, central heating or cold and heat integrated breeding.

Owner:安吉云湖科技有限公司 +1

Pilot equipment for catalyst detection

InactiveCN109557239AReduce flow rateIncrease utilization and soak timeChemical analysis using catalysisThermal insulationElectric heating

The invention relates to the field of catalyst test devices, in particular to pilot equipment for catalyst detection. The pilot equipment comprises a box, a top cover, a catalyst cabin, a smoke backflow cabin, a sealing cover and a base, wherein the box is fixed on the base; the smoke backflow cabin is mounted in the box; the catalyst cabin is fixed in the smoke backflow cabin; the top cover covers the box; and thermal insulation layers are arranged in the top cover and the box. Smoke in the pilot equipment for catalyst detection is reacted and filtered in the catalyst cabin and then backflowsfrom the smoke backflow cabin, the catalyst cabin is thermally insulated and heated, and the electric energy for heating is reduced, so that afterheat reutilization is realized; and a baffle plate and an electric heating plate are added to reduce the flow speed of the smoke in the backflow process and carry out temperature compensation, so that the catalyst cabin is better thermally insulated andthe afterheat utilization rate is increased.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

A kitchen fume purification device and system based on low temperature plasma technology

InactiveCN106731545BIncrease in sizeSmall degradation efficiencyGas treatmentDispersed particle filtrationEngineeringHigh pressure

The invention provides a kitchen fume purification device and system based on low-temperature plasma technology, which includes a fume pre-treatment module, a low-temperature plasma catalytic module, and a spray cleaning module connected in sequence. The metal mesh and the oil tank connected to the lower end of the metal mesh. The low-temperature plasma catalytic module includes a plurality of parallel discharge tubes. The two ends of the discharge tubes are fixed on the shell of the reactor through a porous plate. The two ends of the electrode are connected to the high-voltage electrode plate, the outside of the discharge tube is wrapped with a ground electrode, the middle of the inside is equipped with a catalyst and the tail is equipped with activated carbon. The spray cleaning module uses the heat released during the low-temperature plasma reaction to heat the cooling medium. Further, the metal mesh is blown with the cooling medium that has reached the set temperature requirement. The invention realizes the synergistic effect of the plasma and the catalyst and the reuse of waste heat, can achieve better treatment effect and ensure economical operation.

Owner:CHONGQING UNIV

Waste heat annealing system suitable for total oxygen kiln furnace

PendingCN109399899AReuse of waste heatDischarge temperature requirements meetFurnace typesIncreasing energy efficiencyFlueProcess engineering

The invention relates to the field of waste heat utilization, in particular to a waste heat annealing system suitable for a total oxygen kiln furnace. The waste heat annealing system comprises a totaloxygen kiln furnace and an annealing furnace, wherein the top of the total oxygen kiln furnace is provided with a smoke discharging channel, the smoke discharging channel is provided with a heat exchanger, an air inlet of the heat exchanger is communicated with an air inlet pipe, an air outlet of the heat exchanger is communicated with one end of a heat insulation pipe, the other end of the heatinsulation pipe is connected with an air inlet of the annealing furnace, an air outlet of the annealing furnace is connected with an air outlet pipe, an induced draft fan is arranged on the air inletpipe, and a heat-adjusting fan is arranged on the heat insulation pipe. The problem is solved that for decreasing the emissions produced in glass manufacture, the total oxygen kiln furnace is usuallyused for replacing an existing horse shoe flame kiln furnace, a heat accumulation chamber is omitted by adopting the design of the total oxygen kiln furnace, the temperature of a flue outlet reaches 120 DEG C and accordingly the temperature of discharged smoke dust is excessively high and waste heat cannot be effectively utilized.

