Waste heat boiler with reheating dry quenching function

A waste heat boiler and coke CDQ technology, which is applied in the direction of steam boilers, boiler water pipes, steam boiler accessories, etc., can solve the problems of low power generation efficiency of waste heat power plants, reduce environmental pollution and corrosion of equipment, reduce air and Effects of water pollution and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical scheme of the present invention will be further explained with reference to the following specific examples. The following examples are only to provide a possible solution, but not to limit the invention.

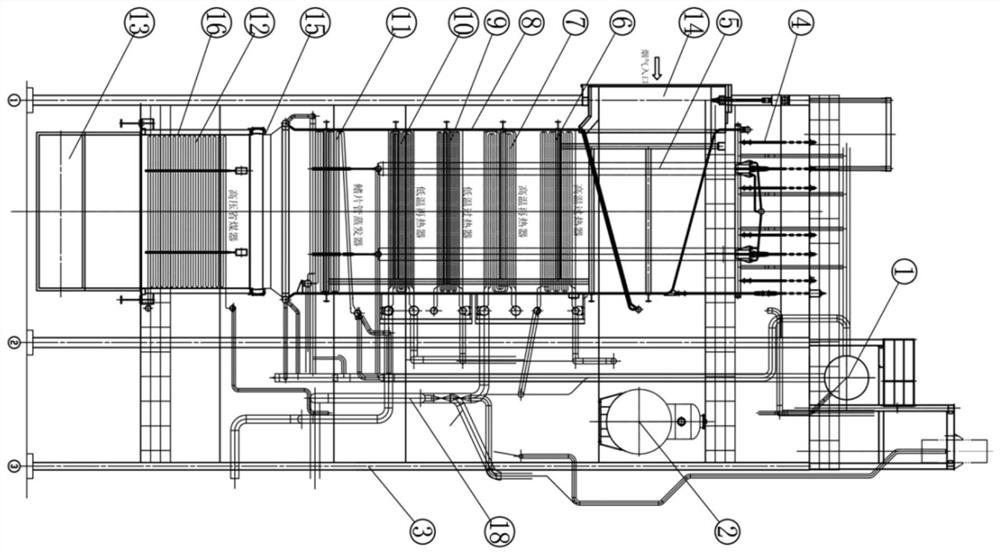

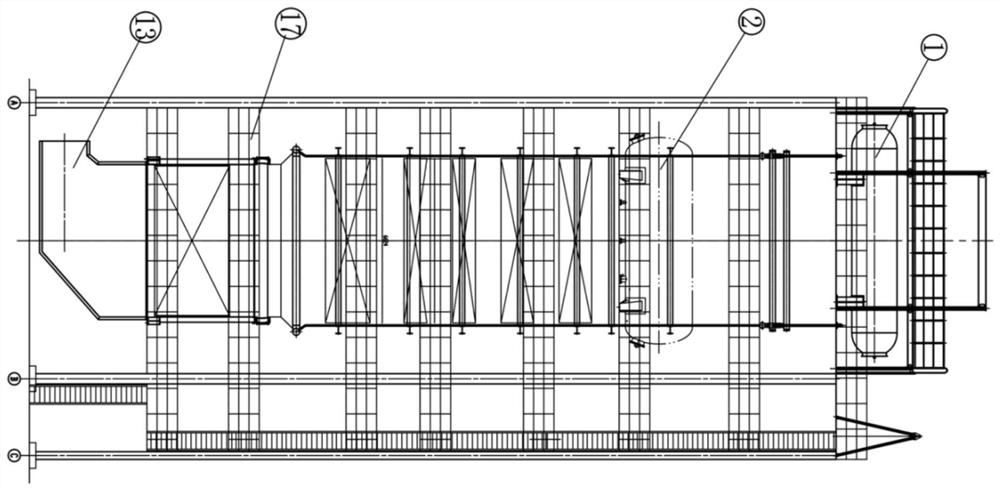

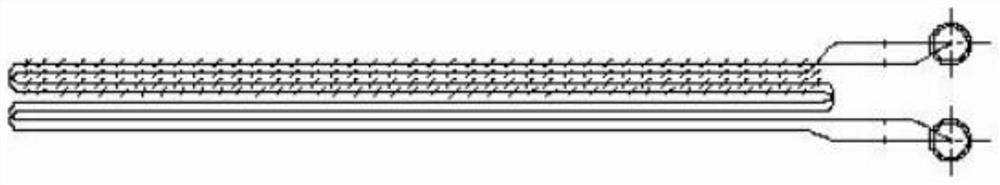

[0046] refer to Figure 1-3 ,

[0047] The temperature of flue gas from the coke quenching process is about 880 ~ 980℃, and it enters the boiler inlet flue from the upper end through the flue gas channel lined with brick walls. At the inlet section, the air flow turns 90 and flows downward. First, the heat is transferred to the heating surface of the preset evaporator formed by the water wall of the front wall, and then flows through the high-temperature superheater, high-temperature reheater, low-temperature superheater, low-temperature reheater and fin tube evaporator surrounded by the water wall. The water wall of the boiler is designed as the heating surface tube of the evaporator to absorb the radiation and heat release in the flue gas process. Then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com