A system for producing hydrogen-rich syngas by catalytically reforming bio-oil with iron ore

A catalytic reforming and iron ore technology, applied in hydrogen/synthesis gas production, hydrogen, inorganic chemistry, etc., can solve the problems of catalyst deactivation, low iron ore grade, etc., and achieve the effect of reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

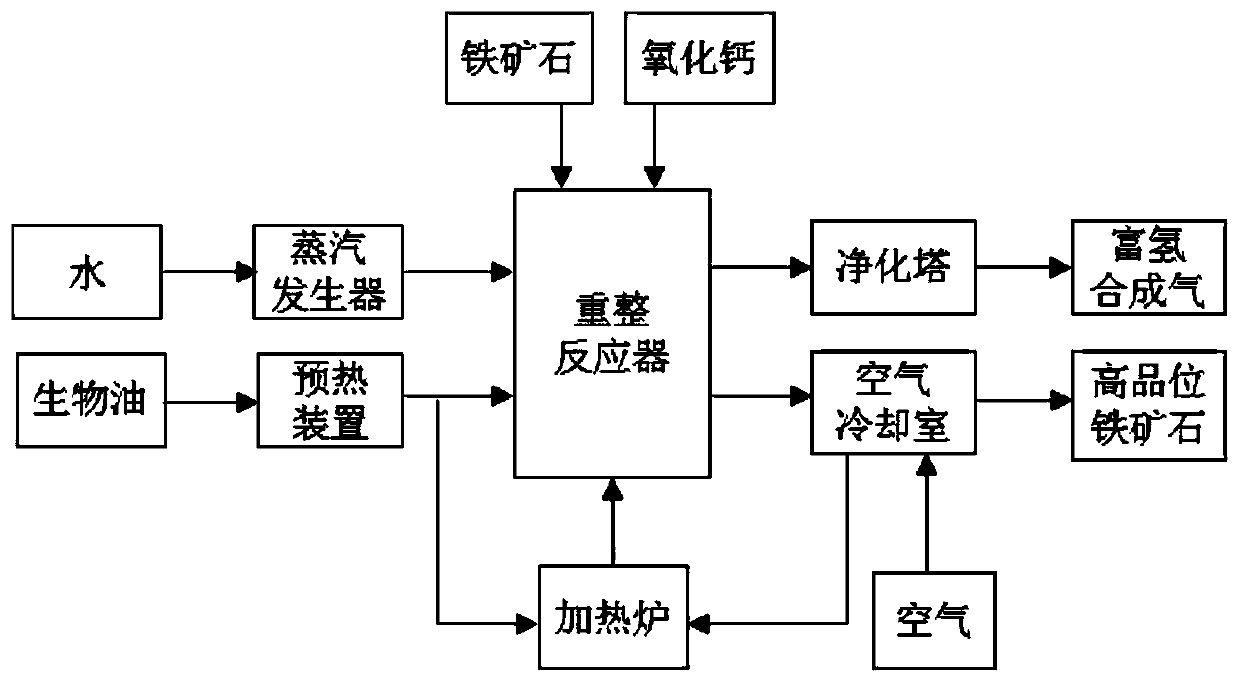

[0026] Such as figure 1 As shown, the present invention includes preheating device, steam generator, reforming reactor, heating furnace, purification tower and air cooling chamber;

[0027] The bio-oil is sent to the reforming reactor after being preheated by the preheating device, and the steam generator sends water vapor into the reforming reactor, and the iron ore and calcium oxide are respectively sent to the reforming reactor through the feeding device. The heating furnace produces high-temperature flue gas to provide heat for the reforming reactor;

[0028] Bio-oil, iron ore, water vapor, and calcium oxide are catalytically reformed in the reforming reactor to generate crude hydrogen-rich synthesis gas and high-temperature carbon-coated iron ore;

[0029] The crude hydrogen-rich synthesis gas is sent to a purification tower, condensed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com