Equipment for treating VOCs (volatile organic chemicals) exhaust gases and use method of equipment

A waste gas and equipment technology, which is applied in the field of VOCs waste gas treatment equipment, can solve the problems of small contact area between gas and liquid, short contact time, and failure to meet environmental protection, so as to increase the contact area and contact time, treat waste gas thoroughly, reduce The effect of small devices taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

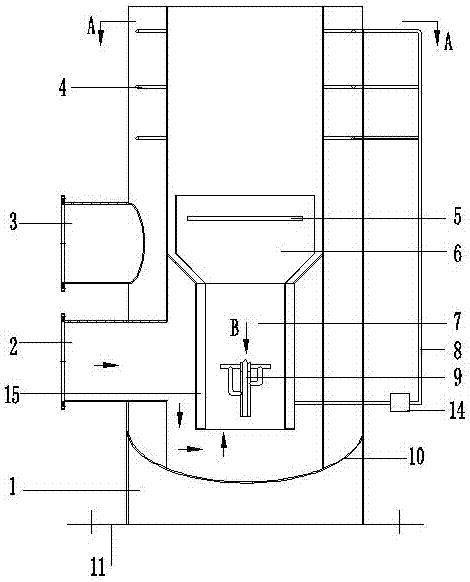

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

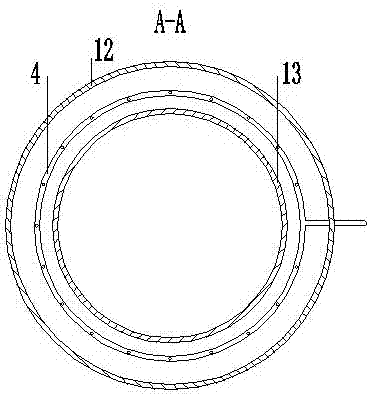

[0030] Such as figure 1 A device for treating VOCs waste gas is shown, which includes an inner cylinder 13 and an outer cylinder 12 fixed vertically. The bottom of the outer cylinder 12 is provided with a head 10, and the lower end of the inner cylinder 13 is affixed to the head 10 and formed by The head is sealed, and a cylindrical support seat 1 is fixed under the outer cylinder wall connected to the head 10. The lower end of the cylindrical support seat 1 is provided with a connecting flange 11, and the connecting flange 11 is fixed on the ground .

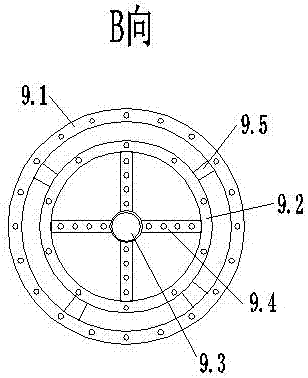

[0031] The interlayer cavity between the inner cylinder 13 and the outer cylinder 12 is connected to the low-concentration exhaust gas pipeline 3, the inner cavity of the inner cylinder 13 is connected to the high-concentration exhaust gas pipeline 2, and a valve communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com