Efficient energy-saving natural gas perlite expansion equipment

A high-efficiency, energy-saving, natural gas technology, applied in the field of natural gas perlite expansion equipment, can solve problems such as excessive energy consumption and exhaust pollution, and achieve the effect of improving efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

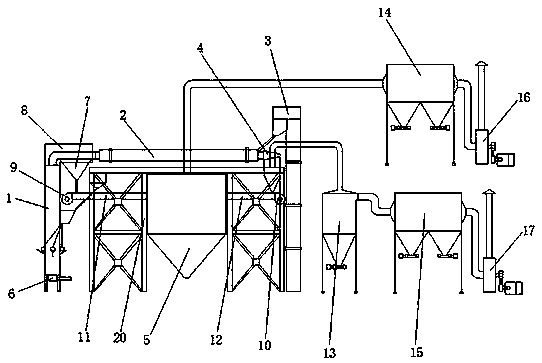

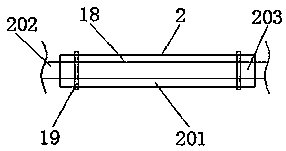

[0027] Such as figure 1 As shown, a high-efficiency energy-saving natural gas perlite expansion equipment includes a drying mechanism, a recovery mechanism and a dust removal mechanism. The drying mechanism includes an expansion equipment 1, a dryer 2, a hoist 3, a cyclone separator 4, and a natural gas burner 6 And the water tank 8, the feed end of the dryer 2 is connected with the discharge end of the hoist 3 through a pipeline, the dryer 2 is located on the top of the expansion device 1, and is flush with the water tank 8 and the cyclone separator 4, and the inside of the dryer 2 A radiating pipe 18 is installed, and the radiating pipe 18 communicates with the water tank 8 and the cyclone separator 4 respectively, and the water tank 8, the expansion device 1 and the natural gas burner 6 communicate in sequence.

[0028] In use, the dryer is directly connected to the expansion device, and the heat generated by the natural gas burner at the bottom of the expansion device can ...

Embodiment 2

[0031] Based on Embodiment 1, the recovery mechanism includes a silo 5, a first fan 9, a second fan 10, a first conveying pipe 11 and a second conveying pipe 12, the hopper 5 is arranged in the steel frame 20, and the hopper 5 first enters The feed port communicates with the first fan 9 through the first air delivery pipe 11 , and the second feed port of the silo 5 communicates with the second fan 10 through the second air delivery pipe 12 .

[0032] In use, the existing recovery mechanism mixes the solid particles produced by the cyclone separator and the expansion equipment through the fan, and then transports them to the silo together. Particles are conveyed separately, which improves the conveying efficiency and reduces the burden on equipment.

Embodiment 3

[0034] Based on Embodiment 2, the dust removal mechanism includes a first bag filter 14 and a first centrifugal induced draft fan 16, the feed end of the first bag filter 14 communicates with the silo 5 through a pipeline, and the discharge end of the first bag filter 14 It communicates with the first centrifugal induced draft fan 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com