A waste heat recovery device for boiler flue gas purification

A waste heat recovery device and flue gas purification technology, applied in circuit devices, battery circuit devices, electrical components, etc., can solve problems such as heat energy loss, and achieve the effect of dust removal and waste heat reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

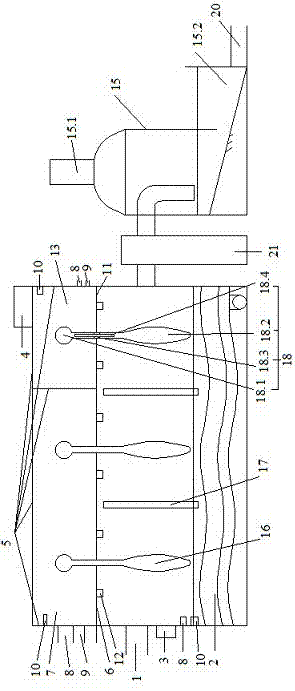

[0017] In order to increase dust removal efficiency and waste heat recovery and utilization, the present invention proposes a boiler flue gas purification waste heat recovery device.

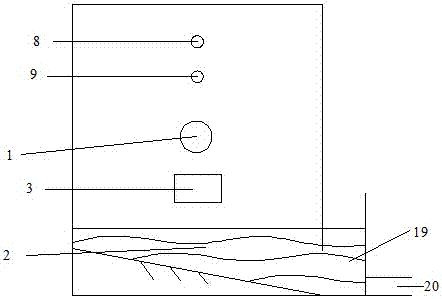

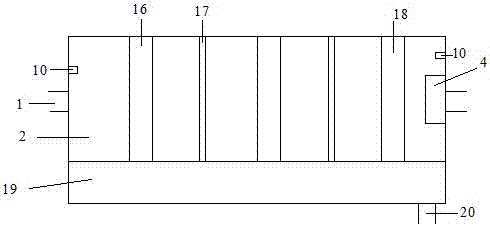

[0018] This waste heat recovery device for filtering flue gas purification includes a boiler air outlet 1, which is characterized in that the upper closed water pool 2 is connected to the boiler air outlet 1, and a PLC controller 3 is installed on the outer wall of the water pool 2 under the boiler air outlet 1 The top of the pool 2 has a storage battery 4; the top of the pool 2 is a thermal insulation layer 5; the bottom of the thermal insulation layer 5 is connected with a heat conducting plate 6; the thermal conducting plate 6 and the heat insulating layer 5 form a first closed space 7; the first closed space 7 There is a water inlet 8 and a water outlet 9 outside the left side; there is an inductor 10 in the left side of the first closed space 7; a heat shield 11 is installed next to the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com