Owner:李福全

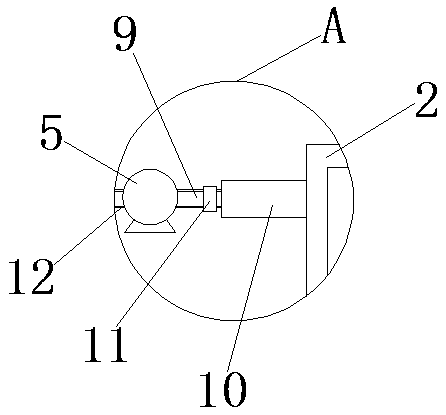

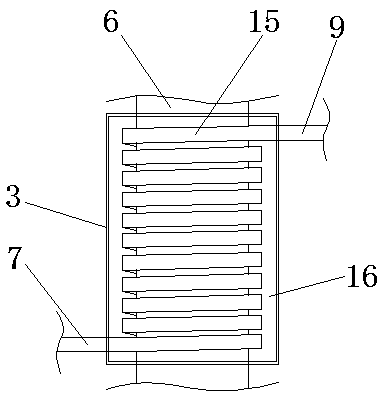

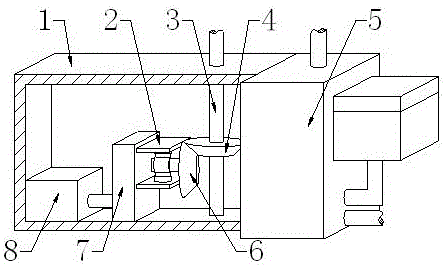

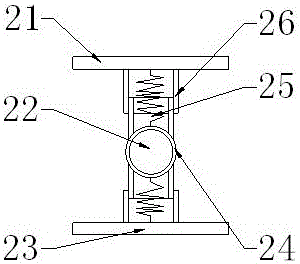

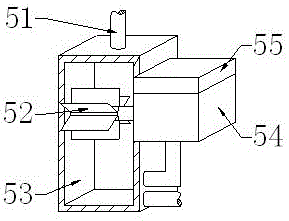

Entertainment machine transmission mechanism

The invention provides an entertainment machine transmission mechanism. The entertainment machine transmission mechanism comprises an upper layer plate, a transmission shaft, a lower layer plate, a lantern ring, springs, a rotary wheel, a case II, a generator and a storage battery, wherein the transmission shaft is arranged under the upper layer plate, the bottom of the transmission shaft is provided with the lower layer plate, the transmission shaft is provided with the lantern ring, the springs are symmetrically mounted at the upper end and the lower end of the lantern ring and the lower end of the upper layer plate and the upper end of the lower layer plate respectively, the upper layer plate is connected with the lantern ring through the corresponding spring, and the lower layer plate is connected with the lantern ring through the corresponding spring, so that a vibration absorbing function can be achieved ; the right end of the case II is provided with the generator, the upper end of the generator is provided with the storage battery, the rotary wheel is arranged inside the case II, and the generator penetrates the case II and is connected with the rotary wheel, so that waste heat recycling, energy saving and environmental protection can be achieved. The entertainment machine transmission mechanism is convenient to use and operate, high in stability and reliability and capable of prolonging the service time.

Owner:中山市童年游乐设备有限公司

A waste heat recovery device for boiler flue gas purification

ActiveCN105709532BAchieve dust removalReuse of waste heatBatteries circuit arrangementsUsing liquid separation agentInsulation layerProgrammable logic controller

A boiler flue gas cleaning waste heat recycling device comprises a boiler air outlet.The boiler flue gas cleaning waste heat recycling device is characterized in that a water tank with the sealed upper portion is connected with the boiler air outlet, a programmable logic controller (PLC) is positioned below the boiler air outlet and installed on the outer wall of the water tank, and the top of the water tank is provided with a storage battery.The top of the water tank is provided with a heat insulation layer, and the lower portion of the heat insulation layer is connected with a heat conduction plate.The heat conduction plate and the heat insulation layer form a first sealed space.A water inlet and a water outlet are positioned outside the left side of the first sealed space, a sensor is positioned in the left side of the first sealed space, and a heat insulation plate is installed beside the heat conduction plate.A spraying nozzle is installed below the heat insulation plate.The heat insulation plate and the heat insulation layer form a second sealed space, and a water inlet and a water outlet are positioned outside the right side of the second sealed space.The boiler flue gas cleaning waste heat recycling device has the advantage that flue gas dedusting and waste heat reuse are achieved.

Owner:桃源县泰香粮油科技开发有限公司

A system and method for treating heavy oil wastewater and reusing power plant boilers

ActiveCN104671607BEfficient use ofReuse of waste heatTreatment using aerobic processesScale removal and water softeningEngineeringSuperheated steam

The invention discloses a system and method of a power station boiler for treating and recycling heavy oil wastewater. The system comprises a heavy oil thermal recovery well, a silicon removal reactor and a softening reactor which are connected with one another in sequence, wherein the softening reactor is connected with a liquid inlet of an evaporator, a condensed water outlet of the evaporator is sequentially connected with a biological aerated filter and a desalting device, and a water producing outlet of the desalting device is connected with a power station boiler and steam turbine system; a silicon removal medicament dosing opening is formed in the silicon removal reactor, a softening medicament dosing opening is formed in the softening reactor, and a steam exhaust outlet of a steam turbine in the power station boiler and steam turbine system is connected with a heat source inlet of the evaporator; and a superheated steam outlet of the power station boiler in the power station boiler and steam turbine system is connected to the heavy oil thermal recovery well. By adopting the system disclosed by the invention, co-production of water, heat and electricity can be achieved, the heat energy can be effectively used, and the cycle thermal efficiency can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

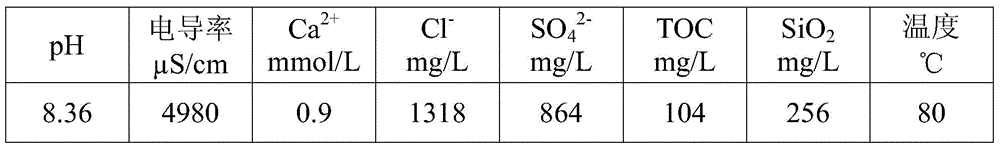

Method and system for utilizing waste heat of cooling water of bell-type furnace

PendingCN114739169AImprove comfortSave resourcesIncreasing energy efficiencyFurnace coolingWater pipeWater supply

