Combustion pool smoke discharging heat recovery and purification system

A flue gas emission and purification system technology, applied in the direction of combustion methods, water heaters, exhaust gas devices, etc., to achieve the effect of removing soot particles, important economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

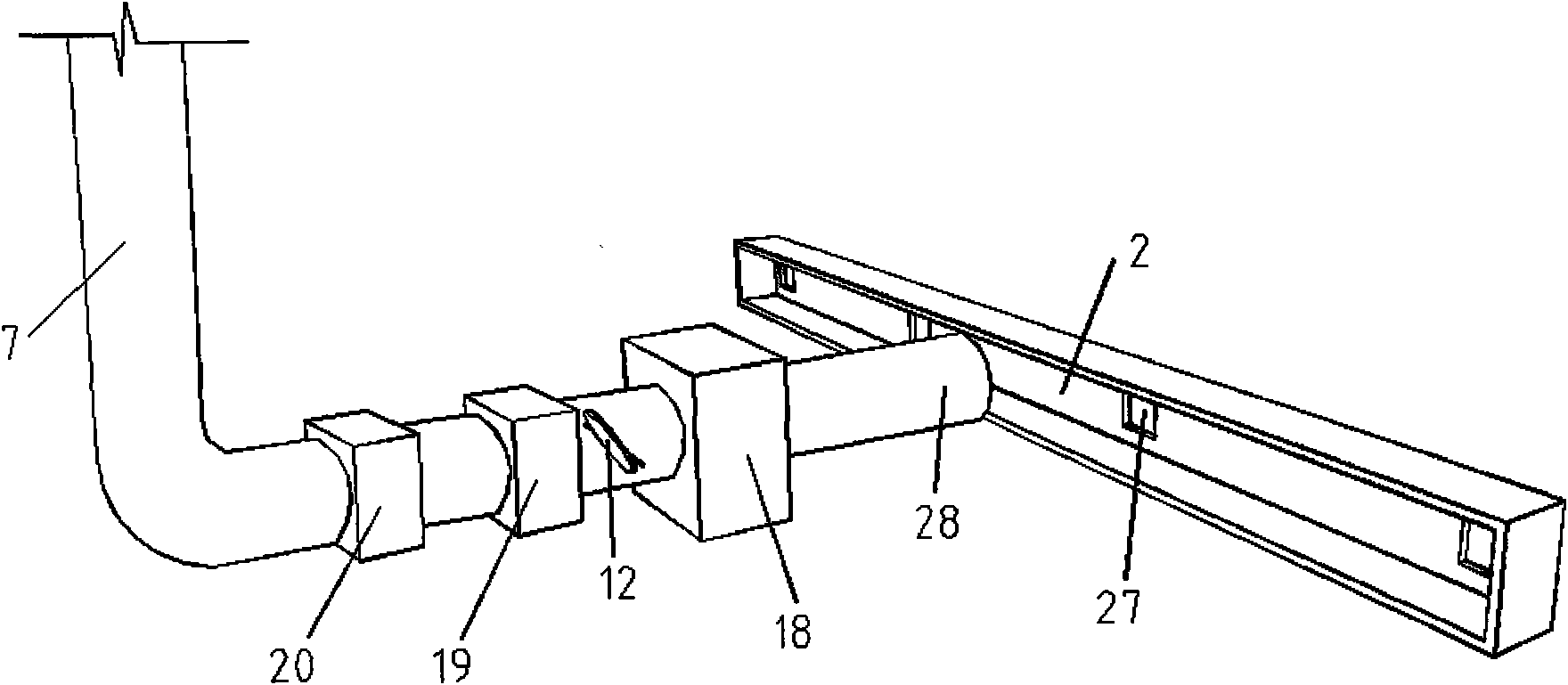

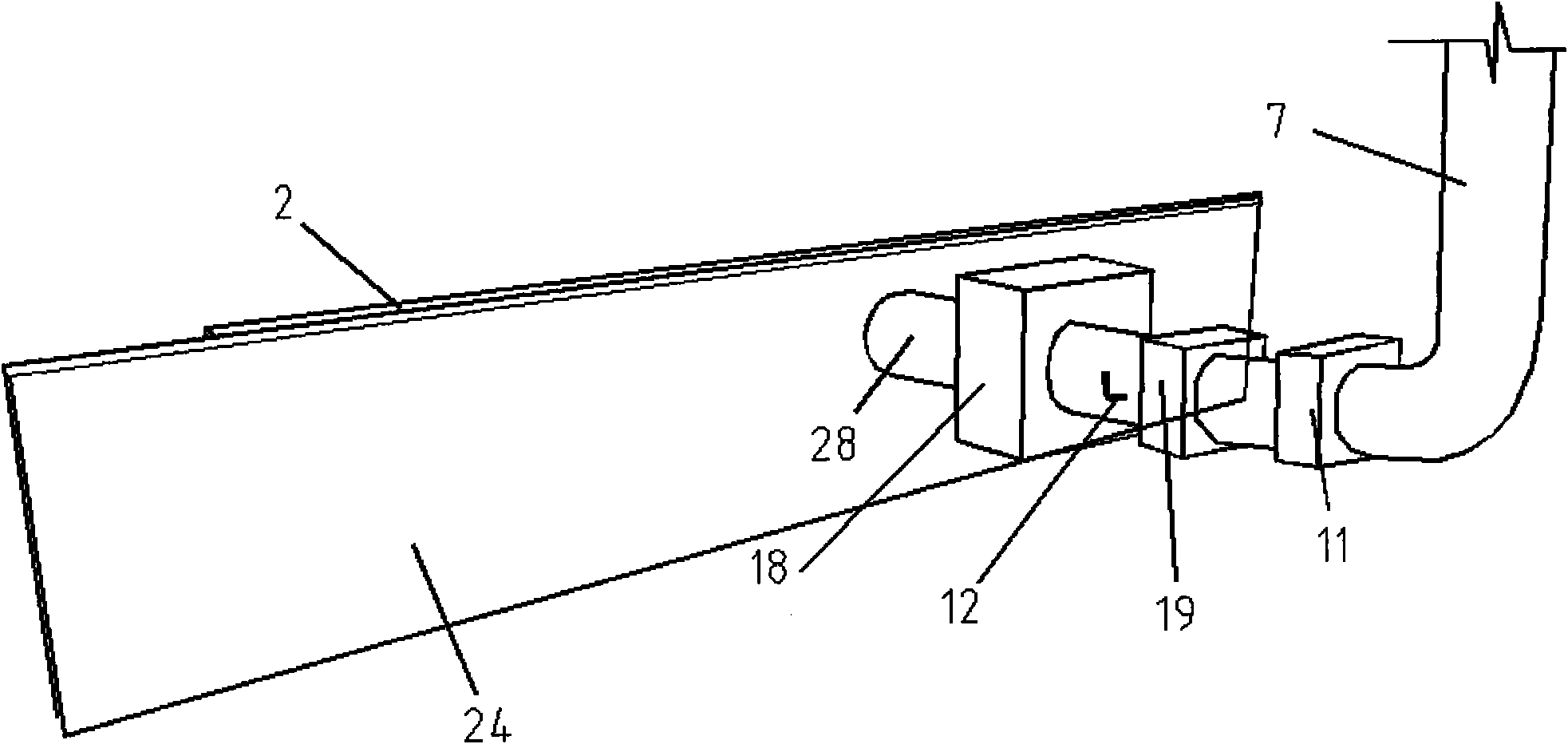

[0013] Specific implementation plan one: if Figure 1~3 As shown, the exhaust heat recovery and purification system of the combustion pool is mainly composed of the combustion pool wall 24, the horizontal flue 2, the chimney 7, the flue gas control valve 12, the flue gas waste heat recovery device 18, the flue gas dust removal device 19, and the flue gas purification The device 20 is composed of other components, which sequentially perform waste heat utilization of flue gas, removal of flue gas particles, and removal of sulfur oxides and nitrogen oxides from flue gas.

