Multi-source coupling heat pump waste heat utilization system

A technology of coupling heat pump and waste heat, applied in heat pump, energy industry, fluid heater and other directions, can solve the problems of large energy loss and not widely used, and achieve the effect of saving fuel and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

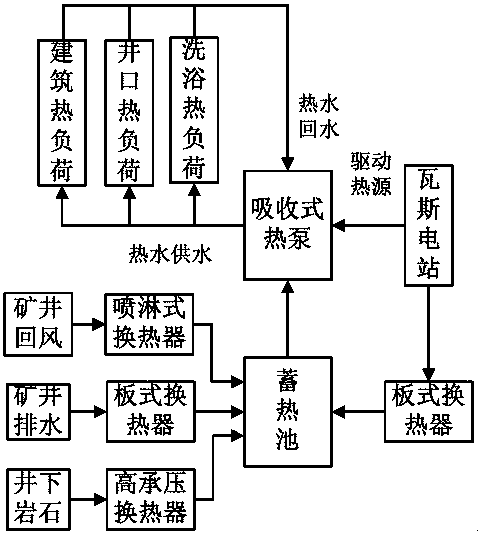

[0020] 1. Multi-source coupling heat pump waste heat utilization system, taking absorption heat pump waste heat utilization as the object, and obtaining the influence of various factors on system performance. The mass conservation equation and energy conservation equation are used in the calculation process. The waste heat sources that can be used in the mining area, the heat supply process of different heat sources are obtained, and the multi-source coupling heat pump waste heat utilization system is obtained. It provides technical reference for the construction of multi-source coupled absorption heat pump waste heat utilization system in mining areas and other industries.

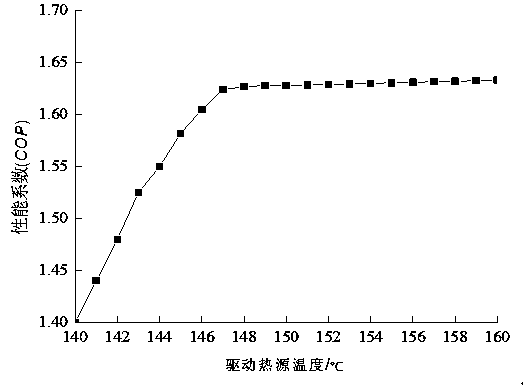

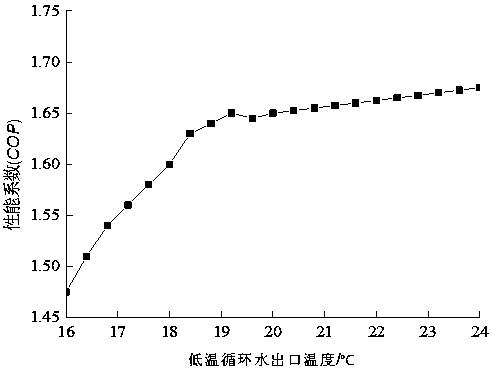

[0021] 2. Factors affecting system performance coefficient, including: driving heat source temperature, circulating water outlet temperature, hot water return temperature, hot water supply temperature. The absorption heat pump system is calculated, the influencing factors of the system performance coeffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com