The invention relates to a bell-type furnace cooling water waste heat utilization method and system. The bell-type furnace cooling water is conveyed into a non-pressure water return pool; the bell-type furnace cooling water in the non-pressure water return pool is conveyed to the bell-type furnace inner cover through a water return pump and used for cooling the bell-type furnace inner cover; conveying to a bell-type furnace platform for cooling the bell-type furnace platform; and the air is conveyed to the air-conditioning terminal unit for air-conditioning heating. Meanwhile, the inner cover of the bell-type furnace, the non-pressure water return pool and the water return pump form a heating circulation system; the bell-type furnace coil base, the non-pressure water return pool, the water return pump, the circulating water cooling tower, the circulating water collecting pool and the circulating water supply pump form a water supplementing circulating system. The non-pressure water return pool, the water return pump, the air-conditioning water heating water pipe, the air-conditioning terminal unit and the air-conditioning water return pipe form a heating circulating system; according to the invention, the waste heat of the cooling water of the bell-type furnace is recycled, and resources are saved.

Owner:湖南华菱涟钢特种新材料有限公司 +1

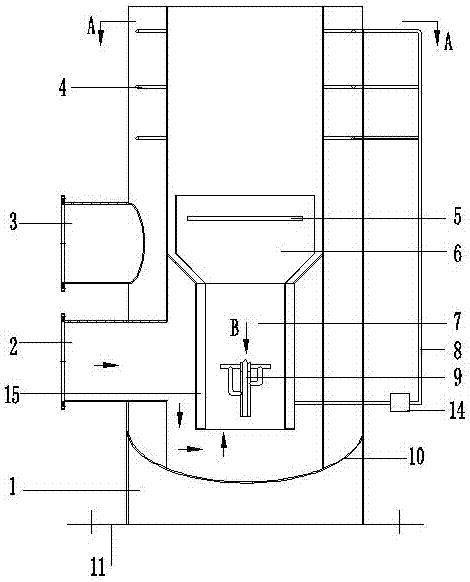

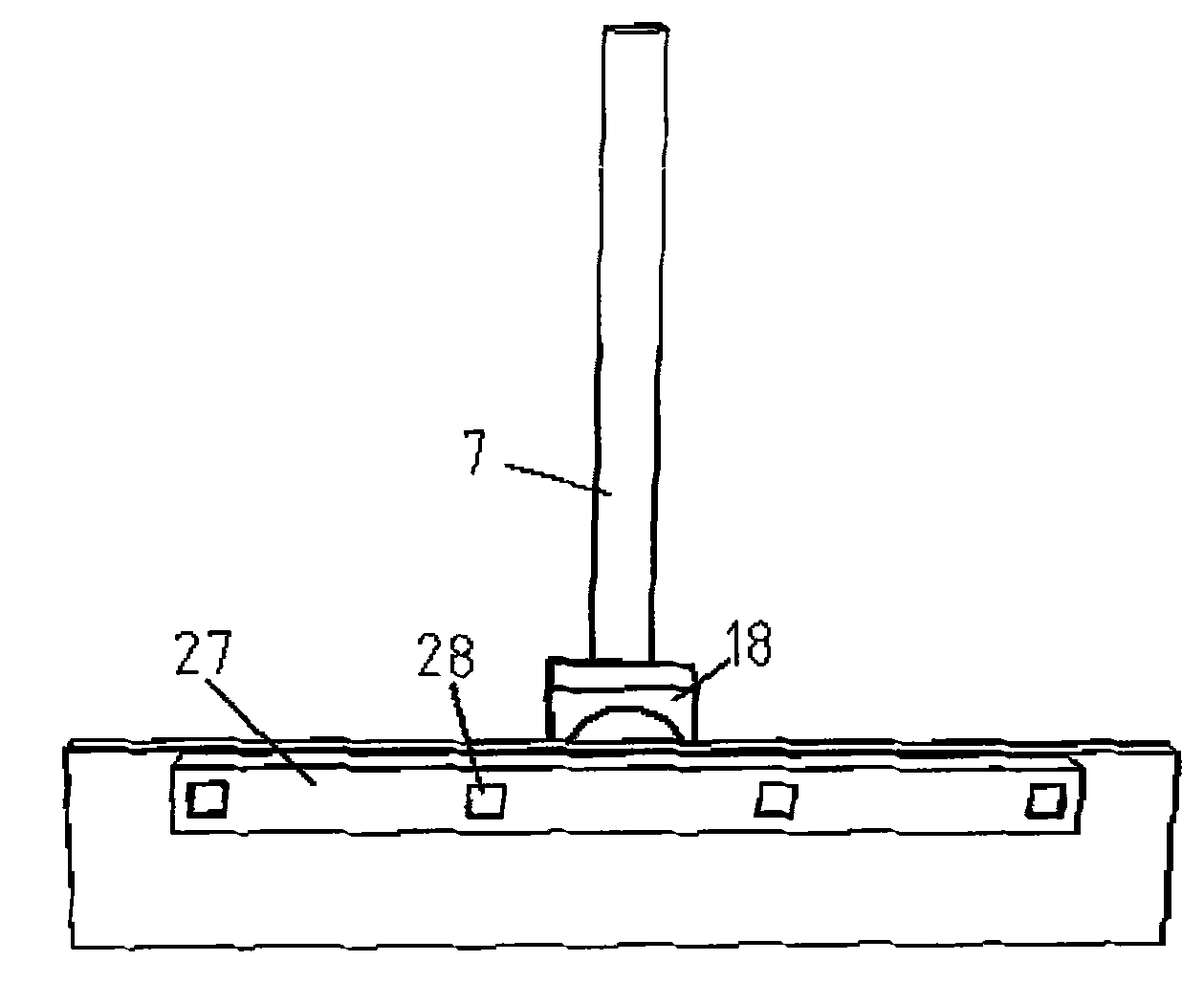

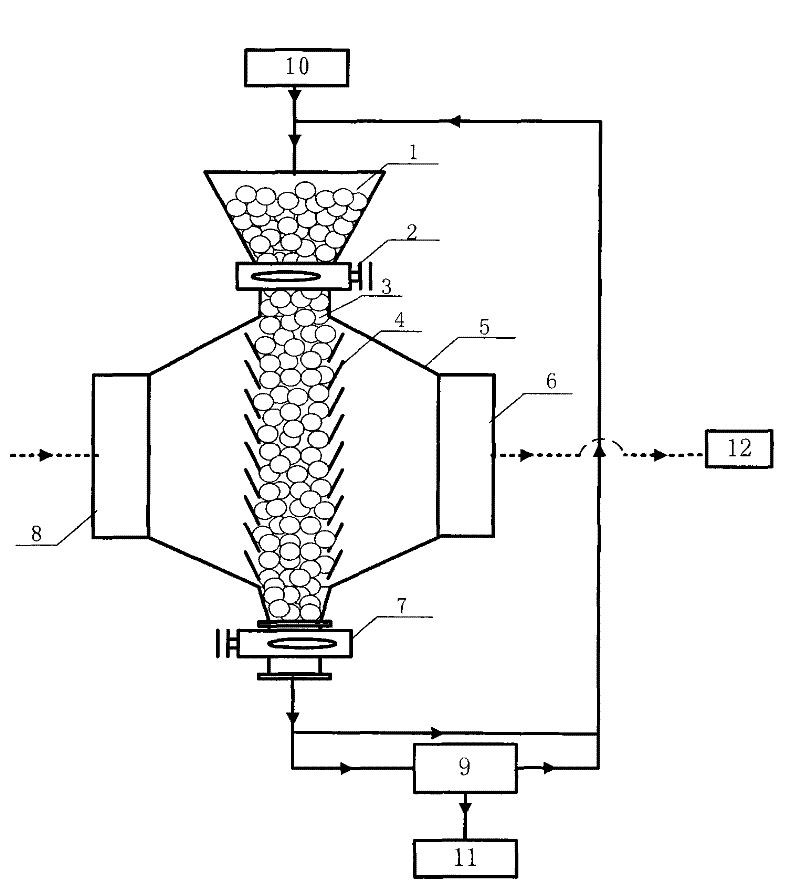

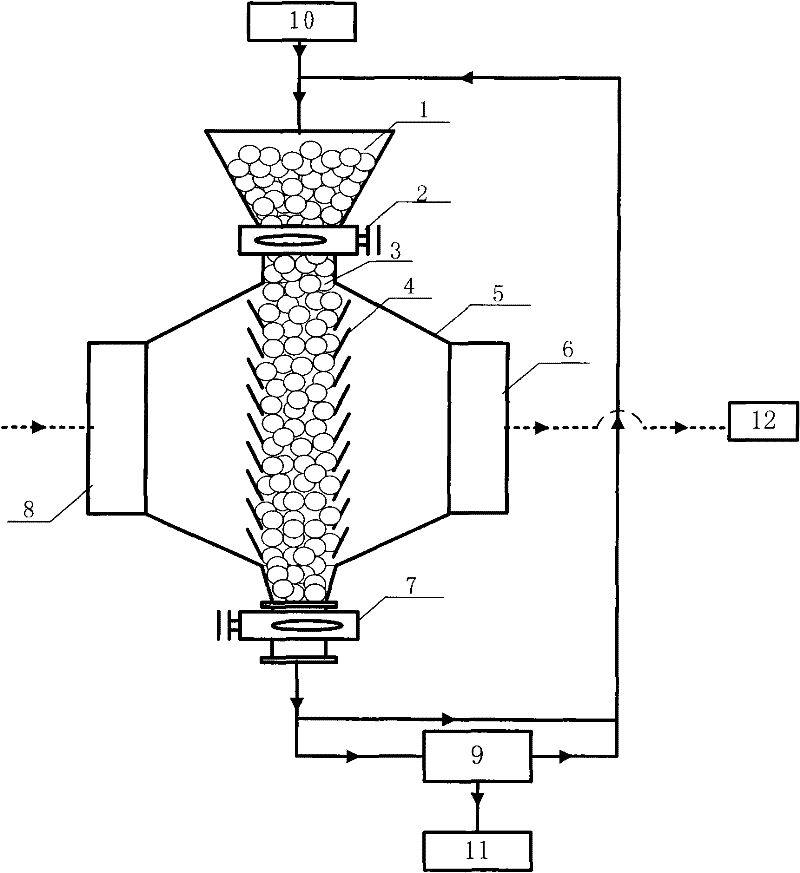

Device and method for removing harmful components in cement kiln flue gas by using cross-flow moving bed

