System and method for improving normal-temperature desorption greenhouse treatment efficiency by utilizing high-temperature soil waste heat

A technology of normal temperature desorption and treatment efficiency, applied in the field of soil treatment, can solve the problems that it is difficult to achieve the ideal treatment efficiency and restoration effect, the implementation of restoration has a large impact, and the temperature is high and it is difficult to transport, so as to achieve reasonable and full utilization, improve restoration efficiency, The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

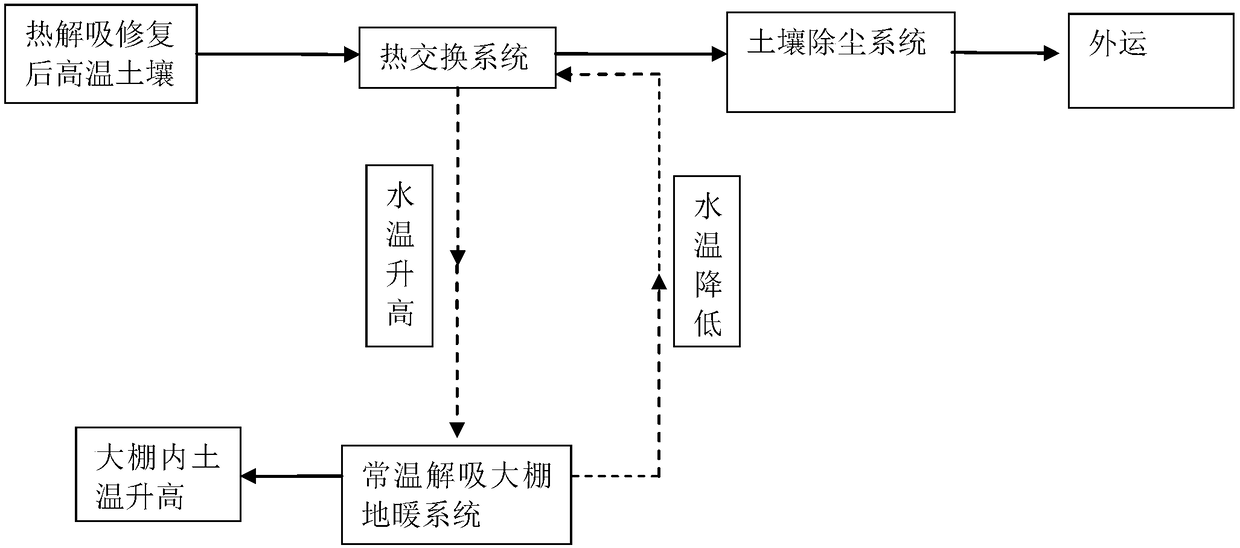

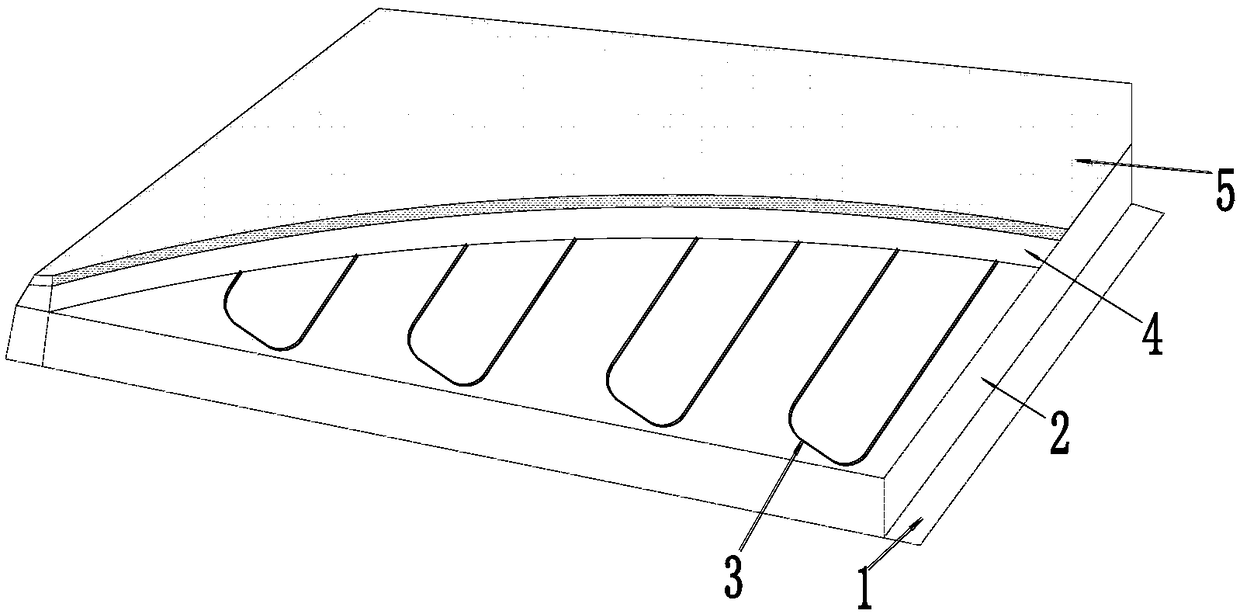

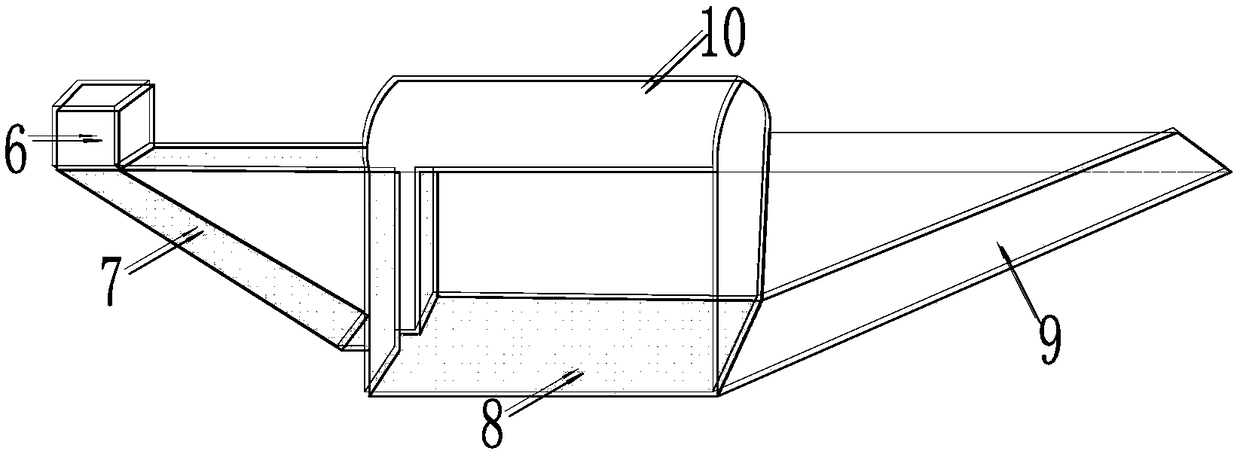

[0027] Such as figure 1 — image 3 As shown, the present invention utilizes high-temperature soil waste heat to improve the treatment efficiency of normal-temperature desorption greenhouses. The system includes a heat exchange system, a normal-temperature desorption greenhouse floor heating system and a soil dust removal system. The structure of the normal-temperature desorption greenhouse floor heating system is as follows: figure 2 As shown, it includes heating coil 3, steel plate surface layer 5, filling layer 4, heat insulation layer 2 and moisture-proof layer 1, and steel plate surface layer 5, filling layer 4, heat insulation layer 2 and moisture-proof layer 1 are arranged in sequence from top to bottom , The heating coil 3 adopts a parallel type, placed above the heat insulating layer 2, and the filling layer 4 is arranged between the heating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com