Compact type permanent magnet brushless motor with equal-resistance duplex winding and redundant hall structure

A permanent magnet brushless motor, double winding technology, applied in the shape/style/structure of the winding conductor, the shape/style/structure of the magnetic circuit, electrical components, etc., can solve problems such as system failure, and achieve the reduction of complex procedures and structure The effect of simple, high torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

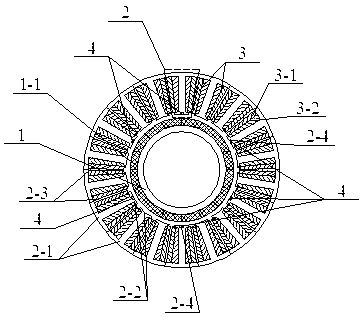

[0010] Specific implementation mode one: as figure 1 , figure 2 As shown, it is composed of a hollow disc permanent magnet rotor 1, a stator 2, a double-layer winding 3, and six Hall elements 4;

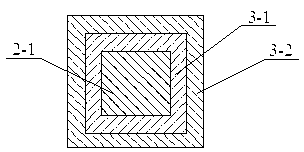

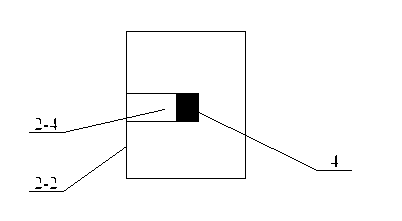

[0011] The double-layer winding 3 is composed of the first-layer winding 3-1 and the second-layer winding 3-2; the second-layer winding 3-2 is socketed on the first-layer winding 3-1; the stator 2 is composed of multiple stator cores 2- 1 composition; each stator core 2-1 has a stator tooth 2-2, and multiple stator cores 2-1 are connected end to end to form mutually spaced stator teeth 2-2 and stator slots 2-3, and all stator teeth 2 Three-phase symmetrical double-layer winding 3 is wound on -2 in a fractional slot type, the number of turns of the first layer of winding 3-1 in each phase of double-layer winding 3 is equal, and the number of turns of each phase of double-layer winding 3 in the second layer of winding The number of turns of 3-2 is equal, the number of turns of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com