ActiveCN101785953BSolve the problem of crust cloggingReduce firing heat consumptionDispersed particle separationHazardous substanceFlue gas

The present invention is a device and method for removing harmful components of cement kiln flue gas by using a cross-flow moving bed, which is carried out according to the following steps: adsorption carrier particles (3) fall into a cross-flow moving bed absorber from a hopper (1) (5); the high-temperature flue gas enters the cross-flow moving bed absorber (5) and the low-temperature adsorption carrier particles (3) to carry out cross-flow flow, and the harmful components in the flue gas condense on the adsorption carrier particles (3); the discharge valve ( 7) Control the discharge rate of the adsorption carrier (3); after the cleaning device (9) completes the washing and drying of the adsorption carrier (3), the adsorption carrier particles (3) are returned to the hopper (1) to realize the separation of the carrier particles Recycling. The replenishment of the adsorption carrier particles (3) is completed from the replenishment bin (10). The invention can effectively solve the problem of skin blockage caused by the cyclic enrichment of harmful components such as alkali, chlorine, sulfur, etc., avoid a large increase in energy consumption due to emptying, and can also separate harmful substances in the flue gas for further processing. Resource reuse.

Owner:SOUTHEAST UNIV

Drying control method, device and computer-readable storage medium

ActiveCN107576013BEfficient drying operationSolve the problem of dripping water making the ground slipperyMechanical apparatusSpace heating and ventilation safety systemsEngineeringHumid climate

The invention discloses a drying control method. The drying control method comprises the following steps that whether the gravity value measured by a gravity sensor is greater than the preset gravitythreshold or not is determined; when the gravity value is greater than the preset gravity threshold, whether the humidity value measured by a first humidity sensor is greater than the first preset humidity value or not is determined; when the humidity value measured by a first humidity sensor is greater than the first preset humidity value, whether an outdoor machine is currently in a working state or not is determined; and when the outdoor machine is currently in the working state, the driving device is controlled to adjust the wind angle of a wind guiding plate. The invention further discloses a drying control device and a computer readable storage medium. By means of the drying control method, automatic feedback adjusting can be achieved according to the operating condition of the air-conditioner, clothing hanging, clothing and humidity of the ground, the problem that the clothing is difficultly dried in the humid climate area is solved, the problem of waste heat reuse of the air conditioner is also solved, and the use efficiency of the drying function of the outer machine is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Rural small-scale multifunctional biomass heat and gas cogeneration heating device

ActiveCN106403000BMeet heating needsAvoid pollutionSpecific water treatment objectivesTreatment involving filtrationRural areaEnvironmental engineering

