Method and system for utilizing waste heat of cooling water of bell-type furnace

A bell-type furnace and cooling water technology, which is applied to bell-type furnaces, furnace cooling, furnaces, etc., can solve the problems of energy consumption, resource waste, heat loss, etc., and achieve the effect of improving comfort and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

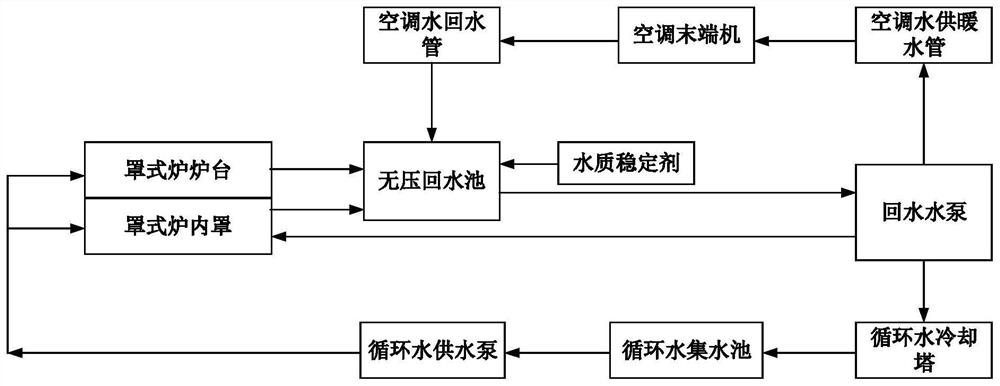

[0030] A method for utilizing waste heat of cooling water in a bell-type furnace, comprising the following steps:

[0031] Step 1, the cooling water of the bell-type furnace includes the spray cooling water of the inner hood of the bell-type furnace and the cooling water of the bell-type furnace table; pressure back into the pool;

[0032] In step 2, the cooling water of the bell-type furnace in the pressureless return water tank is transported to the inner hood of the bell-type furnace through the return water pump for cooling the inner hood of the bell-type furnace; The water pump is transported to the bell-type furnace hearth for cooling of the bell-type furnace hearth; the cooling water of the bell-type furnace in the non-pressure return water pool is transported to the air-conditioning terminal unit through the return water pump for air-conditioning heating.

Embodiment 2

[0034] A method for utilizing waste heat of cooling water in a bell-type furnace, comprising the following steps:

[0035] Step 1, the cooling water of the bell-type furnace includes the spray cooling water of the inner hood of the bell-type furnace and the cooling water of the bell-type furnace table; pressure back into the pool;

[0036] In step 2, the cooling water of the bell-type furnace in the pressureless return water tank is transported to the inner hood of the bell-type furnace through the return water pump for cooling the inner hood of the bell-type furnace; The water pump is transported to the bell-type furnace hearth for cooling of the bell-type furnace hearth; the cooling water of the bell-type furnace in the pressureless return water pool is transported to the air-conditioning terminal unit through the return water pump for air-conditioning heating;

[0037] In step 3, the air-conditioning water produced after heating by the air-conditioning is transported to th...

Embodiment 3

[0039] A method for utilizing waste heat of cooling water in a bell-type furnace, comprising the following steps:

[0040] Step 1, the cooling water of the bell-type furnace includes the spray cooling water of the inner hood of the bell-type furnace and the cooling water of the bell-type furnace table; pressure back into the pool;

[0041] In step 2, the cooling water of the bell-type furnace in the pressureless return water tank is transported to the inner hood of the bell-type furnace through the return water pump for cooling the inner hood of the bell-type furnace; The water pump is transported to the circulating water cooling tower; the cooling water of the bell-type furnace is cooled by the circulating water cooling tower and then flows into the circulating water sump; the bell-type furnace cooling water in the circulating water The furnace hearth is used for cooling the bell-type furnace hearth; the cooling water of the bell-type furnace in the non-pressure return water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com