Polyphase brushless electric motor

A brushless motor and armature technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as the influence of magnetic flux concentration, and achieve the effect of ensuring magnetic flux concentration, high torque, and multiple parallel air gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

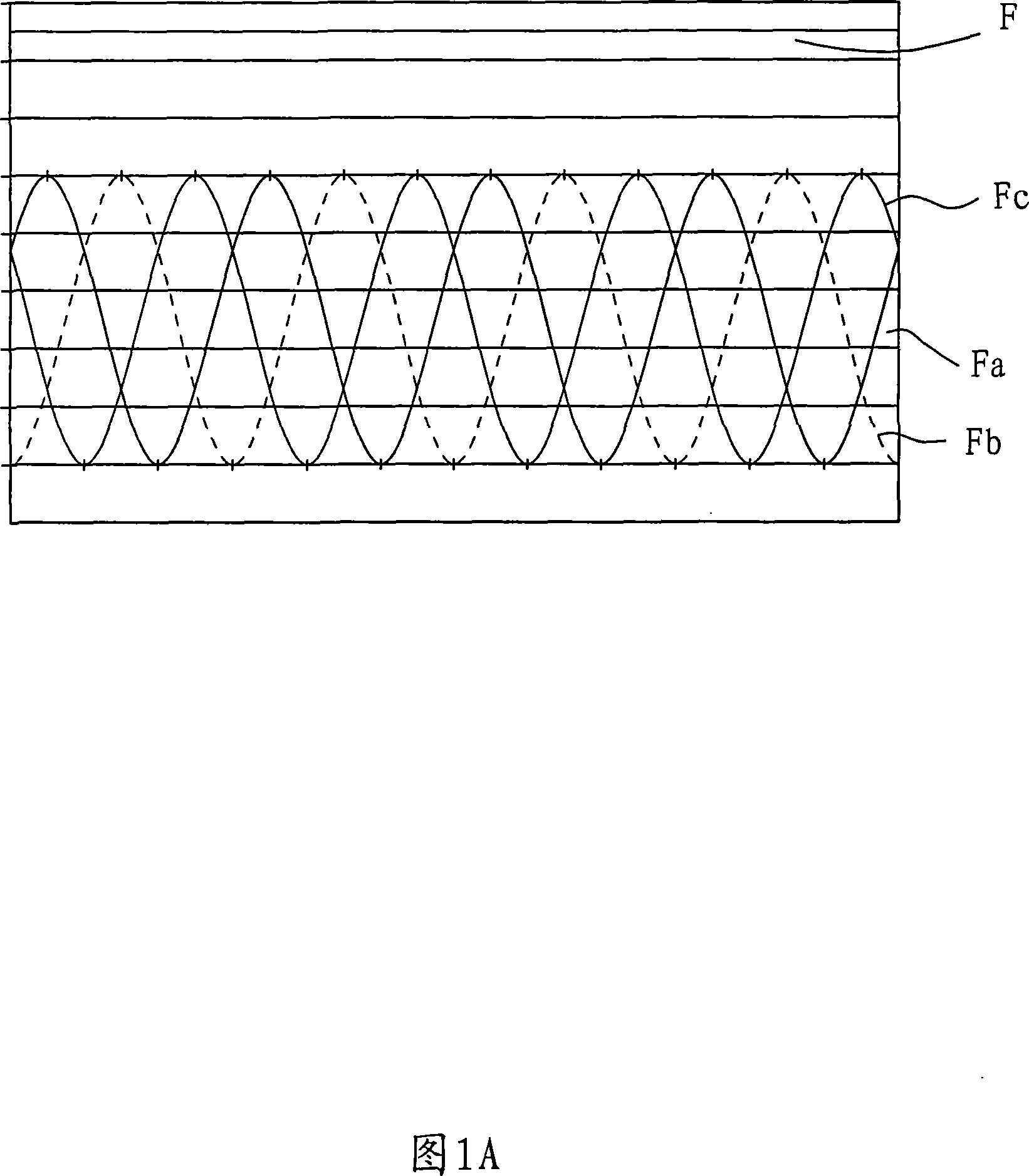

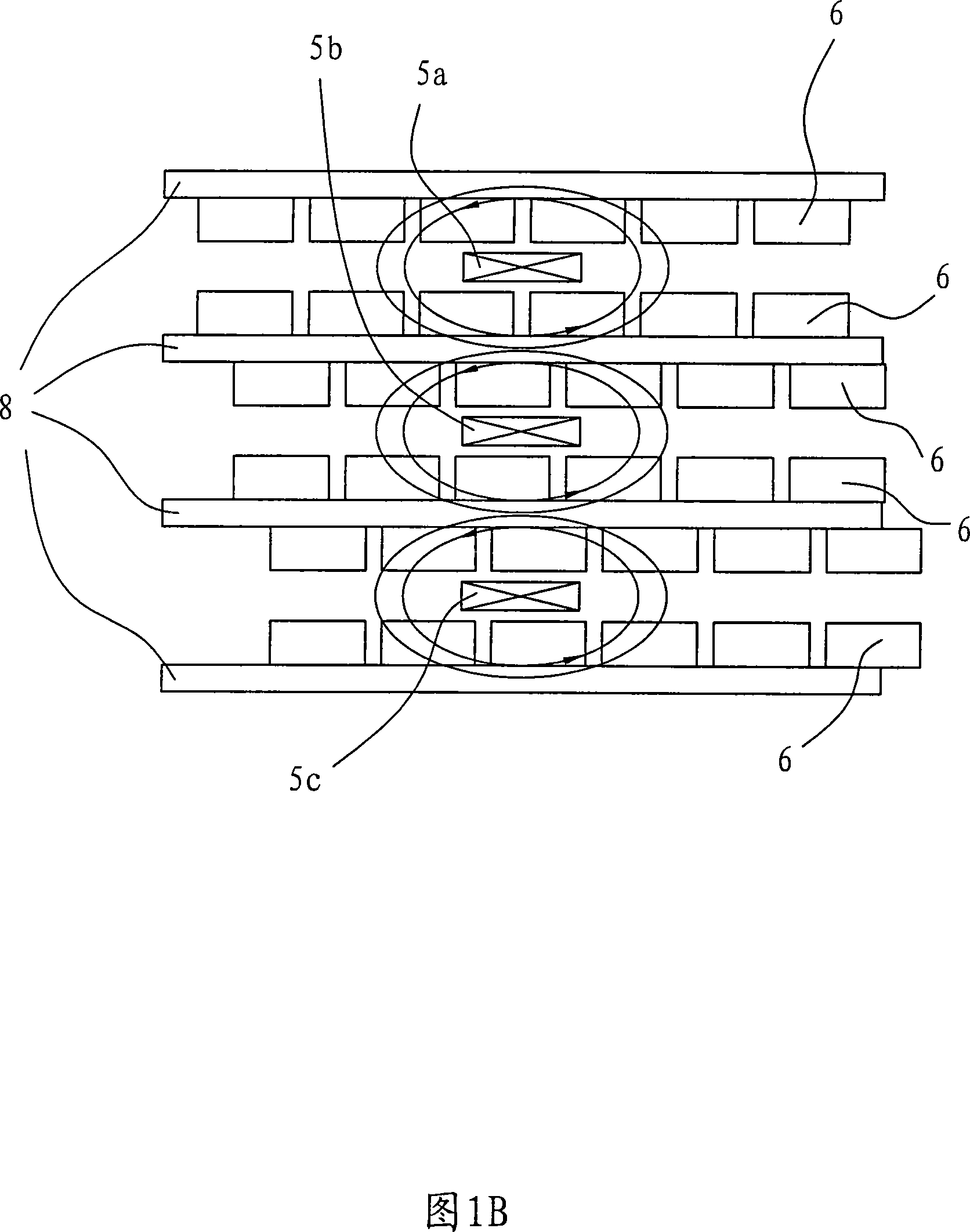

[0079] The brushless motor of the present invention has an armature member containing several magnetically isolated electromagnet components to interact with a field magnet member containing several magnetic components, so as to obtain concentration of magnetic flux and even utilization of force, and by increasing The pole surface area of the field magnet members and corresponding armature members across several air gaps facilitates a more even utilization of forces, eg Maslov et al. US Patent Grant No. 6891306 and related applications mentioned above.