Owner:ZHENGZHOU UNIV

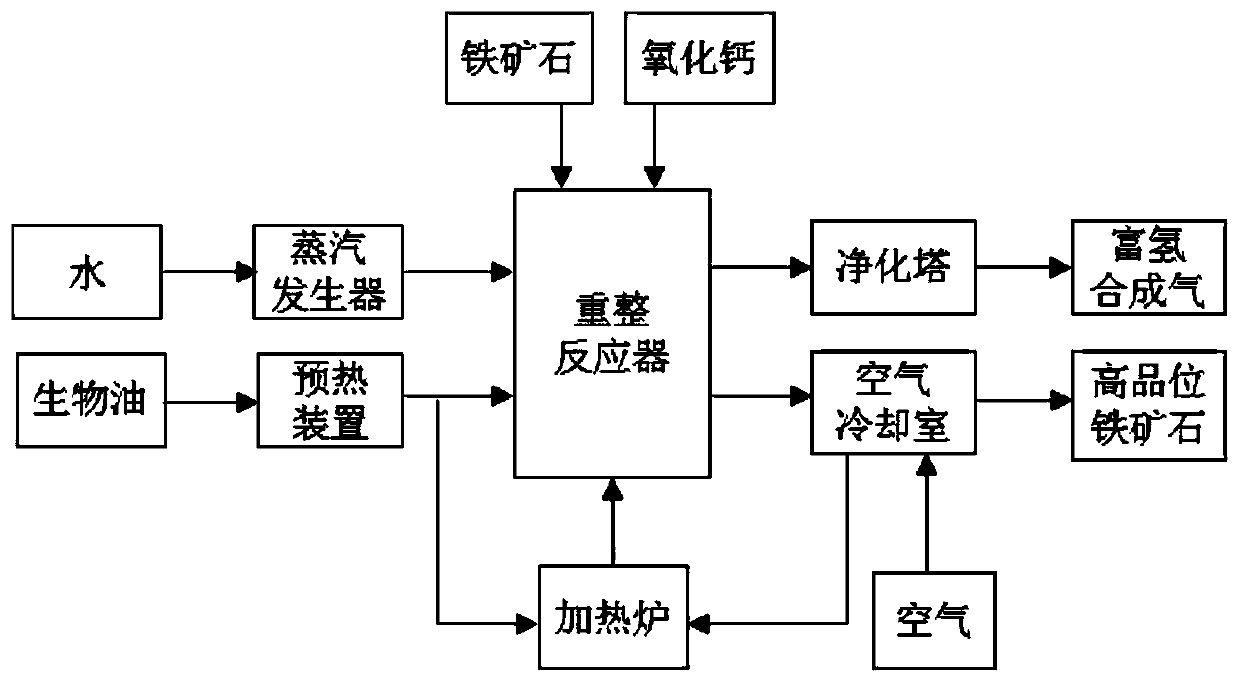

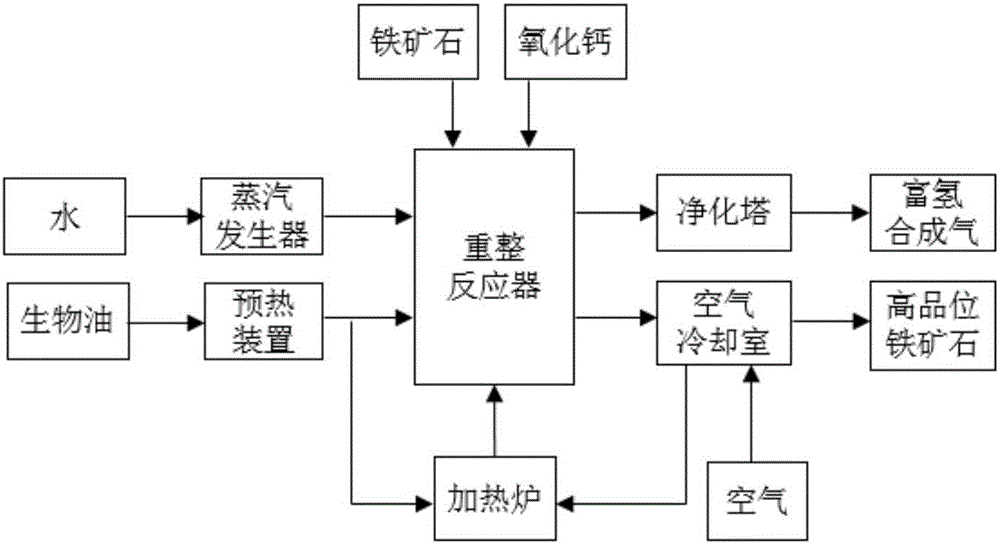

A system for producing hydrogen-rich syngas by catalytically reforming bio-oil with iron ore

ActiveCN106744683BSolve Catalyst ProblemsSolve the problem of generally low qualityHydrogenChemical industryCatalytic reformingCooling chamber

Owner:HUAZHONG UNIV OF SCI & TECH

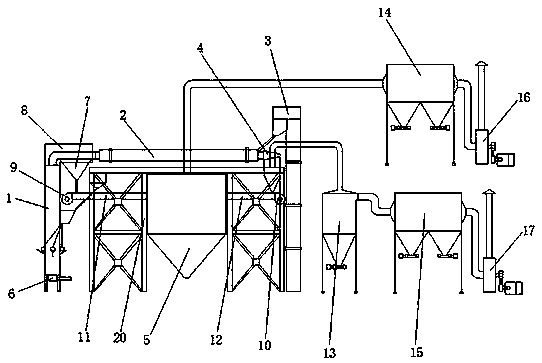

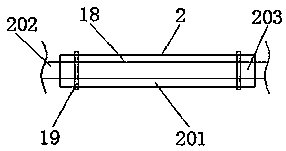

Efficient energy-saving natural gas perlite expansion equipment

The invention relates to the field of natural gas perlite expansion equipment and in particular to efficient energy-saving natural gas perlite expansion equipment which comprises a drying mechanism, arecycling mechanism and a dust collection mechanism, wherein the drying mechanism comprise expansion equipment, a drying machine, a lifting machine, a cyclone separator, a natural gas combustor and awater tank; the feeding end of the drying machine is communicated with the discharge end of the lifting machine through a pipeline; the drying machine is positioned at the top of the expansion equipment and is parallel to the water tank and the cyclone separator; a heat radiation tube is mounted inside the drying machine; the heat radiation tube is communicated with the water tank and the cycloneseparator respectively; the water tank, the expansion equipment and the natural gas combustor are communicated in sequence. By adopting the equipment, the connection relationship of the components ischanged on the basis of conventional perlite expansion equipment, the waste heat of the drying machine and the expansion equipment can be recycled, heating of a combustor such as a fire ejector is not needed any longer, and the problems of exhaust pollution and excessive energy consumption can be solved.

Owner:XINYANG BAOZI ENVIRONMENTAL PROTECTION EQUIP

System for preparing hydrogen-rich synthesis gas by employing iron ore catalytic reforming of bio-oil

ActiveCN106744683ASolve Catalyst ProblemsSolve the problem of generally low qualityHydrogenChemical industryCatalytic reformingCooling chamber

The invention discloses a system for preparing a hydrogen-rich synthesis gas by employing iron ore catalytic reforming of bio-oil, belongs to a system for preparing a hydrogen-rich synthesis gas through catalytic reforming of the bio-oil, and aims at solving the problems of inactivation of a catalyst caused by an existing process for preparing the hydrogen-rich synthesis gas by employing iron-based catalyst reforming of the bio-oil and a low iron ore grade in China at present to achieve high values of the bio-oil and the iron ore. The system comprises a preheating device, a steam generator, a reforming reactor, a heating furnace, a purifying column and an air cooling chamber. The system is simple in formation, efficient, energy-saving, economic, and high in engineering realizability and wide in application range of raw materials; the added value of a product of a technology for iron ore catalytic reforming of the bio-oil is increased; and the method is suitable for high-value utilization of various biomass-based bio-oil products and grade improvement technologies of various low-grade iron ores.