specific Embodiment approach 2

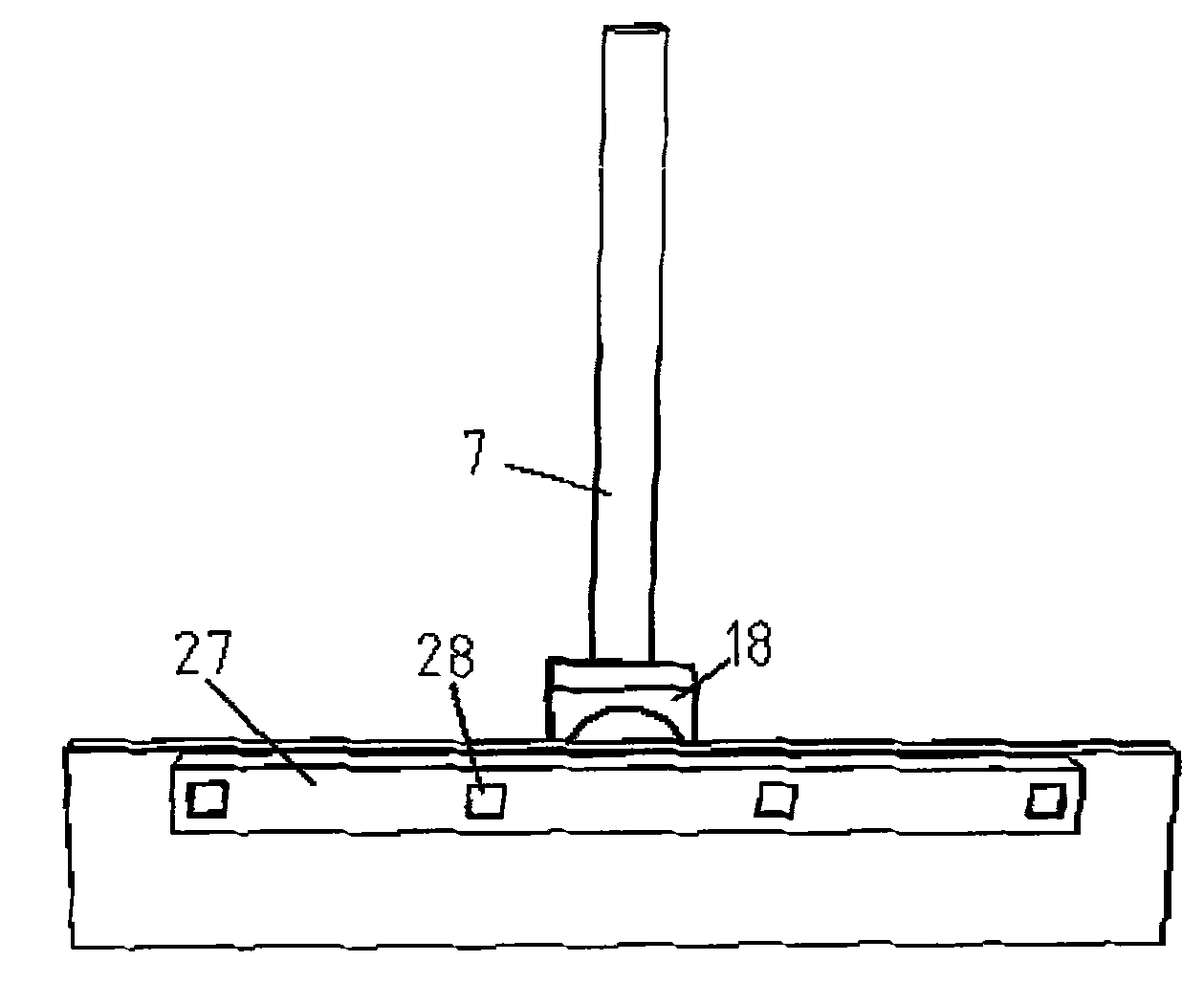

[0014] Specific implementation plan two: if Figure 1~4 As shown, the flue gas waste heat recovery device 18 is located at the chimney inlet 28, and is composed of 21 water pipes, 22 water inlets, and 23 water outlets. After the flue gas passes through the flue opening 27, it is collected at the chimney inlet 28. After entering the flue gas waste heat recovery device 18, it exchanges heat with the water pipe 21, replenishes water through the water inlet 22, and takes the heated water out through the water outlet 23, which is convenient for use.

specific Embodiment approach 3

[0015] Specific implementation plan three: if Figure 2~4 As shown, the flue system is composed of a horizontal flue 2 , several flue openings 27 , a flue gas purification device 11 , and a vertical chimney 7 . The horizontal flue 2 is located at the back of the combustion pool wall 24 and consists of four symmetrical flue openings 27 . The flue gas is collected by the flue opening 27 and collected at the horizontal flue 2. The flue gas passes through the flue gas waste heat recovery device 18, the flue gas dust removal device 19, and the flue gas purification device 20 for purification and dust removal, and finally is discharged from the chimney 7. A flue gas control valve 12 is also provided at the bottom of the chimney, and the smoke exhaust volume is controlled by changing the angle of the flue gas control valve 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com