Automatic temperature regulation and control system based on server waste heat

An automatic adjustment and control system technology, applied in heating systems, space heating and ventilation details, refrigerators, etc., can solve the problems of high power consumption of servers, increased cooling costs, heat waste, etc., to improve the comfort of experience , Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

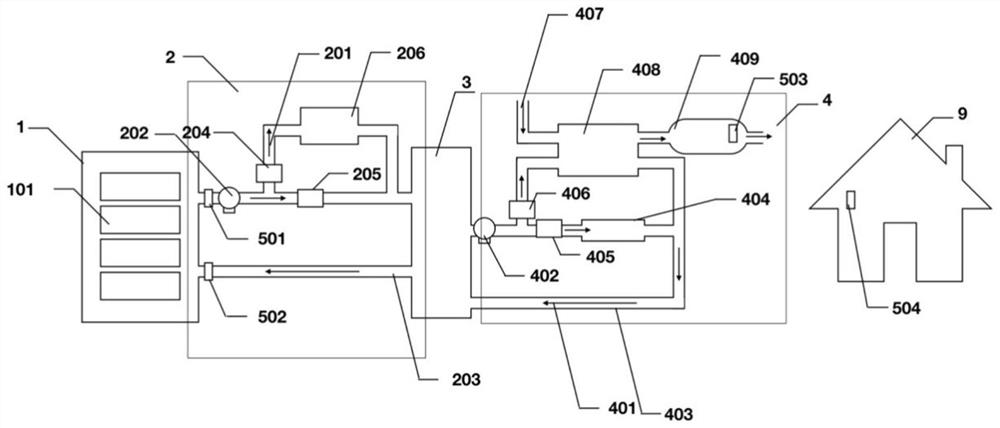

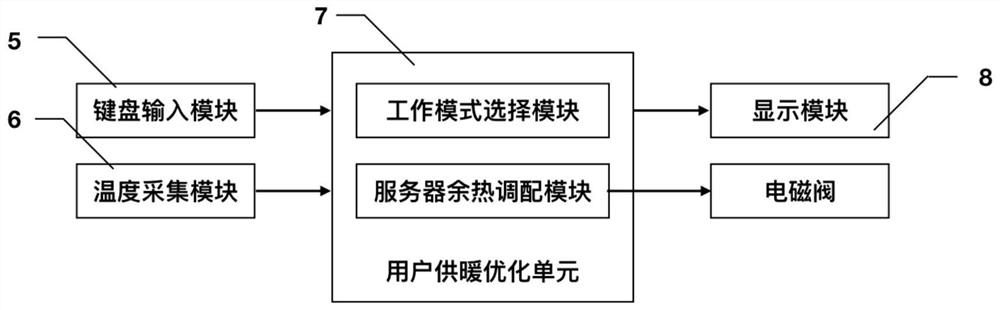

[0021] The present invention provides an automatic temperature adjustment system based on server waste heat, such as figure 1 and 2 As shown, it can be applied in the field of home heating. The present invention consists of a server waste heat collection unit 1, a cold liquid circulation unit 2, a first heat exchanger 3, a water circulation unit 4, a temperature acquisition module 5, a keyboard input module 6, a user heating optimization unit 7, a display module 8 and a user terminal 9 Composition: The server waste heat collection unit 1, the cold liquid circulation unit 2, the first heat exchanger 3, the water circulation unit 4 and the user terminal 9 are connected in sequence.

[0022] The server waste heat collection unit 1 is used to collect the waste heat generated by the server 101 during data processing. There are multiple servers 101 placed in the server waste heat collection unit 1, and the servers 101 are immersed in the cold liquid 201 of the cold liquid circulati...

Embodiment 2

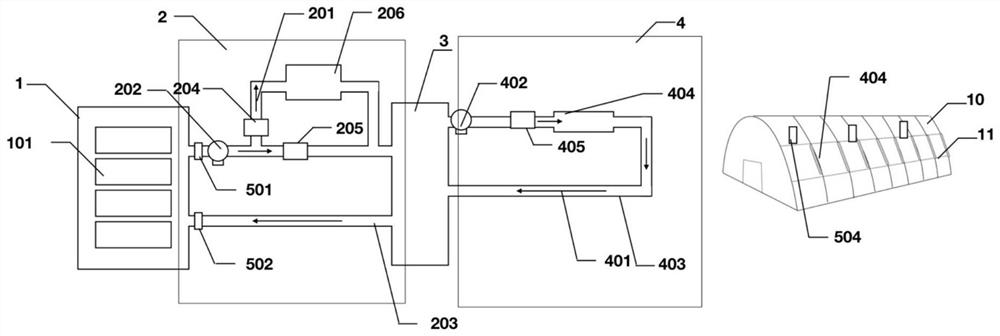

[0038] Such as image 3 As shown, the present invention is applied in the field of greenhouse heating, and its system structure is similar to that of Embodiment 1, the difference is that:

[0039] One end of the water circulation pump 402 in the water circulation unit 4 is connected to one end of the first heat exchanger 3, and the other end of the water circulation pump 402 is connected to one end of the radiator 404; the other end of the radiator 404 is passed through the water circulation The pipe 403 is connected to one end of the first heat exchanger 3; the water circulation unit 4 does not include a hot water supply end, and the heat supply terminal radiator 404 adopts a column type or a steel circular wing type hot-dip galvanized radiator, and Angle 0-90 degree is vertically fixed on the keel support 11 of greenhouse 10.

[0040] The server waste heat allocation module 702 mainly realizes the allocation of server waste heat by controlling the cooling liquid output temp...

Embodiment 3

[0042] Such as Figure 4 As shown, the present invention can be applied in the field of central heating, and its system structure is similar to Embodiment 1, the difference is:

[0043] The server heat collecting unit 1 includes a plurality of cabinets 102, and the cabinets 102 have a plurality of servers 101 built in; the cold liquid outlets of the cabinets 102 are all inserted into the fifth temperature sensor 505, which is used to monitor the temperature of each cabinet 102. The outlet temperature of the cold liquid prevents the internal temperature of individual boxes 102 from being too high.

[0044] One end of the water circulation pump 402 in the water circulation unit 4 is connected to one end of the first heat exchanger 3, and the other end of the water circulation pump 402 is connected to one end of the radiator 404; the other end of the radiator 404 is passed through the water circulation The pipe 403 is connected with one end of the first heat exchanger 3 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com