Owner:HUAZHONG UNIV OF SCI & TECH

A thermal desorption remediation system for contaminated soil with waste heat reuse

ActiveCN105080957BReasonable structureEasy to operateContaminated soil reclamationEngineeringThermal desorption

The invention relates to a thermal desorption restoration system for polluted soil with waste heat reuse, comprising: a thermal desorption device, a heat supply device, an exhaust gas treatment device and a surface heat exchange device. device, heat supply device and exhaust gas treatment device. The thermal desorption repair system uses the surface heat exchange device to preheat the combustion air at normal temperature with the high-temperature tail gas generated during the repair process, realizing the reuse of waste heat from the tail gas; the initial cooling of the tail gas is carried out in the form of waste heat exchange , reduces the burden of secondary cooling, and reduces the input cost of secondary cooling equipment; the soil thermal desorption repair system of the present invention has reasonable structure, simple operation, convenient use, no secondary pollution, and realizes the reuse of waste heat from exhaust gas, and has the advantages of Broad application prospects and practical value.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

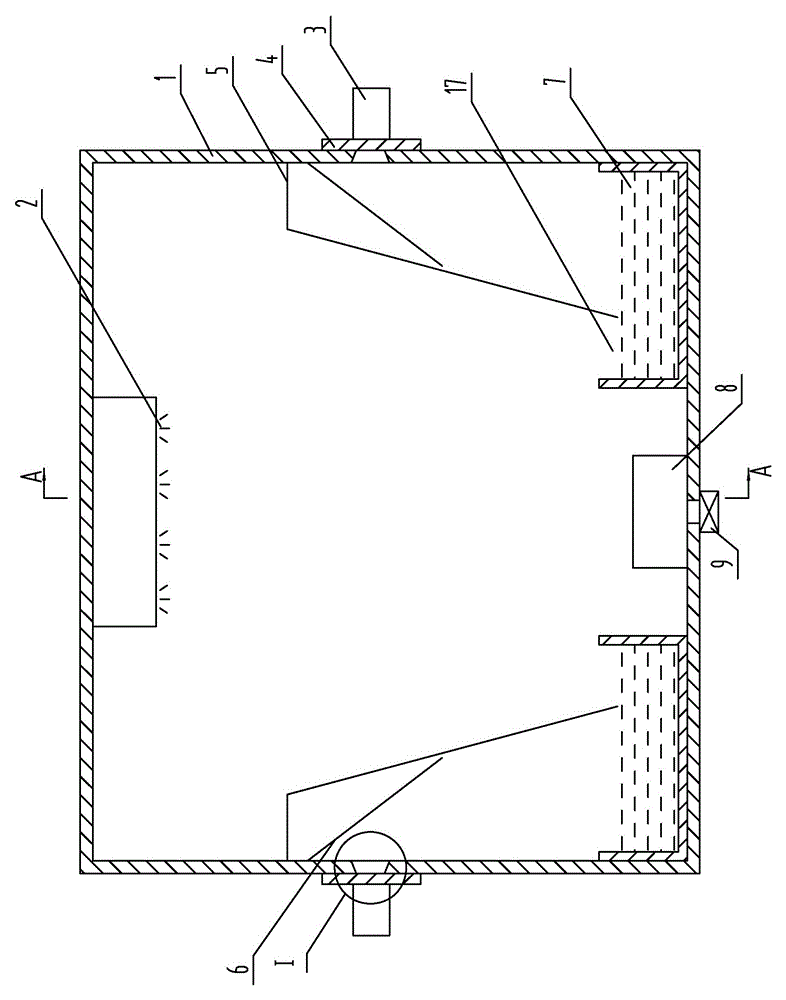

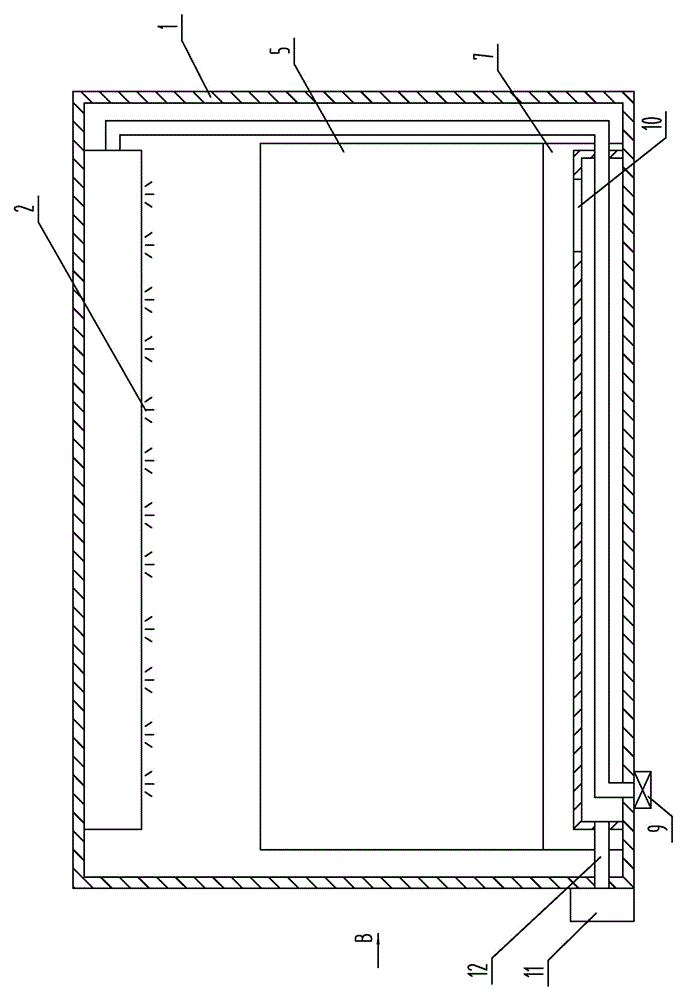

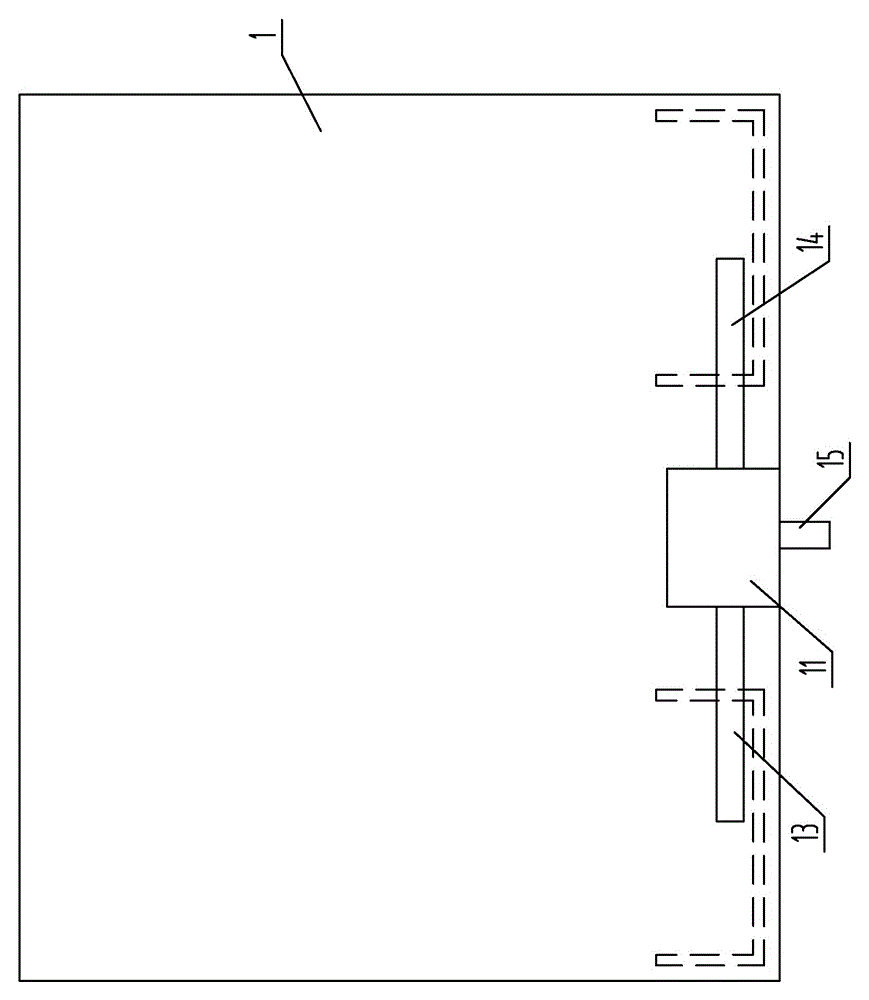

Wood drying method and device

InactiveCN104990374AAvoid intermediate delivery pathsDry evenlyDrying gas arrangementsDrying machines with local agitationEvaporationPulp and paper industry

The invention discloses a wood drying method and device and belongs to the technical field of drying technologies. The wood drying device comprises a box. Steam generating devices are arranged in the box. The wood drying device is characterized in that the steam generating devices are located on the two sides of the bottom of the box, a steam supply port of the steam generating device is formed in the lower portion of the box, the upper portion of the box is provided with a hot air port, the lower portion of the box is provided with a steam outlet, and the steam outlet is located below the seam supply port. By the adoption of the wood drying device, generated steam can directly steam and dry wood, the heat loss of the steam is reduced, the steaming temperature of the wood can be easily raised, the evaporation speed of moisture in the wood is increased, insect killing and sterilizing can be better achieved, and the service life of the wood is prolonged; in the later period of drying, steam supply is stopped, steam in the wood is replaced by hot air, and therefore the drying effect on the wood is improved; moisture in the wood is steamed out through moisture, the wood is evenly dried, the condition that the wood deforms in the drying process due to sharp heating is avoided, and therefore the drying quality of the wood is improved.

Owner:山东德润机电设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com