Catalyst for producing polytrimethylene terephthalate, and preparation method and application thereof

A technology of polytrimethylene terephthalate and catalyst, which is applied in the field of preparation of this catalyst, can solve the problems of titanium compound deactivation, changing the balance of polytrimethylene terephthalate, no mention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Mix 142g of tetraisopropyl titanate with 124g of ethylene glycol and 22.5g of tartaric acid, and react for 4 hours at 100°C in a stirred reactor. Add 37g of zinc lactate to the reactant. Medium, react at 120°C for 4 hours. The reaction product is placed in a reactor equipped with a fractionation device, and isopropanol and water are distilled out to prepare a catalyst. The catalyst is mixed with 1,3-propanediol, wherein the mass fraction of titanium atoms is 4%.

[0046] 600 grams of terephthalic acid, 440 grams of 1,3 propylene glycol, 1.49g of catalyst and stabilizer phosphoric acid (50ppm relative to terephthalic acid) were mixed to form a slurry, which was added to the polymerization vessel for esterification reaction. The esterification temperature was 230°C, the pressure is 0.25MPa, the water produced by the reaction is discharged through the rectification device, and the reaction is carried out for 2 hours. After the esterification is over, the pressure is reduced...

Embodiment 2-4

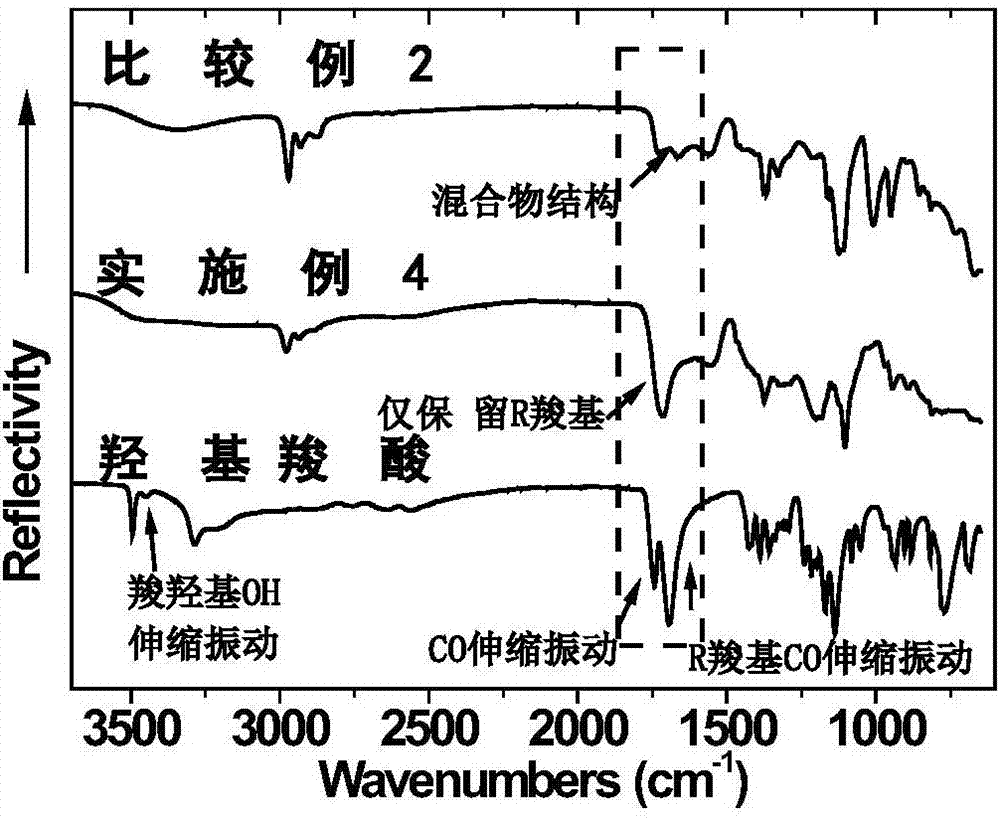

[0049] The same catalyst preparation method as in Example 1 was adopted, except that the addition amount of tartaric acid was 75 g, 120 g, and 190 g, respectively.

Embodiment 5-6

[0051] The same catalyst preparation method as in Example 1 was adopted, except that 172 g of 1,3 propylene glycol and 180 g of 1,4-butanediol were used for linear diols.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com