Wood drying method and device

A wood and equipment technology, applied in the field of drying, can solve problems such as carbonization, unfavorable wood moisture evaporation, uneven drying of wood, etc., and achieve the effects of prolonging service life, reducing heat loss, and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

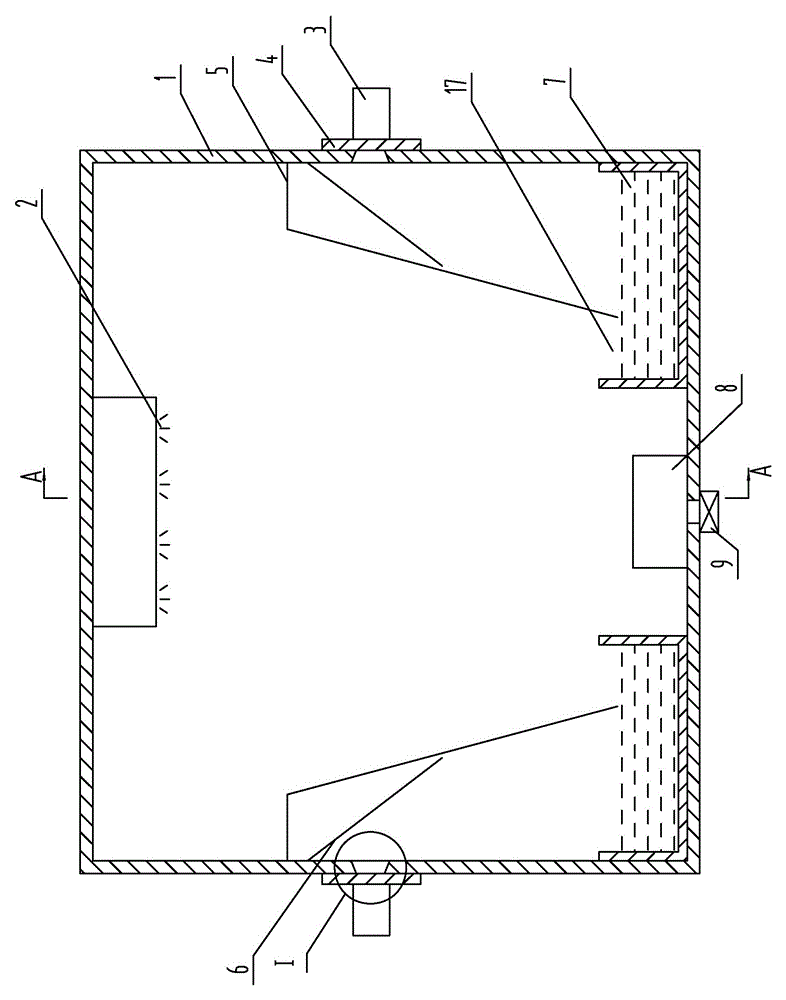

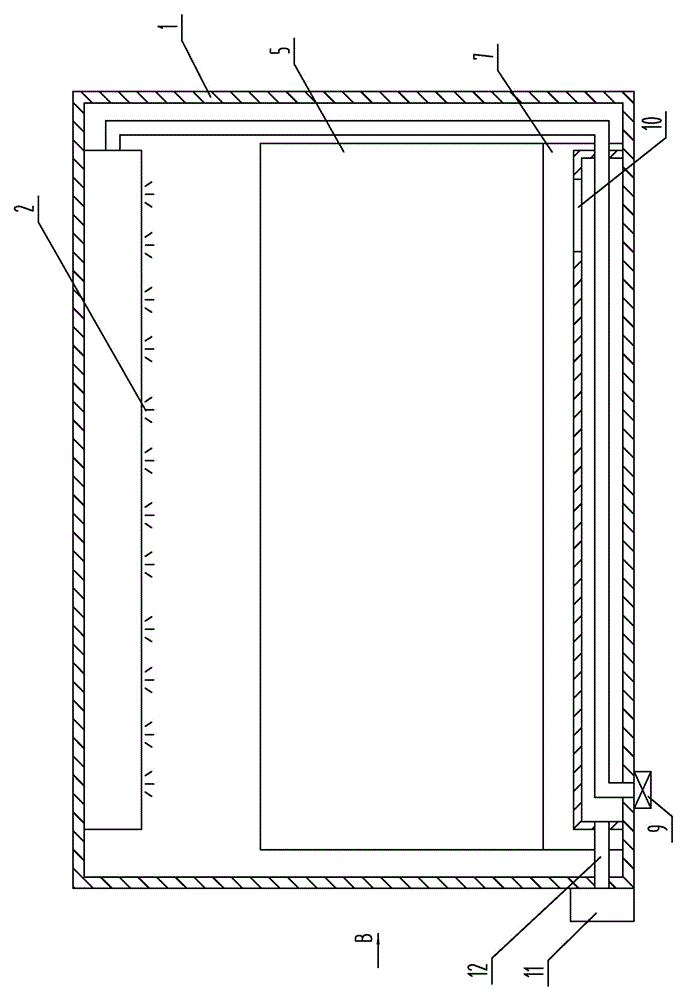

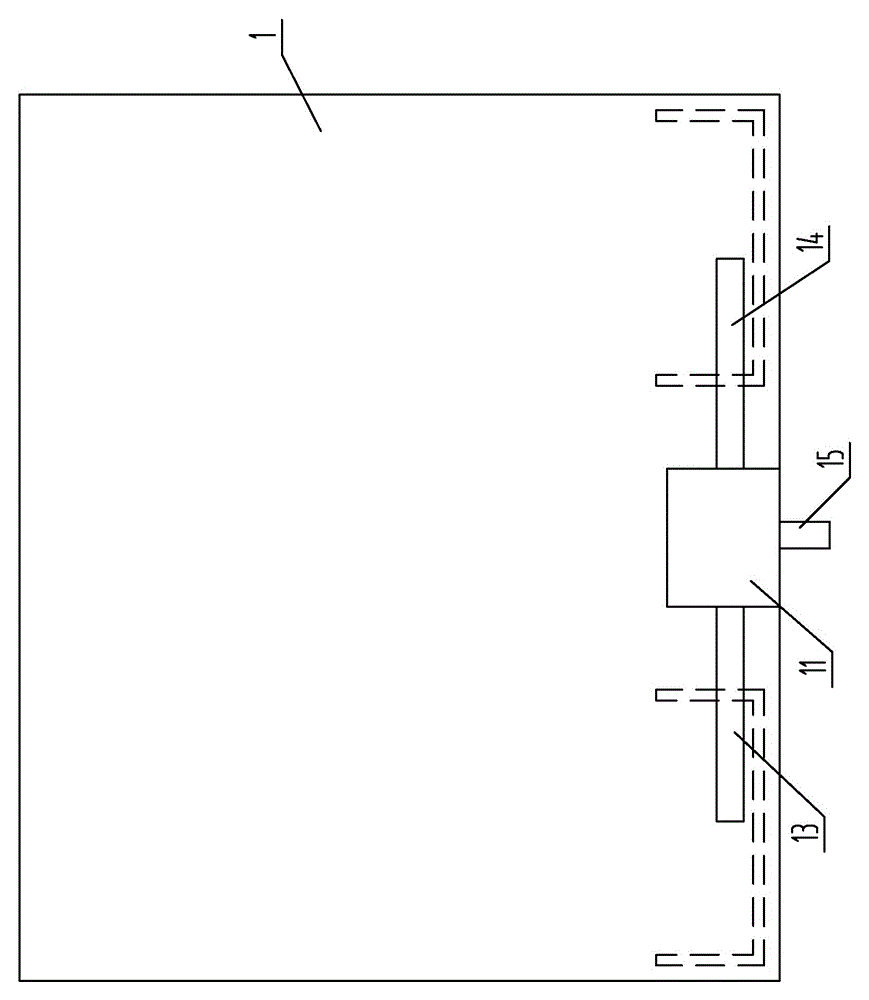

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] In the present invention, the side closer to the center is defined as the inner side. Correspondingly, the side farther from the center is defined as the outer side.

[0034] The main idea of the wood drying method provided by the present invention is: by setting a steam generating device at the bottom of the box body 1, the steam outlet 12 of the steam generating device is opened upwards, and the steam generating device is turned on during the heating and constant-speed drying stage , so that the generated steam directly enters the box body 1 to cook and dry the wood, avoids the intermediate transportation path of the steam in the prior art, reduces the heat loss of the steam, is beneficial to increase the cooking temperature of the wood, and increases the evaporation rate of moisture in the wood At the same time, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com