[0080] The present invention is described in detail below in conjunction with accompanying drawing:

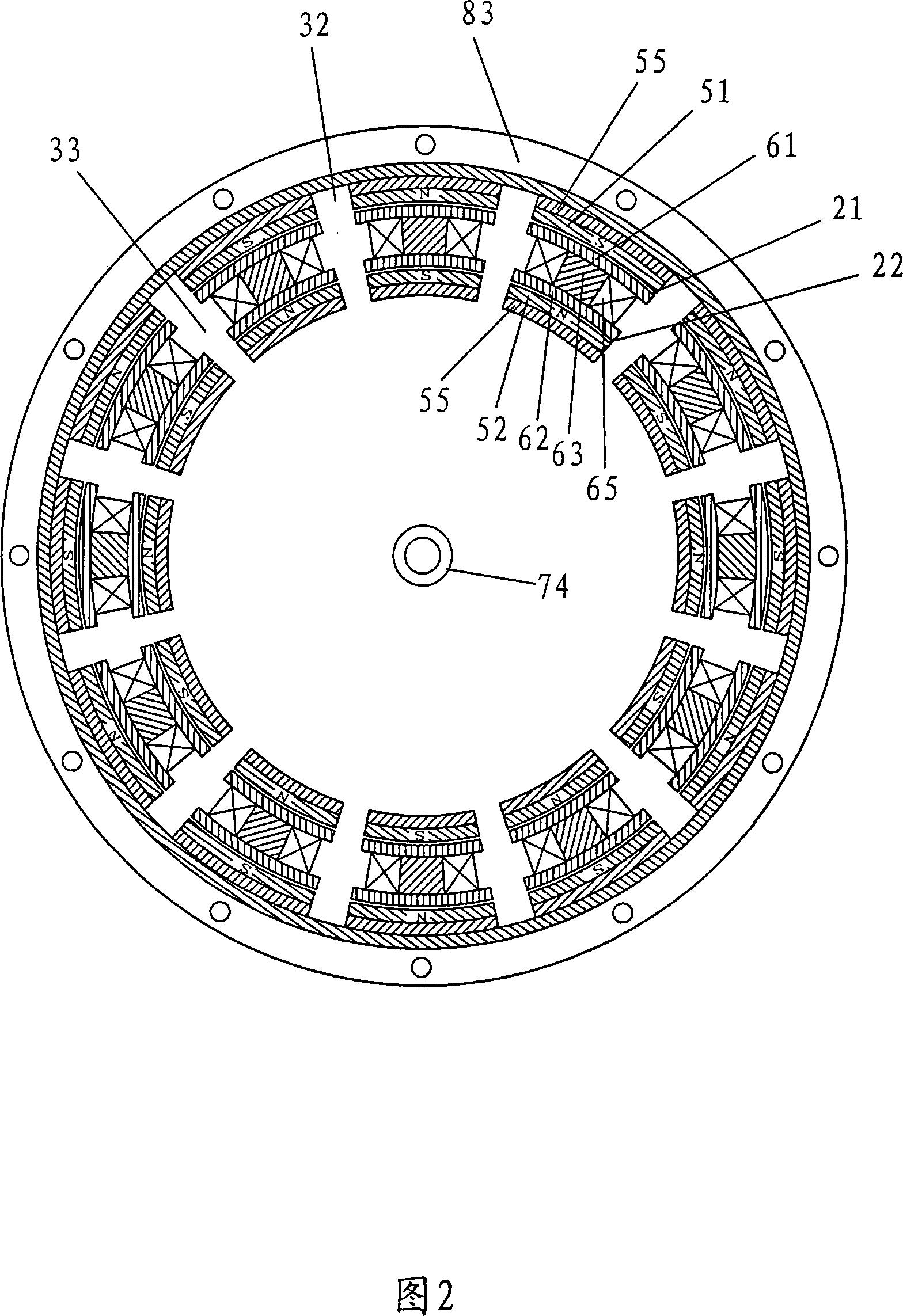

[0081] Fig. 2 is an exemplary cross-sectional view of the field magnet member as the rotor and the armature member as the stator of the brushless motor in Chinese Patent Application No. 200610100123. In the rotor outer ring 83, the rotor contains several magnetic assemblies containing permanent magnets 51 or 52 arranged alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com